iBusiness

Vol.2 No.2(2010), Article ID:1958,10 pages DOI:10.4236/ib.2010.22020

How to Learn Knowledge from Foreign Partner: A Case Study of Japanese Joint Venture in Indonesia

![]()

Department of International Relations, Faculty of Social and Political Sciences, Universitas Indonesia, Depok, Indonesia.

Email: tirta.nugraha@ui.ac.id

Received January 26th, 2010; revised March 12th, 2010; accepted April 15th, 2010.

Keywords: absorptive capacity, knowledge acquisition and sharing, Japanese joint venture, Indonesian firm

ABSTRACT

This research focuses on how local partner learn knowledge from foreign partner in Japanese joint venture in emerging economies context. Contribution of this research is as follows. First, by distinguishing the type and characteristics of each process, this typology enhances our understanding about JV as useful organizational learning mechanism, particularly in Japanese joint venture in emerging economies and about the source of firm’s heterogeneity underlying learning process. Second, this extensive in-depth case study provides the clear evidences of the importance of internal learning capability process to improve technological capability, absorptive capacity, and relational rents generated from resource sharing mechanism. Third, this study, to best knowledge, is a pioneer research in Indonesia since technological issues have been paid little attention from scholars.

1. Introduction

This research focuses on how local partner learn knowledge from foreign partner in Japanese joint venture in emerging economies. It is an in-depth case study explaining internal learning capability transfer from foreign firms; resource sharing within business groups especially in developing human capital; and knowledge acquisition, assimilation, and exploitation process which is so-called absorptive capacity [1,2] in a leading electronic joint venture (JV) firm in Indonesia.

Focus of this study is to understand learning process in Panasonics Manufacturing Indonesia (PMI), a joint venture between Matsushita Electrical Industries and Gobel International. I find the different pattern of learning process and characteristics between blue collar workers (operators) and white collar workers (especially engineers). I also discuss the important roles of Japanese experts, example of technological capability, and underlying key success of learning in PMI.

1.1 Internal Learning Capability Transfer and Absorptive Capacity

International joint venture (IJV) has become popular mode of entry in emerging economies and particularly in Indonesia since 1970s. Recently, IJV has been studied by scholars from resource-based view and knowledge-based view that has focused on how resource acquisition, capability development as source of success in IJV [3,4].

Kogut and Zander [5] argue MNC as an organizational vehicle which has its superior efficiency by transferring knowledge across borders. Host partner, such as in the form of IJV, can learn from foreign partner through internal learning capability transfer. For instance, they can learn routines, production process, and production development up to marketing strategies. These lead to up grading capability of the firm. In addition, up grading capability and then contribute to IJV performance also depends on host partner’s absorptive capacity [6-8]. This research lies in this stream with focus on how host IJV partner learns knowledge starting from understanding manufacturing system, improve it and finding and solving problems. These are what I argue as increasing absorptive capacity of host IJV partner.

2. Method

This research follows the replication logic, rather than sampling logic: whether case companies chosen could provide rich information in the aspects of research constructs [9]. PMI as one of the leading JV firm in Indonesia fits with these criteria. Matsushita, a parent company of PMI, also recognized as high performance business group in terms of technological and managerial capabilities. In addition, PMI has shown their eagerness to be studied by providing access to informants. The author also has long acquaintance with one of directors in other member of Matsushita group in Indonesia who gave recommendation to PMI. It is useful to develop a relationship of mutual trust with respondents. Therefore, PMI also fits for practical reasons.

Letter of inquiry with a research’s proposal explaining the objective, design, protocols and advantage of the research is sent in early 2006. The approval is given shortly and follows by pilot study on April to May 2006. First fieldwork is conducted in June to July 2006 whereas the second is on August to September 2006. The following steps are taken to ensure the good quality of this in-depth case study. First, I met with vice chairman and three senior managers to explain the research protocols and get initial comments and set up the more detailed schedules for field studies.

Second, the main informants are senior manager HR and senior manager R & D. I conduct nine interviews during April to September 2006: twice interviews both with vice chairman and senior manager R & D, and five times interviews with senior manager HR. Each interview is carried out lasting between thirty minutes and two hours. Following the standard procedures in doing case study, I used open-ended and semi-structured questionnaire [10]. Creswell suggests that good case study should meet the standard of quality verification, therefore I conduct triangulation of information - searching for the convergence information - relates directly to data situation in developing case study from data sources, theory, methods, and my self as investigator. In addition, member checking is done by sending the rough draft of writing to the informants after the entire interviews finished. All the interviews are recorded and field notes are also created.

Third, the rationale of this study that makes this study as a single-case study is to confirm, challenge, or extend the theory [10,11]. I use within-case study analysis in this study because several themes identified earlier are being confirmed, challenged, or extended within a single case.

2.1 Indonesia and Brief History of PMI

Indonesia is the largest country in Southeast Asia comprises more than 230 billion people in 2009. Within Association of Southeast Asian Nations (ASEAN), Indonesia has considered as country taking most liberal and neutral investment regime. The government has liberalized foreign direct investment up to 95% for foreign ownership in 1994. It has sharply increased since the government started to attract foreign investment in late 1960s and promoted pro-market policies. As a result, Indonesia has been transforming from agriculture-based country to more manufacturing-based country. Recently the contribution of service sector has increased in addition to manufacturing sector.

The abundant of natural resources, low wages, and liberal government policies attracted foreign investment, particularly Japanese investors since 1960s. Japanese investment has been the biggest and significant especially in light manufacturing industries such as electronics, machinery as well as more capital intensive industries such as automotive. Kosuke Imashimizu, president director of Japan External Trade Organization (JETRO) in year 2006 mentioned how important Indonesia for Japan. He said that historically, Japan is the largest investor in Indonesia.

PMI was built on July 1970 as joint venture between Matsushita Electrical Industrial Co. Ltd (MEI) with 60% and Gobel International (GI) with hold 40% of shares. However, its history starts from 1950s when the owner of Gobel, Mr. Moh. Gobel established Transistor Radio Manufacturing limited company which pioneered in radio transistor manufacturing. After he went to Japan as foreign student and met Mr. Konosuke Matsushita, the founder of MEI. In 1960, MEI and Transistor Radio Manufacturing limited company agreed to sign of technical cooperation. Based on the technical cooperation, this company was able to produce first black and white television in Indonesia in 1962. As the cooperation worked well, both parties agreed to establish joint venture, National Gobel in 1970-currently changed its name to PMI.

In 1974, Gobel established Met Gobel limited company as support the trading activities and importing products of Matsushita to Indonesia which not produced by PMI. This company also imported both consumer electronic product and professional electronics products such as broadcasting devices and capital equipment for the factory.

During 1980s and 1990s, Matsushita Gobel as a group strengthened her presence in Indonesia by establishing other sister companies such as Panasonic Gobel Battery Industry (manganese, lithium coin, torchlight), Panasonic Gobel Indonesia (sole agent of PMI), Panasonic Shikoku Electronics Indonesia (VCR, CD-ROM, and Combo TV for export), Panasonic Battery Batam (battery NICAD) and Panasonic Electronic Device Indonesia (ceramic components, speaker, inductive products and other related products). Incorporation with Matsushita Electric Works, they established Panasonic Electric Works Gobel Manufacturing Indonesia (PEWGMI) which produce lighting fixture, components, wiring devices; Panasonic Electric Works Gobel Sales Indonesia (sole agent and distributors of PEWGMI); Panasonic Electronic Device Batam, Panasonic Semiconductor Indonesia (semiconductors, microchips) and Panasonic Shikoku Electronics Batam (peripheral products).

PMI has 9 products line such as audio, fan, television, air conditioner, refrigerator, washing machine, electric iron, water pump and pants press. The oldest is audio business unit that established in 1970 with 2,000,000 production capacity per year. Manufacturing of fan and television started a year later in 1971 with 1,500,000 and 600,000 production capacities per year, respectively. Two year later, PMI established air condition business unit in 1973 with 250,000 production capacity per year. Production of refrigerator began in 1975 with 420,000 capacities per year. Washing machine, electric iron and water pump production established in 1979, 1985, and 1988, respectively. PMI produces 140,000 washing machines, 380,000 electric iron and 1,500,000 water pump per year. The latest product is pant press which started in 1995 with 25,000 production capacity per year.

PMI capital is US $ 23 million with Rp 1.595 trillion in sales (2005).

2.2 Learn How to Manufacture the Product

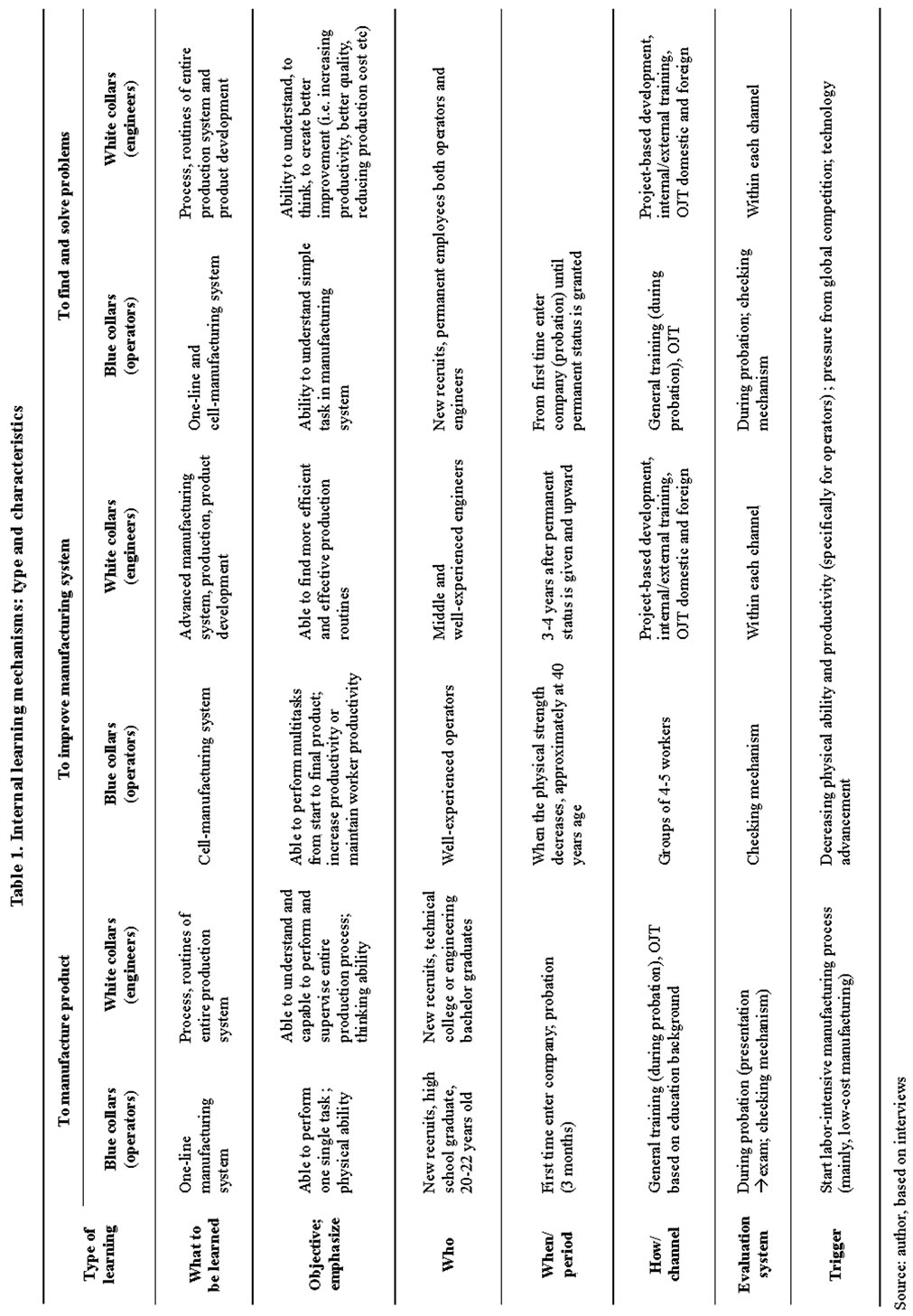

The objective of this type of learning is to understand one single task to perform manufacturing process. Focus of this learning is for new recruits both blue collars and white collars employees. Table 1 provides summary of type and characteristics of internal learning mechanism at PMI.

2.2.1 Development of New Recruits of Blue Collars Employees

As electrical and households appliances manufacturer, PMI is part of labor-intensive industries, therefore the development of operators (blue collars) with emphasis on physical ability is important. New recruits are mainly high school graduates whose age around 20-22 years old. The objective is to perform one single task within oneline manufacturing activities through general training within three months probation period. They were asked to present what they understand about the process. There are “examinations” conducted in the end of week and particularly in the end of month to evaluate the progress of each operator. When they passed the “exam” then they granted permanent employee status. After that, the new recruits are assigned on OJT in more advance manner to understand and perform manufacturing tasks. He or she should be able to understand the relations between theoretical and practical matters. They are pushed to find problems and then find solutions. If they can not find any single problem and solution, they are considered as “can not learn properly”. For new recruits, they are mainly working in single task in one-line manufacturing process. Each performs one single job. During 3 to 4 years commonly the new recruits can accumulate knowledge about manufacturing process and related jobs.

2.2.2 Development of New Recruits of White Collars Employees

Along with the higher educational background (mainly graduates from technical college or engineering department/bachelor), the objective here is to develop engineers who understand and capable to perform the whole or entire production process started from input (raw material checks, material warehouse management etc), production, assembly, and final products. They also should understand supporting activities such as product planning, purchasing, product engineering, production engineering and quality control. This type of workers should be able to perform inspection tasks for whole process.

Says Senior HRD manager: “In the probation period, new recruits white collars employees are doing on the job-training (OJT). They assist their senior employees in wherever the senior performs their job. For instance, in the audio factory, new recruits should carefully examine the process from the beginning until the end of product. Those with electronics background (vis-à-vis mechanical) should examine the process from electronics point of view as well as those with mechanical background should understand the process from the mechanical engineering. Therefore, they can understand the actual process in the factory with their educational background. Thereby they can give assessment based on their expertise. If they can find the weakness of the process and or ideas for improvements, they can be considered “have learned”. If it happens smoothly during probation period, new recruits will have higher chance to be recruited as permanent employees.” (Interview, May 5, 2006).

There are similarity with new recruits of blue collars workers in terms of general training and process of recruitment such as three months probation, presentation, and exam. However, I found the emphasis of developing ability to find problems and then produce solutions of the workers. The role of factory manager is crucial in performing the evaluation of workers. He checked daily reporting of the workers based on their field (either electronics or mechanics), conducted test or quizzes related with the tasks, conducted end of week’s test and end of month’s assessment which usually took longer time. These mechanisms intended to ensure the progress of capability development of workers.

2.3 Learn How to Improve Manufacturing System

Objective of this type of learning is to improve better manufacturing system. Focus is for relatively mature blue collars employees and well-experienced white collars employees.

2.3.1 Development of Older Blue Collars Employees

As time goes by older blue collars workers are able to work better because of learning by doing. Since this is labor-intensive industry, physical ability of blue collar is important. The older the worker, at the point of time, their ability to produce results decrease. The challenge here is to create additional capability of blue collars workers in order to stay productive. Therefore the trigger to exploit new competency of older blue collars workers is when their productivity is decreasing along with their age, at around 40 years old. The productivity of blue collars employees can be compared among those whose age is 20 to 30 years and those whose age is 40 years. For in-

stance, in audio factory 20 to 30 years’ old employees can do mounting (putting particular component in to circuit board) 10,000 sets everyday. But 40 years old employees, can only produce 9,000 sets per day. On the other hand, labor cost is increasing because each year there is a salary increment. To cope with this problems, the company develop new competency of blue collars workers from “ability to perform single task within oneline manufacturing” to “ability to perform multitasks within cell-system manufacturing”.

In the single task manufacturing process, one can only produce or perform one single task assigned to her/him in the long assembly line which usually needs 30 employees to finish. On the other hand, within cell-production system 4-5 workers are assigned as a group in order to produce a particular product from the beginning until the finished product. Each employee can perform more than one task; it can be 5 or 10 tasks. Those 4-5 workers with well experience, multiple competencies can work together in “shadow-line” that is especially created for these people. The combination of 4-5 well-experienced blue collars workers can increase their productivity or at least to maintain as previous productivity level.

In this system, the level of productivity for each employee can still be measured. For instance, one employee produces 800 sets while other produces 1000 sets, competition happens among them. By competing each other, knowledge exploitation process materializes because they will put more efforts to produce. The more they produce, the more the payment they get. To do so, employee should be trained in additional ability move from general expertise to more specific ability. For instance, training in one-package specific ability of soldering, mounting, inspection and screwing.

In this process, I found that the role of factory manager to motivate the person is a key success of this process. It combines with better reward system for more productive workers. More competent workers who are more productive will be granted more rewards in terms of financial rewards.

2.3.2 Development of Well Experienced-White Collar Employees

The development of well experienced white collars employees are mainly through such mechanism: project-based development, internal training and domestic seminars/ lectures, external training and overseas seminar/lectures, and OJT in overseas.

Project-based development After completing probation period, engineers start working as permanent employees. Based on the evaluation from the factory manager during the probation period, they were assigned to the job/task which is most related to his/her capability. For example, engineer who seems to be fit in assembly process during probation period, then he/she will be assigned to that job for the first time. However, after some time they will be assigned to other jobs in order to acquire all knowledge and manufacturing capabilities. Usually after 3-4 years of learning, engineers can accumulate good manufacturing capabilities.

Project-based development means to create capable engineers by assigning them into particular product development project that create a product from zero. A project is led by senior engineer and comprises of some engineers who work together closely even they were divided into sub-sub team according to their expertise. In this project team, they should think and create model based on some specifics information including features, shape, price, component availability, user-friendliness, and easy to be repaired if broken etc. This information is supplemented by result of market research conducted by the company and secondary data such as industry trend. The information captures customer’s preference, necessity towards the products and their segments. Therefore, the engineers should be able to interpret customer’s preference including taste and transform it into the final product. The ability of understanding customer’s preference or needs is very important as stated by the informant: “Product engineers should be able to act as if they are part of the segment in order to have better understanding customer’s preference. However, sometimes engineers are reluctant to do it because they think that the product should be sophisticated and with newest technology regardless of the different segments. They think product for villagers (people living in country side) should have same features and function that is for urban people. In fact, it’s totally different. To make them understand, to fight their ego, is very difficult.” (Interview, July 18, 2006).

This is an example of project-based development in order to develop engineering capabilities. For instance, radio cassette project. Engineers should think comprehensively from technical matters, designs, considering production capability owned by the factory for producing the product, deadline of product launching and also should consider the price that can be afforded by customer. By keeping deadline of product launching in mind, therefore he or she should think and work harder to meet the schedule and deadline. Two or three engineers are assigned in the sub teams. The number of engineers in each team is based on the needs of each projects as well as based on the expertise owned by each engineers. The number of sub teams is also based on the needs of the projects considering the complexity and sophisticated the product that will be produced. All the process is supervised and controlled by manager.

This kind of project usually starts from market survey to understand the customer needs, segment, and behavior. The survey also provides the information about competitors including product’s price. The team also buy the competitors products to understand what is their strength and weakness of the product, not to imitate their product because Matsushita has own brand name and standard. By understanding the weakness and strength of the competitor’s products, engineers understand the weakness and strength of PMI’s products. If they think their product is worse than competitor’s product, they challenged themselves to catch up and even create much better product with all means. As one informant mention that is so-called “engineer’ spirit”.

Valuable information not only derived from survey, but also from books, journals, as well as from the networks they have. These sources of information and knowledge are useful when they need some ideas of improvements or when they find difficulties about technical problems. Engineers are very common to have contact with previous college acquaintance, their teacher at school and mentors in university.

Engineers are talented person with full of ideas and in high spirit to implement many kind of technology including most sophisticated technology they know. Sometimes they have personal conflict between their eagerness to implement their ideas which usually includes most sophisticated technology and customer’s needs which sometimes does not need such sophisticated technology, specifically for customers in country side.

For instance, the debate between the usage of transistor instead of integrated circuit (IC) for the radio cassette for the customers in country side. Engineers propose IC for the radio cassette they will produce because the technology is higher and follows the international technological trends, but it will cost much for customer in the country side. For transistor, to turn on the power of the radio only needs 1.2 volt that can be supplied by 2 batteries of 1.5 volt. These batteries are available in many stores with cheap price, therefore affordable for the customers. Using the IC will need higher voltage to turn on the power which is 1.8 volt (higher voltage than 1.2 volt). Therefore, if radio cassette use transistor, the battery will last longer than use IC. With longer batteries, the customers are happier because it cost money less. In addition, the radio cassette with transistor is much easier to be repaired because they only need to change the transistor. The private electronics service counters throughout the country are usually able to repair with new transistor which is widely available in the electronics stores, including in country side. However, from the point of view production cost is much higher for radio cassette with transistor because needs longer process, the customer’s needs and satisfaction is much more important for PMI.

From this point, the concept of R & D in this factory, particularly for radio cassette (audio) factory emphasize on development side which considers more on applicability. Rather, research side that is more basic science. My informant also underlines that “we are proud of our product, a radio cassette with transistors because customers perceive our radio higher quality as long-life product compare to others. It makes our product famous…From the technological point of view we can learn that sometimes we do not need high or sophisticated technology in our products but more appropriate technology that fits with customer’s need. Even though this technology is almost sunset but we still can produce much profit from those products, including for export market.” (Interview, July 18, 2006).

In addition to think the appropriate technical specification and design of the product, engineers should also consider that product can be manufactured in their factory. In other words, the product should be easily produced in accordance with production capability in the factory. Moreover, the product also should also be repaired easily not only as part of after sales service counters, but also in many private radio cassette service counters throughout the country.

My informant underlines that “usually each engineer joins one project each year, but if they can collaborate in two projects each year, it can be considered as a great learning process. These kinds of engineering knowledge and capabilities can not be found at school. The engineers accumulate the knowledge and capabilities in the factory, what I called it ‘factory as school’, vis-à-vis a formal school like college or university.” (Interview, July 24, 2006).

Internal and external training and domestic/overseas seminars/courses The company also held internal training for engineers. They have “Matsushita Global Institute”, a group’s training development center, but act as independent entity provides general training such as application of manufacturing techniques in the factory and also customized training for engineers based on company’s requirements. Says senior manager, “We ask the Institute to create special program for us…for example, how to create same perception between sales person and production employees…sometimes there is a conflict or misunderstanding between them…sales person claims that they want to sell product but the stocks are unavailable…or on the other hand, production employee said that they already produced products but sales person does not sell it…then we ask the Institute to train them in more practical and applicable manner…and these kinds of program increase their performance positively…” (Interview, May 5, 2006).

The company also sends engineers to external training within the country (domestic) with regards to their technical expertise. In addition to acquire more technical knowledge, they also get more experience, broaden their horizon and build networks from reputable universities and make friends who help the engineers in doing their work when it is needed.

Overseas seminars or lectures also can be a channel for engineers’ capability development. In this seminar, they do not only learn about technical expertise but also how to build the networks among people.

OJT in overseas Main mechanism to develop relatively well-experience white collars workers is through OJT in other company within their groups domestically and abroad. As part of Matsushita group, well experienced-engineers have been sent to R & D facility in Singapore and working together in other company such as in Malaysia and Thailand. Furthermore, local engineer from PMI who sent to Singapore for 3 years has been assigned as chief engineer in their last 2 years. He leads a special team including Singaporean engineers to develop audio product. Says senior manager, “The quality of our engineers is good…they are not behind foreign engineers in terms of quality…we can compete…yet we send engineers to become chief engineer in Matsushita group’s company in Singapore…but we lack in facilities…therefore as a whole (combination between engineers and facilities, added) we are behind them…that’s our weakness…” (Interview, May 5, 2006).

Regular training in Japan was also assigned either short term or long term ranging from weeks, months until 2 or 3 years. Through OJT, they learned and applied some techniques or skills directly into the particular task. For example, they sometimes brought “jobs” from JV company in Indonesia to parent firm in Japan. They can not complete it in Indonesia because of lack of testing facilities such as electro magnetic compatibility (EMC). In line with the timing for product deployment to the market, they tried to finish the jobs with help, support and supervision from Japanese experts in parent company. As one of informant says: “With help from experts, we can acquire more knowledge and broaden our horizon within different learning circumstances” (Interview, July 24, 2006).

2.4 Learn How to Find Problems and Solutions

Despite learn how to manufacture the product and to improve manufacturing system, I found the unique way of learning how to find problems and solutions. This type of learning occurs for new recruits of white collars employees.

I underlined the important of “checking mechanism” to ensure learning process of engineers. The tight control and evaluation from factory manager especially in the end of month’s assessment is indispensable in deciding whether new recruits” have learned something” or “have not learned yet”. In the end of month’s meeting, he performed three ways as checking mechanisms:

1) To check “book of training” of the workers. If the new recruits wrote many notes, the manager praised them as “doing proper learning”. According to the manager, if the workers wrote many notes, it means that he or she was eager to think of “something” about the production process. Actually, they could write anything about the process that mainly as tacit knowledge. By taking a note, he or she then can read it again in the afternoon. It can be considered as part of assimilation process of new knowledge. If they can not understand than they can consult with senior engineers or directly to factory manager about what they found.

2) To evaluate workers’ ability in finding problems and then finding solutions of the problems according to his field specialty (e.g. electronics or mechanics). If they can find problems, then try to find solutions meaning that new recruits “are thinking”, generate own ideas, or try to synthesize between theoretical background they have and practical matter in the factory. The typical problem that may rise is how to increase productivity, to shorten lead time, to reduce costs by shortening lead time, or point improvement. The management hopes either new recruit can think how to create better quality from the engineering point of view or reducing production cost. New recruits can propose anything such as better lay out of production etc. If new recruits can not find any single problems, factory manager assess them with lower capability of learning. If it happens until the end of third month, they are termed as persons who do not want to think. Therefore, they might not eligible to be granted the permanent employee status because in this type of worker the main emphasis is on “ability to think”, to create better improvement, not physical matter. This is the main different with blue collars workers. Here I termed this mechanism as “learning by finding problems and solutions”.

3) To motivate new recruits to learn more and more by creating “embarrassing environment” during the meeting. Factory manager strongly challenged and criticized new recruits by telling them their lack of ability to learn, to pump up their spirit to learn more, to work harder and to be tougher, and sometimes he made them crying. The ultimate goal of this mechanism is to produce engineers who able to create better improvement overtime and able to compete with others.

3. Role of Japanese Experts in JV Company

As JV, Japanese experts always remain in JV company as representative of parent company regardless new products, techniques, or system will be launched or not. They stay usually for 5 years. Japanese experts sent to JV company has different expertise ranging from electronics, mechanical and production. The decision to send Japanese experts is depended upon the strategy that JV will pursue to strengthen the company. For example, if in the first phase, they decide to strengthen engineering so parent company will send senior engineers who have expertise in engineering. Then, if they decide to strengthen production capacity and efficiency, therefore parent company will send senior production engineers.

The role of the Japanese experts in JV company are as follows:

1) As advisor, they give advice to the company regarding particular matters such as engineering and production. Their main job is firstly to guarantee quality, reliability, and safety of the products or production processes meet the parent company standard. Therefore, they can use brand name of parent company. As the senior engineer, his involvement is in a way of advising, supervising and solving the problems when the local engineers can not solve it. Transfer of know how occurs during these processes.

During their assignment time in JV company, there is usually only one person senior engineer in the particular field of expertise. Therefore, sometimes it is necessary to send local engineers to acquire additional expertise to parent company or other factory within group’s company abroad. In case of developing 2-doors refrigerator, many expertises are needed such as mechanical design, electronics, cooling system etc. However, Japanese expert usually only hold one expertise, so to fulfill this lack two local engineers were sent to parent company in Japan to learn how to develop this refrigerator. Therefore, in the same time both engineers in JV company side and those who sent to parent company side develop 2-doors refrigerator together. They exchange the information.

2) As window, they teach JV company management as well as engineers regarding new rules, system, or special requirement as part of parent company standard. In this case, they act as “bridge” between parent company and JV company vice versa. For example, since 2004 JV company is obliged to follow ROHS (restriction used of hazardous materials) program. Because it is new program and no body in JV company knows, therefore they explain the substance of the program and how should it be proceed. As on of informant says: “in this manner, Japanese expert act as window in each factory. They do reporting, target setting, distributing the documents. As this is new program from parent company, therefore, the meeting has been held for all JV company under the same group and they conduct real case study for each factory”.

3) As motivator and mentor, they give motivation to local engineers to pursue better capability in the future. He tells one of informant about his experience as Japanese senior engineer including efforts to balance life as employee in Japanese company and his personal life. Despite working together in the factory, he taught my informant technical matters during off-work. They also went to social gathering together such as dinner, sport activities and singing songs. He wanted to see my informant to be one of future capable engineer within JV company. He kept his eye on my informant’s learning process. My informant says: “I am a young engineer in this company before I met him (Japanese expert) many years ago, then I had long discussion with him. He told me both good and bad side working as engineer in Japanese company, about balancing life in the company and family. He convinced me that success at work that is for the advancement of family life. The better he works, the better life is for family too. He wanted me to learn from his experiences and wanted to see me as key person for this company in the future. Since than, I worked harder from early in the morning until 9 or 10 pm to learn more to understand work as engineer with high spirit and discipline. That is what I learned from Japanese experts, responsibility and hardworking”.

4. Discussion and Conclusions

This research has examined how to learn from foreign partner in the context of Japanese joint venture in Indonesian electronic industry. Specifically, this research provides three type and mechanism in learning for both blue and white collars workers.

Technological Capability. After 36 years JV and plus 10 years technical assistance, PMI has been able to develop their technological capability. For example in audio (radio/tape/cassette) as the oldest production that started from 1970. Now, PMI can produce and design from 0 (zero). In the beginning of production only minor changes and modifications were made. Since 1986, audio department has started to make major changes and create own design. For example, engineer worked hard to find the special taste of Indonesia people such as sound with high treble and bass audio. They read some electronics journals, consults with their mentor including former supervisor in college, discuss with friends in their networks, and discuss with Japanese expert and convince parent company about this product. Finally, PMI can fully design and produce audio which meet with local tastes not only the sound but also the physical performance of the product since 2000.

Key Success. Based on discussion above, I can summarize some underlying key success in learning process at PMI as follows:

1) Good training system particularly with strong determination of managers (factory manager and HRD manager) to train blue and white collars workers. They conduct unique way of learning using checking mechanism, learning by finding problems and solutions, creating embarrassing environment for workers. This create strong fundamental of absorptive capacity ranging from acquiring, assimilating, transforming and exploitation into such technological capability.

2) Managers have been successful to motivate workers in human resources development by applying some principles as follows: a) Long life learning process to acquire knowledge, not only from formal school but company as school for the workers; b) Try to always be in the good health by regular sports exercises; c) Discipline; d) Responsibility; and e) Hardworking.

3) The existence of Japanese experts has created mutual benefits and two-way rounds of learning both from parent company side and JV company. PMI earned more advanced techniques, skills and knowledge from parent company while Japanese experts learned about local knowledge such as culture, languages, and market. Local partner also perform daily operations and deal with workers’ problems as well as with the government. Both parent and local partners work together in their own roles.

4) Successful technology or knowledge transfer is based on principle “willingness to give from parent, and willingness to learn from local partner”. Matsushita gave opportunity to PMI to develop product based on their needs and local taste (such as audio products). On the other hand, PMI has put all their efforts to utilize this opportunity. This contributes to the concept of absorptive capacity that both foreign and local partner are needed to ensure successful absorptive capacity.

5) Being part of group membership, especially as JV, PMI has benefited from world wide production networks that provide human networking, accumulating experience and knowledge and sharing testing facilities including R & D facilities.

The contribution of this research is as follows. First, by distinguishing the type and characteristics of each process, this typology enhances our understanding about JV as useful organizational learning mechanism, particularly in Japanese joint venture in emerging economies [12] and about the source of firm’s heterogeneity underlying learning process [13,14]. Second, this extensive indepth case study provides the clear evidences of the importance of internal learning capability process to improve technological capability; and absorptive capacity [15-17]; and relational rents generated from resource sharing mechanism [18,19]. Third, this study, to best knowledge, is a pioneer research in Indonesia since technological issues have been paid little attention from scholars.

For the managers, this research recommends ways to acquire, assimilate, and utilize the knowledge especially from foreign partner in JV. The typology of learning in this study can be used as benchmark in examining technological as well as managerial capabilities in other firms. Therefore, the managers can create appropriate strategies for their firm considering who are the foreign partner and resource and or capabilities they have as local partner.

The limitation of this study is that insights from parent’s company can not be examined, yet it will enrich the understanding of two-ways learning between parent and local partner, particularly from their motivation and parent’s global strategies. As Matsushita is recognized as one of world class companies, future studies examining the effect of being member of high performance business group is also worth. A comparison with other type of IJV ownership will also enrich our understanding.

REFERENCES

- W. Cohen and D. Levinthal, “Absorptive capacity: A New Perspective on Learning and Innovation,” Administrative Science Quarterly, vol. 35, No. 1, 1990, pp. 128-152.

- S. A. Zahra and G. George, “Absorptive Capacity: A Review, Reconceptualization, and Extension,” Academy of Management Review, vol. 27, no. 2, 2002, pp. 185-2003.

- M. A. Lyles and J. E. Salk, “Knowledge Acquisition from Foreign Parents in International Joint Ventures,” Journal of International Business Studies, vol. 27, no. 5, 1996, pp. 877-904.

- A. Inkpen and P. Beamish, “Knowledge, Bargaining Power, and The Instability of International Joint Ventures,” Academy of Management Review, vol. 22, No. 1, 1997, 1960, pp. 177-202.

- A. Kogut and U. Zander, “Knowledge of the Firm and the Evolutionary Theory of the Multinational Corporation,” Journal of International Business Studies, vol. 4, no. 24, 1993, pp. 625-645.

- M. A. Lyles and J. E. Salk, “Knowledge Acquisition from Foreign Parents in International Joint Ventures,” Journal of International Business Studies, vol. 27, no. 5, 1996, pp. 877-904.

- W. Cohen and D. Levinthal, “Absorptive Capacity: A New Perspective on Learning and Innovation,” Administrative Science Quarterly, vol. 35, No. 1, 1990, pp. 128-152.

- P. J. Lane, J. E. Salk, and M. A. Lyles, “Absorptive capacity, learning, and performance in international joint ventures,” Strategic Management Journal, vol. 22, No. 1, 2001, pp. 1139-1161.

- J. R. Lee and J. S. Chen, “Internationalization, Local Adaptation, and Subsidiary’S Entrepreneurship: An Explanatory Study on Taiwanese Manufacturing Firms N Indonesia and Malaysia,” Asia Pacific Journal of Management, vol. 20, No. 1, 2003, pp. 50-72.

- J. W. Creswell, “Qualitative inquiry and research design: Choosing among five traditions,” Sage Publications, London, 1998.

- R. K. Yin, “Case Study Research: Design and Methods”, Second Edition, Sage, 1994.

- J. F. L. Hong, H. Easterby-Smith and R. S. Snell, “Transferring Organizational Learning Systems to Japanese Subsidiaries in China,” Journal of Management Studies, vol. 43, No.5, 2006, pp. 1027-1058.

- S. Lall, “Technological Capabilities and Industrialization,” World Development, vol. 20, No. 2, 1992, pp. 165-186.

- W. Xie and G. Wu, “Differences between Learning Process In Small Tigers and Large Dragons: Learning Processes of Two Color TV (CTV) Firms within China,” Research Policy, vol. 32, No. 8, 2003, pp. 1463-1479.

- W. Cohen and D. Levinthal, “Innovation and Learning: Two Faces on R & D,” Economic Journal, vol. 99, No. 3, 1989, pp. 569-596.

- W. Cohen and D. Levinthal, “Absorptive Capacity: A New Perspective on Learning and Innovation,” Administrative Science Quarterly, vol. 35, No. 1, 1990, pp. 128-152.

- S. A. Zahra and G. George, “Absorptive Capacity: A Review, Reconceptualization, and Extension,” Academy of Management Review, vol. 27, no. 2, 2002, pp. 185-2003.

- J. H. Dyer and H. Singh, “The Relational View: Cooperative Strategy and Sources of Interorganizational Competitive Advantage,” Academy of Management Review, vol. 23, No. 4, 1998, pp. 660-679.

- T. N. Mursitama, “Creating Relational Rents: The Effects of Business Groups on Affiliated Firms’ Performance in Indonesia,” Asia Pacific Journal of Management, vol. 23, No. 4, 2006, pp. 537-557.