125

C. U. ANIZ ET AL.

tion (TPD), ICP-AES, TG/DTG, etc. The results of the

BET surface area and ammonia-TPD data are given in

Tables 1 and 2 respectively. TPD studies were done us-

ing Pulse Chemisorb 2705 from Micromeritics. Samples

were degassed in helium in a quartz reactor, at 200˚C,

and then cooled to ambient temperature. 5% NH3 in he-

lium gas (from Bheruka gases, Bangalore) is admitted to

the sample for 15 min to saturate the sample. Physi-

sorbed ammonia was purged away, keeping the sample at

100˚C. Sample temperature was raised to 700˚C at a rate

of 10˚C/min measuring the outlet desorbed ammonia

using a calibrated TCD.

Nitrogen adsorption-desorption measurements were

done on a volumetric Micromeritics Tristar apparatus at

Liquid N2 temperature, 77.35 K. On an average 33

points were taken for each sample. The average mass of

the sample was 0.3 g. Pore size distributions were calcu-

lated using BJH method and surface areas were taken

from BET isotherms.

The temperature-programmed reduction studies (TPR)

were performed in Micromeritics PulseChemisorb-2705,

which incorporates a thermal conductivity detector

(TCD). Samples were activated/surface-cleaned in he-

lium at 200˚C for 30 minutes, then cooled to ambient

temperatures. The reactive gas composition was 10%

balance N2, its consumption was measured while heating

the sample up to 750˚C at a rate of 10˚C/min.

2.3. Kinetic and Catalytic Studies

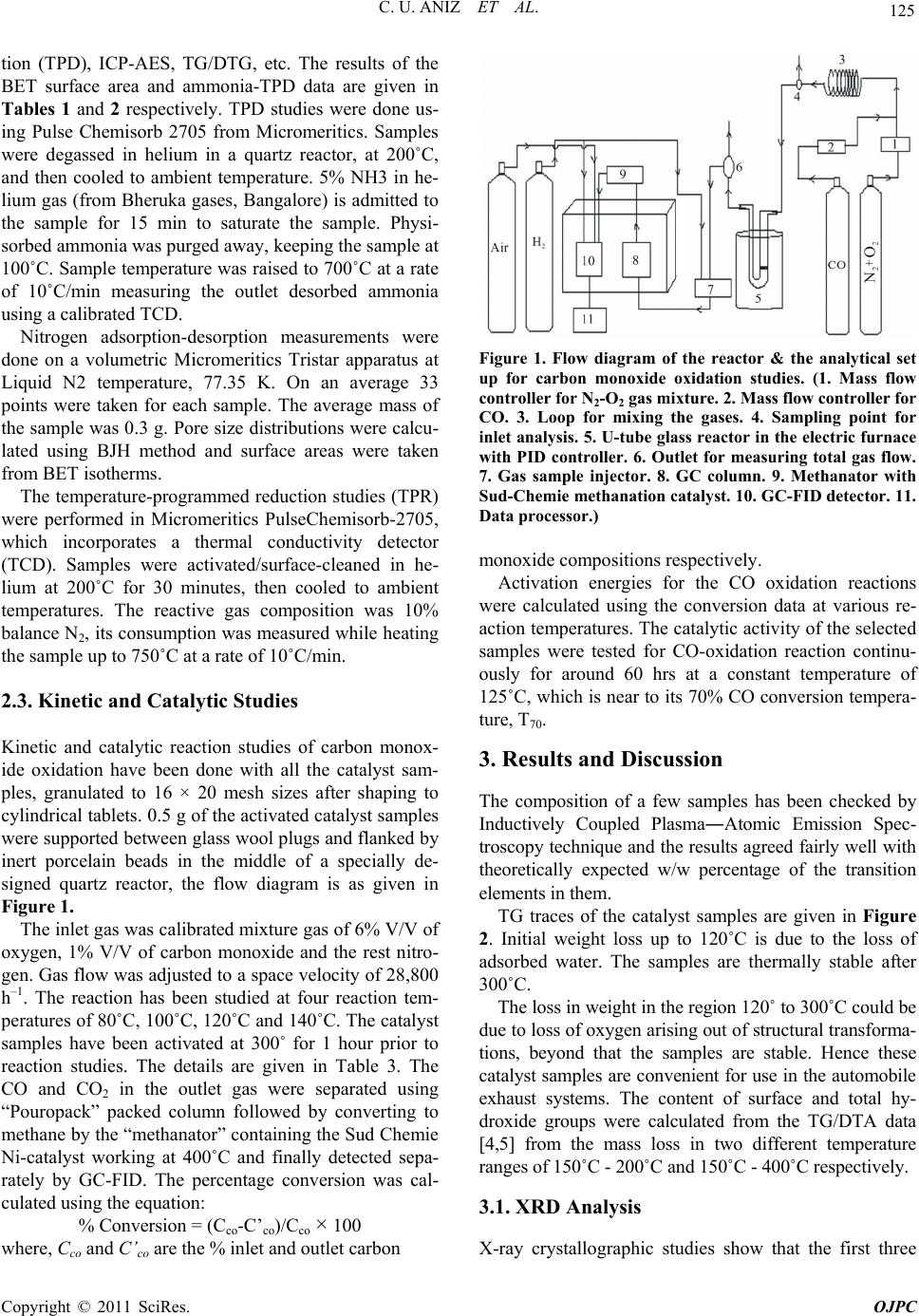

Kinetic and catalytic reaction studies of carbon monox-

ide oxidation have been done with all the catalyst sam-

ples, granulated to 16 × 20 mesh sizes after shaping to

cylindrical tablets. 0.5 g of the activated catalyst samples

were supported between glass wool plugs and flanked by

inert porcelain beads in the middle of a specially de-

signed quartz reactor, the flow diagram is as given in

Figure 1.

The inlet gas was calibrated mixture gas of 6% V/V of

oxygen, 1% V/V of carbon monoxide and the rest nitro-

gen. Gas flow was adjusted to a space velocity of 28,800

h–1. The reaction has been studied at four reaction tem-

peratures of 80˚C, 100˚C, 120˚C and 140˚C. The catalyst

samples have been activated at 300˚ for 1 hour prior to

reaction studies. The details are given in Table 3. The

CO and CO2 in the outlet gas were separated using

“Pouropack” packed column followed by converting to

methane by the “methanator” containing the Sud Chemie

Ni-catalyst working at 400˚C and finally detected sepa-

rately by GC-FID. The percentage conversion was cal-

culated using the equation:

% Conversion = (Cco-C’co)/Cco × 100

where, Cco and C’co are the % inlet and outlet carbon

Figure 1. Flow diagram of the reactor & the analytical set

up for carbon monoxide oxidation studies. (1. Mass flow

controller for N2-O2 gas mixture. 2. Mass flow controller for

CO. 3. Loop for mixing the gases. 4. Sampling point for

inlet analysis. 5. U-tube glass reactor in the electric furnace

with PID controller. 6. Outlet for measuring total gas flow.

7. Gas sample injector. 8. GC column. 9. Methanator with

Sud-Chemie methanation catalyst. 10. GC-FID detector. 11.

Data processor.)

monoxide compositions respectively.

Activation energies for the CO oxidation reactions

were calculated using the conversion data at various re-

action temperatures. The catalytic activity of the selected

samples were tested for CO-oxidation reaction continu-

ously for around 60 hrs at a constant temperature of

125˚C, which is near to its 70% CO conversion tempera-

ture, T70.

3. Results and Discussion

The composition of a few samples has been checked by

Inductively Coupled Plasma―Atomic Emission Spec-

troscopy technique and the results agreed fairly well with

theoretically expected w/w percentage of the transition

elements in them.

TG traces of the catalyst samples are given in Figure

2. Initial weight loss up to 120˚C is due to the loss of

adsorbed water. The samples are thermally stable after

300˚C.

The loss in weight in the region 120˚ to 300˚C could be

due to loss of oxygen arising out of structural transforma-

tions, beyond that the samples are stable. Hence these

catalyst samples are convenient for use in the automobile

exhaust systems. The content of surface and total hy-

droxide groups were calculated from the TG/DTA data

[4,5] from the mass loss in two different temperature

ranges of 150˚C - 200˚C and 150˚C - 400˚C respectively.

3.1. XRD Analysis

X-ray crystallographic studies show that the first three

Copyright © 2011 SciRes. OJPC