Journal of Quantum Informatio n Science, 2011, 1, 149-160 doi:10.4236/jqis.2011.13021 Published Online December 2011 (http://www.SciRP.org/journal/jqis) Copyright © 2011 SciRes. JQIS 149 On the Reversal Effects of the Velocity Quotient on the Directions of Changes of Finishing Results of Conventional and Flexible Grinding Zdzislaw Pluta, Tadeusz Hryniewicz Politechnika Koszalinska, Mechanical Engineering Department, Koszalin, Poland E-mail: Tadeusz.Hryniewicz@tu.koszalin.pl Received September 30, 2011; revised November 3, 2011; accepted November 10, 2011 Abstract The paper presents the problem of right direction of changes of the velocity quotient in view of getting ad- vantageous smoothing results of material finishing using a compact elastic wheel. In fact the problem has been considered reversely in comparison with the change direction of the velocity quotient on the grounds of knowledge on grinding using ceramic wheels. The specifics of performance of the elastic wheels are consid- ered. The investigation was carried out on the effect of their peripheral velocity on the directions of smooth- ing. The problem is considered by presenting it on the background of determined results of grinding using a ceramic wheel. The dependence of a determined roughness measure of the smoothed surface on the velocity quotient is delivered. The forms of a function approximating experimental dependences of the subject roughness measure on the mentioned quotient have been derived. Furthermore, the results coming out of the performed experimental studies have been presented. Keywords: Elastic Grinding Wheel, Peripheral Velocity, Velocity Quotient, Measure of Surface Roughness, Potential Field, Potential Band, Nominal Quotient Constant, Real Quotient Constant 1. Introduction and Problem Presentation The elastic grinding wheels, as indicated e.g. in one of the book literature [1], belong to special abrasive tools. They possess specific features which evidently different- tiate them among other tools used to abrasive machining. The subject grinding wheels do not produce an effect on the workpiece in geometric-kinematic way as it is ob- served e.g. during grinding using ceramic wheels. The surface smoothing with the elastic wheels takes place in the dynamic action with the dynamics having relatively ordered character. It results from the manner of grains fixation and their displacement in the wheel structure. Contrary to these compact elastic grinding wheels, other elastic tools (for instance, flaky disks or buffing wheels) may smooth the material with manifold increased and less ordered dynamics. The strew/pour tools (for instance, the abrasive tapes/belts) also allow to perform with a relatively ordered dynamics but in the degree respect- tively lesser than the elastic wheels. These former tools allow the working abrasive grains to be displaced one against another, and in consequence, for more harmoni- ous cooperation during the material machining. The process of surface finishing with elastic wheels is dynamized advantageously. The treatment is intensified by the unstable zone of this tool which contacts the ma- chined material. The abrasive grains are not there in such an energetic state as they are on the free peripheral sur- face of the grinding wheel behind the machining zone. Here the energetic states may be tentative only when the change of the kind of variable motion occurs (for in- stance, retarded-accelerated, and reverse: accelerated-re- tarded). Here is the generally described performance of an ela- stic wheel, presented mainly in the work [2]. The abra- sive grains of the near-surface peripheral layer come in contact with the workpiece and with this loose their ki- nematic energy, moving further (in the machining zone) with a variable motion against itself, machined surface and the nominal trajectory. Such a turbulent flux of abra- sive grains moves through the whole machining zone, then coming back to its primary energetic state, regaining the primary kinematic energy. Pulsating under machining, the grains change the primary surface structure, making  Z. PLUTA & T. HRYNIEWICZ 150 it more advantageous from the viewpoint of expected technological requirements. The claims of improvement of the surface roughness and the growth of gloss of sur- face are the most important. In contact with the machined workpiece the abrasive grains decrease their inertia and centrifugal reaction whereas the elasticity of their fixations may change not only quantitatively, but also qualitatively. The bond, first extended, attempts to return to the zero state, and at the greater in-feeds may even undergo the compression. The grains in this zone perform the work which is non-be- havioral, because their firm energetic states are not pre- served. That is the specifics of performance of the compact elastic grinding wheels, manufactured by many compa- nies of abrasive manufacture profile [3-8]. It would be useful and advantageous to present the subject abrasive tools in view of revealing some essential differences be- tween the performance of elastic and rigid (ceramic) grinding wheels. The reference to the ceramic wheel will be still necessary. Of course, that provided the compara- tive analysis is to be concerned on the influence of pe- ripheral velocity on the determined machining effects. To reveal the essential problem it is worthy comparing the two totally different ways of abrasive machining: grinding and finishing/smoothing, i.e. the machining of material with a rigid wheel (usually ceramic), and a compact elastic wheel. The technology of grinding using a ceramic wheel is generally known. However, it is wor- thy noting a comparative criterion that is the peripheral velocity of wheel and its influence on the finishing re- sults of the treatment which is the surface roughness. It is known that with the increase of peripheral veloc- ity of ceramic grinding wheel the roughness of the ma- chined surface decreases, respectively; it has been pre- sented in the literature [9-11]. It is connected, as ex- plained in the work [12], with the decrease of thickness of the layer cut by a single edge and the increasing amount of heat in the machining zone, and with this the temperature of elements of the machining system. The work [13] adds that then the grains loading decreases, and with this the grinding wheel performs as more hard. The consequence of such a performance of the wheel is longer work of its grains, which is less frequency of its spalling. Together with the increase of peripheral veloc- ity of the grinding wheel, as mentioned above, the fre- quency of the grain contact with the machined material is greater, whereas the time of this contact is lesser, res- pecttively. These advantageous conditions, favouring the de- crease of roughness, are illustrated by a plot (Figure 1) excerpted from the reference [12], being the image of the dependence of the surface unevenness height (created by Figure 1. Dependence of measures a , of surface roughness (formed by a material grinding) on the velocity quotient v and the peripheral velocity of grinding wheel [12]. qs v the material grinding) on the peripheral velocity of the grinding wheel, that is s Rfv. The same curve relates also with the dependence of arithmetic mean of the profile deviation of the mean line, that is a, on the velocity quotient v, so the ratio of the peripheral ve- locity R q v of the grinding wheel to the peripheral veloc- ity v of the ground workpiece. Concerning this, the plot covers also the coordinates axes, related to the men- tioned magnitudes. The hardened manganese steel (C = 0.5%, Mn = 1%) was used as a ground material. The tool was the grinding wheel of the grain size No. 46 made of semi-precious aloxite 97A. The peripheral velocity of the ground work- piece was assumed v = 30 m·min–1, and the longitu- dinal feed 0.3 12 p aH mm·rev–1, where H is the width of the wheels. There were two values of depth e of the grinding wheel penetration in the machined mate- rial: 0.01 and 0.05 mm. a Of course, that range of variability of the peripheral velocity of grinding wheel does not exhaust the kine- matic possibilities of the wheel at all. Here the upper limit of the variability interval of this parameter was caused by the shattering effect of the wheel (its resis- tance to disrupture). Under other conditions the wheels rotate with the velocities v equal: 100 m·s–1 [9], and even 320 m·s–1 [10]. Furthermore, that kinematic pa- rameter results from the given resistance criterion of the tool with both of them being correlated positively: the greater strength of the wheel to disrupture (shattering), the higher its peripheral velocity. Moreover, taking into account the finishing/smooth- ness criterion one should note the wheel should operate Copyright © 2011 SciRes. JQIS  151 Z. PLUTA & T. HRYNIEWICZ with the highest possible velocity. Here both the rough- ness and the velocity are correlated negatively. That means the increase in peripheral velocity of the wheel results in the decrease of roughness of the newly created surface. Thus, to obtain the advantageous surface results the highest possible peripheral velocity should be pro- vided to the grinding wheel. That is the so called the gold rule of grinding. The quest of connection of surface roughness with the peripheral velocity of the grinding wheel (also the veloc- ity quotient) is then determined univocally and used in practice; however, the relations of these magnitudes re- ferred to the compact elastic wheels have not been as- sumed and/or used until now. Then it is worthy present- ing first the history of usage of these grinding wheels, together with the outline of their development and stu- dies over the influence of the peripheral velocity of this type of tools on the directions of changes of the finishing results of smoothing. To solve the problem, first the history of usage of the compact elastic wheels and the effect of their peripheral velocity on the directions of changes of the finishing results of treatment, are delivered. Those special abrasive tools, covering one of many manufactured geometric assortments, are made in Poland by the Fabryka Tarcz Ściernych in Grodzisk Mazowiecki [5]; their production was begun in 1973. There were only some foreign com- panies, such as SLIP-NAXOS [3], ARTIFEX [4], KLINGSPOR [6], and LUKAS [7] which started to do it earlier. These tools contain the abrasive grains displaced in the entire mass of the resin bond, so they are compact tools. The work [14] treats on polishing using the single crystals of silicon by the elastic aloxite grinding wheels. The way of manufacture of that kind of wheels has been also described. The process of their manufacture con- sisted of the following stages: mixing the polyurethane and abrasive grains; smearing the mixture over the steel base plate creating the layer of thickness of about 15 mm; leaving such prepared abrasive-polyurethane material for 3 - 4 days for the chemical reactions to occur. It is wor- thy mentioning that the Polish literature [15,16] treats in extension on the manufacture of the polyurethane elastic abrasive tools. The journal “Werkstatt und Betrieb” covers the results of finishing of the steel SW18 and the brass MO59 by means of elastic wheels of the properly differentiated characteristics [17], as well as the results of cutting ma- terials using flexibly fixed grains of the post-copper slag [18]. “Schleifen und Trennen” presents some aspects of manufacture and usage of the grinding wheels of porous elastic wheels [19]. It is worthy turning the attention on the work [11], published by the journal “Maschinen und Werkzeug”. Based on the example of the grinding wheels of Artifex the advantages of abrasive tools on the elastic bond (of the flexibility detected even on touch), have been dis- cussed. It was stated that the use of these wheels requires the relative high rotational velocities especially in rela- tion to the grinding pins (diameters of 5 to 30 mm). It is treated about a high cutting output of which the per- formance is achieved at not a big compression force and the tool velocity, equaling up to 30 m·s–1. On the world edition market the problems of finishing using the compact elastic wheels has been noted only in recent decade. At the beginning of this decade (2001) a work appeared treating of the curvilinear finishing of surfaces using the grinding pins of a special design [20]. The concept, structure, shape, and the manufacture pro- cedure of the susceptible abrasive tool made of thermo- setting polyurethane elastomer coated with abrasive ma- terial of aluminum oxide, have been discussed there. This tool enables the finishing treatment thanks to the ability to deform and conforming the shape of the ma- chined surface in the machining zone. The following effects were studied, such as: obtained surface roughness, the mentioned machining effectiveness and durability in the process of treatment of high-alloy tool steel, previ- ously machined by milling. Then the work [21] appeared, concerned with elastic properties of the flexible abrasive tools of polyurethane bonds. There the results of the studies of the wheel prop- erties with the outline of their modification in view of increasing the effectiveness of the process of abrasive smoothing have been presented. Recently, in 2009, the works [22,23] appeared. The ar- ticle [22] presents first the characteristics of the initial conditions, relating to the peripheral smoothing using elastic wheels. These conditions are determined by the incision angle, depending on the peripheral velocity of the grinding wheel, in-feed, and the workpiece velocity. Such a determined dependence was used to forecast the directions of roughness changes. It was stated, based on the results of experimental verification of the prognoses, that the finishing results of the peripheral smoothing may be anticipated with a success, making use of the men- tioned prognosis indicator. The work [23] explains much wider those initial con- ditions of cutting. It has been proved that one cannot smooth a material using a rotating wheel with a critical velocity, which the velocity is connected with the wheel resistance to disrupture. The wheel velocity has to be respectively lower, because in that case the effect of the grain size on the surface roughness is significantly less, and moreover it affects advantageously the finishing re- sults of the smoothing. Copyright © 2011 SciRes. JQIS  Z. PLUTA & T. HRYNIEWICZ 152 The history of usage of the elastic grinding wheels in- dicates they were exploited quite variably. There were three directions of activities concerned with their exploi- tation when non-uniform rules were used. It was about the direction of value changes of the peripheral velocity of those tools. The history of using the compact elastic wheels considered in this aspect requires including also Polish literature to the analysis. In that case the picture will be complex in character. At first the smoothing process was realized with the peripheral velocity denoted on the elastic grinding wheel, not changing it in any value direction (of course that ve- locity was decreased itself, resulting from the wheel wear during the process of smoothing). One has to add that the mentioned peripheral velocity refers to the strength of the wheel to disrupture or the shattering. Such an ap- proach to the kinematics of smoothing has been treated e.g. by the works [15,19]. The work [11] testifies that the kinematic rule is still in force concerning the smoothing technology, none the less it is unjust from the viewpoint of main, the most important criterion of the estimation of the grinding wheel cuttability, i.e. the results of this ma- chining. Furthermore, there were the attempts to interfere in the exploitational characteristics of the wheel, creating such conditions of its fixation to allow operating the wheel with the increased peripheral velocity [24,25]. The ac- tivities were focused onto elaboration of the proper ways of fixation of the wheels. It was also taken into account that the elastic wheel during its work should have the possibility to a considerable freedom of changes of the geometric form. It is to avoid the creation of non-advan- tageous 3D states of stresses. A further considerable increase of the peripheral ve- locity of the wheel was possible by its fixation from the external side of the peripheral surface [26,27]. That way a new non-conventional kind of abrasive smoothing was created, where the internal surface (hole) became the active working surface of the wheel. In reference to the external peripheral smoothing (cla- ssical smoothing) none of these two mentioned directions of activities ensured a decrease of roughness of the ma- chined surface. That time the thing was set on head, go- ing in a reverse direction, radically decreasing the pe- ripheral velocity of the wheel. It appeared that very ad- vantageous smoothing results were obtained. They are discussed in such exemplary works like [22,23,28,30]. The history of using the compact elastic grinding wheels testifies the ways leading to the best solutions cannot be determined in advance. Such is the nature of the cognitive activities. The problem is because the sub- ject elastic wheels are the tools of a specific structure. The presented descriptions indicate it has not been taken into account in a sufficient degree at determining the ef- fect of the tool velocity on the finishing results. This is why that primary improper direction of the cognition took place. In the next section that essential thread of the work, concerning the effect of the velocity quotient on the fini- shing results of peripheral smoothing, is to be presented in detail. That will make it possible to compare that characteristics with the earlier one (see Figure 1), re- garding the grinding. 2. Dependence of the Roughness Measure of Machined Surface on the Velocity Quotient That title characteristics (Figure 2) has been created basing on the study results excerpted from the works [2,22,30]. They are the study results of the effect of machining Figure 2. Dependence of measure of the smoothed surface on the velocity quotient for two different in-feeds. Copyright © 2011 SciRes. JQIS  153 Z. PLUTA & T. HRYNIEWICZ parameters on the surface roughness machined by the grinding wheels of porous elastic bonds. The experi- ments were performed in the conditions of plunge/in- depth smoothing of flat surface that is without a cross- feed. The electrolytic copper, containing in its chemical contents minimum 99.9% Cu, designated as Cu99.9E and the feature M1E, was the machined material. The flat semi-elastic grinding wheels T1A P of the bond BPE, containing the grains of aloxite 99A of number 46, were used, that is T1A 125 × 20 × 20 99A 46P BPE The wheel velocity v, longitudinal feed v and the in-feed a are contained in the following intervals closed on both sides: 31.5; , 14 8; 2, 0.4;0.1 , with the units corresponding to: m/s, m/min, mm/d·str., respectively. The assumed in the studies the kind of smoothing excludes one of the machining parameters, namely the cross-feed. The number of passages 5 p i was assumed as a constant. Through a proper statistic elaboration of the study re- sults, after performing the whole related procedure, the following empirical (statistic-experimental) formula was obtained: 0.54 1.27 1.07 0.67 esf a p va Rv (1) with the parameter a (the mean arithmetic profile de- viation from the mean line) expressed by the unit in [μm]. The units of the remaining magnitudes, for which the Formula (1) fulfills its role, are as follows: R v [m/s], a [mm], v [m/min], respectively. One should note that the measure of surface roughness, that is a, was determined here for f0.1; 0.2 mm/ d·str. The peripheral velocity of the wheel assumed the following values: 14; 21; and 31.5 m/s. That third ma- chining parameter, which is the longitudinal feed Ra v had the following values: 2; 4; and 8 m/min. Therefore, there were nine different values of the ve- locity quotients v obtained, that is the ratio of the ve- locities of the grinding wheel q v to the longitudinal feed v q . Thus, v = 105; 157.5; 210; 236.25; 315; 420; 427.5; 630; 945. Of course the same units are related to, namely [m/s]. The measurement results a of the smoothed surface for the whole these values of the quo- tient are presented in Table 1. q R v It is worthy noting that these two systems of experi- mental points are displaced in the way that the line relat- ing with the exponential and degressively rising func- tions may be drawn. That may be described analytically to obtain a result determined by a physical formula. That new formula is to possess a physical sense, being not an empirical (statistic-experimental) formula, without such Table 1. Measurement results of roughness measure of the smoothed surface. af, mm/d·str. 0.1 0.2 No. qv Ra, µm 1 105 0.175 0.37 2 157.5 0.21 0.49 3 210 0.28 0.53 4 236.25 0.245 0.60 5 315 0.35 0.77 6 420 0.42 0.98 7 427.5 0.42 0.91 8 630 0.49 1.19 9 945 0.56 1.47 a sense. Furthermore, first a general and then detailed descrip- tion of this kind of curve, which then could approximate those sets of experimental points, should be presented. 3. Derivation of the Form of Function Approximating Experimental Dependence of the Subject Roughness Measure on the Velocity Quotient That dependence may be created without any problem, however, under one condition. To do this, the whole space of changes of the roughness measure, regarding first of all the initial conditions of the process, should be related to and considered. That question, so essential, has been related to in the literature [2,22,23,31]. Indeed, the initial conditions regarded the surface finishing using elastic grinding wheels [2,22,23], concerning generally the tool life under cut [31], but the essence of it is analogous and should be related to the description of any process or phenomenon. At the very source, one should take advantage of the primary, general form of differential equation, describing any phenomena or processes, occurring in fact with vari- able, non-linearly variable velocity. Of course, it is about the velocity (rate), not a speed (vector magnitude); the velocity being the intensity (gradient) of changes of the considered magnitude, being a scalar magnitude, and here, not connected with time. The mentioned source differential equation [2] has the following form: d Zd N N (2) where dZ—total differential of dependent variable, dN— total differential of independent variable, —partial derivative of dependent variable, referred to the indepen- N Copyright © 2011 SciRes. JQIS  Z. PLUTA & T. HRYNIEWICZ Copyright © 2011 SciRes. JQIS 154 dent variable. The signs are the algebraic operators, fulfilling a determined role. The sign has a formal meaning, just confirming the physical sense of the de- termined dependence. The sign ascribes such a sense to a determined record. course in the point 1, where the process of smoothing using a determined grinding elastic wheel has its end. Thus one should take into consideration both the be- ginning and the end of variability intervals of the de- pendent variable a and independent one v. These limits of both of the mentioned variables have their physical meaning concerned with the studied techno- logical system. The initial point corresponds with the zero peripheral velocity of the wheel, which is the pa- rameter as the measure of roughness of the surface smoothed by the motionless grinding wheel. The final point of the curve refers to the neuralgic machining situa- tion, while the wheel operates on the limit of the resis- tance to disrupture. Therefore, further work of the wheel, above the terminal velocity, is impossible. R q 0 a R For the considered variables the Formula (2) has the following form: da v R q a R (3) because the dependent variable is , and the inde- pendent variable . a R v Now this dependence should be integrated on both sides, remembering that the total differential is the state function. Furthermore, that requires the determination of states, i.e. the limits of integrating: bottom and top. q Here the quantum nature of the described system may be noticed. A part of the system has been revealed; be- hind the limits, for a determined elastic wheel, that sys- tem does not exist. That example proves the macro-real- ity has also such a quantum nature. The literature [31] provides further examples confirming that nature. There the analytical quantum changes of the tool life under cut, The scheme of creation of the adequate description of the dependence av is presented in Figure 3, showing all elements of this process of reasoning. The curve illustrating that dependence comes out of an initial point of coordinates , , and then it proceeds expo- nentially and degressively rising. It completes its real q 0 a R Rf 0 Figure 3. Indicatrix of dependence of the roughness measure a on the velocity quotient . v q  Z. PLUTA & T. HRYNIEWICZ 155 the changes dependent on the main velocity, being the sta tool or the workpiece velocities, have been presented. The mentioned limits, concerning the studied techno- logical system, are the potential fields. These fields are situated on two directions; one of them is the direction of changes of the parameter a R, whereas the second one is the direction of changes of the velocity quotient, that is v q. On the first direction there are: bottom roughness ble potential field 0 a BSPF , top roughness stable potential field 0 a TSPF ness unstable potential , rough field 1 a APF , an nominal roughness potential d the field a NPF . On the second direction there are the following fields: quotient stable potential field 0 SPF , v q quotient unstable potential field 1 v q PF . Bete ween th fields 0 a BSPF and 0 a TSPF s a potential there i band. The fields 0 a TSPF 1 , a APF, and 0 SPF v q and 1 v q PF delim, it the interstate space (dotted area) wheronential and degressively rising changes of e the exp the parameter a R take place. The curve of roughness measure, comprised between the points 0 - 1, is the envelope of the right-angled trian- gles, moving with its horizontal leg on the nominal po- tential field a NPF ; with the horizontal leg being invariable and the nominal quotient constant Θ, and the vertical leg changing respectively, decreasing with the displacing triangle in the direction of the veloc- ity quotient. That nominal field is situated symmetrically against the level of the end of the described system, on the distance equal the length of the real space-time in the direction of the surface roughness measure. Therefore over the real (proper) space there is an im- pr equal to oper space situated, where the curve (dashed line) ap- proaches towards the asymptote, being the mentioned potential field. This creation forms an auxiliary design, required to the description of the real curve, reflecting the adequate dependence of a R on v q. Now one may begin to intate thEquation (3), and in fact egre only one of its version, regarding the sign ; it concerns the analyzed course of the parameter R, that is the course indeed exponential, but rising degreively, where the increments of the studied roughness parameter decrease, respectively. Therefore a ss dd a R Rq av v q (4) By integrating the Equation (4), one has to denote the limits of integrals of the total differentials. That means 110 0 dd a av Rq q aaa v v aa RRR q vq RR R (5) and further 10 d 2d a aa a v R RR Rq (6) or 10 d1d 2 a v aa a Rq RR R (7) One may notice the partial derivative h tuted by the quotient of the regular total differentials. It co as been substi- uld be done that way as the regular total differentials have been distinctly determined by introducing the limits of their integrals. Furthermore, by intergrating both sides of the Equa- tion (7), one obtains the result 10 * 1 ln 2aa a RR RqC v (8) that is ** 10 2eeee vvv qq CC aa a RR RC q (9) After taking into account that for the magni- tude 0 v q 0 a R , one obtains 10 2aa CRR (10) and astituting (10) t fter subo (9), and then, regarding a 0 aa RRR 010 21e v q RR RR (11) aa aa Now one may determine the second coo point 1, that is. It is obtained by introducing the pa- ra (12) an rdinate of the 1 v q meter a R and the mentioned coordinate v q to the Equation (11). Thus 1 1 1 ln 2 v q d 1 ln 2 v q (13) Therefore the Equation (11) is cally for determined mathemati- 0, v q , whereas physically for 1 0, vv q. Furthermore, however, that equation is not adjusted to the practical usage because it co q ntains a nominal quotient constant; placed on the nominal field, being the asymptote, with that improper (mathematic) Copyright © 2011 SciRes. JQIS  Z. PLUTA & T. HRYNIEWICZ 156 he part of the curve of the parameter a R approaching it. It should be expressed as a function of its real quotient constant * . That dependence may derived by taking advantage of the scheme (Figure 4). From t Thales of Milesios theorem the following proportion results be * 10 10 2aa aa RR RR (14) so (15) and * 2 * 2 (16) and after regarding the dependence (13) 1 * 2ln2 v q (17) and (18) Thus, after substituting (15) to ( 1* 2ln2 v q 11), one obtains * 010 2 21e v q aa aa RR RR ( 19) And then the equation is adjusted to the where the adequate characteristics of the studied system ex real space, ist. Figure 4. Auxiliary scheme to the derivation of dependence between the nominal and real quotient constant. Ta d theory, first of all one hould determine the values of coordinates , with the * 4. Statistic Elaboration of Results of Experimental Studies king advantage of the presente s* qv coordinates determining the position of the straight line, tangent to the searched, adequate course of the parameter a R. These coordinates result from the Formula (17), then 1 *v v q q (20) 2ln2 The calculation results of these indicate that they are lower in values than the experi- m where the symbol denotes th coordinates (Table 2) ental coordinates. The values * v q should be now elaborated statistically by approximating them according to the dependence 0* 0 aa v RRkq (21) 0 k he in (m e initial coefficient of intensity (rate) of tcrement a R, that is the surface roughness measure ean arithmetic profile deviation from the mean line). That coefficieis with the same the first derivative of the function av Rfq for 0 v q nt , then 0 0 d dv a vq R kq (22) For the general written linear dependence of this type yabx (23 oefficients a and b are dete ) the c following formulae: rmined according to the 111 2 2 11 nnn niiii iii nn ii ii xyx y b nx x (24) Table 2. Results of measurements and calculations of the magnitude characterizing the studied technological reality. af, mm/d·str. af, mm/d·str. 0.1 0.2 Ra, µm qv Ra, µm qv * v q * v q 0.175 105 76 105 76 0.37 0.21 157.5 113 157.113 0. 236. 427. 0.49 5 0.28 210 151 0.53 210 151 245 236.25 170 0.60 25 170 0.35 315 227 0.77 315 227 0.42 420 302 0.98 420 302 0.42 427.5 308 0.91 5 308 0.49 630 0.56 945 453 680 1.19 1.47 630 945 453 680 Copyright © 2011 SciRes. JQIS  Z. PLUTA & T. HRYNIEWICZ Copyright © 2011 SciRes. JQIS 157 11i b 1n n ii ayx 5) with the formulae being the result of us least sum of the deviations squares of i n (2 ing the rule of the experimental and theoretical values, resulting from the position of linear regression function. That rule is described in detail in the literature, e.g. [32-35]. The comparison of the magnitudes needed to calculate the values of the coefficients of the linear regression: initial roughness parameter a R and the initial coeffi- cient of intensity (rate) of the increment of a R in the Formula (21) is presented in Table 3. The coefficient is described by the following formu- lae: 0 ** nnn vav a ii ii nq RqR 11 1 02 2 ** 11 iii nn vv ii ii k nq q (26) 0* 0 11 1nn aa ii ii RRkq n v (27) Thus for mm/d·str. 0.1 f a 4 02 9 2480 9 1059.3824803.156.55 10 975452 k μm (28) 04 13.156.55 1024800.17 9 a R μm (29) Therefore (30) By substituting the terminal limit va 0. 4* 0.176.55 10 av Rq lue of a R, that is 56 μm to the Equation (30), one obtains ** 595 v q . Thus 2595 1190 , thlts fromla (15). T) may be now presented in the quantitative form, by introducing the values 00.17 a R μm, 10.56 a R μm, and 595 at resu the Formuhe dependence (11 to it. Therefore 1190 0.170.78 1 v q a Re (31) That has been also presented graphically (Figure 5). That is a quantitative dependence of the roughness mea- sure a R on the velocity quotient v q for the in-feed 0.1 f a mm/d·str. Furtrmore, for 0.2hef a mm/d·str. 4 02 9 2555.223118.52k 2480 710 9 9754522480 μm (32) 04 17.31 18.52 1024800.30 9 a R μm (33) Therefore (34) By substituting the terminal limit valu 1. 4* 0.3018.52 10 av Rq e of a R, that is 47 μm to the Equation (34), one obtains ** 632 v q . Thus 2 6321264 , thlts from at resu Table 3. Comparison of magnitudes needed to calculat the Formula (15). T) may be now presented in the quantitative form, by introducing the e the values of coefficients of linear regression. he dependence (11 af, mm/d·str. af, mm/d·str. ai 0.1 0.2 , µm * vi q 2 * vi q * va i i qR ai , µm * vi q 2 * vi q * va i i qR i 1 0.175 76 5776 13.30 0.37 76 5776 28.12 2 0.21 113 12769 23.73 0.49 113 12769 55.37 3 0.28 151 22801 42.28 0.53 151 22801 80.03 4 0.245 170 28900 41.65 0.60 170 28900 102.00 5 0.35 227 51529 79.45 0.77 227 51529 174.79 6 0.42 302 91204 126.84 0.98 302 91204 295.96 7 0.42 308 94864 129.36 0.91 308 94864 280.28 8 0.49 453 205209 221.97 1.19 453 205209 539.07 9 0.26 380 462400 380.80 1.47 680 462400 999.60 3.15 2480 975452 1059.38 7.31 2480 975452 2555.22  Z. PLUTA & T. HRYNIEWICZ 158 a Figure 5. Dependence of roughness measure on the velocity quotient for the in-feed ·str. v q0.1 f amm/d values 00.30 a R μm, 11.47 a R μm, and 1264 to it. Therefore 1264 0.30 2.34 v q a R 1 e (35) That has been also presented graphi That is a quantitative dependence of the sure presented material the rules of using of tic grinding wheels are not the same, cally (Figure 6). roughness mea- a R on the velocity quotient v q for the in-feed 0.2 f a mm/d·str. 5. Summary It results from the the compact elas congruent to the rules relating to the rational exploitation of the ceramic wheels. These rules are in fact reversal and cannot be a criticless copy of the rules of grinding using the mentioned ceramic wheels. It is important not to follow the groundless technological imitation, relying on the equality of the two operations: smoothing/flexible grinding and a conventional grinding. Thus, as it has been indicated, to obtain the advanta- geous finishing results by machining using the elastic grinding wheel, the possibly least values of the velocity quotient should be used; contrary to the grinding using a ceramic wheel where the direction of the value changes of this parameter should be reversal. That is quite a valuable observation; knowing that it is not necessary to a Figure 6. Dependence of roughness measure on the velocity quotient for the in-feed ·str. manufacture the elastic wheels of such numerous a d differentiated sizes of the abrasive grain. The effect g wheel v q0.2 f amm/d n of the size of this component of the wheel is essential only in case of grindinusing the ceramics. It is worthy underlining the presented and completely solved the quest of elaboration of the experimental mate- rial, the sets of points of the coordinates being the veloc- ity quotient and a determined surface roughness measure, respectively. The introduced quantitative dependences have a physical meaning which is their essential attri- bute. That type of courses, degressively rising, are charac- teristic for many different systems; they have no analyti- cal and uniform physical description. The courses do not possess a separate interval of the physical definition, turning towards the asymptote, and that is possible only Copyright © 2011 SciRes. JQIS  Z. PLUTA & T. HRYNIEWICZ 159 hus commonly used parabolic regres- si may be used with a success to the approxim of anical Polishing of Metals,” W Warszawa, 1968. amentals of Surface Smoothing Using Elea- sic Grinding Wheels,” Wydawnictwo Politechniki Kosza- heel for Polishing and Micro-Chips cki, Po- mme of Kronem-R-Flex Abrasives,” Prospectus Abrasive Materials. Delivery Programme ed Grinding Fundamental High Peripheral Velocities e, and Ero- Annals of CIRP, Vol. 23, No. 1, 1974, pp. 103-104. sive Tools of Porous Elastic Bonds,” rasive Tools of on the Surface Quality,” Werkstatt und ed from Post-Copper Slag,” Werkstatt und Trennen, Vol. ternational in mathematics. There are some new achievements of the presented work. Firstly, it is the quantitative approach to the effect of velocity quotient on the roughness measure of ma- chined surface. T Post on, relying on substitution of the multiple experimental points has been abandoned. It was discovered that a sig- nificant decrease of velocity quotient leads to the essen- tial influencing roughness of the treated material. More- over, the presented model may have a broader applica- tion. It results that the presented here the method of elabo- ration of sets of experimental points, with the system indicating their exponential and degreessively rising course, ation 107, No. 2, 1983, pp. 7-11. [20] S.-S. Cho, Y.-K. Ryu and S.-Y. Lee, “Curved Surface Finishing with Flexible Abrasive Tool,” In experimental material, characterizing also other phe- nomena or processes. 6. References [1] M. Rodziewicz, “MechNT, [2] Z. Pluta, “Fund lińskiej, Koszalin, 2007. [3] “‘Soft’ Grinding W Removal,” Prospectus of SLIP-NAXOS, 2000. [4] “Elastic Grinding Wheels,” Catalogue of ARTIFEX, 1999. [5] “Elastic Polishing Wheels,” Prospectus of Grinding Wheels Manufacture of Grodzisk Mazowie land, 1998. [6] “Progra of KLINGSPOR, 2001. [7] “Grinding and Polishing,” Catalogue of LUKAS, 2002. [8] “Systems of ,” Catalogue of 3M, 1997. T. Sierżant, E. Weiss and Z.[9] Weiss, “Selected Problem of High-Speed Grinding,” Biuletyn Techniczny, Vol. 19 s , No. 9-10, 1975, pp. 109-114. [10] F. I. Klocke, “High-Spes and State of the Art in Europe, Japan and the USA,” Annals of the CIRP, Vol. 46, No. 2, 1977, pp. 715-724. [11] “Grinding with Elastic Bond. Favour Effectiveness of Machining,” Maschinen und Wer- kzeug, Vol. 100, No. 1-2, 1999, pp. 44-45. [12] J. Kaczmarek, “Fundamentals of Chip, Abrasiv sive Treatment,” WNT, Warszawa, 1970. [13] L. Burnat, “Grinding and Superfinish of Metals,” WNT, Warszawa, 1962. [14] M. Kieda, A. Hamada and S. Shiratori, “Polishing of Sili- con Single Crystals with an Elastic Wheel,”the [15] Z. Pluta and K. Woźniak, “Some Aspects of Manufacture and Use of Abra ępy Technologii Maszyn i Urządzeń, Vol. 7, No. 3, 1983, pp. 39-56. [16] K. Woźniak, “Manufacture of Elastic Ab Polyurethane Bonds,” Chemik, Vol. 35, No. 11-12, 1982, pp. 137- 141. [17] Z. Pluta, “Effect of Machining Parameters using Elastic Grinding Wheels Betrieb, Vol. 7, No. 6, 1988, pp. 487-489. [18] Z. Pluta and K. Woźniak, “Cutting Ability with Abrasive Grains Obtain Betrieb, Vol. 121, No. 10, 1988, pp. 843-847. [19] W. Kacalak and Z. Pluta, “Grinding and Polishing Using Elastic Abrasive Wheels,” Schleifen und Journal of Machine Tools Manufacture, Vol. 42, No. 2, 2002, pp. 229-236. doi:10.1016/S0890-6955(01)00106-7 [21] S. Makuch and W. Kacalak, “The Elastic Properties of the Flexible Grinding Tools with Polyurethane Bonds,” Advances in Manufacturing Science and Technology, Vol. 30, No. 1, 2006, pp. 89-99. [22] Z. Pluta and T. Hryniewicz, “Verification of Forecasts on Surface Finishing Results of Peripheral Smoothing,” In- ternational Journal of Advanced Manufacturing Tech- nology, Vol. 42, No. 5-6, 2009, pp. 515-522. doi:10.1007/s00170-008-1616-0 [23] Z. Pluta and T. Hryniewicz, “Initial Cutting Conditions by Abrasive Grain Fixed Flexibly,” International Journal of Advanced Manufacturing Technology, Vol. 43, No. 5-6, 2009, pp. 440-448. doi:10.1007/s00170-008-1722-z [24] Z. Pluta, “Butt-Mounted Elastic Wheel,” Utility Pattern tility nd Device to Smooth External Ro- , Vol. 64, No. 3, 1991, pp. ur Metals,” the Surface Roughness Smoothed by the RP No. 55144, 1997. [25] Z. Pluta, “Mounting to Fix Flat Abrasive Wheels of High Susceptibility,” Patent RP No. 171852, 1997. [26] Z. Pluta and A. Markiewicz, “Elastic Wheels,” U Pattern RP No. 53832, 1996. [27] Z. Pluta, “The Way a tary Surface with a Disk-Type Grinding Wheel of High Susceptibility,” Patent RP No. 168170, 1996. [28] Z. Pluta, “The Effect of Bond Kind on Some Properties of Elastic Wheels,” Mechanik 110-116. [29] K. Woźniak and Z. Pluta, “Use of Elastic Abrasive Wheels of Post-Copper Slag to Polish Colo Werkstatt und Betrieb, Vol. 120, No. 1, 1987, pp. 55-58. [30] Z. Pluta and K. Woźniak, “The Effect of Machining Para- meters on Grinding Wheels of Porous Elastic Bonds,” Postępy Tech- nologii Maszyn i Urządzeń, Vol. 11, No. 1-2, 1987, pp. 45-58. [31] Z. Pluta and T. Hryniewicz, “Advanced Model of the Tool Edge Blunting under Machining,” International Journal of Advanced Manufacturing Technology, Vol. 51, No. 1-4, Copyright © 2011 SciRes. JQIS  Z. PLUTA & T. HRYNIEWICZ Copyright © 2011 SciRes. JQIS 160 2010, pp. 35-43. doi:10.1007/s00170-010-2595-5 [32] K. Mańczak, “Technique of Experiment Planning,” WNT, Warszawa, 1976. Introduction to Scientific Studies,” 2nd “Statistical Adjustment of Data,” Wiley, ist of More Important Notations [33] H. Szydłowski, “Theory of Measurements,” PWN, Wars- zawa, 1978. [34] E. B. Wilson Jr., “ Edition, PWN, Warszawa, 1968. [35] W. E. Deming, New York, 1938. L* —real quotient constant 0 BSPF —bottom roughness stable potential field a a—in-feed a 0 v—velocity in the feed motion TSPF —top roughness stable potential field v—peripheral velocity of the grinding wheel rowth of 1 a APF —roughness unstable potential field v k q—velocity quotient —initial coefficient of intensity of the g oughness a NPF —nominal roughness potential field 0 measure of the surface r 0 v q SPF 1 a R—surface roughness measure (mean arithmetic pro- file deviation from the mean line) —quotient stable potential field v q PF —quotient unstable potential field —nominal quotient constant

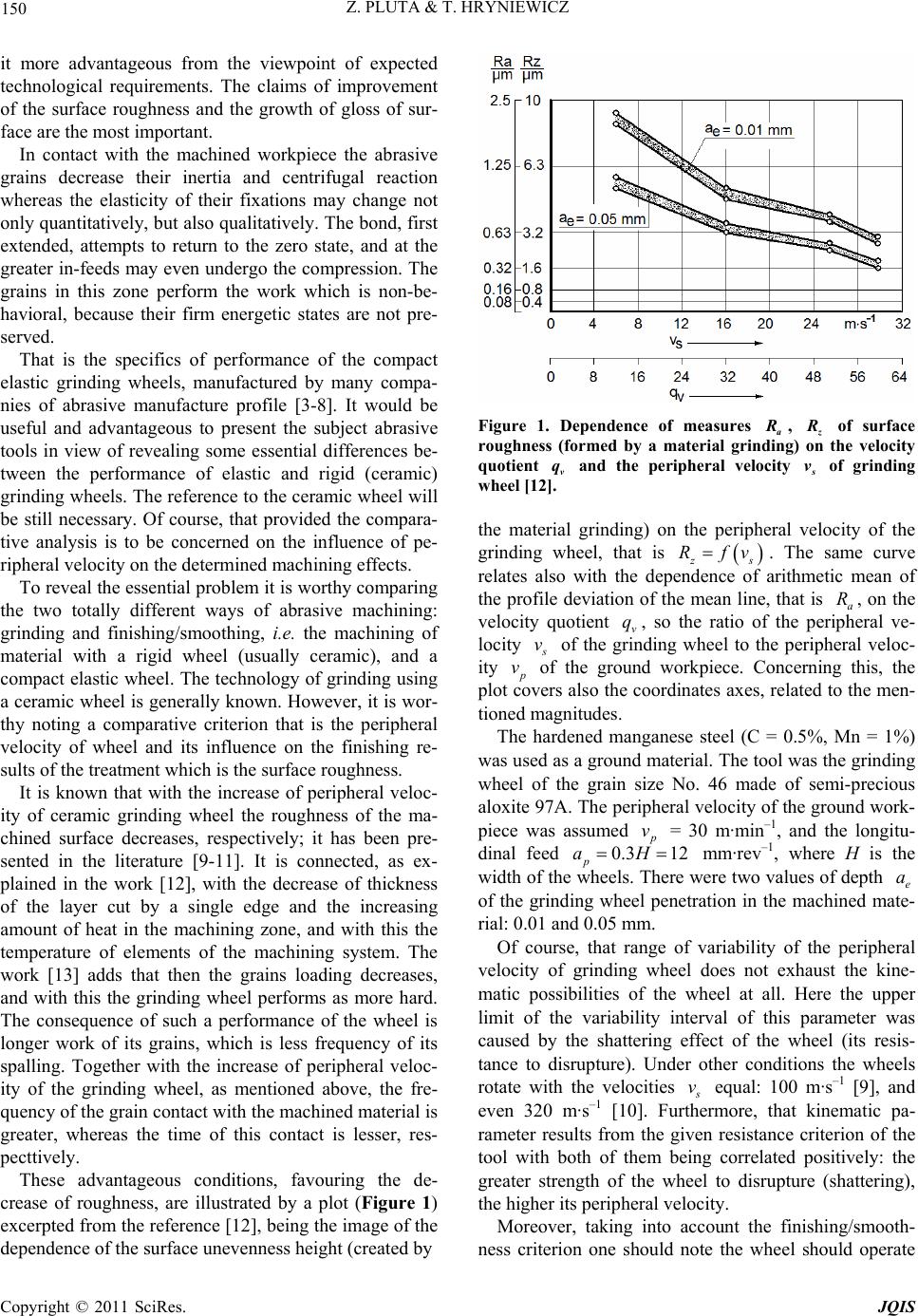

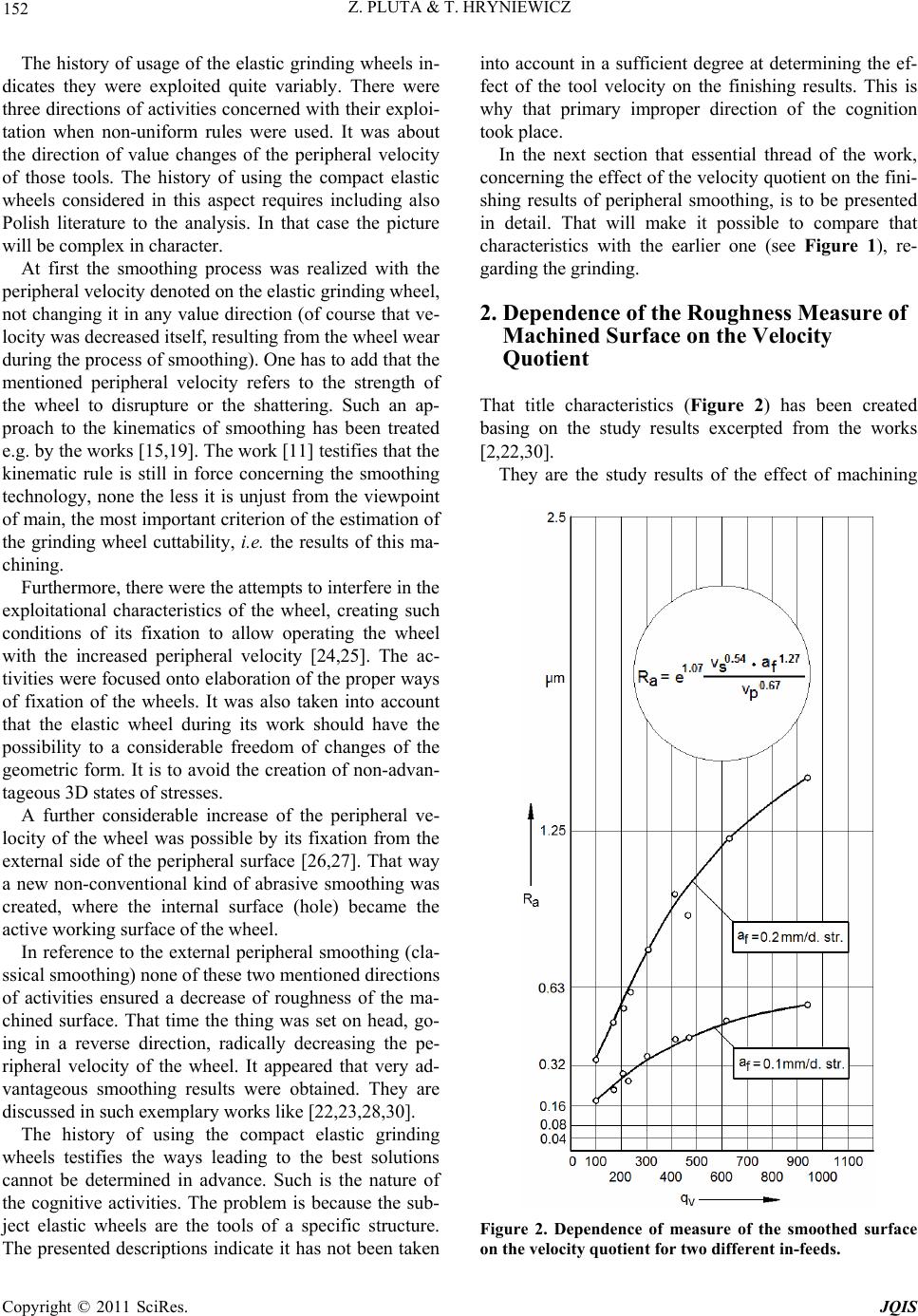

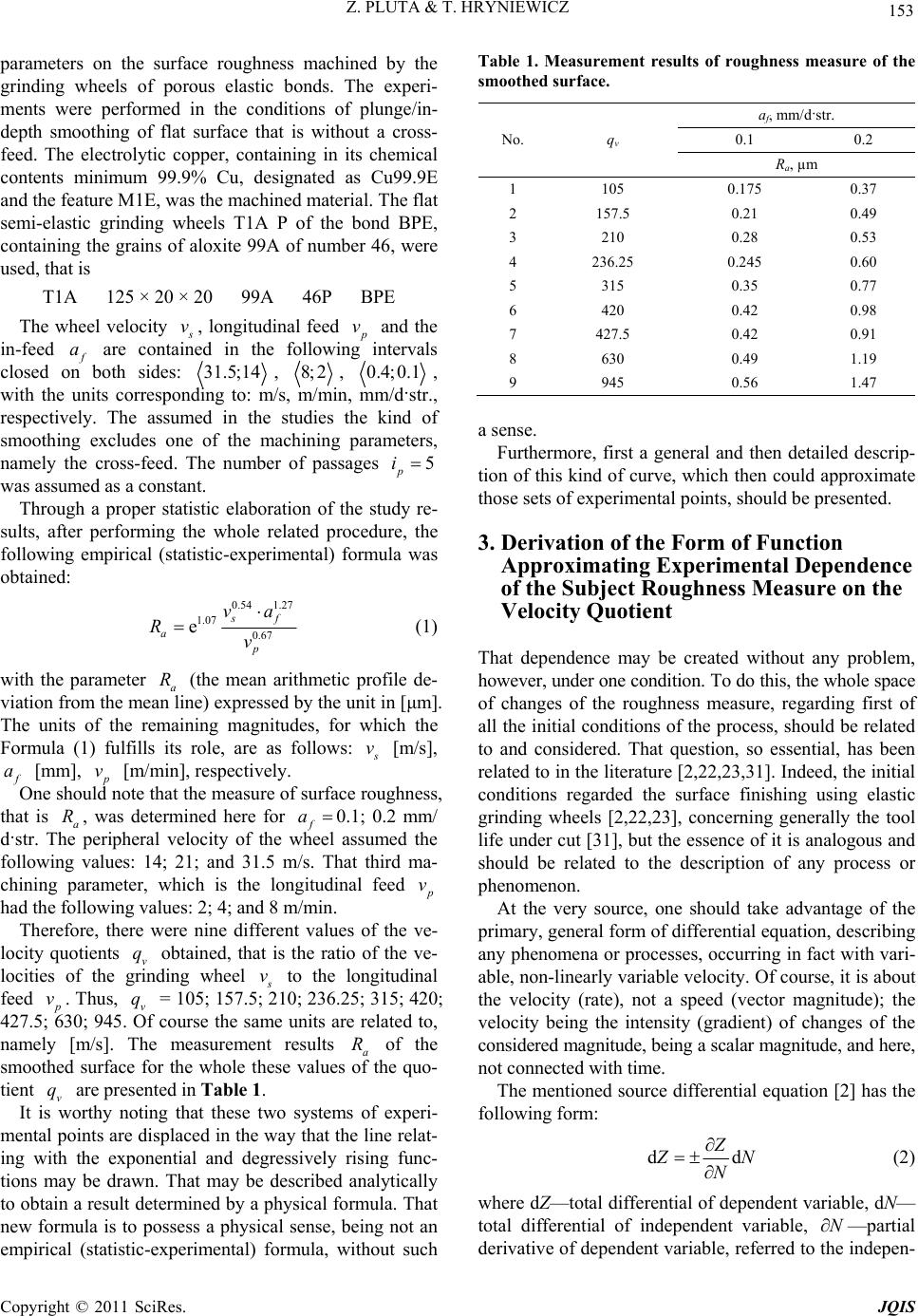

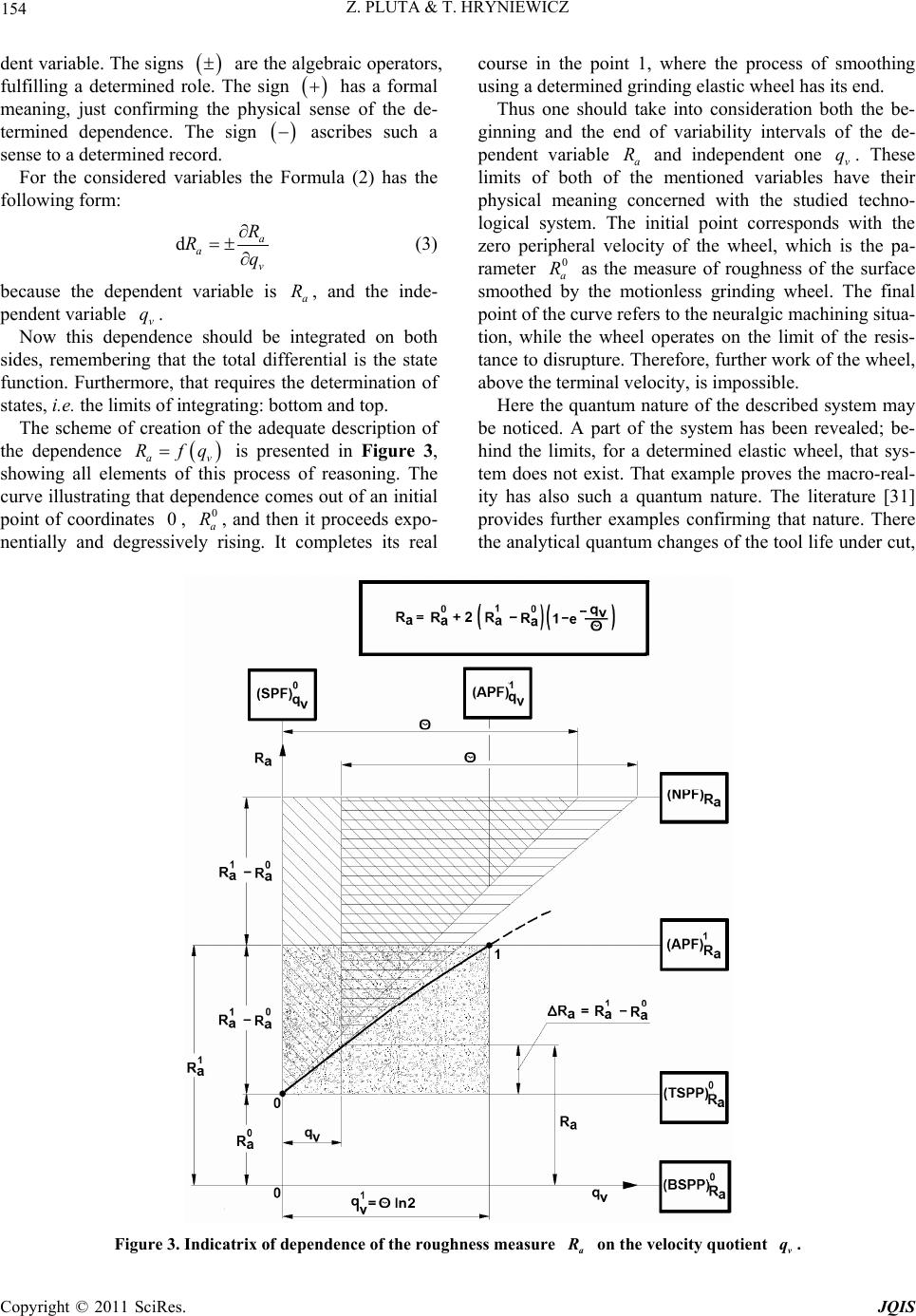

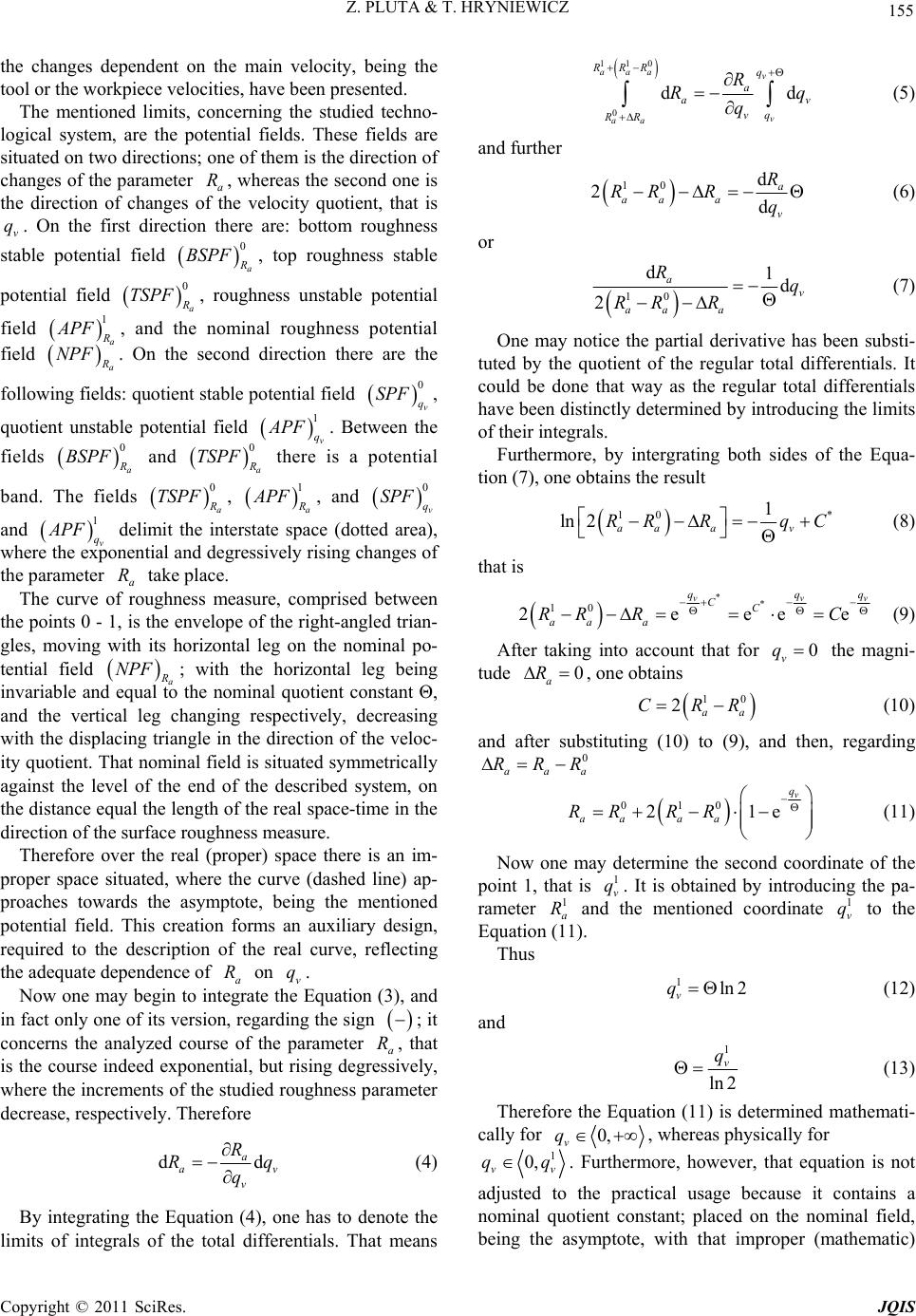

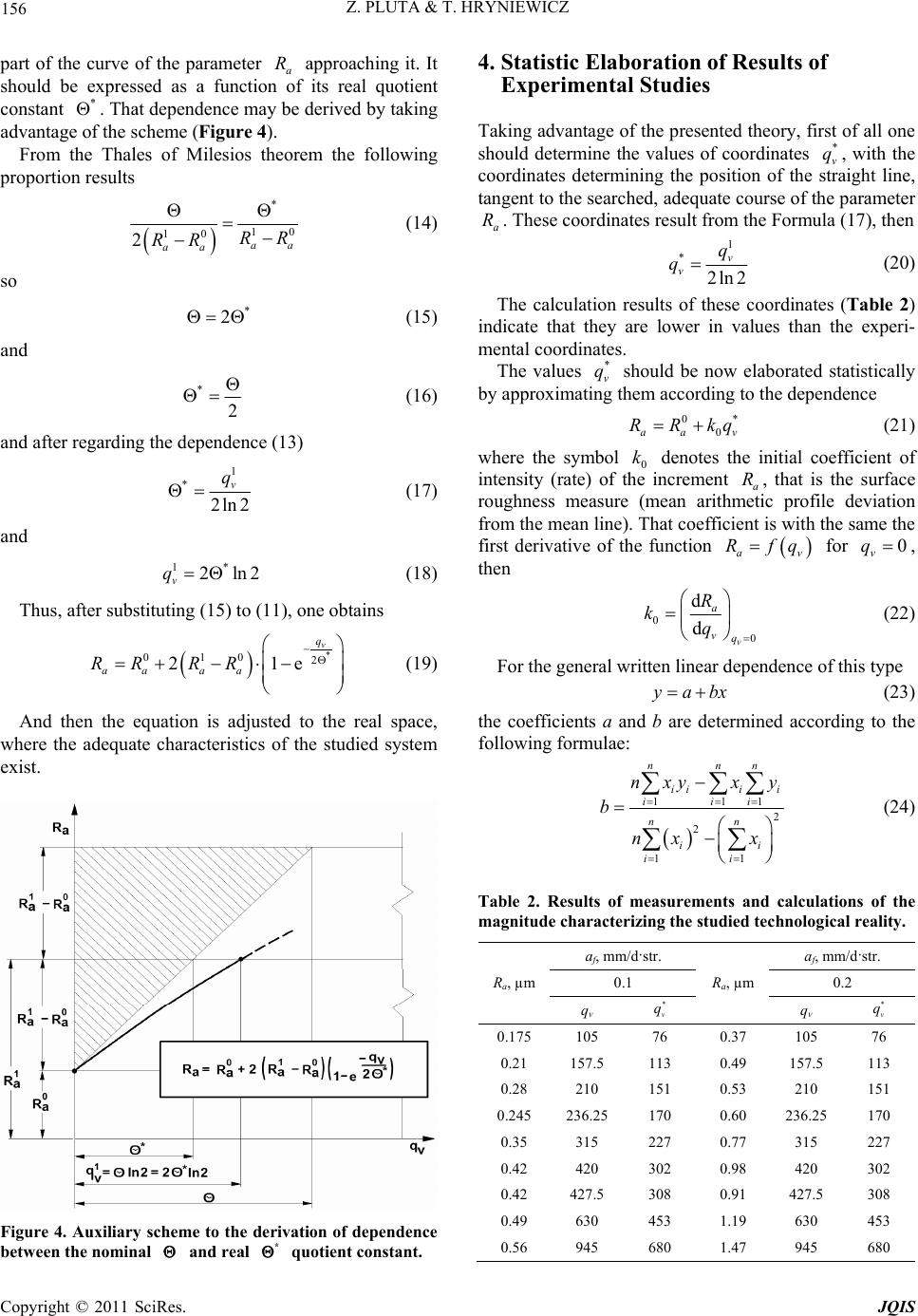

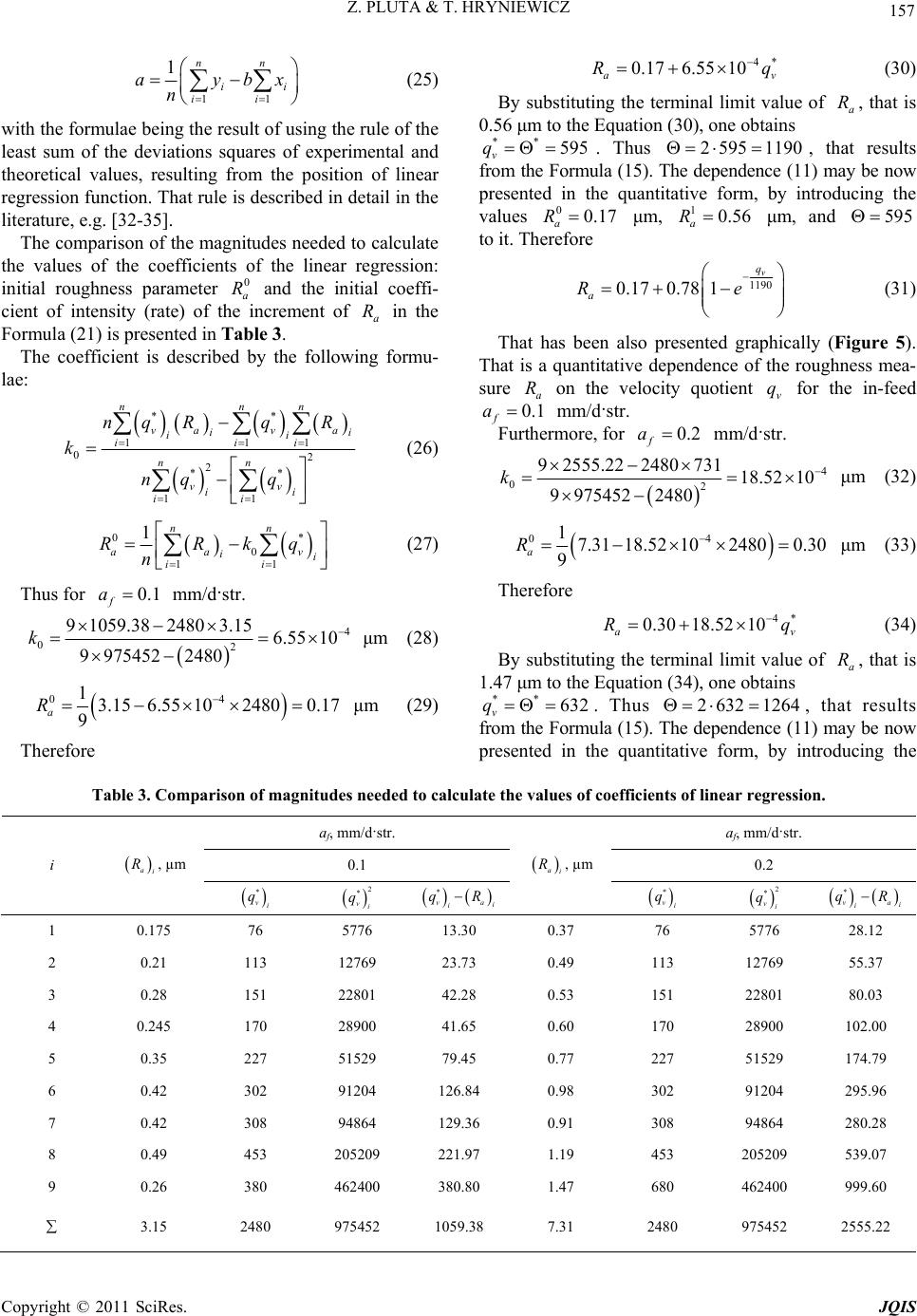

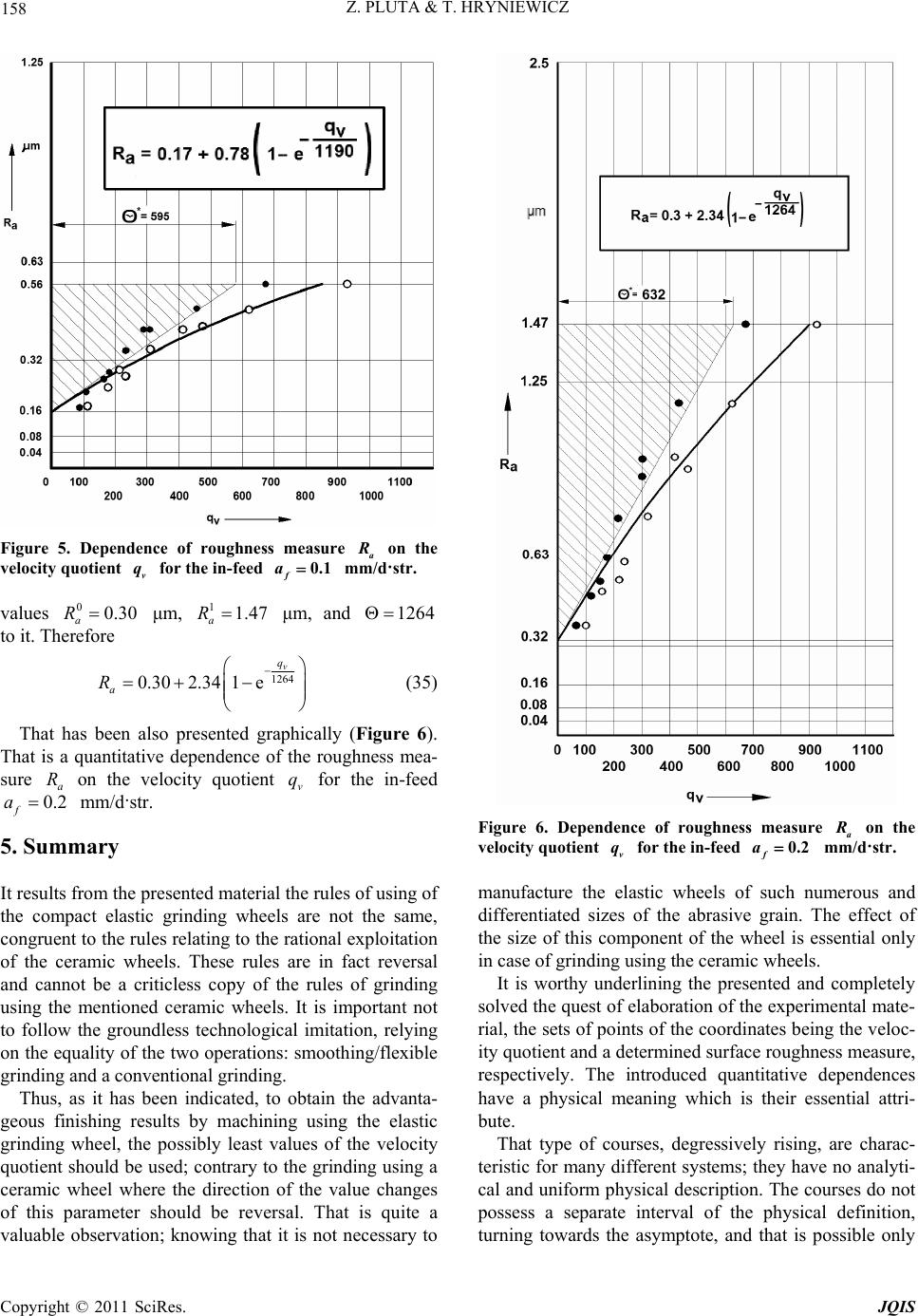

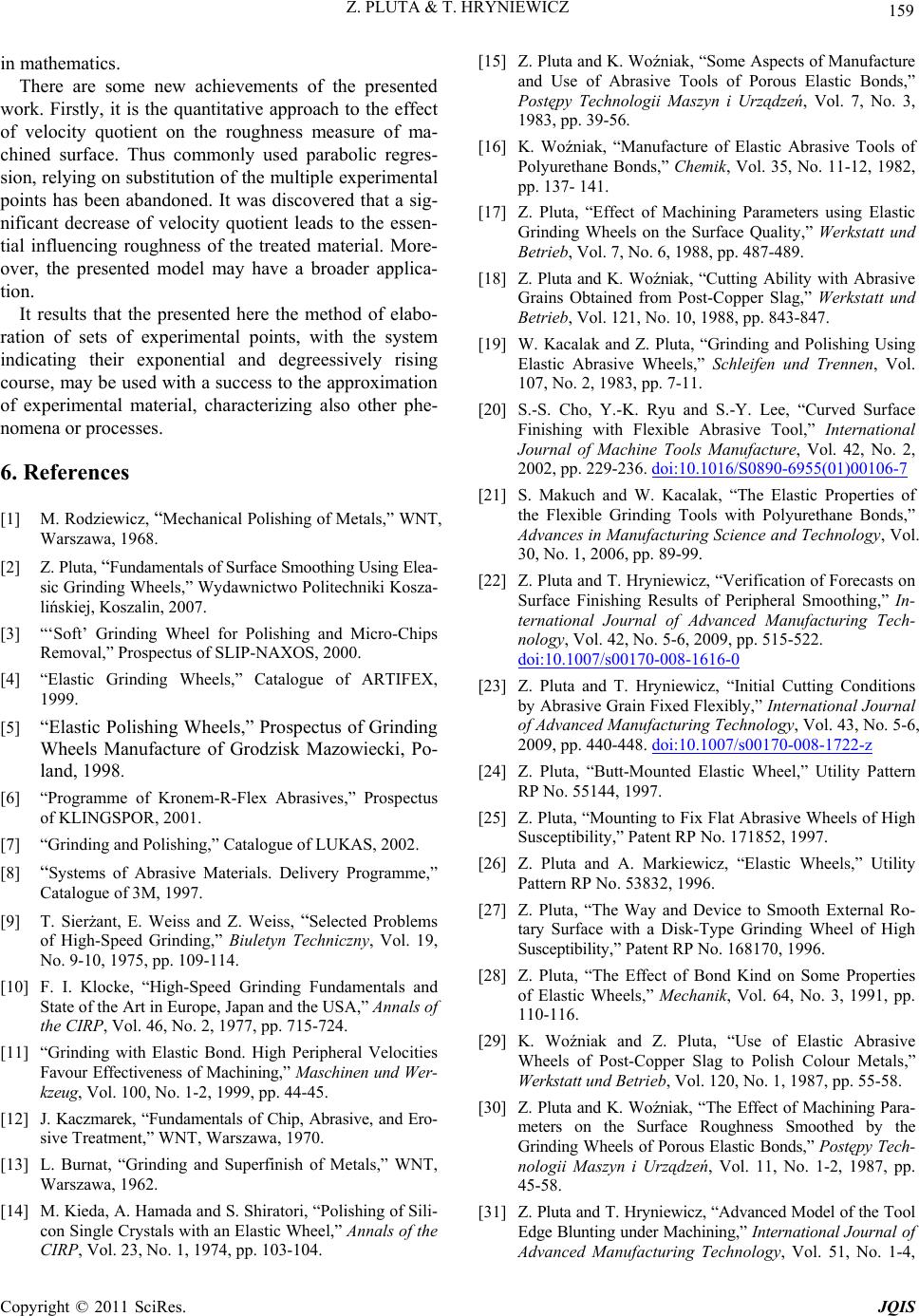

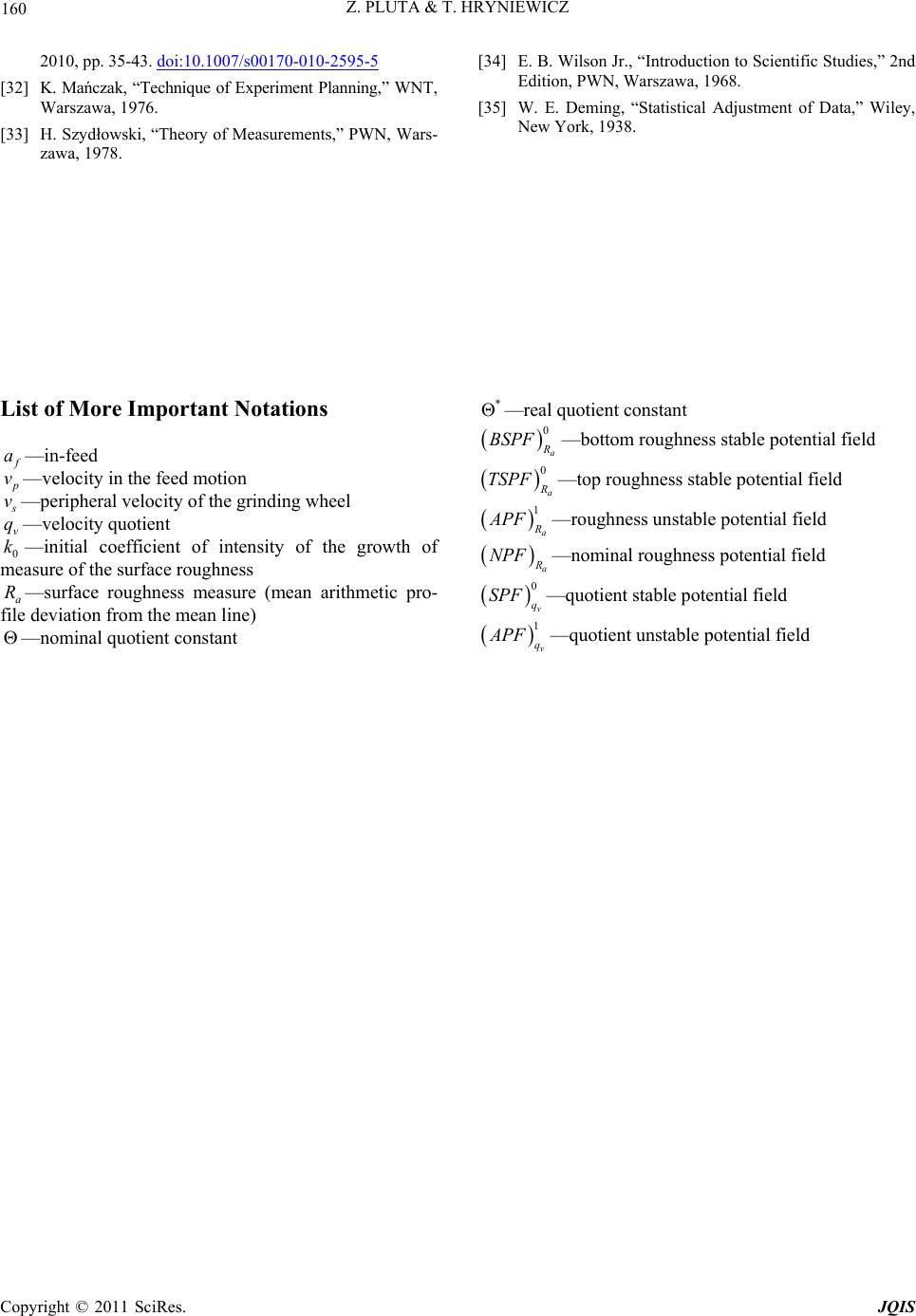

|