Paper Menu >>

Journal Menu >>

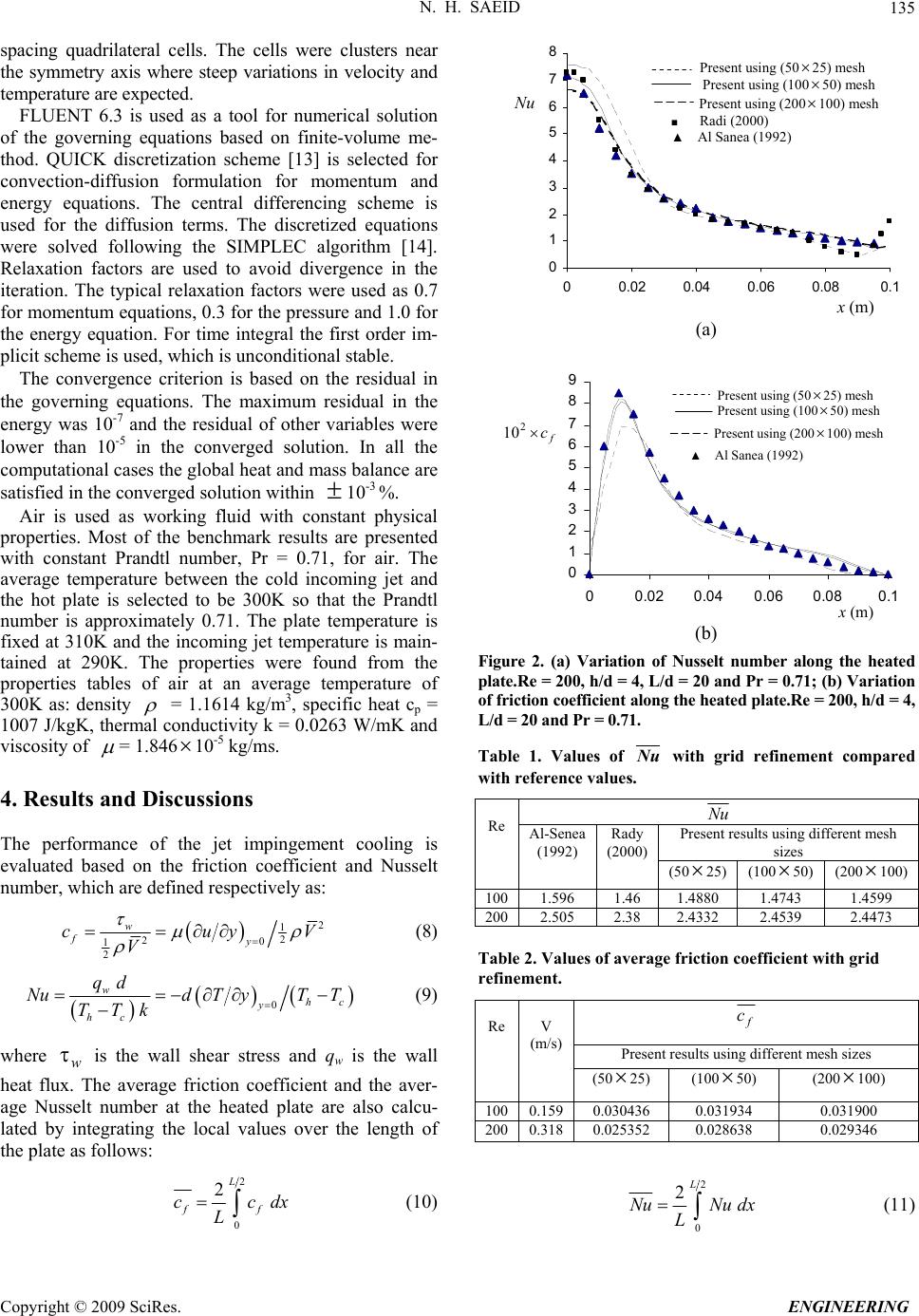

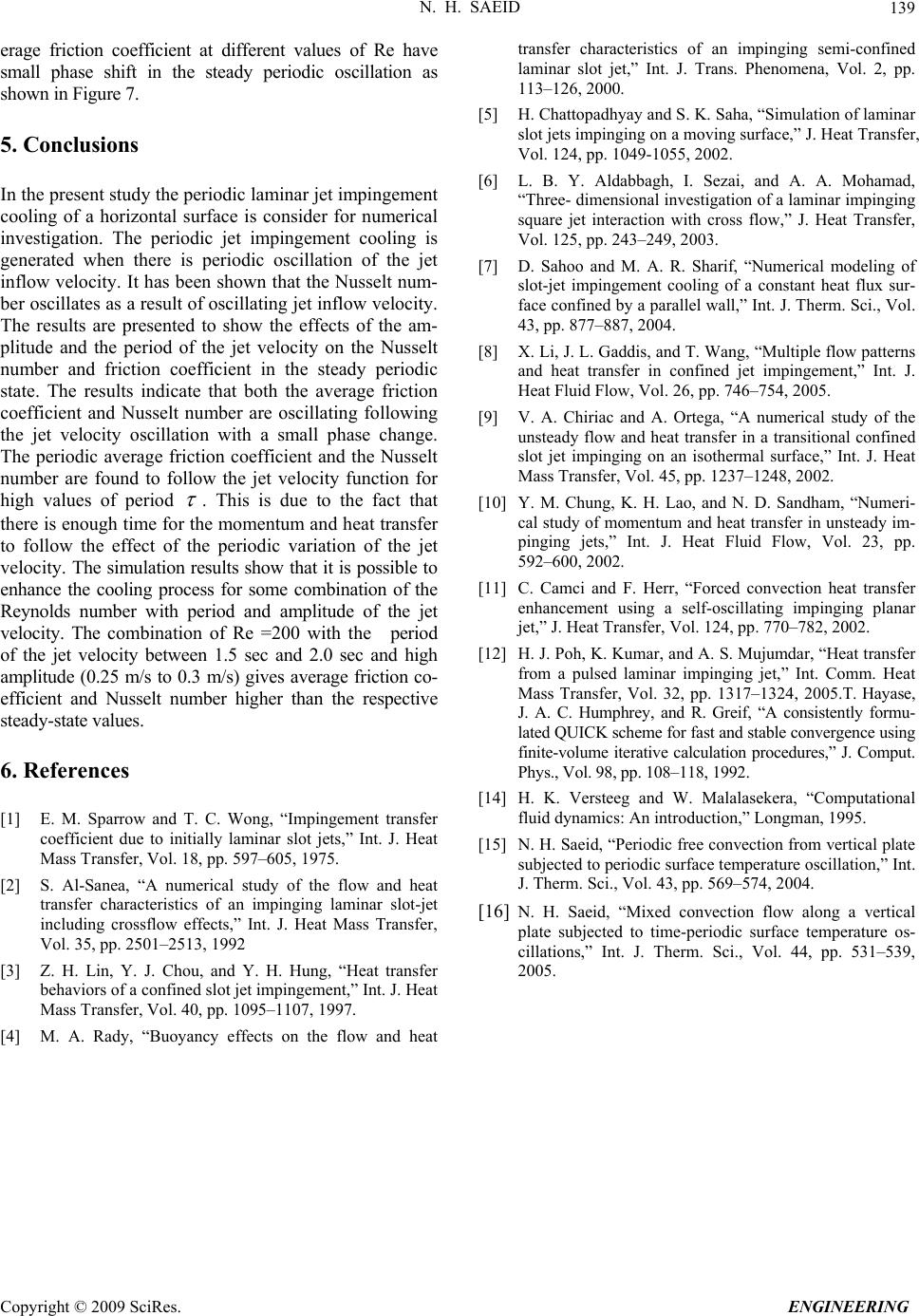

Engineering, 2009, 1, 133-139 doi:10.4236/eng.2009.13016 Published Online November 2009 (http://www.scirp.org/journal/eng). Copyright © 2009 SciRes. ENGINEERING Effect of Oscillating Jet Velocity on the Jet Impingement Cooling of an Isothermal Surface Nawaf H. SAEID Department of Mechanical, Manufacturing and Materials Engineering, The University of Nottingham Malaysia Campus, Semenyih, Malaysia E-mail: nawaf.saeid@nottingham.edu.my Received January 10, 2009; revised February 21, 2009; accepted February 23, 2009 Abstract Numerical investigation of the unsteady two-dimensional slot jet impingement cooling of a horizontal heat source is carried out in the present article. The jet velocity is assumed to be in the laminar flow regime and it has a periodic variation with the flow time. The solution is started with zero initial velocity components and constant initial temperature, which is same as the jet temperature. After few periods of oscillation the flow and heat transfer process become periodic. The performance of the jet impingement cooling is evaluated by calculation of friction coefficient and Nusselt number. Parametric study is carried out and the results are presented to show the effects of the periodic jet velocity on the heat and fluid flow. The results indicate that the average Nusselt number and the average friction coefficient are oscillating following the jet velocity os- cillation with a small phase shift at small periods. The simulation results show that the combination of Re =200 with the period of the jet velocity between 1.5 sec and 2.0 sec and high amplitude (0.25 m/s to 0.3 m/s) gives average friction coefficient and Nusselt number higher than the respective steady-state values. Keywords: Heat Transfer, Unsteady Convection, Jet Impingement, Periodic Oscillation, Numerical Study 1. Introduction Jet Impinging is widely used for cooling, heating and drying in several industrial applications due to their high heat removal rates with relatively low pressure drop. In many industrial applications, such as in cooling of elec- tronics surfaces, the jet outflow is confined between the heated surface and an opposing surface in which the jet orifice is located. Recently many researchers [1–7] have carried out numerical and experimental investigations of laminar impinging jet cooling with different fluids and under various boundary conditions. The literature review reveals that the behavior of the two-dimensional laminar impinging jet is not well un- derstood. Numerical results of Li et al. [8] indicate that there exist two different solutions in some range of geo- metric and flow parameters of the laminar jet impinge- ment flow. The two steady flow patterns are obtained under identical boundary conditions but only with dif- ferent initial flow fields. This indicates that the unsteady state analysis is important to have better understanding of the flow and heat transfer in jet impingement. Fi- nite-difference approach was used by Chiriac and Ortega [9] in computing the steady and unsteady flow and heat transfer due to a confined two-dimensional slot jet im- pinging on an isothermal plate. The jet Reynolds number was varied from Re=250 to 750 for a Prandtl number of 0.7 and a fixed jet-to-plate spacing of H=W= 5. They found that the flow becomes unsteady at a Reynolds number between 585 and 610. Chung et al. [10] have solved the unsteady compressible Navier–Stokes equa- tions for impinging jet flow using a high-order finite dif- ference method with non-reflecting boundary conditions. Their results show that the impingement heat transfer is very unsteady and the unsteadiness is caused by the pri- mary vortices emanating from the jet nozzle. Camci and Herr [11] have showed that it is possible to convert a stationary impinging cooling jet into a self- oscillating-impinging jet by adding two communication ports at the throat section. Their experimental results show that a self-oscillating turbulent impinging-jet con- figuration is extremely beneficial in enhancing the heat removal performance of a conventional (stationary) im- pinging jet. It is of great importance to investigate the  N. H. SAEID Copyright © 2009 SciRes. ENGINEERING 134 y d Vj (t) Tc 0 x h 0 x x Th L s Figure 1. Schematic diagram of the physical model and coordinate system. effect of periodic flow on the performance of the laminar jet impingement cooling process. Such investigation has been carried out numerically by Poh et al [12] to study the effect of flow pulsations on time-averaged Nusselt number under a laminar impinging jet. The target wall in this study is considered from the stagnation point until the exit. The whole target wall is subjected to a constant heat flux. The working fluid is water and the flow is as- sumed to be axi-symmetric semi-confined. They found that the combination of Re = 300, f = 5 Hz and H/d = 9 give the best heat transfer performance. In applications such as electronics the components are usually considered as discrete heat sources and the cool- ing fluid is air. Therefore the objective of the present study is to investigate the periodic laminar jet impinge- ment of air to cool a discrete and isothermal heat source. 2. Mathematical Model A schematic diagram of impinging jet is shown in Figure 1. The jet exits through a slot of width d with distance h from the target-heated surface. All walls are adiabatic except the target plate where temperature is constant (Th) and higher than the jet exit temperature (Tc). The mathematical formulation of the present problem is based on the following assumptions: 1) the flow is two-dimensional, laminar and income- pressible; 2) initial temperature and velocity profiles are ass- umed to be uniform across the jet width; 3) the thermo-physical properties of the fluid are constants and obtained at average temperature of the jet inlet and heater temperatures; and 4) the viscous heating is neglected in the energy con- servation. Based on the above assumptions, the governing equations for the unsteady heat and fluid flow are as follows: Mass conservation equation 0 uv xy (1) Momentum conservation equations 1uuu uu uv txyxxyy 1vvvvv uv txyxxyy p y (3) Energy conservation equation TTTTT uv txyxxyy (4) where u and v are velocity components in x and y-directions respectively, T is temperature, p is pressure and t is time. , and are kinematic viscosity and thermal diffusivity of the fluid respectively. Due to the symmetry around y-axis, only one-half of the flow field is considered for computational purpose. Therefore the initial and boundary conditions are: Initial condition u (x,y,0) = v (x,y,0) = 0 and T(x,y,0) = Tc (5) At x = 0 symmetry 0 uvT xxx (6a) At x = (L/2+s) exit 0 uvT xxx (6b) At y = 0 lower wall u = v = 0 and T = Th for 2 x L otherwise 0 T y (6c) At y = h upper boundary u = 0, v = - Vj (t) and T = Tc for 2dx other- wise u = v =0 T y (6d) The present study investigates the effect of the jet veloc- ity - Vj (t) when it has a periodic variation with the flow time as: 2 () cos j Vt Vt (7) where V is the average jet velocity, and and are the amplitude and period of the oscillation respectively. The length of the lower adiabatic wall has an impor- tant influence on the accuracy of the results, where the exit boundary condition can be realistic. In the present study the length of the lower adiabatic wall is selected to be 3 times the heated surface (L/2) similar to that adopted by Rady [4]. 3. Numerical Solution Procedure p x (2) The solution domain was meshed by divided it into  N. H. SAEID135 spacing quadrilateral cells. The cells were clusters near the symmetry axis where steep variations in velocity and temperature are expected. FLUENT 6.3 is used as a tool for numerical solution of the governing equations based on finite-volume me- thod. QUICK discretization scheme [13] is selected for convection-diffusion formulation for momentum and energy equations. The central differencing scheme is used for the diffusion terms. The discretized equations were solved following the SIMPLEC algorithm [14]. Relaxation factors are used to avoid divergence in the iteration. The typical relaxation factors were used as 0.7 for momentum equations, 0.3 for the pressure and 1.0 for the energy equation. For time integral the first order im- plicit scheme is used, which is unconditional stable. The convergence criterion is based on the residual in the governing equations. The maximum residual in the energy was 10-7 and the residual of other variables were lower than 10-5 in the converged solution. In all the computational cases the global heat and mass balance are satisfied in the converged solution within 10-3 %. Air is used as working fluid with constant physical properties. Most of the benchmark results are presented with constant Prandtl number, Pr = 0.71, for air. The average temperature between the cold incoming jet and the hot plate is selected to be 300K so that the Prandtl number is approximately 0.71. The plate temperature is fixed at 310K and the incoming jet temperature is main- tained at 290K. The properties were found from the properties tables of air at an average temperature of 300K as: density = 1.1614 kg/m3, specific heat cp = 1007 J/kgK, thermal conductivity k = 0.0263 W/mK and viscosity of = 1.84610-5 kg/ms. 4. Results and Discussions The performance of the jet impingement cooling is evaluated based on the friction coefficient and Nusselt number, which are defined respectively as: 2 1 2 20 1 2 w fy cuy V V (8) 0 w hc y hc qd NudT yTT TTk (9) where is the wall shear stress and qw is the wall heat flux. The average friction coefficient and the aver- age Nusselt number at the heated plate are also calcu- lated by integrating the local values over the length of the plate as follows: w 2 0 2L ff cc L 0 1 2 3 4 5 6 7 8 00.02 0.04 0.06 0.080.1 Present using (50 25) mesh Present using (100 50) mesh Nu Present using (200 100) mesh ■ Radi (2000) ▲ Al Sanea (1992) x (m) (a) 0 1 2 3 4 5 6 7 8 9 00.02 0.040.06 0.080.1 Present using (50 25) mesh Present using (100 50) mesh f c 2 10 Present using (200 100) mesh ▲ Al Sanea (1992) x (m) (b) Figure 2. (a) Variation of Nusselt number along the heated plate.Re = 200, h/d = 4, L/d = 20 and Pr = 0.71; (b) Variation of friction coefficient along the heated plate.Re = 200, h/d = 4, L/d = 20 and Pr = 0.71. Table 1. Values of Nu with grid refinement compared with reference values. Nu Present results using different mesh sizes Re Al-Senea (1992) Rady (2000) (50 25) (10050) (200 100) 1001.596 1.46 1.4880 1.4743 1.4599 2002.505 2.38 2.4332 2.4539 2.4473 Table 2. Values of average friction coefficient with grid refinement. f c Present results using different mesh sizes Re V (m/s) (50 25) (10050) (200 100) 1000.1590.030436 0.031934 0.031900 2000.3180.025352 0.028638 0.029346 2 0 2L NuNu dx L (11) dx (10) Copyright © 2009 SciRes. ENGINEERING  N. H. SAEID Copyright © 2009 SciRes. ENGINEERING 136 The effect of mesh size on the accuracy of calculating friction coefficient and Nusselt number is studied for steady flow with constant jet velocity. The present results obtained using different mesh sizes are compared with the results of Al-Senea [2] and Rady [4]. The results presented in Figure 2(a) and Table 1 shows the compari- son of local and average Nusselt number respectively. Figure 2(b) and Table 2 show the simulation results for local and average friction coefficient respectively. The present results show that the mesh with 10050 quadri- lateral cells in the x and y directions respectively gives results with acceptable accuracy. The mesh is designed so that the jet width, which is d/2 = 0.005 m is divided into 10 cells (control volumes). The heated surface L/2 = 0.1 m (which gives L/d = 20) is discretized into 50 divi- sions and the remaining adiabatic lower wall is divided into 50 divisions. The height h = 0.04 m (where h/d = 4) in the vertical direction is divided into 50 divisions. The results shown in Figures 2 and Tables 1 and 2 also show that halving or duplicating the mesh size have minor ef- fects on the values of the Nusselt number and friction coefficient. Therefore the results obtained using mesh with 10050 quadrilateral cells can be considered as grid independent results. Good agreements of the present results with those references cited in [2] and [4] are ob- served for two different values of the Reynolds number in the laminar regime. Where Re is the Reynolds number defined based on average jet velocity and jet width as: dVRe . It is worth mentioning that the values of f c are not listed in the references [2] and [4]. In unsteady flows in general and especially periodic flows, the time step size has a great influence of the ac- curacy of the results. The time step size can be made to be a function of the frequency/period of the flow oscilla- tion as implemented by Saeid [15,16]. In the present pe- riodic flow problem, the time step size is selected a func- tion of the period of the jet flow oscillation as 100t sec. To study the effect of the amplitude of the oscillation on the flow, the jet velocity is made to osci- llate with time according to Equation (7) with fixed values of period = 10 sec and Re = 200. It is important to note that the definition of Reynolds number in the present study is based on average jet velocity. To get Re = 200, the average jet velocity should be 0.318 m/s since the geometry of the problem and the air properties are assumed constants. Therefore the maxi- mum amplitude of the oscillation is selected to be 0.3 m/s so that there will be always positive impinging velocity on the target surface. The initial conditions in the unsteady simulation are defined in (5) which assume that the solution domain is filled with stagnant air at jet temperature. Then the jet starts to inflow and the target surface temperature in- 0.5 1 1.5 2 2.5 3 3.5 8082.5 8587.5 9092.5 9597.5100 = 0.0, 0.1, 0.15, 0.2, 0.25, 0.3 m/s Nu t (sec) (a) (b) Figure 3. (a) Oscillation of N u with = 10 sec and Re = 200; (b) Oscillation of f c with = 10 sec and Re = 200. creases suddenly from Tc to Th. At this time the value of Nusselt number goes to very high value. Then, when the jet velocity oscillates the calculated values of average Nusselt number is found to oscillate accordingly. This oscillation becomes steady periodic oscillation after some periods of oscillation. The steady periodic oscilla- tion is achieved when the amplitude and the average values of the average Nusselt number become constant for different periods. The numerical results of oscillation of the average Nusselt number in the ninth and tenth periods with = 10 sec and Re = 200 is shown in Figure 3(a). The corre- sponding oscillation of the average friction coefficient in the ninth and tenth periods is shown in Figure 3(b). Both the Nusselt number and the friction coefficient are observed to oscillate in all the cases for different values of with a small phase change with the jet oscillation (which is cosine wave). For small values of the amplitude of the jet inflow oscillation ( = 0.1 m/s to 0.2 m/s), the calculated average Nusselt number is oscillating in smooth sinusoidal oscillation as shown in Figure 3. The effect of the period of the jet inflow velocity is studied and the results are shown in Figures 4a and 4b as Nu against ωt and f c against ωt respectively, where ω is the frequency of the oscillation ( 2). Figure 4 shows clearly how the period of the jet velocity influences the periodic variation of Nu and f c for  N. H. SAEID Copyright © 2009 SciRes. ENGINEERING 137 1.75 2 2.25 2.5 2.75 3 56.832 57.83258.832 59.832 60.83261.832 62.832 Nu = 1, 1.5, 2, 3, 5, 10 sec ωt 1o o t t NuNu dt (13) where to represents the time required to reach the steady periodic oscillation process (around 9 periods of oscilla- tion). Figures 5(a) and 5(b) show respectively the varia- tion of Nu and f c with for different values of the period of the jet oscillation and constant Re =200. For small values of (less than 0.15 m/s), the cyclic average value of the space-averaged Nusselt number (Nu) is decreasing with the increase of either or as shown in Figure 5(a). Figure 5(b) shows that f c also decr- eases with the increase of either or for small values of . (a) 0.015 0.02 0.025 0.03 0.035 0.04 0.045 56.832 57.832 58.832 59.832 60.832 61.832 62.832 f c = 1, 1.5, 2, 3, 5, 10 sec ωt This means that the cooling process is deteriorated by using oscillating jet under these conditions. The results presented in Figure 5 show also the possibility of cooling enhancement when the period of the jet velocity between 1.5 sec and 2.0 sec and high amplitude (0.25 m/s to 0.3 m/s) with Re = 200. At these conditions the cyclic average value of both the space-averaged friction coefficient and Nusselt number are found to be higher than the steady-state value (when = 0) as shown in Figure 5. (b) Figure 4. (a) Periodic oscillation of Nu with = 0.1 m/s, and Re = 200; (b) Periodic oscillation of f c with = 0.1 m/s, and Re = 200. Re = 200 with forcing amplitude = 0.1. At high values of there will be enough time for the momentum and heat transfer to follow the effect of the periodic variation of the jet velocity. Therefore the avera- ge Nusselt number and average friction coefficient are found to follow the jet velocity function (cosine- function) for high values of (5 and 10) as shown in Figure 4. 2.2 2.3 2.4 2.5 2.6 00.05 0.10.150.20.25 0.3 τ = 1.0 sec τ = 1.5 sec τ = 2.0 sec τ = 3.0 sec τ = 5.0 sec τ = 10 sec Nu (m/s) (a) The amplitude of both the average Nusselt number and average friction coefficient oscillation is higher for larger periods of jet oscillation. Figure 4 shows also, as decreases, the peak values of average Nusselt number and average friction coefficient are delayed. The results presented in Figures 3 and 4 show the oscillation of both the average Nusselt number and average friction coefficient according to the jet velocity oscillation; therefore it is important to introduce the cyclic average value of the space-averaged friction coefficient and Nusselt number defined respectively as: 0.025 0.026 0.027 0.028 0.029 0.03 0.031 0.032 00.05 0.1 0.15 0.20.25 0.3 τ = 1.0 sec τ = 1.5 sec τ = 2.0 sec τ = 3.0 sec τ = 5.0 sec τ = 10 sec f c ( m/s ) (b) Figure 5. (a) Variation of Nu with at Re =200; (b) Variation of f c with 1o o t ff t cc dt (12) at Re =200.  N. H. SAEID 138 Figure 6. Isotherms, T = 1K (left) and streamlines (right) for a cycle of oscillation with ε = 0.3 m/s, = 2 sec, and Re= 200. 0 0.5 1 1.5 2 2.5 3 3.5 4 99.1 9.29.3 9.4 9.5 9.6 9.79.8 9.910 Re = 100, 200, 300 Nu t (sec ) (a) 0 0.01 0.02 0.03 0.04 0.05 99.1 9.2 9.3 9.4 9.5 9.6 9.7 9.8 9.910 Re = 300, 200, 100 f c t (s e c) (b) Figure 7. (a) Periodic oscillation of Nu with = 0.1 m/s and = 1 sec; (b) Periodic oscillation of f c with = 0.1 m/s and = 1 sec. From the results presented in Figure 5 it can be seen that the increase of Nu is about 2.3% while the increase in f c is 2.6% when the period of the jet velocity is 2.0 sec and amplitude of 0.3 m/s with Re = 200. In order to have better understanding, the period of the last cycle is divided into eight time steps. At each time step the isotherms and streamlines are shown in Figure 6 for the periodic oscillation with = 0.3 m/s, = 2 sec and Re = 200. The isotherms show some high temperature points on the heated target wall. These hot spots are moving along the heated surface according to the jet velocity oscillation. Obviously when the jet velocity is small near the minimum at t = 84 sec (=0.018 m/s) the temperature near the target surface is high. Figure 6 show that the oscillation of the jet velocity leads to wash away the heated spots after they appear above the heated surface with some delay. The average Nusselt number j V value at t = 8 sec (= 0.530 m/s) is higher that that j V at maximum velocity at t = 88 sec, (= 0.618 m/s). j V Finally the effect of the Reynolds number on the peri- odic jet impingement cooling process is studied and the results are depicted on Figure 7. The range of the Rey- nolds number is selected to be in the laminar regime. Ob- viously increasing the Reynolds number by increasing the jet velocity leads to the increase in the average Nusselt number and reduce the friction coefficient as shown in Figure 7(a) and (b) respectively. It is observed that the oscillation of both the average Nusselt number and the av- Copyright © 2009 SciRes. ENGINEERING  N. H. SAEID139 erage friction coefficient at different values of Re have small phase shift in the steady periodic oscillation as shown in Figure 7. 5. Conclusions In the present study the periodic laminar jet impingement cooling of a horizontal surface is consider for numerical investigation. The periodic jet impingement cooling is generated when there is periodic oscillation of the jet inflow velocity. It has been shown that the Nusselt num- ber oscillates as a result of oscillating jet inflow velocity. The results are presented to show the effects of the am- plitude and the period of the jet velocity on the Nusselt number and friction coefficient in the steady periodic state. The results indicate that both the average friction coefficient and Nusselt number are oscillating following the jet velocity oscillation with a small phase change. The periodic average friction coefficient and the Nusselt number are found to follow the jet velocity function for high values of period . This is due to the fact that there is enough time for the momentum and heat transfer to follow the effect of the periodic variation of the jet velocity. The simulation results show that it is possible to enhance the cooling process for some combination of the Reynolds number with period and amplitude of the jet velocity. The combination of Re =200 with the period of the jet velocity between 1.5 sec and 2.0 sec and high amplitude (0.25 m/s to 0.3 m/s) gives average friction co- efficient and Nusselt number higher than the respective steady-state values. 6. References [1] E. M. Sparrow and T. C. Wong, “Impingement transfer coefficient due to initially laminar slot jets,” Int. J. Heat Mass Transfer, Vol. 18, pp. 597–605, 1975. [2] S. Al-Sanea, “A numerical study of the flow and heat transfer characteristics of an impinging laminar slot-jet including crossflow effects,” Int. J. Heat Mass Transfer, Vol. 35, pp. 2501–2513, 1992 [3] Z. H. Lin, Y. J. Chou, and Y. H. Hung, “Heat transfer behaviors of a confined slot jet impingement,” Int. J. Heat Mass Transfer, Vol. 40, pp. 1095–1107, 1997. [4] M. A. Rady, “Buoyancy effects on the flow and heat transfer characteristics of an impinging semi-confined laminar slot jet,” Int. J. Trans. Phenomena, Vol. 2, pp. 113–126, 2000. [5] H. Chattopadhyay and S. K. Saha, “Simulation of laminar slot jets impinging on a moving surface,” J. Heat Transfer, Vol. 124, pp. 1049-1055, 2002. [6] L. B. Y. Aldabbagh, I. Sezai, and A. A. Mohamad, “Three- dimensional investigation of a laminar impinging square jet interaction with cross flow,” J. Heat Transfer, Vol. 125, pp. 243–249, 2003. [7] D. Sahoo and M. A. R. Sharif, “Numerical modeling of slot-jet impingement cooling of a constant heat flux sur- face confined by a parallel wall,” Int. J. Therm. Sci., Vol. 43, pp. 877–887, 2004. [8] X. Li, J. L. Gaddis, and T. Wang, “Multiple flow patterns and heat transfer in confined jet impingement,” Int. J. Heat Fluid Flow, Vol. 26, pp. 746–754, 2005. [9] V. A. Chiriac and A. Ortega, “A numerical study of the unsteady flow and heat transfer in a transitional confined slot jet impinging on an isothermal surface,” Int. J. Heat Mass Transfer, Vol. 45, pp. 1237–1248, 2002. [10] Y. M. Chung, K. H. Lao, and N. D. Sandham, “Numeri- cal study of momentum and heat transfer in unsteady im- pinging jets,” Int. J. Heat Fluid Flow, Vol. 23, pp. 592–600, 2002. [11] C. Camci and F. Herr, “Forced convection heat transfer enhancement using a self-oscillating impinging planar jet,” J. Heat Transfer, Vol. 124, pp. 770–782, 2002. [12] H. J. Poh, K. Kumar, and A. S. Mujumdar, “Heat transfer from a pulsed laminar impinging jet,” Int. Comm. Heat Mass Transfer, Vol. 32, pp. 1317–1324, 2005.T. Hayase, J. A. C. Humphrey, and R. Greif, “A consistently formu- lated QUICK scheme for fast and stable convergence using finite-volume iterative calculation procedures,” J. Comput. Phys., Vol. 98, pp. 108–118, 1992. [14] H. K. Versteeg and W. Malalasekera, “Computational fluid dynamics: An introduction,” Longman, 1995. [15] N. H. Saeid, “Periodic free convection from vertical plate subjected to periodic surface temperature oscillation,” Int. J. Therm. Sci., Vol. 43, pp. 569–574, 2004. [16] N. H. Saeid, “Mixed convection flow along a vertical plate subjected to time-periodic surface temperature os- cillations,” Int. J. Therm. Sci., Vol. 44, pp. 531–539, 2005. Copyright © 2009 SciRes. ENGINEERING |