Journal of Environmental Protection

Vol. 3 No. 7 (2012) , Article ID: 21128 , 7 pages DOI:10.4236/jep.2012.37074

Defluoridation of Water by a Biomass: Tinospora cordifolia

![]()

1Bhilai Institute of Technology, New Raipur, India; 2Centre for Environmental Science & Engineering, Department of Engineering Chemistry, Bhilai Institute of Technology, Durg, India.

Email: drpiyush_pandey@yahoo.com, drmadhurima_pandey@yahoo.com, rekha.sharma.ssitm@gmail.com

Received March 11th, 2012; revised April 15th, 2012; accepted May 17th, 2012

Keywords: Sequestration; Defluoridation; Biosorption; FT-IR spectrum; Permissible

ABSTRACT

This research is focused on the search of a biomass for the sequestration of fluoride from drinking water. Defluoridation of water was studied by batch experiments in biosorption process. The biomass was found to reduce fluoride to permissible limit 1.5 mg/L as prescribed by WHO. The efficiency of the sorption process was investigated under different experimental parameters such as pH 7, standing time 120 min and biomass doses 7.0 g with 5 mg/L concentration of fluoride. Neutral pH was identified as the optimum condition of the medium and 120 minutes was the best contact time for maximum fluoride adsorption. The experimental data was found good fitting to Langmuir and Freundlich isotherm models. In interference study tolerable effect was found with 50 mg/L concentration of co-ions, whereas increasing the concentration of co-ions retarded the fluoride removal capacity in some extent. FT-IR spectrum analysis showed fluoride binding in the different frequency ranges of the biomass. Eventually, this plant biomass is recommended as a suitable and low cost adsorbent to reduce fluoride into standard permissible limit.

1. Introduction

The occurrence of high fluoride in groundwater has drawn considerable attention the world over, since groundwater is the main source of fluoride intake [1]. Mineral sediments as well as discharge of industrial wastewater containing fluoride is a key contributor to groundwater and surface water pollution [2]. According to World Health Organization (WHO) guidelines, the optimum concentration of fluoride in drinking water is 1.5 mg/L [3]. According to the Indian standards for drinking water [4] the desirable limit of fluoride in drinking water is 1.0 mg/L; however, in the absence of any alternate source, maximum permissible limit is 1.5 mg/L. Fluoride ion in water exhibits unique properties, as its concentration in optimum dose in drinking water is advantageous to health and excess concentration beyond the prescribed limits affects the health [5]. Fluoride in drinking water has both beneficial and harmful effects on human health [6]. Fluoride in minute quantity is an essential component for normal mineralization of bones and formation of dental enamel [7]. When the concentration of fluoride is more than 4 mg/L, it causes softening of bones, ossification of tendons and neurological damage in several cases [8]. Whereas low fluoride content (<0.60 mg/l) in drinking water can cause dental caries and poor development of bones [9], high fluoride content (>1.0 mg/L) can lead to dental and skeletal fluorosis [10].

Excessive consumption of fluoride for a long term can lead to skeletal damage, dental fluorosis, mental disorders in children, osteosclerosis and structural changes in DNA [11]. The most common health problems due to intake of fluoride are dental and skeletal fluorosis [12]. Though fluoride enters the body mainly through water, food, industrial exposure, drugs, cosmetics etc. drinking water is the major source (75%) of daily intake [13].

High fluoride concentration in the ground water and surface water in many parts of the world is a cause of great concern. The occurrence of high fluoride concentration beyond permissible limit in groundwater is a problem faced by many countries notably India, Sri Lanka, Pakistan, China and parts of East Africa. The problem of excessive fluoride in ground water in India was first detected in Nellore of Andhra Pradesh in 1937 [14]. More than 60 million people including children in India are suffering with dental, skeletal and non skeletal forms of fluorosis [15].

The high fluoride levels in drinking water and its impacts on human health have increased the importance of defluoridation studies [16]. Defluoridation was reported by adsorption [17], chemical treatment [18], ion exchange [19], membrane separation [20], electrolytic de-fluoridation [21] and electro dialysis [22] etc. Among various processes, adsorption was reported to be an effective, environmentally friendly and economical one [23]. The advantages of biosorption are very well known, the contaminants in water are removed by getting concentrated onto a disposed of [24]. Biosorption offers advantages of high efficiency in dilute effluents and no nutrient requirements. Recently considerable interest was observed on the application of biosorbent materials for removal of various pollutants. It provides a cost-effective solution for water management [25]. Adsorption is a mass transfer process in which a constituent in the liquid or gas phase is accumulated on solid or liquid phase and separated from its original environment [26]. Due to more simple design of adsorption unit, lack of sludge production and low investment costs, the adsorption process has more advantages than other methods in removal of pollutants from water and wastewater [27]. The uptake of anions has become a growing concern in the field of biosorption [28]. Investigators reported various types of adsorbents namely activated alumina [29], titanium-rich bauxite [30], synthetic resins [31], manganese oxide-coated alumina [32], carbon nanotubes [33], fish bone charcoal [34], rice husk carbon [35], with different degrees of success.

2. Materials and Methods

2.1. Plant Collection and Preparation of the Biomass

Plant was collected from different localities of Bhilai town ship C. G. in district Durg. The plant biomass used for the removal of fluoride ions from aqueous solutions. The plant was washed with deionised water to remove dirt and other particulate matter then cut into small pieces, sundried for 7 days then kept in a hot airoven at 60˚C till dryness. It was then powdered and sieved through 1.18 µM sieve for getting uniform size biosorbent.

2.2. Biosorption Experiment

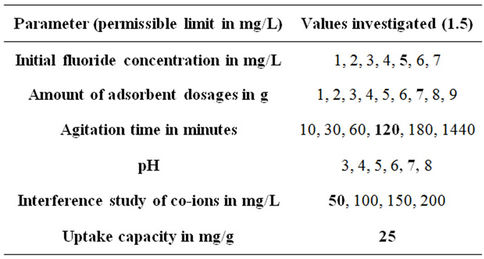

The biosorption capacity of biomass was determined by contacting various concentrations (1 - 7 mg/L) of 50-ml fluoride solution in 250-ml plastic beakers with 1 - 9 g of biomass. The filtrate containing the residual concentration of fluoride was determined by Orion ion meter (290A). For the determination of rate of fluoride biosorption, the supernatant was analysed for residual fluoride after the contact time of 10 - 1440 minutes. The effect of pH on fluoride sorption by biomass was determined at pH values of 3 - 8. Values of experimental operating parameters investigated are given in Table 1. Adsorption isotherm studies were carried out with different initial concentrations of fluoride while maintaining the adsorbent dosage. Pseudo first order model were fitted better when compared with the second order kinetic model. Langmuir and Freundlich models were applied to the

Table 1. Variation of experimental operating parameters of fluoride.

adsorption isotherm and different constants were generated. The Langmuir and Freundlich adsorption parameters and correlation coefficient were also calculated from the adsorption isotherm data.

3. Result and Discussion

3.1. Effect of Adsorbent Dose on Fluoride Adsorption

Biomass dose is an important parameter owing to its effect on efficiency and on the amount of fluoride removed per unit weight of biomass. The effect of biosorbent dosage (1 - 9 g/50ml) on the percentage removal of fluoride was studied. The fluoride adsorption increased with the increasing amount of the adsorbent as higher doses of the adsorbent provided more active sites. The dose of adsorbent having the optimum fluoride removal efficiency was found to be 7 g/50ml. Further increase in doses did not resulted in the considerable increase in defluoridation. This is due to the overlapping of the active sites at higher concentrations of the adsorbents, thus reducing the net surface area. Hence 7 g of the biomass was taken as the dose possessing the optimum fluoride removal efficiency and this was fixed as the dose of the material for further experiments.

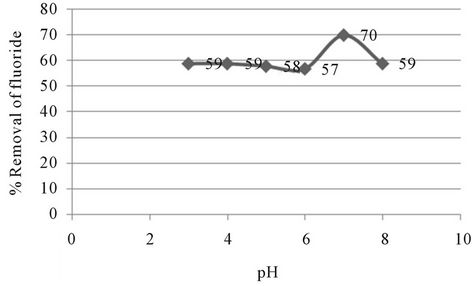

3.2. Effect of pH on Biosorption

The pH of the aqueous solution is an important controlling parameter in the adsorption process. Thus, the role of hydrogen ion concentration was examined at pH values of 3 to 8. This was adjusted by adding 0.5 N HCl or 0.1 M NaOH. The effect of pH (3 - 8) on the removal of fluoride for a constant biosorbant dosage of 7 g/50 ml, and fluoride ion concentration of 5 mg/L was studied. It was found that pH had a marked effect on the fluoride uptake in this experiment. The percentage adsorption of fluoride ion was found to maximum at pH 7 (Figure 1) and then it decreased with a further increase of pH. The optimum pH for the removal of fluoride was found to be 7.

Figure 1. Showing effect of pH on % removal of fluoride.

3.3. Time Dependence Studies for Fluoride Binding

The variation in percentage removal of fluoride with time was studied using the solution of fluoride with initial concentration of 5 mg/L, adsorbent dosage 7 g at pH 7. The time was varied from 10 to 1440 min. On increasing the contact time, the percentage removal was found to gradually increase till 120 min. Further increase in time decreased the removal of fluoride. Hence, the optimum contact time for fluoride removal was 120 min (Figure 2) at pH 7. Further increase in contact time does not increase the uptake due to saturation of fluoride ions on the available sites present on adsorbent material. This means that the biomass requires contact time of 120 minutes for the removal of the maximum amount of fluoride. For the optimization of other parameters, the contact time of 120 minutes was considered as the equilibrium time.

3.4. Effect of Initial Fluoride Concentration

To achieve the maximum adsorption capacity of fluoride, the experiment was conducted under optimum conditions (adsorbent doses fixed at 7 g/50 ml, fixed contact time of 120 min at pH 7). The effect of initial fluoride concentration was studied by varying fluoride concentration from 1 to 7 mg/L. The results indicate that the percentage removal were remaining constant (70%) after the 5 mg/L concentration of fluoride solution. This is due to lack of available active sites on the adsorbent surface.

3.5. Study on the Adsorption Kinetics

In this kinetic study the experiment was conducted in which the concentration of fluoride was 5 mg/L (where time varied from 10 min to 1440 min at 25˚C). The amount of fluoride adsorbed q (mg/g) increased and log(qe – q) decreased from 10 min to 120 min, whereas from 120 min to 1440 min q (mg/g) decreased and log(qe – q) increased. The value of co-relation coefficient R2 is greater (0.99) than (0.82) showing the effect of time on adsorption process before and after equilibrium time.

Figure 2. Showing effect of contact time on % removal of fluoride.

3.6. Sorption Equilibria Studies

The linear plots of Ceq/q vs. Ceq show that adsorption follows the Langmuir adsorption model. The essential characteristics of the Langmuir isotherms can be expressed in terms of a dimensionless constant separation factor or equilibrium parameter, RL, which is defined as RL = 1/(1 + bCo)

where b is the Langmuir constant and Co is the initial concentration of fluoride. The RL value indicates the shape of isotherm. According to McKay et al. (1982), RL values between 0 and 1 indicate favourable adsorption. Kf(1.047) and n(1.325) were calculated from the slopes of the Freundlich plots. According to Kadirvelu and Namasivayam (2000), n values between 1 and 10 represent beneficial adsorption. The magnitude of Kf and n shows easy separation of fluoride. The value of n, which is related to the distribution of bonded ions on the sorbent surface, is indicating that adsorption of fluoride is favorable.

3.7. Co-Ions Competition and Biosorption Interference

Co-ions competition and interference experiments are performed to find out the interference of other species with the binding of the target metal ion to the biomass. Competition between chemical species for the binding sites depends on factors such as the chemistry of the metal, pH of the solution, the nature of the binding sites, the amount of binding sites, the diversity of chemical species, metal ion concentration, and the selectivity of the biomass to bind certain species. The interference studies of co-ions (50 - 200 mg/L) with 5 mg/L solution of fluoride were investigated. In this study tolerable effect was found with 50 mg/L concentration of co-ions (Cl, NO3, SO4, PO4, Cr, Cd, Ca, Mg, Mo, Ni, Cu, Fe, Mn), whereas increasing the concentration, retarded the fluoride removal capacity in some extent.

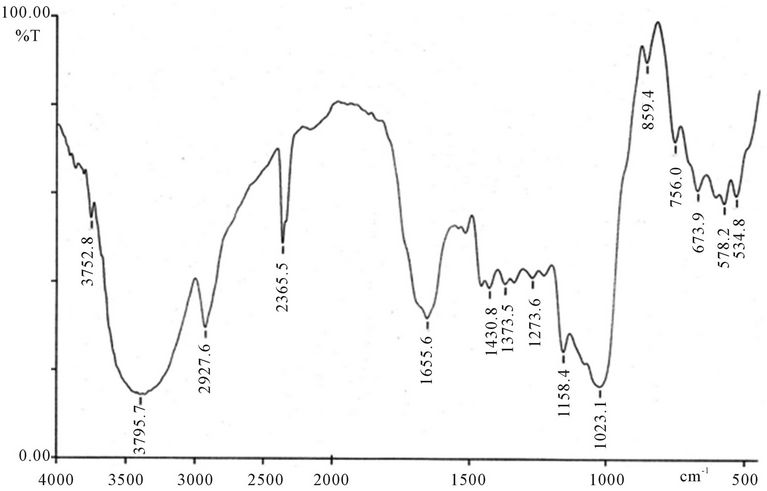

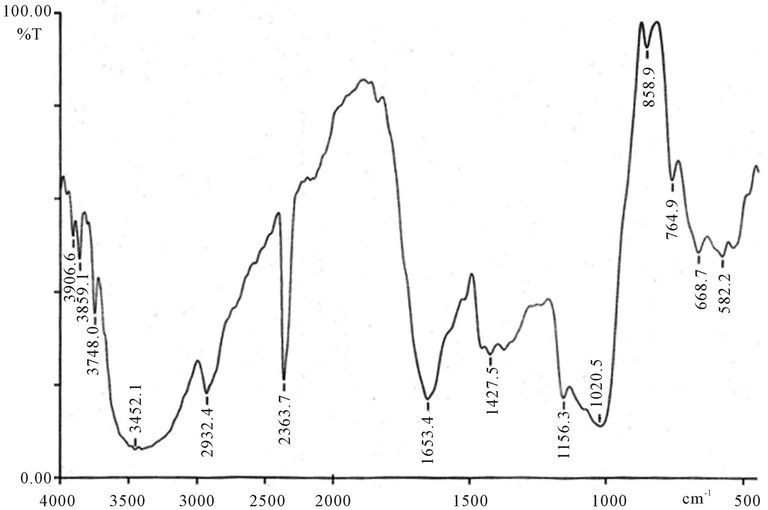

3.8. Interpretation of FT-IR Spectra

On comparing the IR spectra it was found that there are significant changes in the fresh and exhausted biomass spectra. The identification of absorption spectrum shows the range, type, vibration and functional groups of the biomass. FT-IR study of fresh biomass (Figure 3) and exhausted biomass (Figure 4) shows major differences in the region 500 - 1600 cm−1 range is assigned to −NH2 groups in different parts of the biomass. Frequency ranges of biomass indicating bonding of fluoride with the amines groups of biomass. Hence, based on FT-IR spectrum analysis it can be conclude that the fluoride binding in the biomass takes place by the substitution of amine groups.

3.9. Applicable to Treatment of Fluoride at Neutral pH

Permissible limit of fluoride contaminated water for use

Figure 3. FT-IR spectra of fresh biomass.

Figure 4. FT-IR spectra of exhausted biomass.

in irrigation and other purposes are higher than the limit for drinking water. This biomass was applicable to defluoridation treatment of drinking water within standard WHO permissible limit (1.5 mg/L) at neutral pH without changing the chemical nature of water. The appreciable results were being obtained without disturbing the pH of the water.

3.10. Significance of the Plant Biomass

Plant material was readily, locally available, rich in proteins and calcium, caused no change in the pH of the treated water, and gave good result at neutral pH, their residue after use was easy to dispose off without changing the pH of the disposed field. This plant material was used as a cost effective, potential natural biosorbent for defluoridation of water. Comparison of the adsorption capacities of different sorbents are shown in Table 2.

3.11. Mass Balance of Fluoride in the System

Desorption study was carried out to account for the mass balance of fluoride in the system as its concentration in optimum dose in drinking water is advantageous to health. For this the loaded biomass after a single exposure to the known amount of fluoride was carried out for desorption. The result shows that about 55% of the adsorbed amount of fluoride could be leached easily after first attempt of desorption only. Remaining up to 99.9% of the fluoride was desorbed after sub sequential attempts of this study.

4. Conclusion

The biomass of the natural plant demonstrated a good capacity of fluoride biosorption, highlighting its potential for the drinking water treatment process. pH had a strong effect on biosorption capacity and the optimum pH found 7. The biosorption was rapid and equilibrium achieved within 120 min. The uptake capacity of fluoride was found to be 25 mg/g. The results indicate that Langmuir and Freundlich sorption models were good agreement with the experimental results. Further, the biosorbents are characterized by FT-IR spectral analyses. The biomass found to be very efficient, instantaneous and economical for removing fluoride from drinking water. This biosorptive material is very useful to reduce fluoride within standard WHO permissible limit (1.5 mg/L) at neutral pH. The significant results were being obtained without disturbing the pH of the water. The fluoride containing biomass can be dumped as a solid waste material in pits

Table 2. Comparison of the adsorption capacities of different sorbents for defluoridation.

without changing the chemical nature of soil because the whole experimental parameters were identified at the neutral pH 7.

REFERENCES

- J. Cao, Y. Zhao, J. W. Lin, R. D. Xirao and S. B. Danzeng, “Environmental Fluoride in Tibet,” Environmental Research, Vol. 83, No. 3, 2000, pp. 333-337. doi:10.1006/enrs.2000.4066

- V. K. Gupta, A. Lmran and V. K. Sain, “Defluoridation of Wastewaters Using Waste Carbon Slurry,” Water Research, Vol. 41, No. 15, 2007, pp. 3307-3316. doi:10.1016/j.watres.2007.04.029

- G. Zhang, Y. Gao, Y. Zhang and P. Gu, “Removal of Fluoride from Drinking Water by a Membrane Coagulation Reactor (MCR),” Desalination, Vol. 177, No. 1-3, 2005, pp. 143-155. doi:10.1016/j.desal.2004.12.005

- BIS, “Indian Standards for Drinking Water-Specification,” Bureau of Indian Standards, New Delhi, 1991.

- S. Venkata Mohan, P. Nikhila and S. J. Reddy, “Determination of Fluoride Content in Drinking Water and Development of a Model in Relation to Some Water Quality Parameters,” Fresenius Environmental Bulletin, Vol. 4, 1995, pp. 297-302.

- R. C. Maheshwari and Meenakshi, “Fluoride in Drinking Water and Its Removal,” Journal of Hazardous Materials, Vol. 137, No. 1, 2006, pp. 456-463. doi:10.1016/j.jhazmat.2006.02.024

- D. Jackson, J. J. Murray and C. G. Fairpo, “Lifelong Benefits of Fluoride in Drinking Water,” British Dental Journal, Vol. 134, No. 10, 1973, pp. 419-422. doi:10.1038/sj.bdj.4803012

- G. Karthikeyan, A. Pius and G. Alagumuthu, “Fluoride Adsorption Studies of Montmorillonite Clay,” Indian Journal of Chemical Technology, Vol. 12, 2005, pp. 263- 273.

- N. Subba Rao and D. J. Devdas, “Fluoride Incidence in Groundwater in an Area of Peninsula India,” Environmental Geology, Vol. 45, No. 2, 2003, pp. 243-251. doi:10.1007/s00254-003-0873-3

- A. K. Chaturvedi, K. P. Yadva, K. C. Yadava, K. C. Pathak and V. N. Singh, “Deflouridation of Water by Adsorption on Fly Ash,” Water, Air, Soil Pollution, Vol. 49, No. 1-2, 1990, pp. 51-61. doi:10.1007/BF00279509

- M. Emamjomeh and M. Sivakumar, “Fluoride Removal by a Continuous Flow Ectrocoagulation Reactor,” Journal of Environmental Management, Vol. 90, No. 2, 2009, pp. 1204-1212. doi:10.1016/j.jenvman.2008.06.001

- A. V. Jamode, V. S. Sapkal and V. S. Jamode, “Defluoridation of Water Using Inexpensive Adsorbents,” Journal of the Indian Institute of Science, Vol. 84, 2004, pp. 163- 171.

- K. Sarala and P. R. Rao, “Endemic Fluorosis in the Village Ralla, Anantapuram in Andhra Pradesh an Epidemiological Study,” Fluoride, Vol. 26, 1993, pp. 177-180.

- H. E. Short, G. R. Mc Robert, T. W. Bernardand and A. S. Mannadiyar, “Endemic Fluorosis in the Madras Presidency,” Indian Journal of Medical Research, Vol. 25, 1937, pp. 553-561.

- K. Shushila, “Fluorosis Management Programme in India: The Impact Due to Networking between Health and Rural Drinking Water Supply,” International Association of Hydrological Sciences, Vol. 260, 2000, pp. 159-165.

- S. Chidambaram, A. L. Ramnathan and S. Vasudevan, “Fluoride Removal Studies in Water Using Natural Materials,” Water SA, Vol. 29, No. 3, 2003, pp. 339-343.

- A. M. Raichur and M. Jyoti Basu, “Adsorption of Fluoride onto Mixed Rare Earth Oxides,” Separation and Purification Technology, Vol. 24, No. 1-2, 2001, pp. 121- 127. doi:10.1016/S1383-5866(00)00219-7

- E. J. Reardon and Y. Wang, “Limestone Reactor for Fluoride Removal from Waste Waters,” Environmental Science & Technology, Vol. 34, No. 15, 2000, pp. 3247- 3253. doi:10.1021/es990542k

- B. Singh, P. K. Kumar Sen and J. Maunder, “Removal of Fluoride from Spent Pot Liner Leachate Using Ion Exchange,” Water Environment Research, Vol. 71, No. 1, 1999, pp. 36-42. doi:10.2175/106143099X121571

- A. Dieye, C. Larchet, B. Auclair and C. Mar-Diop, “Elimination des Fluorures Parla Dialyse Ionicque Croisee,” European Polymer Journal, Vol. 34, No. 1, 1998, pp. 67-75. doi:10.1016/S0014-3057(97)00079-7

- N. Mameri, H. Lounici, D. Belhocine, H. Grib, G. F. Prion and Y. Yahiat, “Defluoridation of Sahara Water by Small Electro Coagulation Using Bipolar Aluminium Electrodes,” Separation and Purification Technology, Vol. 24, No. 1-2, 2001, pp. 13-119. doi:10.1016/S1383-5866(00)00218-5

- M. Hichour, F. Persin, J. Sandeaux and C. Gavach, “Water Defluoridation by Donann Dialysis and Electro Dialysis,” Separation and Purification Technology, Vol. 18, No. 1, 2000, pp. 1-11. doi:10.1016/S1383-5866(99)00042-8

- S. Venkata Mohan, S. Ramanaiah, B. Rajkumar and P. Sarma, “Biosorption of Fluoride from Aqueous Phase onto Algal Spirogyra IO1 and Evaluation of Adsorption Kinetics,” Bioresource Technology, Vol. 98, No. 5, 2007, pp. 1006-1016. doi:10.1016/j.biortech.2006.04.009

- B. Volesky, “Biosorption and me,” Water Research, Vol. 41, No. 18, 2007, pp. 4017-4029. doi:10.1016/j.watres.2007.05.062

- B. Volesky and Z. R. Holan, “Biosorption of Heavy Metals,” Biotechnology Progress, Vol. 11, No. 3, 1995, pp. 235-250. doi:10.1021/bp00033a001

- J. Crittenden, R. Trussell, D. Hand, K. Howe and G. Tchobanoglous, “Water Treatment: Principles and Design,” John Wiley and Sons, New York, 2005.

- M. Malakootian, A. Almasi and H. Hossaini, “Pb and Co Removal from Paint Industries Effluent Using Wood Ash,” International journal of Environmental Science and Technology, Vol. 5, No. 2, 2008, pp. 217-222.

- D. Kratochvil and B. Volesky, “Advances in the Biosorption of Heavy Metals,” Trends in Biotechnology, Vol. 16, No. 7, 1998, pp. 291-300.

- S. Ghorai and K. Pant, “Investigations on the column Performance of Fluoride Adsorption by Activated Alumina in a Fixed-Bed,” Chemical Engineering Journal, Vol. 98, No. 1-2, 2004, pp. 165-173. doi:10.1016/j.cej.2003.07.003

- N. Das, P. Pattanaïk and R. Das, “Defluoridation of Drinking Water Using Activated Titanium-Rich Bauxite,” Journal of Colloid and Interface Science, Vol. 292, 2005, pp. 6-45.

- S. Meenakshi and N. Viswanathan, “Identification of Selective Ionexchange Resin for Fluoride Sorption,” Journal of Colloid and Interface Science, Vol. 308, No. 2, 2006, pp. 438-450.

- S. Maliyekkal, A. Sharma and L. Philip, “ManganeseOxide-Coated Alumina: A Promising Sorbent for Defluoridation of Water,” Water Research, Vol. 40, No. 19, 2006, pp. 3497-3506.

- Y. H. Li, S. Wang, X. Zhang, J. Wei, C. Xu, Z. Luan and D. Wu, “Adsorption of Fluoride from Water by Aligned Carbon Nanotubes,” Materials Research Bulletin, Vol. 38, No. 3, 2003, pp. 469-476. doi:10.1016/S0025-5408(02)01063-2

- D. J. Killedar and D. S. Bhargava, “Effects of Stirring Rate and Temperature on Fluoride Removal by Fishbone Charcoal,” Indian Journal of Environmental Health, Vol. 35, No. 2, 1993, pp. 81-87.

- N. Prabavathi, T. Ramachandramoorthy, R EdisonRaja, B. Kavitha, C. Sivajiand and R. Srinivasan, “Drinking Water of Salem District Estimation of Fluoride and Its Defluoridation Using Lignite Rice Husk and Rice-Husk Powder, ” International Journal of Environment and Pollution, Vol. 23, No. 3, 2003, pp. 304-308.

- S. Ayoob and A. K. Gupta, “Insights into Isotherm Making in the Sorptive Removal of Fluoride from Drinking Water,” Journal of Hazardous Materials, Vol. 152, No. 3, 2007, pp. 976-985.

- Z. C. Di, Y. H. Li, X. J. Peng, Z. K. Luan and J. Liang, “Adsorption of Fluoride by Aligned Carbon Nanotubes Supported Ceria Nanoparticles,” Solid State Phenomena, vol. 121-123, 2007, pp. 1221-1224.

- S. Dey, S. Goswami and U. C. Ghosh, “Hydrous Ferric Oxide (HFO)—A Scavenger for Fluoride from Contaminated Water,” Water, Air and Soil pollution, Vol. 158, No. 1, 2004, pp. 311-323. doi:10.1023/B:WATE.0000044854.71497.b6

- M. Bhatnagar, A. Bhatnagar and S. Jha, “Interactive Biosorption by Microalgal Biomass as a Tool for Fluoride Removal,” Biotechnology Letters, Vol. 24, No. 13, 1991, pp. 1079-1081. doi:10.1023/A:1016086631017

- V. K. Gupta, L. Ali and V. K. Saini, “Defluoridation of Waste Waters Using Waste Carbon Slurry,” Water research, Vol. 41, No. 15, 2007, pp. 3307-3316. doi:10.1016/j.watres.2007.04.029

- S. Sinha, Pandey, K. P. Mohan and K. P. Singh, “Removal of Fluoride from Aqueous Solutions by Eichhornia Crassipes Biomass and Its Carbonizsed Form,” Industrial & Engineering Chemistry Research, Vol. 42, No. 26, 2003, pp. 6911-6918. doi:10.1021/ie030544k

- S. M. Maliyekkal, A. K.Sharma and L. Philip, “Manganese-Oxide-Coated Alumina: A Promising Sorbent for Defluoridation of Water,” Water Research, Vol. 40, No. 19, 2006, pp. 3497-3506. doi:10.1016/j.watres.2006.08.007

- S. Ghorai and K. K. Pant, “Equilibrium, Kinetics and Breakthrough Studies for Adsorption of Fluoride on Activated Alumina,” Seperation and Purification Technology, Vol. 42, No. 3, 2005, pp. 265-271. doi:10.1016/j.seppur.2004.09.001

- P. A. Shirke and P. Chandra, “Flouride Uptake by Duckweed Spirodela Polyrrhiza,” Flouride, Vol. 24, No. 3, 1991, pp. 109-112.

- P. A. Methodis and P. Selvapathy, “Studies on Removal of Fluoride from Water by Used Tea Leaves Carbon,” Third International Conference on Plants and Environmental Pollution, Lucknow, 29 November-2 December 2005.

- G. Karthikeyan and S. S. llango, “Fluoride Sorption Using Moringa Indica Based Activated Carbon,” Iranian Journal of Environmental Health Science & Engineering, Vol. 4, No. 1, 2007, pp. 21-28.

- R. P. Singh, Y. Singh and D. Swaroop, “Defluoridation of Groundwater in Agra City Using Low Cost Adsorbents,” Bulletin of Environmental Contamination and Toxicology, Vol. 65, No. 1, 2000, pp. 120-125. doi:10.1007/s001280000103

- A. V. Jamode, V. S. Sapkal and V. S. Jamode, “Defluoridation of Water Using Inexpensive Adsorbents,” Journal of the Indian Institute of Science, Vol. 84, 2004, pp. 163- 171.