M. WILKENS ET AL.

253

tion ratio c/c0 in the filtrate and a factor for the adsorp-

tion of the mother liquid in the filter cake.

In Figure 1 an ideal washing curve and an exemplary

real washing curve are shown. For an ideal washing

process or flushing process a complete exchange of the

mother liquid by the washing liquid happens at a wash-

ing ratio of 1. This means it is possible to clean the filter

cake with the same amount of washing liquid as the

amount of mother liquid in the filter cake.

The real washing curve is divided in three characteris-

tic areas [2,3]; the displacement regime (I), the intersti-

tial regime (II) and the diffusion regime (III). During the

displacement regime the washing liquid displaces the

mother liquid in a kind of a plug flow. Due to this only

mother liquid is detected in the washing filtrate. The end

of displacement regime is indicated by the detection of a

concentration ratio lower than one in the washing filtrate.

At this point a mixture of mother and washing liquid

leaves the filter cake and the interstitial regime starts.

During the last regime of the washing process (III) the

removal of the mother liquid is dominated by diffusion

mechanisms (diffusion regime). The remaining impuri-

ties in the filter cake diffuse out of stagnant areas into the

primary stream. This removal often occurs slowly be-

cause of sterical barriers. Quite long time scales are

needed to achieve a significant impurity removal [4].

2. Materials

For the research of the adsorption properties on a wash-

ing process an aluminosilicate (Dorkafill, x50 = 1.65 µm)

in three different surface modifications is used. The sur-

faces vary from hydrophilic (DF600) over hydrophilic-

hydrophobic (DF601) to hydrophobic (DF602). Because

of the identical shape and particle size distribution the

filtration and flushing are only influenced by structure

effects, which result from the different particle-fluid in-

teractions [5].

The two liquids water and methanol are used as

mother and washing liquid. Characteristic of this system

is that the progression of the dynamic viscosity depends

on the mixing ratio of water and methanol, with a maxi-

mum at a methanol percentage of 40 vol.-percent.

3. Methods

3.1. Filtration

The filter cake formation is performed with a lab scale

suction filter (nutsch filter) according to VDI 2762. The

filtration area is 19.64 cm² (diameter 50 mm). The proc-

ess parameters are a solid volume concentration of 0.2

and a filtration pressure of 3 bar. For the displacement

washing a fully saturated filter cake is needed, because

of this the filtration is stopped when the suspension

reaches the filter cake. With the known porosity of each

system it is possible to calculate the amount of liquid

staying in the filter cake, which is necessary for the cal-

culation of the washing ratio during the flushing step.

3.2. Flushing

For the flushing process the filter cake (inside a cake

formation unit) is removed from the suction filter into a

combined compression-washing unit.

Before and during the washing the filter cake is com-

pressed by a pneumatic piston with a constant pressure of

3.5 bar to prevent fissuring and crack formation. The

washing liquid flow is provided by a pressure difference

of 2 bar.

For the composition analyses of the washing liquid

(concentration ratio in the filtrate) samples in an interval

of ΔW = 0.05 are taken. A Karl-Fischer-Titrator and a

gas chromatograph (GC) are used for the analysis.

4. Results

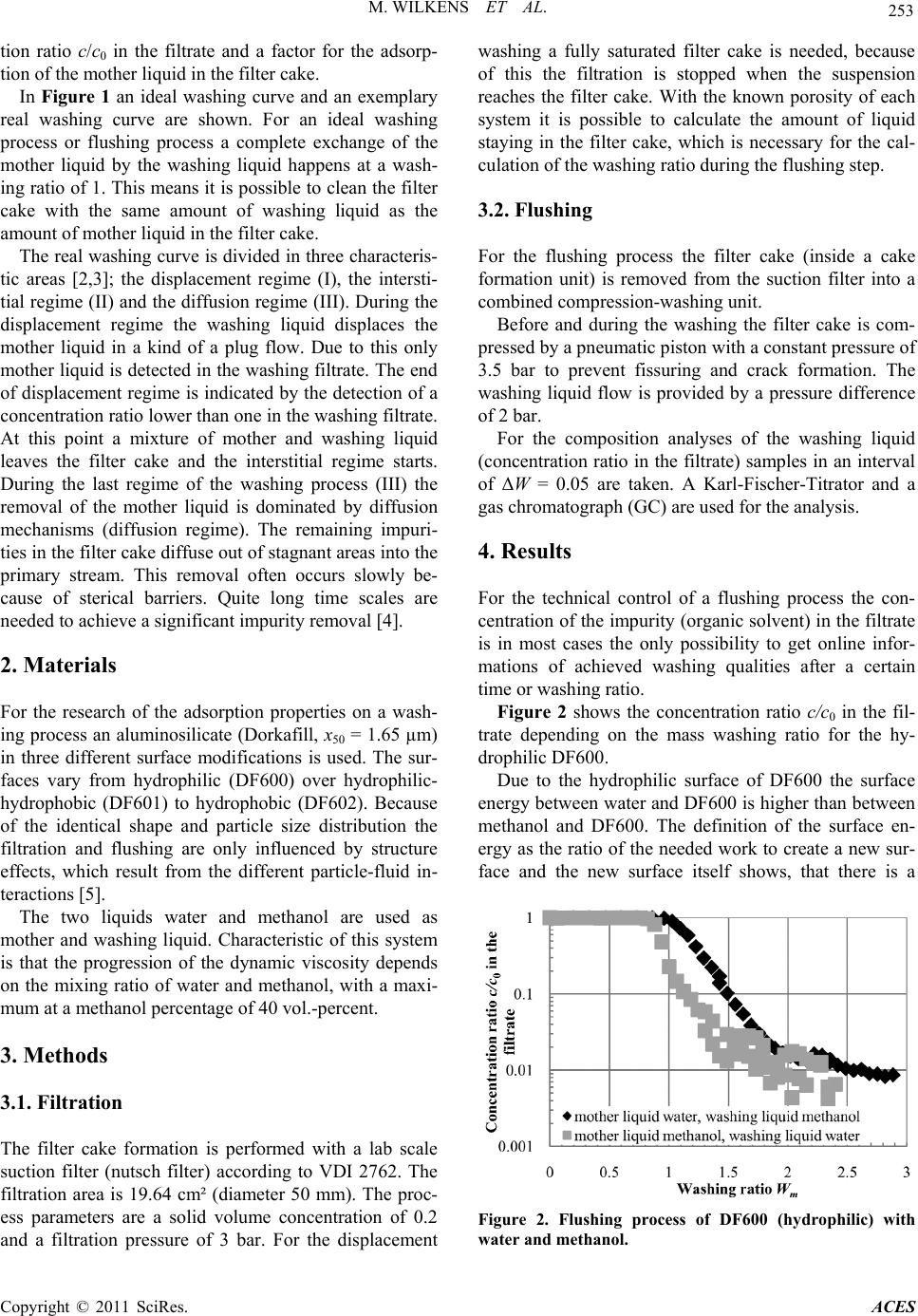

For the technical control of a flushing process the con-

centration of the impurity (organic solvent) in the filtrate

is in most cases the only possibility to get online infor-

mations of achieved washing qualities after a certain

time or washing ratio.

Figure 2 shows the concentration ratio c/c0 in the fil-

trate depending on the mass washing ratio for the hy-

drophilic DF600.

Due to the hydrophilic surface of DF600 the surface

energy between water and DF600 is higher than between

methanol and DF600. The definition of the surface en-

ergy as the ratio of the needed work to create a new sur-

face and the new surface itself shows, that there is a

Figure 2. Flushing process of DF600 (hydrophilic) with

water and methanol.

Copyright © 2011 SciRes. ACES