S. KUMAR ET AL. 17

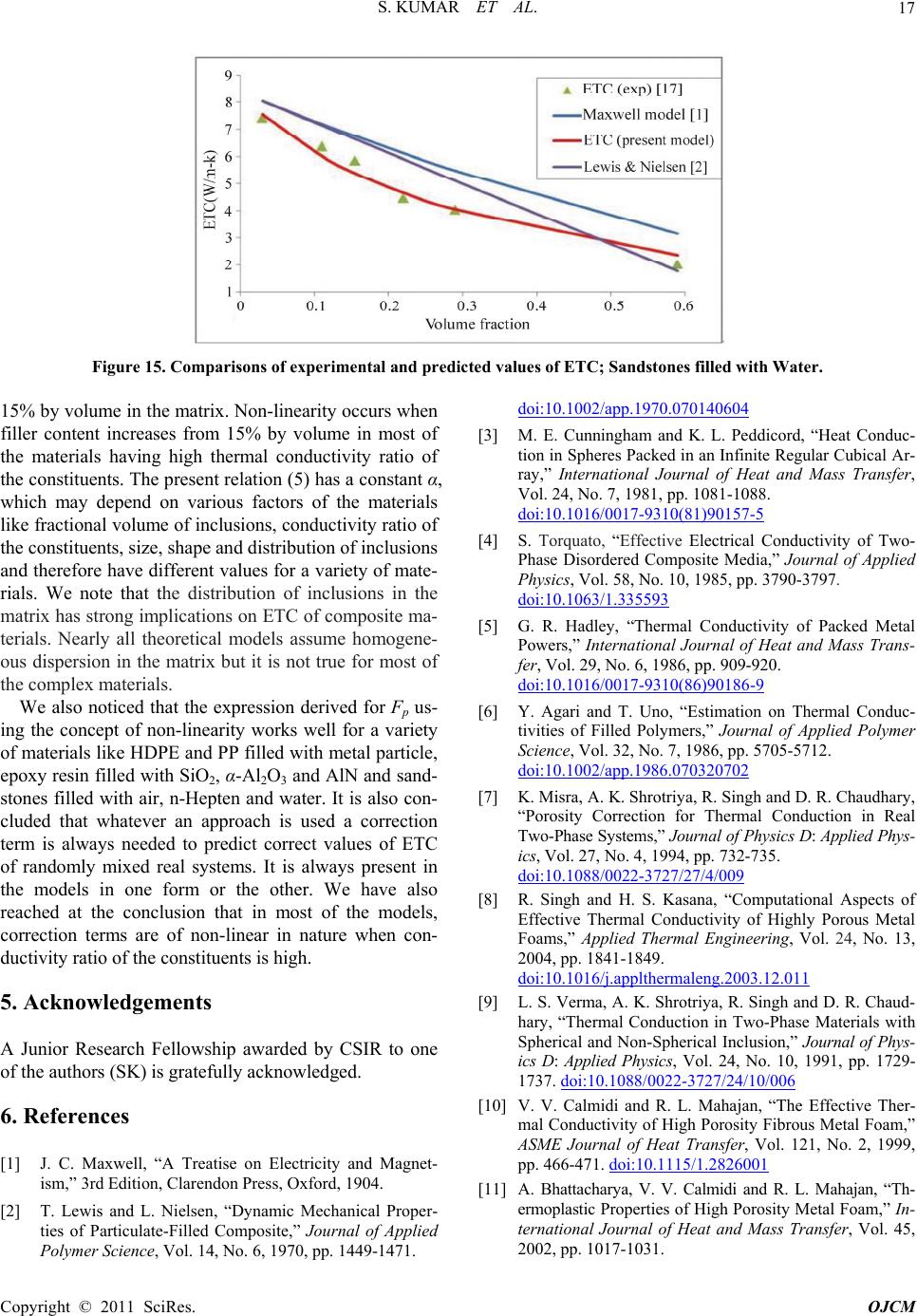

Figure 15. Comparisons of experimental and predicted values of ETC; Sandstones filled with Water.

15% by volume in the matrix. Non-linearity occurs when

filler content increases from 15% by volume in most of

the materials having high thermal conductivity ratio of

the constituents. The present relation (5) has a constant α,

which may depend on various factors of the materials

like fractional volume of inclusions, conductivity ratio of

the constituents, size, shape and distribution of inclusions

and therefore have different values for a variety of mate-

rials. We note that the distribution of inclusions in the

matrix has strong implications on ETC of composite ma-

terials. Nearly all theoretical models assume homogene-

ous dispersion in the matrix but it is not true for most of

the complex materials.

We also noticed that the expression derived for Fp us-

ing the concept of non-linearity works well for a variety

of materials like HDPE and PP filled with metal particle,

epoxy resin filled with SiO2, α-Al2O3 and AlN and sand-

stones filled with air, n-Hepten and water. It is also con-

cluded that whatever an approach is used a correction

term is always needed to predict correct values of ETC

of randomly mixed real systems. It is always present in

the models in one form or the other. We have also

reached at the conclusion that in most of the models,

correction terms are of non-linear in nature when con-

ductivity ratio of the constituents is high.

5. Acknowledgements

A Junior Research Fellowship awarded by CSIR to one

of the authors (SK) is gratefully acknowledged.

6. References

[1] J. C. Maxwell, “A Treatise on Electricity and Magnet-

ism,” 3rd Edition, Clarendon Press, Oxford, 1904.

[2] T. Lewis and L. Nielsen, “Dynamic Mechanical Proper-

ties of Particulate-Filled Composite,” Journal of Applied

Polymer Science, Vol. 14, No. 6, 1970, pp. 1449-1471.

doi:10.1002/app.1970.070140604

[3] M. E. Cunningham and K. L. Peddicord, “Heat Conduc-

tion in Spheres Packed in an Infinite Regular Cubical Ar-

ray,” International Journal of Heat and Mass Transfer,

Vol. 24, No. 7, 1981, pp. 1081-1088.

doi:10.1016/0017-9310(81)90157-5

[4] S. Torquato, “Effective Electrical Conductivity of Two-

Phase Disordered Composite Media,” Journal of Applied

Physics, Vol. 58, No. 10, 1985, pp. 3790-3797.

doi:10.1063/1.335593

[5] G. R. Hadley, “Thermal Conductivity of Packed Metal

Powers,” International Journal of Heat and Mass Trans-

fer, Vol. 29, No. 6, 1986, pp. 909-920.

doi:10.1016/0017-9310(86)90186-9

[6] Y. Agari and T. Uno, “Estimation on Thermal Conduc-

tivities of Filled Polymers,” Journal of Applied Polymer

Science, Vol. 32, No. 7, 1986, pp. 5705-5712.

doi:10.1002/app.1986.070320702

[7] K. Misra, A. K. Shrotriya, R. Singh and D. R. Chaudhary,

“Porosity Correction for Thermal Conduction in Real

Two-Phase Systems,” Journal of Physics D: Applied Phys-

ics, Vol. 27, No. 4, 1994, pp. 732-735.

doi:10.1088/0022-3727/27/4/009

[8] R. Singh and H. S. Kasana, “Computational Aspects of

Effective Thermal Conductivity of Highly Porous Metal

Foams,” Applied Thermal Engineering, Vol. 24, No. 13,

2004, pp. 1841-1849.

doi:10.1016/j.applthermaleng.2003.12.011

[9] L. S. Verma, A. K. Shrotriya, R. Singh and D. R. Chaud-

hary, “Thermal Conduction in Two-Phase Materials with

Spherical and Non-Spherical Inclusion,” Journal of Phys-

ics D: Applied Physics, Vol. 24, No. 10, 1991, pp. 1729-

1737. doi:10.1088/0022-3727/24/10/006

[10] V. V. Calmidi and R. L. Mahajan, “The Effective Ther-

mal Conductivity of High Porosity Fibrous Metal Foam,”

ASME Journal of Heat Transfer, Vol. 121, No. 2, 1999,

pp. 466-471. doi:10.1115/1.2826001

[11] A. Bhattacharya, V. V. Calmidi and R. L. Mahajan, “Th-

ermoplastic Properties of High Porosity Metal Foam,” In-

ternational Journal of Heat and Mass Transfer, Vol. 45,

2002, pp. 1017-1031.

C

opyright © 2011 SciRes. OJCM