World Journal of Engineering and Technology

Vol.07 No.02(2019), Article ID:92470,8 pages

10.4236/wjet.2019.72023

Structural Condition and Deficiencies of Present Constructed Bridges over Zahirshahi Canal and Proposal of New Design Using AASHTO Codes

Abdul Khaliq Karimi1, Abdul Bari Jaheed2, Bashir Ahmad Aasim3, Javed Ahmad Farooqi3

1Civil Department, Engineering Faculty, Kandahar University, Kandahar, Afghanistan

2Water and Environmental Engineering Department, Engineering Faculty, Kandahar University, Kandahar, Afghanistan

3Department of Civil Engineering and Architecture, University of the Ryukyus, Okinawa, Japan

Copyright © 2019 by author(s) and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY 4.0).

http://creativecommons.org/licenses/by/4.0/

Received: February 14, 2019; Accepted: May 14, 2019; Published: May 17, 2019

ABSTRACT

This paper addresses a comprehensive design of RCC T-beam Bridge based on AASHTO design standards. The bridge is designed and proposed to be constructed over an irrigation canal (Zahirshahi canal) of Kandahar province, Afghanistan that has more than 30 bridges over it. Yet they are not enough, and the demand for construction of new bridges is gradually arising because of the vast urbanization in the surrounding of the canal. Most of the bridges on this canal are Reinforced Concrete Slab (RCS) bridges; these type bridges are limited by capacity and are generally found only in smaller spans. Since they can only span short distances and are often constructed as multiple-span bridges with vertical supports between the abutments to allow a longer length. All constructed slab bridges over Zahirshahi canal are four-span bridges. Constructing multi-span bridges on the canal decreases waterway due to the existence of many piers and footings that could increase the water level during the peak flow, even, sometimes can cause over flow. Taking into consideration these deficiencies of the present (RCS) bridges, two-span RCC T-beam Bridge is one of the best alternatives to be constructed over the canal. In addition, canal cross-sectional dimensions are almost constant along its length, though the construction of two-span RCC T-beam bridge is applicable at any point of the canal. The design is selected based on exclusive survey of the area during all seasons including the peak flowing of the canal.

Keywords:

Zahirshahi Canal, RCC T-Beam Bridge, AASHTO Design Standards

1. Introduction

Afghanistan is reported to be one of the least developed countries in the world, and civil war being one of the major cause and obstacle of least development. During this tragedy of four decades, almost all vertical and horizontal infrastructures have been devastated; especially road network system has been significantly ruined which affected all aspects of the life, including health and tradition. Considering the geographical location of the country and having no access to sea, road network system remains to be the backbone of the country in terms of exporting and importing goods. Today Afghanistan’s 93% of products are being imported; the country is almost completely dependent upon its neighbors to supply basic goods, much as the flour, sunflower oil, grain, pasta varieties and other [1] . In this since, bridge is considered to be the crucial part of this network which is considerably affected by this tribulation. Most of the highway bridges are collapsed throughout the network and a vast part of them has succeeded their service life.

Bridge structure undergoes the processes of gradual destruction in the course of time resulting in various defects reducing its overall condition. In order to keep the infrastructure serviceable, its assessing is a crucial issue [2] [3] . The degradation processes of reinforced concrete are very complex [4] [5] [6] [7] ; however, the major cause of structural damage here is the current conflict in the area. Still, today, engineers and designers have to cope with difficult requirements. Economics of the structural design is being taken into account increasingly; which leads to further reduction of capacity reserve margin. The structure must fulfill the requirements for strength and reliability, but also has to be as simple and subtle as possible [8] .

In Afghanistan, approximately all bridges are made of reinforced concrete materials. Whereas, in the world, the major structural material for over a century, and still the most popular material for public structures is reinforced concrete. It was believed that the concrete structure is durable enough to maintain its shape for many decades. Recently, however, the fact that the corrosion of steel reinforcements for concrete structures severely degrade the durability of concrete has been recognized. Also, as major transport infrastructure, bridges are of great importance to modern society considering their critical performance in social, industrial, economic and other various aspects of a society [9] . During the life cycle, they are exposed to several types of environmental and manmade loads such as wind, traffic, earthquakes and other loads. In order to maintain the economic situation of a country, specifically Afghanistan, bridges are to be maintained and concerned the most. Based on this fact, suitable place with the reasonable design has to be considered in prior, while planning and constructing a bridge.

In this paper an attempt is made to propose an appropriate design for the famous canal (Zahirshahi canal) in Kandahar province in Afghanistan. Zahirshahi canal is an irrigation canal originates from one of the biggest rivers of Afghanistan called Arghandab River located in the north part of the province shown in Figure 1. Based on carrying out a physical survey, more than 30 bridges are constructed over the canal such as, concrete bridges and traditional mud bridges having different shapes and design shown in Figure 2. Yet they are not enough and still the demand is gradually arising because of vast urbanization in the surrounding area of the canal. The existing bridges have been constructed based on the demand of the time, in which the usage of vehicle was very limited and the number of inhabitants was considerably less in the area.

Most of the bridges over Zahirshahi canal are Reinforced Concrete Slab (RCS) bridges, they are limited by capacity and are generally constructed for smaller spans, as slab-bridge is well adapted for spans from 3 m to about 8 m. On the other hand, RCS bridges are comparably constructed with the thicker slabs which consume high amount of materials that result in larger dead loads but, in T-beam bridges, beam is casted monolithically with the slab, the flange also takes up the compressive stresses which means it will be more effective in resisting the sagging moment acting on the beam, consequently the depth of beam can be reduced and in long span can be constructed.

Considering the above mentioned disadvantages of (RCS) bridges and all aspects (cross-section dimensions, soil bearing capacity, flow level and environmental effects) of the canal, two-span RCC T-beam Bridge is one of the best option to be constructed over the canal, and even for replacing the old bridges. Though, this work presents a comprehensive design of two-span RCC T-beam Bridge for the mentioned canal.

2. Primary Considerations and Geometrical Outline of the Bridge

T-beam Bridge is a common choice among the designers for small and medium span bridges. The reinforced cement concrete T-beam bridges consist of concrete slabs supported by a series of longitudinal concrete beams. T-beam bridge is commonly adopted type bridge for span range 10 m to 25 m [10] . The structure is so named because the main longitudinal girders are designed as T-beam integral with part of the deck slab, which is cast monolithically with the girders. Simply supported T-beam bridge span of over 30 m are rare as the dead load become too heavy. The number of longitudinal girders depends on the width of the road. The loads on bridge deck and foundations may be both static and dynamic. Static loads are principally the weights of the bridge super structures and substructures. Dynamic loads which occur during the operation of the bridge, result from forces generated by inertia of deck parts, during the movement of the traffic, wind and earthquake. With the increasing rate of urbanization and rapid infrastructure development, the need for complex transportation systems has also increased; often leading to road and bridge geometries with unconventional, noncollinear configurations.

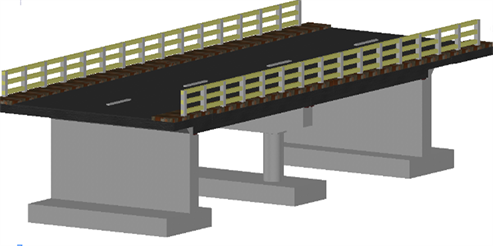

The two span RCC T-beam bridge design considered in this study is to be applied to Zahirshahi canal in Kandahar province. The bridge consists of two equal spans with total length 18 m supported by two columns and four beams shown in Figure 3.

3. Analysis and Design

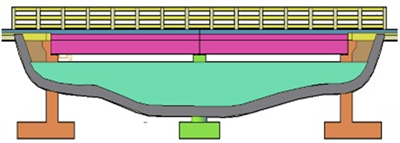

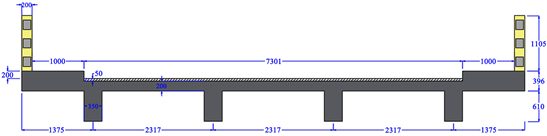

Considering 20 mm afflux, the linear waterway of the canal is calculated as 18,000 mm, thus the length of the bridge is decided to be 18 m. The bridge consists of two equal-span length of 9 m shown in Figure 4 and, meanwhile four longitudinal girders and two pedestrians are considered in the bridge superstructure illustrated in Figure 5.

Based on AASHTO recommendations, AASHTO Approximate method of Analysis is easiest and reliable design method to be adopted for manual design, though the authors employed the mentioned design method in this study.

Figure 1. Arghandab river and Zahirshahi canal in Kandahar.

Figure 2. Existing bridges on Zahirshahi canal.

Figure 3. General view of two span T-beam bridge.

Figure 4. Cross sectional view of the canal.

Figure 5. Cross sectionof the bridge.

3.1. Structural Analysis

Generally, for shorter spans, solid reinforced concrete slab cast in-situ is the simplest design to be employed rather than precast. Designing larger span needs to be constructed with the thicker slab which results in a heavy weight that increases the amount of dead load. This load produces a huge amount of stresses which is a problem and could be solved with one of the following methods. Using prestressing technique or reducing the dead load of the slab by including voids “often expanded polystyrene cylinders”. Due to some major concerns, the above mentioned two solutions of the problem are not applicable in Afghanistan, though the best option to be adopted in this case is constructing T-beam bridges over the canal. In this design, both beam and slab are monolithically casted and the compressive stress transfers to flange, which helps the beam in resisting the sagging moment and consequently, the depth of the beam reduces resulting in a better head room for underneath water.

Live Loads

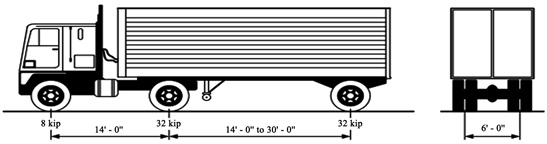

For the design and analysis purposes; the AASHTO HL-97 type vehicle is used as live load on the deck slab, this type vehicle contains three axles which on two rear axles the applied force is 32 kips and on the former axle 8 kips seen in Figure 6. According to AASHTO design standards, the lane load (9.3 KN/m) should be applied alongside with this load.

3.2. Design Procedure

3.2.1. Main Reinforcement

The positive reinforcement steel area is calculated by the following formula.

(1)

It is proposed to use T16-200 bars as +ve reinforcements.

To obtain the required strength, T16-200 is provided as –ve reinforcement.

3.2.2. Cracking Moment

For flexural members, AASHTO 07 required that,

Modulus of rupture of concrete is calculated by:

(2)

Cracking moment is calculated by:

(3)

Minimum flexural strength can be found by:

(4)

Then the results satisfied this equation:

Ok

3.2.3. Temperature & Shrinkage Reinforcement

According to AASHTO standards, the required minimum temperature and shrinkage reinforcement can be calculated by the following formula:

(5)

Proposed reinforcement is T12-200 bars and is founded that: .

T12-200 is provided as temperature & shrinkage reinforcement on the top layer.

3.2.4. Distribution Reinforcement

Distribution reinforcements which are parallel to the traffic direction are required, total of this reinforcement area is obtained by:

(6)

Distribution reinforcement area is calculated and satisfied the above equation. Thus, T12-150 is provided as distribution reinforcement on the bottom layer.

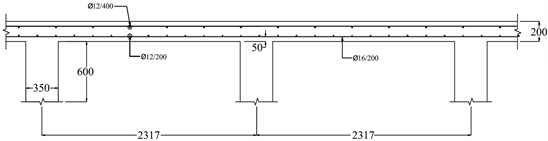

3.3. Reinforcement Arrangement

Arrangement of the steel is illustrated in Figure 7 and described as follows: first the positive and negative reinforcements are placed perpendicular to the traffic direction, positive reinforcement is placed at the bottom of slab and negative at the top of slab, these reinforcements are said as Main Reinforcements which are designed to resist the applied moments. Based on the design procedure, the diameter of the main steel bars is selected as 16 mm having c/c spacing of 200 mm.

Distribution reinforcement is placed parallel to the traffic direction, 12 mm diameter steel bars are used as distribution reinforcement and placed at 200 mm c/c spacing at the bottom of slab.

Based on the design specifications, temperature reinforcements are proposed to be placed on the top of the slab, whereas half of them shall be placed parallel towards traffic direction and others perpendicular.

Figure 6. AASHTO HL-97 type vehicle [11] .

Figure 7. Reinforcement arrangement into slab deck.

4. Conclusion and Recommendations

Obtaining the overall information and analyzing current condition of the existing bridges over Zahirshahi canal, the authors would like to remark that, the existing bridges are neither well-designed nor on suitable locations. The reasons of these deficiencies are as follow:

· Security concerns of the area;

· Lack of professionals;

· Vast urbanization in the area.

Single-span T-beam bridge was also one of the options considered but, the authors have come up with a conclusion that, single-span T-beam bridge is not only uneconomical but requires deep longitudinal girders which could be an obstacle for underneath water flow at the time of peak flowing. Though, in order to illuminate the shortcomings of the existing bridges, two-span T-beam Bridge is one of the best option utilizing AASHTO design standards to be constructed over the canal. The proposed bridge is comparably safe, economic and has good appearance considering the fixed dimensions of the canal.

Conflicts of Interest

The authors declare no conflicts of interest regarding the publication of this paper.

Cite this paper

Karimi, A.K., Jaheed, A.B., Aasim, B.A. and Farooqi, J.A. (2019) Structural Condition and Deficiencies of Present Constructed Bridges over Zahirshahi Canal and Proposal of New Design Using AASHTO Codes. World Journal of Engineering and Technology, 7, 325-332. https://doi.org/10.4236/wjet.2019.72023

References

- 1. Kuralay, B. and Zhulduz, B. (2014) Connect Central Asia: Role of Afghanistan. Public Administration & Regional Studies 7th Year, No. 2, Galati University Press, Galati, Romania.

- 2. Maksymowicz, M., Cruz, P.J.S. and Bien, J. (2011) Load Capacity of Damaged RC Slab Spans of Railway Bridges. Archives of Civil and Mechanical Engineering, 17, 146-156. https://doi.org/10.1016/S1644-9665(12)60089-2

- 3. Rucka, M., Zima, B. and Kedra, R. (2014) Application of Guided Wave Propagation in Diagnostics of Steel Bridge Components. Archives of Civil Engineering, 60, 493-516. https://doi.org/10.2478/ace-2014-0033

- 4. Bień, J. (2010) Defects and Diagnostics of Bridge Structures. Wydawnictwa Komunikacji Lacznosci, Warsaw. (In Polish)

- 5. Bień, J., Jakubowski, K., Kamiński, T., Kmita, J., Rawa, P., Cruz, P. and Maksymowicz, M. (2007) Railway Bridge Defects and Degradation Mechanisms. In: Bień, J., Elfgren, L. and Olofsson, J., Eds., Sustainable Bridges—Assessment for Future traffic Demands and Longer Lives, Dolnoslaskie Wydawnictwo Edukacyjne, Wroclaw, 105-116.

- 6. Blaszczyński, T. (2011) The Influence of Crude Oil Products on RC Structure Destruction. Journal of Civil Engineering and Management, 7, 146-156. https://doi.org/10.3846/13923730.2011.561522

- 7. Corrosion of Steel in Reinforced Concrete Structures-COST 521. Final Report.

- 8. Andrade, C., Nürnberger, U., Polder, R., Weydert, R. and Seitz, E. (2003) Directorate-General for Research. European Commission.

- 9. Cechákováa, V., Rosmanita, M. and Fojtíka, R. FEM Modeling and Experimental Tests of Timber Bridge Structure. https://www.sciencedirect.com/

- 10. Sandesh Upadhyaya, K. and Sahaya Sachin, F. (2016) A Comparative Study of T-Beam Bridges for Varying Span Lengths. International Journal of Research in Engineering and Technology, 5, 394-398.

- 11. AASHTOO Standard LRFD Specifications (2007).