H. Noritomi et al. / J. Biomedical Science and Engineering 4 (2011) 692-698 697

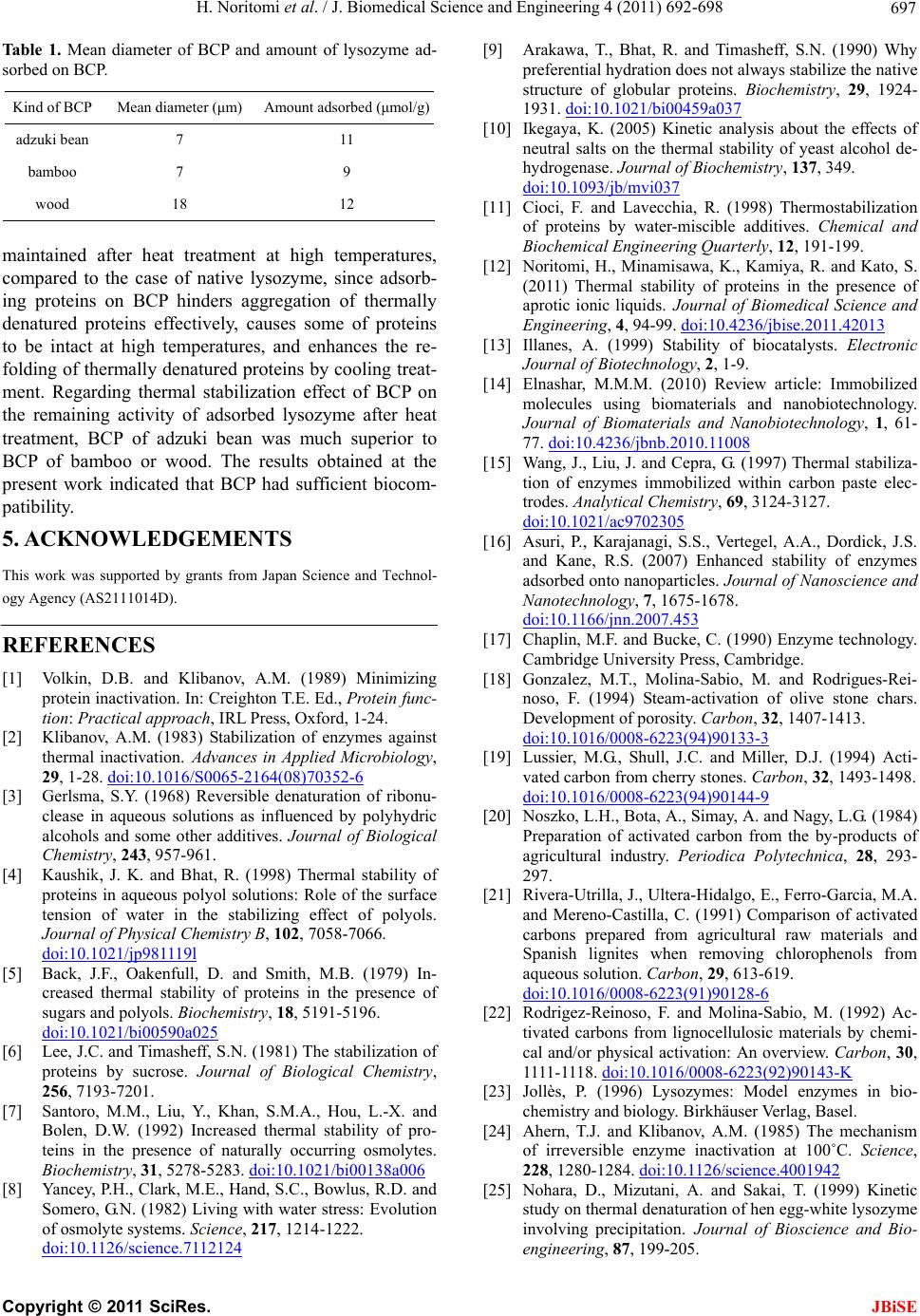

Ta b le 1 . Mean diameter of BCP and amount of lysozyme ad-

sorbed on BCP.

Kind of BCP Mean diameter (μm) Amount adsorbed (μmol/g)

adzuki bean 7 11

bamboo 7 9

wood 18 12

maintained after heat treatment at high temperatures,

compared to the case of native lysozyme, since adsorb-

ing proteins on BCP hinders aggregation of thermally

denatured proteins effectively, causes some of proteins

to be intact at high temperatures, and enhances the re-

folding of thermally denatured proteins by cooling treat-

ment. Regarding thermal stabilization effect of BCP on

the remaining activity of adsorbed lysozyme after heat

treatment, BCP of adzuki bean was much superior to

BCP of bamboo or wood. The results obtained at the

present work indicated that BCP had sufficient biocom-

patibility.

5. ACKNOWLEDGEMENTS

This work was supported by grants from Japan Science and Technol-

ogy Agency (AS2111014D).

REFERENCES

[1] Volkin, D.B. and Klibanov, A.M. (1989) Minimizing

protein inactivation. In: Creighton T.E. Ed., Protein func-

tion: Practical approach, IRL Press, Oxford, 1-24.

[2] Klibanov, A.M. (1983) Stabilization of enzymes against

thermal inactivation. Advances in Applied Microbiology,

29, 1-28. doi:10.1016/S0065-2164(08)70352-6

[3] Gerlsma, S.Y. (1968) Reversible denaturation of ribonu-

clease in aqueous solutions as influenced by polyhydric

alcohols and some other additives. Journal of Biological

Chemistry, 243, 957-961.

[4] Kaushik, J. K. and Bhat, R. (1998) Thermal stability of

proteins in aqueous polyol solutions: Role of the surface

tension of water in the stabilizing effect of polyols.

Journal of Physical Chemistry B, 102, 7058-7066.

doi:10.1021/jp981119l

[5] Back, J.F., Oakenfull, D. and Smith, M.B. (1979) In-

creased thermal stability of proteins in the presence of

sugars and polyols. Biochemistry, 18, 5191-5196.

doi:10.1021/bi00590a025

[6] Lee, J.C. and Timasheff, S.N. (1981) The stabilization of

proteins by sucrose. Journal of Biological Chemistry,

256, 7193-7201.

[7] Santoro, M.M., Liu, Y., Khan, S.M.A., Hou, L.-X. and

Bolen, D.W. (1992) Increased thermal stability of pro-

teins in the presence of naturally occurring osmolytes.

Biochemistry, 31, 5278-5283. doi:10.1021/bi00138a006

[8] Yancey, P.H., Clark, M.E., Hand, S.C., Bowlus, R.D. and

Somero, G.N. (1982) Living with water stress: Evolution

of osmolyte systems. Science, 217, 1214-1222.

doi:10.1126/science.7112124

[9] Arakawa, T., Bhat, R. and Timasheff, S.N. (1990) Why

preferential hydration does not always stabilize the native

structure of globular proteins. Biochemistry, 29, 1924-

1931. doi:10.1021/bi00459a037

[10] Ikegaya, K. (2005) Kinetic analysis about the effects of

neutral salts on the thermal stability of yeast alcohol de-

hydrogenase. Journal of Biochemistry, 137, 349.

doi:10.1093/jb/mvi037

[11] Cioci, F. and Lavecchia, R. (1998) Thermostabilization

of proteins by water-miscible additives. Chemical and

Biochemical Engineering Quarterly, 12, 191-199.

[12] Noritomi, H., Minamisawa, K., Kamiya, R. and Kato, S.

(2011) Thermal stability of proteins in the presence of

aprotic ionic liquids. Journal of Biomedical Science and

Engineering, 4, 94-99. doi:10.4236/jbise.2011.42013

[13] Illanes, A. (1999) Stability of biocatalysts. Electronic

Journal of Biotechnology, 2, 1-9.

[14] Elnashar, M.M.M. (2010) Review article: Immobilized

molecules using biomaterials and nanobiotechnology.

Journal of Biomaterials and Nanobiotechnology, 1, 61-

77. doi:10.4236/jbnb.2010.11008

[15] Wang, J., Liu, J. and Cepra, G. (1997) Thermal stabiliza-

tion of enzymes immobilized within carbon paste elec-

trodes. Analytical Chemistry, 69, 3124-3127.

doi:10.1021/ac9702305

[16] Asuri, P., Karajanagi, S.S., Vertegel, A.A., Dordick, J.S.

and Kane, R.S. (2007) Enhanced stability of enzymes

adsorbed onto nanoparticles. Journal of Nanoscience and

Nanotechnology, 7, 1675-1678.

doi:10.1166/jnn.2007.453

[17] Chaplin, M.F. and Bucke, C. (1990) Enzyme technology.

Cambridge University Press, Cambridge.

[18] Gonzalez, M.T., Molina-Sabio, M. and Rodrigues-Rei-

noso, F. (1994) Steam-activation of olive stone chars.

Development of porosity. Carbon, 32, 1407-1413.

doi:10.1016/0008-6223(94)90133-3

[19] Lussier, M.G., Shull, J.C. and Miller, D.J. (1994) Acti-

vated carbon from cherry stones. Carbon, 32, 1493-1498.

doi:10.1016/0008-6223(94)90144-9

[20] Noszko, L.H., Bota, A., Simay, A. and Nagy, L.G. (1984)

Preparation of activated carbon from the by-products of

agricultural industry. Periodica Polytechnica, 28, 293-

297.

[21] Rivera-Utrilla, J., Ultera-Hidalgo, E., Ferro-Garcia, M.A.

and Mereno-Castilla, C. (1991) Comparison of activated

carbons prepared from agricultural raw materials and

Spanish lignites when removing chlorophenols from

aqueous solution. Carbon, 29, 613-619.

doi:10.1016/0008-6223(91)90128-6

[22] Rodrigez-Reinoso, F. and Molina-Sabio, M. (1992) Ac-

tivated carbons from lignocellulosic materials by chemi-

cal and/or physical activation: An overview. Carbon, 30,

1111-1118. doi:10.1016/0008-6223(92)90143-K

[23] Jollès, P. (1996) Lysozymes: Model enzymes in bio-

chemistry and biology. Birkhäuser Verlag, Basel.

[24] Ahern, T.J. and Klibanov, A.M. (1985) The mechanism

of irreversible enzyme inactivation at 100˚C. Science,

228, 1280-1284. doi:10.1126/science.4001942

[25] Nohara, D., Mizutani, A. and Sakai, T. (1999) Kinetic

study on thermal denaturation of hen egg-white lysozyme

involving precipitation. Journal of Bioscience and Bio-

engineering, 87, 199-205.

C

opyright © 2011 SciRes. JBiSE