N. V. Vier et al. / Natural Science 3 (2011) 955-962

Copyright © 2011 SciRes. OPEN ACCESS

961961

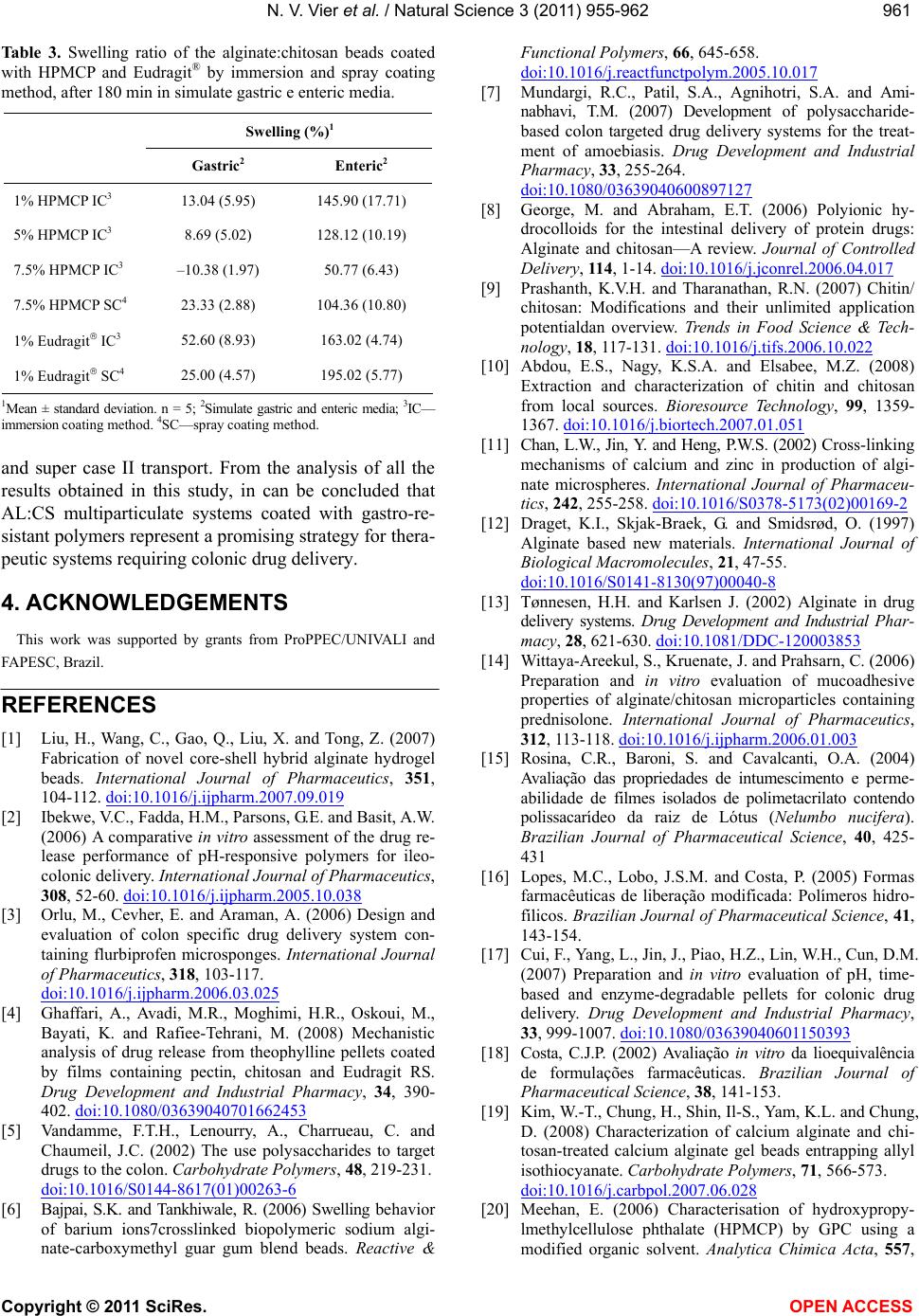

Table 3. Swelling ratio of the alginate:chitosan beads coated

with HPMCP and Eudragit® by immersion and spray coating

method, after 180 min in simulate gastric e enteric media.

Swelling (%)1

Gastric2 Enteric2

1% HPMCP IC3 13.04 (5.95) 145.90 (17.71)

5% HPMCP IC3 8.69 (5.02) 128.12 (10.19)

7.5% HPMCP IC3 –10.38 (1.97) 50.77 (6.43)

7.5% HPMCP SC4 23.33 (2.88) 104.36 (10.80)

1% Eudragit IC3 52.60 (8.93) 163.02 (4.74)

1% Eudragit SC4 25.00 (4.57) 195.02 (5.77)

1Mean ± standard deviation. n = 5; 2Simulate gastric and enteric media; 3IC—

immersion coating method. 4SC—spray coating method.

and super case II transport. From the analysis of all the

results obtained in this study, in can be concluded that

AL:CS multiparticulate systems coated with gastro-re-

sistant polymers represent a promising strategy for thera-

peutic systems requiring colonic drug delivery.

4. ACKNOWLEDGEMENTS

This work was supported by grants from ProPPEC/UNIVALI and

FAPESC, Brazil.

REFERENCES

[1] Liu, H., Wang, C., Gao, Q., Liu, X. and Tong, Z. (2007)

Fabrication of novel core-shell hybrid alginate hydrogel

beads. International Journal of Pharmaceutics, 351,

104-112. doi:10.1016/j.ijpharm.2007.09.019

[2] Ibekwe, V.C., Fadda, H.M., Parsons, G.E. and Basit, A.W.

(2006) A comparative in vitro assessment of the drug re-

lease performance of pH-responsive polymers for ileo-

colonic delivery. International Journal of Pharmaceutics,

308, 52-60. doi:10.1016/j.ijpharm.2005.10.038

[3] Orlu, M., Cevher, E. and Araman, A. (2006) Design and

evaluation of colon specific drug delivery system con-

taining flurbiprofen microsponges. International Journal

of Pharmaceutics, 318, 103-117.

doi:10.1016/j.ijpharm.2006.03.025

[4] Ghaffari, A., Avadi, M.R., Moghimi, H.R., Oskoui, M.,

Bayati, K. and Rafiee-Tehrani, M. (2008) Mechanistic

analysis of drug release from theophylline pellets coated

by films containing pectin, chitosan and Eudragit RS.

Drug Development and Industrial Pharmacy, 34, 390-

402. doi:10.1080/03639040701662453

[5] Vandamme, F.T.H., Lenourry, A., Charrueau, C. and

Chaumeil, J.C. (2002) The use polysaccharides to target

drugs to the colon. Carbohydrate Polymers, 48, 219-231.

doi:10.1016/S0144-8617(01)00263-6

[6] Bajpai, S.K. and Tankhiwale, R. (2006) Swelling behavior

of barium ions7crosslinked biopolymeric sodium algi-

nate-carboxymethyl guar gum blend beads. Reactive &

Functional Polymers, 66, 645-658.

doi:10.1016/j.reactfunctpolym.2005.10.017

[7] Mundargi, R.C., Patil, S.A., Agnihotri, S.A. and Ami-

nabhavi, T.M. (2007) Development of polysaccharide-

based colon targeted drug delivery systems for the treat-

ment of amoebiasis. Drug Development and Industrial

Pharmacy, 33, 255-264.

doi:10.1080/03639040600897127

[8] George, M. and Abraham, E.T. (2006) Polyionic hy-

drocolloids for the intestinal delivery of protein drugs:

Alginate and chitosan—A review. Journal of Controlled

Delivery, 114, 1-14. doi:10.1016/j.jconrel.2006.04.017

[9] Prashanth, K.V.H. and Tharanathan, R.N. (2007) Chitin/

chitosan: Modifications and their unlimited application

potentialdan overview. Trends in Food Science & Tech-

nology, 18, 117-131. doi:10.1016/j.tifs.2006.10.022

[10] Abdou, E.S., Nagy, K.S.A. and Elsabee, M.Z. (2008)

Extraction and characterization of chitin and chitosan

from local sources. Bioresource Technology, 99, 1359-

1367. doi:10.1016/j.biortech.2007.01.051

[11] Chan, L.W., Jin, Y. and Heng, P.W.S. (2002) Cross-linking

mechanisms of calcium and zinc in production of algi-

nate microspheres. International Journal of Pharmaceu-

tics, 242, 255-258. doi:10.1016/S0378-5173(02)00169-2

[12] Draget, K.I., Skjak-Braek, G. and Smidsrød, O. (1997)

Alginate based new materials. International Journal of

Biological Macromolecules, 21, 47-55.

doi:10.1016/S0141-8130(97)00040-8

[13] Tønnesen, H.H. and Karlsen J. (2002) Alginate in drug

delivery systems. Drug Development and Industrial Phar-

macy, 28, 621-630. doi:10.1081/DDC-120003853

[14] Wittaya-Areekul, S., Kruenate, J. and Prahsarn, C. (2006)

Preparation and in vitro evaluation of mucoadhesive

properties of alginate/chitosan microparticles containing

prednisolone. International Journal of Pharmaceutics,

312, 113-118. doi:10.1016/j.ijpharm.2006.01.003

[15] Rosina, C.R., Baroni, S. and Cavalcanti, O.A. (2004)

Avaliação das propriedades de intumescimento e perme-

abilidade de filmes isolados de polimetacrilato contendo

polissacarídeo da raiz de Lótus (Nelumbo nucifera).

Brazilian Journal of Pharmaceutical Science, 40, 425-

431

[16] Lopes, M.C., Lobo, J.S.M. and Costa, P. (2005) Formas

farmacêuticas de liberação modificada: Polímeros hidro-

fílicos. Brazilian Journal of Pharmaceutical Science, 41,

143-154.

[17] Cui, F., Yang, L., Jin, J., Piao, H.Z., Lin, W.H., Cun, D.M.

(2007) Preparation and in vitro evaluation of pH, time-

based and enzyme-degradable pellets for colonic drug

delivery. Drug Development and Industrial Pharmacy,

33, 999-1007. doi:10.1080/03639040601150393

[18] Costa, C.J.P. (2002) Avaliação in vitro da lioequivalência

de formulações farmacêuticas. Brazilian Journal of

Pharmaceutical Science, 38, 141-153.

[19] Kim, W.-T., Chung, H., Shin, Il-S., Yam, K.L. and Chung,

D. (2008) Characterization of calcium alginate and chi-

tosan-treated calcium alginate gel beads entrapping allyl

isothiocyanate. Carbohydrate Polymers, 71, 566-573.

doi:10.1016/j.carbpol.2007.06.028

[20] Meehan, E. (2006) Characterisation of hydroxypropy-

lmethylcellulose phthalate (HPMCP) by GPC using a

modified organic solvent. Analytica Chimica Acta, 557,