Journal of Electromagnetic Analysis and Applications

Vol. 5 No. 5 (2013) , Article ID: 31756 , 6 pages DOI:10.4236/jemaa.2013.55038

Features of Usage of Electromagnetic Field of Extremely Low Frequency for the Storage of Agricultural Products

![]()

1Meat and Fish Products Department, FSBEI HPE, Kuban State Technological University, Krasnodar, Russia; 2Phylology Department, FSBEI HPE, Kuban State Technological University, Krasnodar, Russia.

Email: kasyanov@kubstu.ru, 1syazin@gmail.com

Copyright © 2013 Kasyanov Gennady Ivanovich et al. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Received November 3rd, 2012; revised December 5th, 2012; accepted December 18th, 2012

Keywords: Agricultural Raw Materials; Electromagnetic Processing; Low Frequencies; Storage; Drying

ABSTRACT

The way of increase of storage period of agricultural raw materials under the influence of low frequency electromagnetic field (EMF LF) has been considered in the article. Existing developments of the EMF LF usage on the base of patents have been examined. The results of EMF LF processing of wood, wine, seeds, vegetative, fish and meat products have been presented.

1. Analyses of Existing Developments

The magnetic field as an active factor in agriculture has more than 50-year history. Important applied investigations were made in Russia, the results of which were the creation of technological lines of magnetic systems for pre-processing vegetative plantings seeds. Conditions under which the application of the magnetic field shows stable results stimulation—increase of the yield by 12% - 30%, depending on the culture, the initial quality of the seeds and growing conditions of plants—were found out.

The main application results with the help of gradient magnetic field (GMF) application have been obtained. Low energy consumption of GMF-processing of seeds in combination with a low intension of magnetic field (1 - 12 mT), absence of noise magnetic field outside the zone of seeds processing (a level of tension equals 0.01 mT at a distance of 0.5 m from the processing zone) makes these plants absolutely safe for service personnel. Nonhigh price of GMF-plant complements the advantages of this equipment.

Almost all the scientific works devoted to the impact of electromagnetic field of EMF LF or of GMF, were intended to stimulate the vitality of plants.

The exposure of extremely low frequency electromagnetic field having certain parameters has the property to suppress the growth of fungal microorganisms and bacteria almost completely [1].

The biological effects of modified water with isotopic composition, magnetically processed water and electrochemically activated water were examined [2]. It was shown that the light water can be used to create functional products. The electro-activated water with different pH and the redox potential has been obtained. The relaxation period and the return to the stable condition of water samples have been investigated. It was determined that the addition of alkaline fraction of activated water for the salting of chopped meat let to move the pH to higher values of the isoelectric point of the muscle proteins, which in sausage production can be made by the entering of various phosphates.

The way of agricultural products storage that provides the laying of beet piles has been developed [3]. While the storing before the processing, the roots have been processed by a constant magnetic field (which magnetic induction was 0.1 mT) during 50 min, and the amplitudemodulated electromagnetic field with a carrier frequency of 1 kHz and the frequency modulating oscillations, which are in the low frequency range of 3 - 30 Hz. The method reduces the loss of sucrose in the roots during the storage and increases its output by processing them in a sugar factory.

The way of beet storage in beet-sugar factories has been developed [4]. The method involves laying beets in piles next to it and location close to laser and radiator of electromagnetic field so that the maximum number of lines of the magnetic induction of electromagnetic field permeating beets. During the storage before reprocessing an exposure by extremely low electromagnetic field in the range of 3 - 30 Hz for 40 min with the following processing by the laser radiation in the range of 610 - 680 nm began in roots. The method let to reduce the loss of sugar in the roots during the storage and enhance its release in the beet reprocessing plant.

The method of agricultural seeds processing before seeding which increases the germination of seeds and the performance of the production line has been developed [5]. The seeds before planting are processed by the static magnetic field at its strength of 200 to 900 A/m and at the same time by the electromagnetic field, phase-modulated waves of extremely low range during 40 - 60 min at a field strength of 120 - 1400 A/m.

The way of drying has been developed [6]. The invention relates to the wood and the food industries, in particular, to drying methods of wood and of vegetative and animal raw materials origin. The method consists of the fact that the drying process of wood, fish, meat, cherries, carrots, etc. produced by EMF LF ranges of various modifications, with the carrier frequency for all types of modulated electromagnetic fields can be 30 - 1013 Hz, and the intensity of each of electromagnetic field is 10 - 1400 A/m, the length of exposure is 10 - 900 min. This method reduces the power consumption in the comparison with known methods down to 103 times.

The importance of discovered abilities is difficult to overestimate. There are tremendous opportunities to regulate the development of fungi in the case of safe preservation of agricultural products, for example, in wining to stop the fermentation process or usage in the production of animal feed, etc.

The action of the electromagnetic field (EMF LF) on biological systems was studied almost since the first generators of EMF LF. The exposure of electromagnetic fields on biological systems in the significant tension (leading to thermal effects in biological systems) has been studied sufficiently on this moment, but the weak impact of low-intensity fields (non-thermal nature) has not been sufficiently studied [1].

In an investigation of weak interactions, the traditional approach of describing the object of quantitative characteristics encounters fundamental and insurmountable difficulties. Quantitative characteristics of the exposure (for example, the coherence or an order) have an essential meaning in this sphere [7]. In addition, under the influence of the first type, biological objects usually activate protective mechanisms which help to compensate this effect, but weak influence doesn’t have such effect [8].

The theme of specific action of EMF LF (3 - 30 Hz) was described in many scientific works, especially increased in the last 10 years, but the primary mechanism of this action is unclear to the end till this day [9].

Having based on the results obtained in the sphere of biophysical investigations, it is possible to develop new low-power-consumption methods of processing of fish raw materials with the aim of the reduction of microbial contamination and the shelf life extension. Electromagnetic waves of different ranges propagate in the space differently. Difference in the conditions of electromagnetic waves propagation is caused primarily by the fact that at different frequencies, the ratio changes between the displacement current and the conduction current environment.

2. The Purpose of Investigations

The aim of the investigation was to increase the nutritional value and the commercial quality of agricultural raw materials by processing by impulse EMF LF of the seminal material and laid deposit products.

3. Research Methods and Laboratory Equipment

In this investigation the authors used the device “IMP-04” to measure electromagnetic environment parameters. This device usually is applied to measure the magnetic flux density of electromagnetic fields produced by the EMF LF generator. The frequency ranges of the measured signals of the device were the next: from 5 Hz to 2 kHz—“Band I”, and 2 - 400 kHz—“Band II”.

An important part of the experiment was to use the generator signals LF G3-122, destined for processing of agricultural raw materials in the frequency range 0.001 - 2 × 106 Hz (in increments of 0.001 Hz). The range of adjustment of the output voltage (R = 50 ohms) was 2 × 10 - 6 – 2.5 V.

The main parameters of EMF LF are the wave length (λ) and the frequency (f) which is related to the back wavelength dependence (for the conditions of the wave in the air):

(1)

(1)

where c is speed of light.

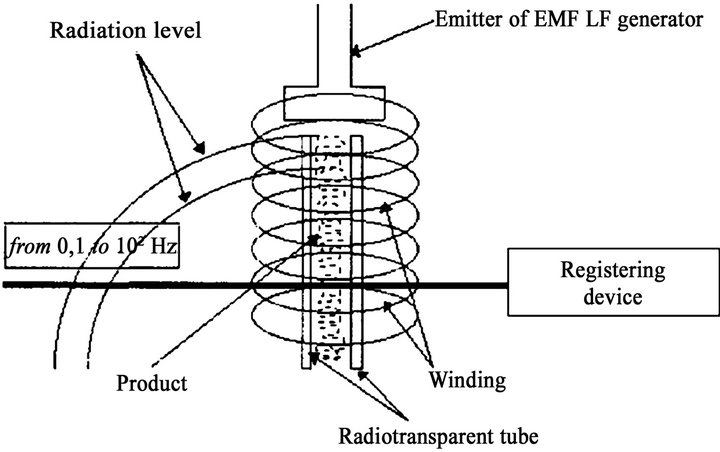

The scheme of processing of liquid environment by EMF LF is presented in Figure 1.

One of the most important ways to reduce losses of vegetable production is the usage of rational storage methods. Existing methods of vegetables storage are well studied. Some of them have wide application both in Russia and abroad (for example, the bulk potato storage with active ventilation), but the usage of the other (Modified Gas Atmosphere, Regulated Gas Atmosphere)

Figure 1. Scheme of processing of liquid environment by EMF LF.

is limited because of the high costs of their implementation. Along with the basic methods, additional ones of increase of the vegetable products preservation (bleach, growth-inhibiting, with surface protective package) are used. Many of the additional storage methods are under study and are debatable. Their efficiency is not confirmed yet in the manufacture. The explore of the possibility of the pulsed low-frequency electric field in the purpose to improve the nutritional value, the quality and the persistence of commercial vegetable production is a very important task which determined the choice of research.

The analysis of the data has shown that the resonance impact effect of EMF LF on the studied parameters is observed at frequencies of 19.52 and of 40.03 Hz.

EMF LF frequencies, which were used to process the fish raw materials that had to be canned, were chosen in accordance to the rapid method to determine the resonant frequencies of biological objects [1]. The simultaneous processing of the magnetic field of extremely low range and of woofer low length (field strength 1 - 150 A /m) and an alternating electric field of frequency 1 - 100 Hz (intensity 0.05 - 50 mV/m) on the researching objects changes pH length, the mass fraction of solids and the refractive index of extracts of meat raw materials.

The authors at first have established the selection effect of the resonance frequency of the objects to hundreds of Hz. Biochemical, histomorphological and microbiological evaluations of fish raw materials in biomodified under influence of EMF LF with resonance frequencies have been performed. Investigated objects have been processed during 20 - 60 min at the magnetic induction 6 mT.

Our investigations let to conclude that the impact of EMF LF (f = 40.03 Hz) on fish raw materials intensifies the maturation process of muscle tissue, also helps to change the degree of moisture connectivity, and acts as a preservation factor (barrier) against the microbiological spoilage.

The elements of barrier technology have been introduced in the industry for more effective managing by the storage of food concentrates. Low-temperature drying, the presence of CO2-extractable complexes, gas-liquid processing and bactericidal packaging are preserving factors in the technology of fish-vegetative concentrates. The most effective barrier method is processing of raw materials and semi-finished products by EMF LF.

The authors comprehensively have investigated the effect of pre-plant seeds and post-harvest production after EMF LF-processing (potatoes, sweet pepper, tomato and cabbage) on the nutritional value, technological properties and the commercial quality of vegetables.

The effects of EMF LF processing on biological objects have been examined. The magnetic field is used to get an effect of the magnetic moments of the researched objects. Lorentz force acting on the electrically charged particle moving in a magnetic field, is always directed perpendicularly to the vectors v and B. Lorentz force is proportional to the charge of the particle g, component velocity v, perpendicular to the magnetic field vector and to the value of the magnetic field B. In the SI system of the units Lorentz force is expressed by the equation:

(2)

(2)

where square brackets denote the vector product.

The set of electrical and magnetic fields indicator “Cyclone 04” (developed in Fryazino city, Moscow region) was used in the research. The apparatus is intended to measure RMS values of the magnetic induction and EMF LF generated by various means. The frequency range of measured signals was from 5 Hz to 2 kHz and the alternating magnetic field meter with a measuring range of 10 - 5000 nT.

4. Results and Discussion

The method of EMF LF processing of sown seeds of plants was developed with the authors’ participation. The method was produced in piles located in the closed warehouse. The activation of seeds was made by the generator of EMF EF running in the automatic mode without people’s presence according to the technological requirements and coordinated with Sanitary Epidemic Department of Russian Federation. Seed volumes processing is not limited. Processing time was 4 - 6 days, depending on the specialties of agricultural raw and phytosanitary condition. One setting during the technological cycle processes up to 150 - 200 tons of seeds.

After the completion of processing, seeds are left on the ageing for the energy exchange between treated and non-treated seeds in the shoulder deep. It is explained by the fact that the EMF LF processing of vegetative raw materials tissues in the range of 6 Hz to 80 Hz results to the formation of biological resonance. Living tissues become themselves as a source of secondary radiation, which stimulates the cell division and accelerates the oxidation and the metabolism in adjacent tissues which don’t experience the direct processing of electromagnetic field. The result of the secondary radiation is the energy exchange in large masses of seeds, from the surface to deeper layers of the bead. The efficiency of the between-seeds energy transfer depends on the temperature and the mass of the grain: the greater the mass of seeds, the greater the effect of the electromagnetic activation and longer the duration of its preservation (100 - 120 days). The temperature for the seed processing and binning (the aftereffect period) may be from 20˚C to 30˚C.

The electromagnetic activation of seed materials can be carried out in a wide range of dates, but more optimal to start processing within 20 - 25 days before sowing (planting). The effect of bio-resonance seeds and cuttings conditions disappears after about 120 days after processing. The significant cost savings compared to other methods of processing is due to the lack of supplies in the combination with the high automation of all the processes.

The estimated price of EMF LF processing of agricultural raw materials depends on the volume of products for the long term storage.

The cost of acreage processing is 0.25 cents/Ha.

The approximate profit in processing of one ton of vegetables (at the decrease of storage losses by 15%) is from 200 to 265 dollars, and of one ton of fruit and berries is from 340 to 470 dollars.

5. Additional Research

The authors have investigated the intensification of technological processes with the usage of low frequency electromagnetic field.

The gas-liquid processing is one of the safe agricultural raw materials processing technologies. The liquid and compressed gases extraction as a part of this technology allows to select target components, save the negative properties of food products, apply soft thermal treatment regimes, etc.

Thus, due to the rapid development of new trends in food processing technology, the liquid and compressed gases extraction has great prospects for implementation processes of a wide range processing of agricultural raw materials and food products. Therefore the problem of the extraction intensification is decisive in implementation of such technologies.

Lots of methods to intensify the extraction process by liquid and compressed gases can be divided into three main groups. The first group includes the intensification methods through the optimization of technological parameters of the extraction process (the choice of pressure parameters, the temperature, and the preparation of raw materials). The second group includes mechanical methods of the intensification (mechanical mixing of raw materials, etc.). The third group includes the methods of influence on the physical parameters of the environment of the extraction process (processing by ultrasonic waves, infrared electromagnetic waves happens). All of the above methods of the process intensification of the extraction by liquid and compressed gases have either the direct mechanical effect or the heat effect on components of the process that is associated with a significant energy costs.

Previously, the effect of electromagnetic oscillations of non-thermal intensity on biological structures is considered insignificant, but at present the authors are working at this problem and have already received a positive effect in the processing of food and agricultural raw materials of non-thermal electromagnetic fluctuations of the intensity at low frequencies. Thus the application of such effects to intensify the process of extraction can greatly reduce the energy consumption of the extraction process.

The research of this area shows that the main problem of setting creation of intensification of the extraction process by the action of low-frequency electromagnetic waves is the creation of the precision EMF LF-generator that is stipulated by the high sensitivity of processed objects to the oscillation frequency.

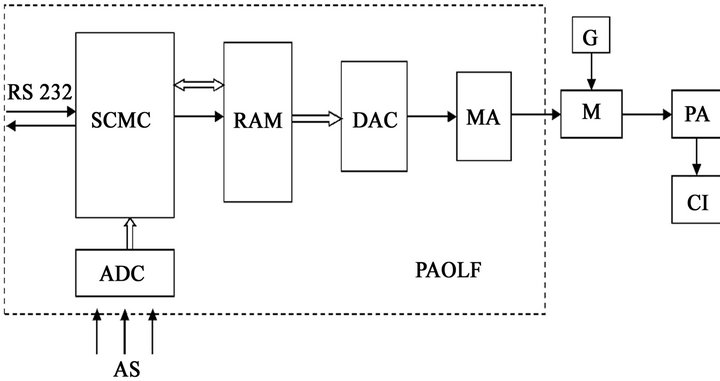

The laboratory setting of intensification of the extraction process (Figure 2), that uses the developed precision low frequency sinusoidal signal generator, has been developed and it has been manufactured at Meat and Fish Products Technology Department of Kuban State Technological University.

The setting includes the precision audio oscillator of low frequency (PAOLF), the high-frequency generator (modulator—M, power amplifier—PA), the coil of inductivity (CI—acts as a radiator low-frequency electromagnetic fluctuations). The sinusoidal wave from the

Figure 2. The laboratory setting for intensification of the extraction process.

generator (G) is modulated by the low-frequency signal (amplitude or frequency modulation) and is converted by the CI through PA in electromagnetic waves.

With the purpose of development of PAOLF the principle of the digital formation of the sine wave signal of low frequency has been used: the period of a sinusoidal signal is divided into a discrete number of time quanta, each of which is formed with corresponding to a given quantum of the numerical value of the signal amplitude. PAOLF is consisted of following: the single-chip microcomputer (SCMC), the random access memory (RAM), the digital-analog converter (DAC), the analog-digital converter (ADC), the matching amplifier (MA). SCMC realizes the formation of the RAM of sinusoidal signal that is then transmitted to DAC to form an analog signal. MA provides buffering of DAC and of the noise filtration associated with the discrete amplitude DAC. ADC allows to connect analog sensors (AS) of pressure, temperature, etc. for the rapid analysis of the process parameters extraction. SCMC also has a serial interface RS-232 communication with the PC.

The developed unit provides the modes of low-frequency processing (by amplitude or by frequency) of modulated electromagnetic oscillations in the range of 1 - 100 Hz ± 0.01 Hz.

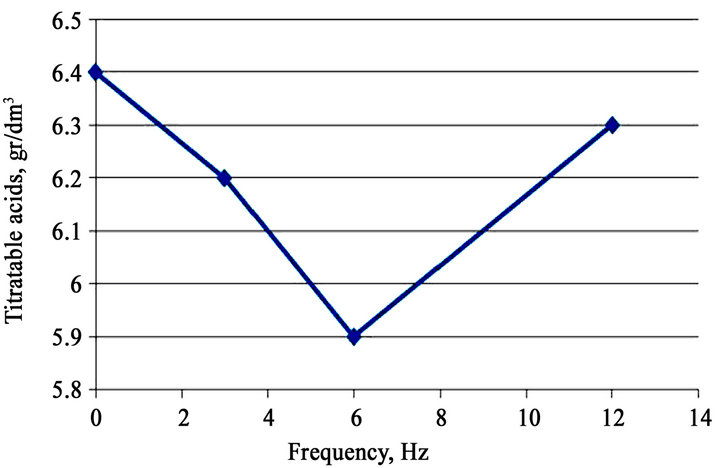

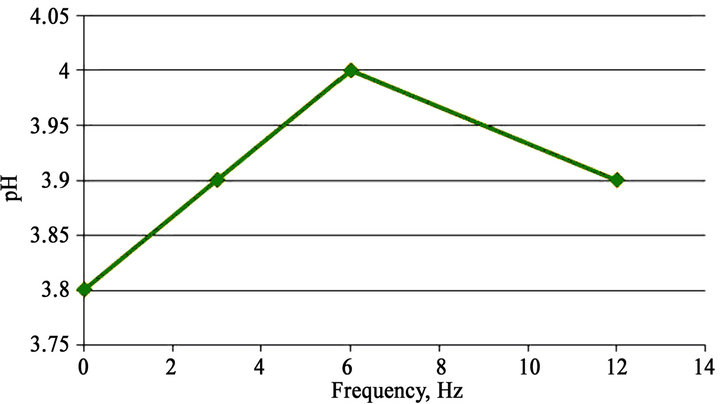

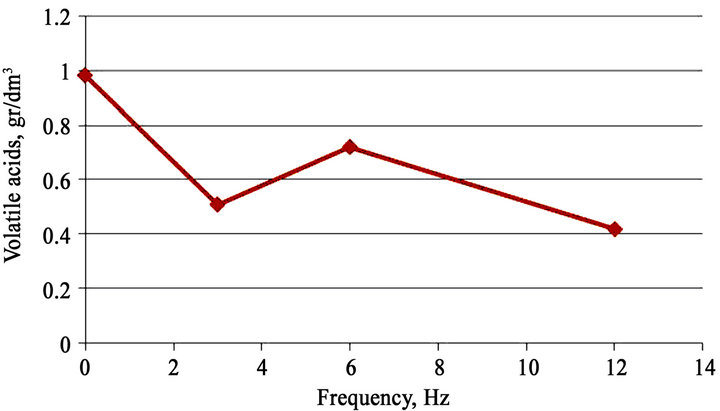

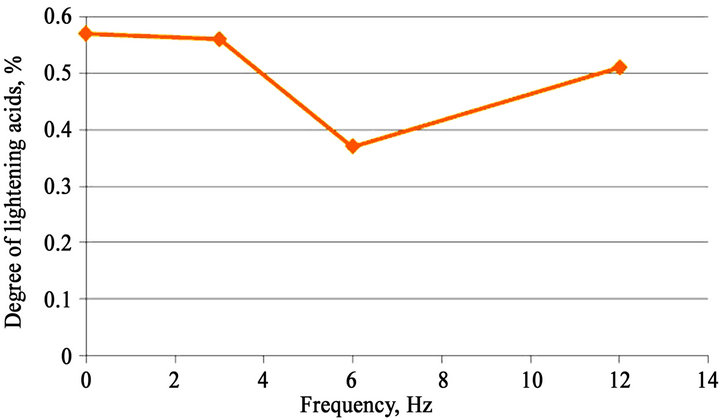

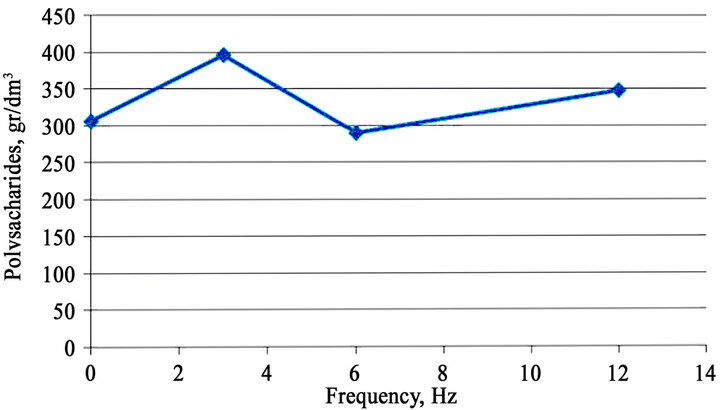

The influence effect of low-frequency electromagnetic field on the properties of wine has been studied (Figures 3 and 4) [10].

6. Conclusions

EMF LF processing of raw materials activates defense reactions of vegetative tissues, thus increases the ability to repair physical damages, reduces the metabolic activity, prolongs a period of profound peace that decreases losses and stabilizes the quality and the nutritional value of products during the long storage.

Figure 3. The influence of frequency of EMF LF processing (processing time = 45 min, B = 1.2 mT) on the change of the content of titratable acids in wine obtained from grapes of Cabernet Sauvignon.

(a)

(a) (b)

(b) (c)

(c) (d)

(d)

Figure 4. (a), (b), (c), (d) The influence of frequency of EMF LF processing (processing time = 45 min, B = 1.2 mT) on the change of the content of pH rate, of volatile acids, of the lightening acids degree, of polysaccharides in wine, obtained from grapes of Cabernet Sauvignon.

At first the regularities of the dependence between the change of the quality of the tomato seeds germination and the time changes of amplitude-modulated and frequency-modulated magnetic fields have been established.

For the practical usage the methodology of EMF LF processing of fish and vegetable raw materials has been proposed and applied. This methodology let to increase the quality of vegetable and fish production by the shelf life prolongation. While special attention was paid to the security of the personnel using the EMF LF generator [11].

By jury's decision of XI International Salon of Inventions and Innovation Technologies “Archimedes-2012” the development of A.V. Grachev and G.I. Kasyanov “The hardware and software signal generator of low and extremely low frequency used in the setting for electromagnetic processing of vegetative and animal raw materials origin” has won a silver medal.

REFERENCES

- M. G. Baryshev and G. I. Kasyanov, “Electromagnetic Processing of Vegetative and Animal Raw Materials Origin,” Kuban State Technological University, Krasnodar, 2002.

- M. G. Baryshev, S. S. Djimak and G. I. Kasyanov, “Application of Water with Modified Isotopic Composition and pH in Meat Industry,” Proceedings of Universities. Food Industry, No. 2-3, 2012, pp. 42-44.

- M. G. Baryshev, G. I. Kasyanov, R. S. Reshetova and G. P. Ilychenko “The Method of Storage Sugar Beet Root,” Russian Federation Patent No. 2172091, 2001.

- M. G. Baryshev, G. I. Kasyanov, R. S. Reshetova and G. P. Ilychenko, “The Method of Storage of Sugar Beet,” Russian Federation Patent No. 2172095, 2000.

- M. G. Baryshev, G. I. Kasyanov, G. P. Ilychenko and V. V. Magerovskiy, “The Method of Processing of Seeds,” Russian Federation Patent No. 2175179, 2001.

- M. G. Baryshev and G. I. Kasyanov, “The Method of Drying of Vegetative and Animal Raw Materials Origin,” Russian Federation Patent No. 2203458, 2003.

- O. U. Gryzlova, T. I. Subbotina and A. A. Hadartsev, “Bioresonance Effects in Time of Electromagnetic Fields Impact: Physical Models and Experiment,” Triada Publishing, Moscow, Tver, 2007.

- M. G. Baryshev, N. S. Vasilyev, N. N. Kulikova and S. S. Djimak, “Low Frequency Electromagnetic Field Impact on Biological Systems,” South Scientific Centre of Russian Science Academy, Rostov on Don, 2008.

- O. U. Gryzlova, “Bioresonance Effects in Natural and Artificial Electromagnetic Fields as the Vitality Factor,” Dissertation for the Degree of Candidate Technical Sciences, Tula State University, Tula, 2005.

- V. T. Hristyuk “Improvement of Wine Technology with Application of Methods of Electrophysycal and Sorption Processing,” Under Redaction of Honored Scientific Worker of Russian Federation, Honored Inventor of Russian Federation, Ecoinvest Publishing, Krasnodar, 2012.

- A. A. Lubomudrov, “Basics of Safety in Time of Working with Sources of Electromagnetic Fields,” IBT Press, Moscow, 2011.