A. B. ELDIN ET AL.

Copyright © 2011 SciRes. AJAC

891

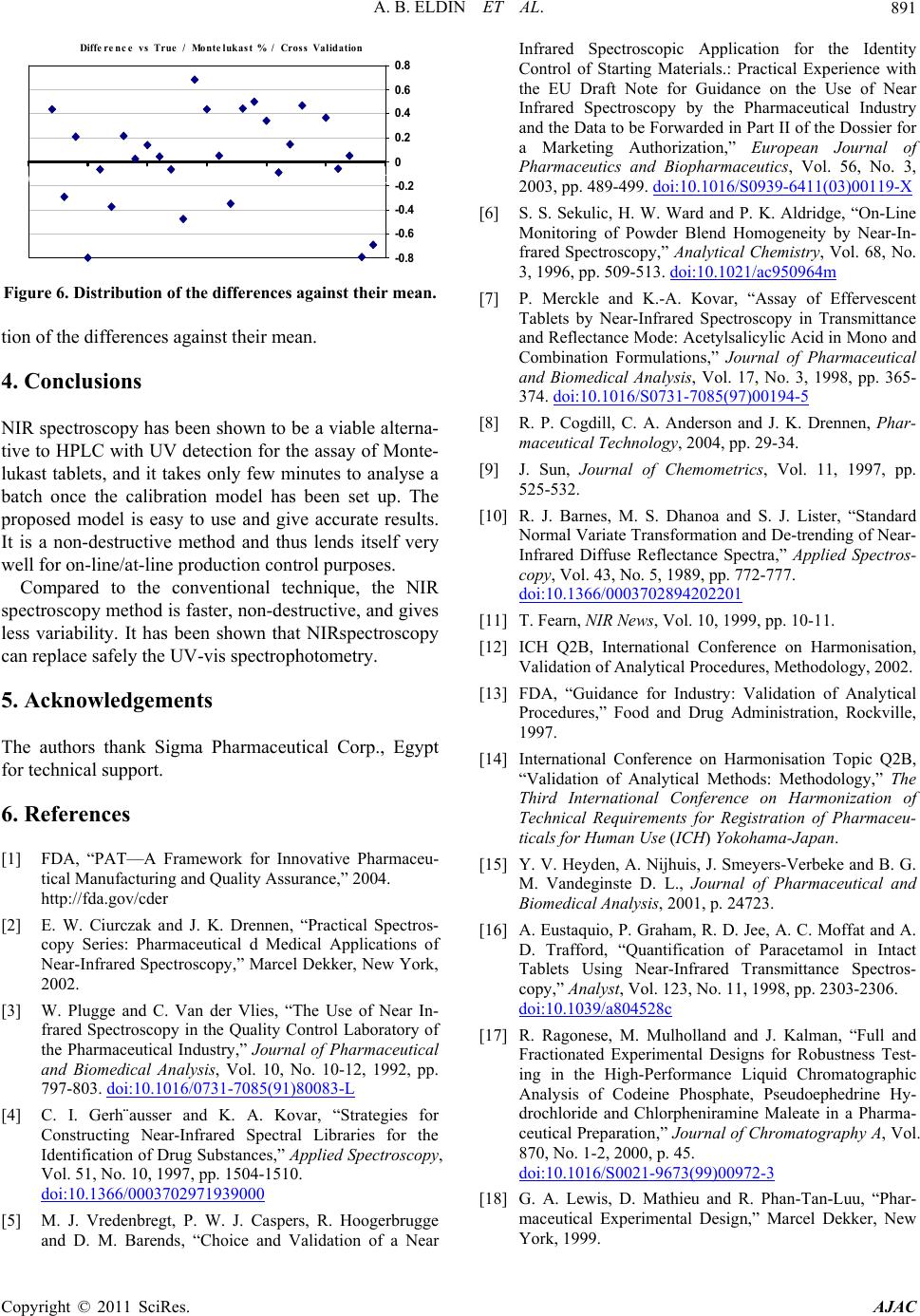

Difference vs True / Montelukast % / Cross Validation

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

051015202530

Figure 6. Distribution of the differences against their mean.

tion of the differences against their mean.

4. Conclusions

NIR spectroscopy has been shown to be a viable alterna-

tive to HPLC with UV detection for the assay of Monte-

lukast tablets, and it takes only few minutes to analyse a

batch once the calibration model has been set up. The

proposed model is easy to use and give accurate results.

It is a non-destructive method and thus lends itself very

well for on-line/at-line production control purposes.

Compared to the conventional technique, the NIR

spectroscopy method is faster, non-destructive, and gives

less variability. It has been shown that NIRspectroscopy

can replace safely the UV-vis spectrophotometry.

5. Acknowledgements

The authors thank Sigma Pharmaceutical Corp., Egypt

for technical support.

6. References

[1] FDA, “PAT—A Framework for Innovative Pharmaceu-

tical Manufacturing and Quality Assurance,” 2004.

http://fda.gov/cder

[2] E. W. Ciurczak and J. K. Drennen, “Practical Spectros-

copy Series: Pharmaceutical d Medical Applications of

Near-Infrared Spectroscopy,” Marcel Dekker, New York,

2002.

[3] W. Plugge and C. Van der Vlies, “The Use of Near In-

frared Spectroscopy in the Quality Control Laboratory of

the Pharmaceutical Industry,” Journal of Pharmaceutical

and Biomedical Analysis, Vol. 10, No. 10-12, 1992, pp.

797-803. doi:10.1016/0731-7085(91)80083-L

[4] C. I. Gerh¨ausser and K. A. Kovar, “Strategies for

Constructing Near-Infrared Spectral Libraries for the

Identification of Drug Substances,” Applied Spectroscopy,

Vol. 51, No. 10, 1997, pp. 1504-1510.

doi:10.1366/0003702971939000

[5] M. J. Vredenbregt, P. W. J. Caspers, R. Hoogerbrugge

and D. M. Barends, “Choice and Validation of a Near

Infrared Spectroscopic Application for the Identity

Control of Starting Materials.: Practical Experience with

the EU Draft Note for Guidance on the Use of Near

Infrared Spectroscopy by the Pharmaceutical Industry

and the Data to be Forwarded in Part II of the Dossier for

a Marketing Authorization,” European Journal of

Pharmaceutics and Biopharmaceutics, Vol. 56, No. 3,

2003, pp. 489-499. doi:10.1016/S0939-6411(03)00119-X

[6] S. S. Sekulic, H. W. Ward and P. K. Aldridge, “On-Line

Monitoring of Powder Blend Homogeneity by Near-In-

frared Spectroscopy,” Analytical Chemistry, Vol. 68, No.

3, 1996, pp. 509-513. doi:10.1021/ac950964m

[7] P. Merckle and K.-A. Kovar, “Assay of Effervescent

Tablets by Near-Infrared Spectroscopy in Transmittance

and Reflectance Mode: Acetylsalicylic Acid in Mono and

Combination Formulations,” Journal of Pharmaceutical

and Biomedical Analysis, Vol. 17, No. 3, 1998, pp. 365-

374. doi:10.1016/S0731-7085(97)00194-5

[8] R. P. Cogdill, C. A. Anderson and J. K. Drennen, Phar-

maceutical Technology, 2004, pp. 29-34.

[9] J. Sun, Journal of Chemometrics, Vol. 11, 1997, pp.

525-532.

[10] R. J. Barnes, M. S. Dhanoa and S. J. Lister, “Standard

Normal Variate Transformation and De-trending of Near-

Infrared Diffuse Reflectance Spectra,” Applied Spectros-

copy, Vol. 43, No. 5, 1989, pp. 772-777.

doi:10.1366/0003702894202201

[11] T. Fearn, NIR News, Vol. 10, 1999, pp. 10-11.

[12] ICH Q2B, International Conference on Harmonisation,

Validation of Analytical Procedures, Methodology, 2002.

[13] FDA, “Guidance for Industry: Validation of Analytical

Procedures,” Food and Drug Administration, Rockville,

1997.

[14] International Conference on Harmonisation Topic Q2B,

“Validation of Analytical Methods: Methodology,” The

Third International Conference on Harmonization of

Technical Requirements for Registration of Pharmaceu-

ticals for Human Use (ICH) Yokohama-Japan.

[15] Y. V. Heyden, A. Nijhuis, J. Smeyers-Verbeke and B. G.

M. Vandeginste D. L., Journal of Pharmaceutical and

Biomedical Analysis, 2001, p. 24723.

[16] A. Eustaquio, P. Graham, R. D. Jee, A. C. Moffat and A.

D. Trafford, “Quantification of Paracetamol in Intact

Tablets Using Near-Infrared Transmittance Spectros-

copy,” Analyst, Vol. 123, No. 11, 1998, pp. 2303-2306.

doi:10.1039/a804528c

[17] R. Ragonese, M. Mulholland and J. Kalman, “Full and

Fractionated Experimental Designs for Robustness Test-

ing in the High-Performance Liquid Chromatographic

Analysis of Codeine Phosphate, Pseudoephedrine Hy-

drochloride and Chlorpheniramine Maleate in a Pharma-

ceutical Preparation,” Journal of Chromatography A, Vol.

870, No. 1-2, 2000, p. 45.

doi:10.1016/S0021-9673(99)00972-3

[18] G. A. Lewis, D. Mathieu and R. Phan-Tan-Luu, “Phar-

maceutical Experimental Design,” Marcel Dekker, New

York, 1999.