A. HAMMUDA ET AL.

Copyright © 2011 SciRes. EPE

599

7. Acknowledgements touch and step tolerable voltages, 184.6% and 263.7%

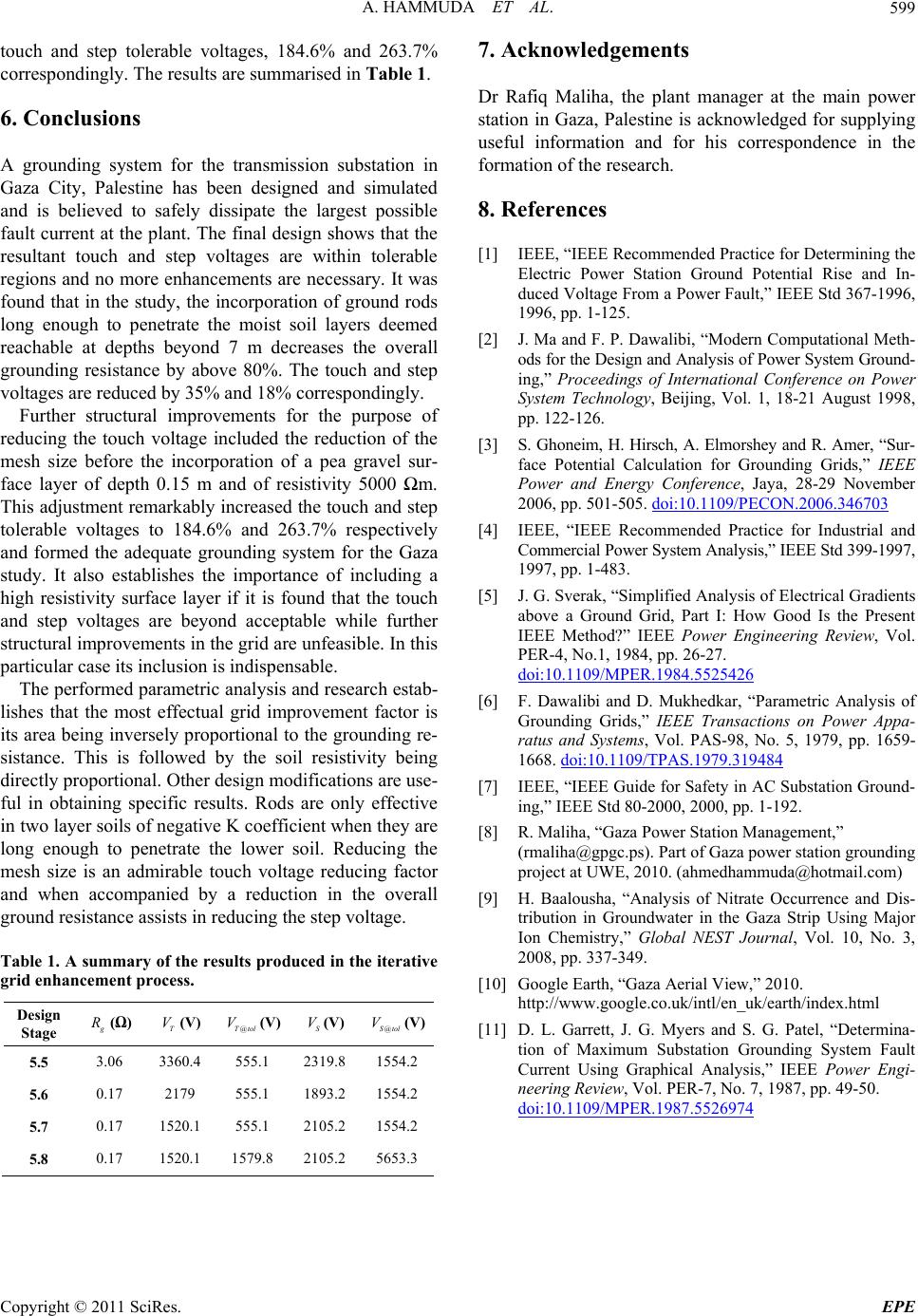

correspondingly. The results are summarised in Table 1.

Dr Rafiq Maliha, the plant manager at the main power

station in Gaza, Palestine is acknowledged for supplying

useful information and for his correspondence in the

formation of the research.

6. Conclusions

A grounding system for the transmission substation in

Gaza City, Palestine has been designed and simulated

and is believed to safely dissipate the largest possible

fault current at the plant. The final design shows that the

resultant touch and step voltages are within tolerable

regions and no more enhancements are necessary. It was

found that in the study, the incorporation of ground rods

long enough to penetrate the moist soil layers deemed

reachable at depths beyond 7 m decreases the overall

grounding resistance by above 80%. The touch and step

voltages are reduced by 35% and 18% correspondingly.

8. References

[1] IEEE, “IEEE Recommended Practice for Determining the

Electric Power Station Ground Potential Rise and In-

duced Voltage From a Power Fault,” IEEE Std 367-1996,

1996, pp. 1-125.

[2] J. Ma and F. P. Dawalibi, “Modern Computational Meth-

ods for the Design and Analysis of Power System Ground-

ing,” Proceedings of International Conference on Power

System Technology, Beijing, Vol. 1, 18-21 August 1998,

pp. 122-126.

Further structural improvements for the purpose of

reducing the touch voltage included the reduction of the

mesh size before the incorporation of a pea gravel sur-

face layer of depth 0.15 m and of resistivity 5000 Ωm.

This adjustment remarkably increased the touch and step

tolerable voltages to 184.6% and 263.7% respectively

and formed the adequate grounding system for the Gaza

study. It also establishes the importance of including a

high resistivity surface layer if it is found that the touch

and step voltages are beyond acceptable while further

structural improvements in the grid are unfeasible. In this

particular case its inclusion is indispensable.

[3] S. Ghoneim, H. Hirsch, A. Elmorshey and R. Amer, “Sur-

face Potential Calculation for Grounding Grids,” IEEE

Power and Energy Conference, Jaya, 28-29 November

2006, pp. 501-505. doi:10.1109/PECON.2006.346703

[4] IEEE, “IEEE Recommended Practice for Industrial and

Commercial Power System Analysis,” IEEE Std 399-1997,

1997, pp. 1-483.

[5] J. G. Sverak, “Simplified Analysis of Electrical Gradients

above a Ground Grid, Part I: How Good Is the Present

IEEE Method?” IEEE Power Engineering Review, Vol.

PER-4, No.1, 1984, pp. 26-27.

doi:10.1109/MPER.1984.5525426

The performed parametric analysis and research estab-

lishes that the most effectual grid improvement factor is

its area being inversely proportional to the grounding re-

sistance. This is followed by the soil resistivity being

directly proportional. Other design modifications are use-

ful in obtaining specific results. Rods are only effective

in two layer soils of negative K coefficient when they are

long enough to penetrate the lower soil. Reducing the

mesh size is an admirable touch voltage reducing factor

and when accompanied by a reduction in the overall

ground resistance assists in reducing the step voltage.

[6] F. Dawalibi and D. Mukhedkar, “Parametric Analysis of

Grounding Grids,” IEEE Transactions on Power Appa-

ratus and Systems, Vol. PAS-98, No. 5, 1979, pp. 1659-

1668. doi:10.1109/TPAS.1979.319484

[7] IEEE, “IEEE Guide for Safety in AC Substation Ground-

ing,” IEEE Std 80-2000, 2000, pp. 1-192.

[8] R. Maliha, “Gaza Power Station Management,”

(rmaliha@gpgc.ps). Part of Gaza power station grounding

project at UWE, 2010. (ahmedhammuda@hotmail.com)

[9] H. Baalousha, “Analysis of Nitrate Occurrence and Dis-

tribution in Groundwater in the Gaza Strip Using Major

Ion Chemistry,” Global NEST Journal, Vol. 10, No. 3,

2008, pp. 337-349.

Table 1. A summary of the results produced in the iterative

grid enhancement process. [10] Google Earth, “Gaza Aerial View,” 2010.

http://www.google.co.uk/intl/en_uk/earth/index.html

Design

Stage

(Ω) T

V(V) @Ttol

V(V) S

V(V) @Stol

V(V)

5.5 3.06 3360.4 555.1 2319.8 1554.2

5.6 0.17 2179 555.1 1893.2 1554.2

5.7 0.17 1520.1 555.1 2105.2 1554.2

5.8 0.17 1520.1 1579.8 2105.2 5653.3

[11] D. L. Garrett, J. G. Myers and S. G. Patel, “Determina-

tion of Maximum Substation Grounding System Fault

Current Using Graphical Analysis,” IEEE Power Engi-

neering Revie w, Vol. PER-7, No. 7, 1987, pp. 49-50.

doi:10.1109/MPER.1987.5526974