Journal of Environmental Protection, 2011, 2, 1084-1094 doi:10.4236/jep.2011.28125 Published Online October 2011 (http://www.scirp.org/journal/jep) Copyright © 2011 SciRes. JEP Soil-Based Biofiltration for Air Purification: Potentials for Environmental and Space Life Support Application Mark Nelson1,2, Hinrich L. Bohn3,4 1Institute of Ecotechnics, Santa Fe, New Mexico and London, UK; 2Biospheric Design Division, Global Ecotechnics Corp., Santa Fe, New Mexico and London, UK; 3Department of Soil Sciences, University of Arizona, Tucson, USA; 4 Bohn Soil Biofiltration Com- pany, Tucson, US A . Email: nelson@biospheres.com Received August 14th, 2011; revised September 17th, 2011; accepted October 11th, 2011. ABSTRACT Soil biofiltration, also known as soil bed reactor (SBR), technology was originally developed in Germany to take ad- vantage of the diversity in microbial mechanisms to control gases producing malodor in industrial processes. The ap- proach has since gained wider international acceptance and continues to see improvements to maximize microbial and process efficiency and extend the rang e of problematica l gases for which the technolog y can be an effective contro l. We review the basic mechanisms which underlay microbial soil processes involved in air purification, advantages and limitations of the technology and the current research status of the approach. Soil biofiltration has lower capital and operating/energ etic costs than conventional technolog ies and is well adapted to hand le contaminants in moderate con- centrations. The systems can be engineered to optimize efficiency though manipulation of temperature, pH, moisture content, soil organic matter and airflow rates. Soil air biofiltratio n technology was mod ified for application in the Bio- sphere 2 project, which demonstrated in preparatory research with a number of closed system testbeds that soil could also support crop plants while also serving as soil filters with airpumps to push air through the soil. This Biosphere 2 research demonstrated in several closed system testbeds that a number of important trace gases could be kept under control and led to the engineering of the entire agricultural soil of Biosphere 2 to serve as a soil filtration unit for the facility. Soil biofiltratio n, coupled with food crop production , as a component of bioregenerative space life support sys- tems has the advantages of lower en ergy use and avoidance of the consumables required for other air purifica tion ap- proaches. Expanding use of soil biofiltration can aid a number of environmental applications, from the mitigation of indoor air pollution, as a method of reducing global warming impact of methane (biogas), improvement of industrial air emissions and prevention of accidental release of toxic gases. Keywords: Soil Biofiltration, Indoor Air Quality, Bioremediation, Ecological Engineering, Air Pollution, Purification, Bioremediation 1. Introduction The past few decades has seen increasing development of soil and compost beds for the purification of industrial discharge airstreams. They have been targeted primarily for the control of objectionable odors and reduction in potentially toxic trace gases. The systems employ either an enriched soil medium or compost in an engineered system which makes use of natural soil processes for the adsorption, dissolution and microbial metabolism of the volatile organic and inorganic gases contained in the effluent air. The present paper will briefly review the development of the technology, the mechanisms which account for its efficacy and consider some of the future potential and limitations of its use as a method of air purification for both environmental applications and in the context of bioregenerative life support systems. 2. History of the Technology The diversity of metabolism of soil living biota has been understood for a long time. There are a tremendous num- ber of biological agents in soils (e.g. one billion bacteria and 100,000 fungi per gram of soil [1]. These soil orga- nisms include fungi, which often account for a majority of the weight of soil living biomass, actinomycetes and  Soil-Based Biofiltration for Air Purification: Potentials for En vironmental and Space Life Suppo rt Application1085 bacteria, both prokaryotes and eukaryotes. All known microbes are found in soil and their metabolic efficacy is assisted by the presence of some 50 types of enzymes which catalyze a wide variety of chemical reactions [2]. The practical utilization of this microbial power in air purification technologies has only really developed in the past fifty years. This is quite different from the situation in wastewater treatment and regeneration where micro- bial action has long been employed in systems as diverse as oxidation trenches, septic tan ks, trickle filter, activated sludge oxidation, aerated ponds etc. utilizing both an- aerobic and aerobic microbial digestion of sewage and other organic and inorganic components of water from industrial and residential sources [3]. The heterogeneity of bacteria present and able to metabolize the wastewater impurities is a benefit and engineers of such systems seek to provide optimal conditions for their performance [4]. Among the earliest literature references to the possibi- lity of using soil b iofiltratio n for control of malodor fro m wastewater treatment was in 1923 by Bach. There were published accounts of such sewage systems in the 1950s in both Germany and the United States. Carlson and Le- iser [4] developed soil biofilters for gas emissions from a sewage plant and their research established biodegrada- tion rather than adsorp tion as the causal mechanism. But the wide-ranging acceptance of this approach as an im- portant air pollution control technology along with de- velopment of practical engineering systems took place primarily in Germany and the Netherlands during the 1970s and 1980s [5]. Some resear ch and applications are underway in the United States as the technology has be- come more widely known, But U.S. systems are still quite few in contrast to Europe where soil and compost beds are now accepted as highly effective and relatively inexpensive means of air purification for many purifica- tions, often being ranked as the best management prac- tice choice among competing technologies for many ap- plications [1,6]. The interest in the use of soil/compost reactors for air purification is part of a growing cooperation between engineers and environmentalists/ecologists to develop more natural systems. A new field, ecological engineer- ing, is exploring a range of new, hybrid approaches which require less intrusive reliance on resources in- cluding sophisticated technologies with high energy de- mands. Because they employ natural methods of bio- logical function these approaches are frequently more adaptable and lower in cost than conventional high-tech alternatives [7]. Ecological engineering encompasses a variety of scale and function from the restoration of damaged ecosystems, the creation of “synthetic ecologies” for the solution of pollution problems, or the harnessing of ecological pro- cesses into engineered systems for specific regeneration or bioremediation [2]. So, from this viewpoint, the engi- neering of soil and compost beds represents a type of ecological engineering, in that it takes a fundamentally ecological approach to air purification (biofiltration). This becomes clearer when so il biofiltration is compared to alternative conv entional systems. 3. Soil Biofiltration vs. Conventional Technologies Soil/compost reactors (henceforth referred to as soil bio- filtration) are systems where beds of the material are set up so that perforated pipes can deliver the discharge air so that it passes through the moist, aerated biological material, where its pollutant gases adh ere to the soil par- ticles, dissolving them into the so il solu tion and exp osing them to microbial digestion (Figure 1). After its residence time in the beds, the air is dis- charged to the atmosphere. The incoming air is actively pumped against the resistance head of the beds. Depend- ing on the substrate used, environmental conditions which affect rates of reaction (especially temperature and moisture content), the nature and concentration of the air impurities and desired degree of removal, the beds are designed for required size and volume, infiltration rate and airstream residence time before discharge [1,8,9]. The primary alternative technologies currently in use for air purification are high temperature incinerators and chemical scrubbing which use chemical capture or oxi- dation to eliminate pollutants, and water washing and adsorption using activated charcoal which separates the impurities from the air. Incinerators operate quickly (in seconds) but produce by-products such as nitrogen and sulfur oxides and require very large energy inputs. Use of highly reactive chemicals such as ozone, hypochlorite and permanganate is highly effective for many volatile organic and inorganic compounds, but not for hydrocar- bons and other less reactive pollutants. In addition, the chemicals are expensive and by nature quite corrosive and thus require more safety precautions in the design and operation of the treatment facility. Water washing does not involve the danger of corrosive chemicals but is ineffective if the pollutants are not water soluble. In ad- dition, large quantities of water are requ ired and must be safely disposed of, posing problems and increasing costs. Activated charcoal filters remo ve 90% of volatile organic compounds, but their efficacy declines as the filters age. Since the compounds are unchanged chemically by the filtration, in some cases the volatile compounds may be recovered when this is economically desirable, thus low- ering costs. Additional problems are that activated car- bon’s performance is lowered when moist, but the mate- Copyright © 2011 SciRes. JEP  Soil-Based Biofiltration for Air Purification: Potentials for En vironmental and Space Life Suppo rt Application Copyright © 2011 SciRes. JEP 1086 Figure 1. (Left): Schematic of a biofilter using compost and compost sieving and (Right): photograph of aerator pipes leading into a soil or compost biofilter [11]. Table 1. Cost comparisons of different methods of air puri- fication to treat 105 cubic feet of air, in US dollars. rial is flammable when dry [1,10]. Soil biofiltration substitutes its own adsorption on soil/compost particles for what is achieved by activated charcoal or other manufactured sorption media, accom- plishes water washing through the dissolution of the im- purities in the soil solution and oxidation is accom- plished at ambient or much lower temperatures by the soil biota [1]. Method of air purification Total cost per 105 cubic feet of air (US dollars) Incineration $130 Chlorination $60 Ozonation $60 Activated charcoal with regene ra ti o n $20 Soil biofiltration $8 4. Cost Comparisons The cost of soil biofiltration is almost always less than convention al alternatives and sometimes dr amatically so. Bohn [1] presents the comparative data in Table 1. broken down organic matter, often 50% - 80% by weight [1]. Another advantage of compost media is its markedly higher microbial densities and consequently higher rates of pollutant degradation [9]. Operating costs are extremely low for soil biofiltration in terms of fuel/chemical consumption as all that is nor- mally required is periodic renewal of the soil/compost materials and energy for moving the air. For incineration, operating costs can total $15 per 105 cubic feet per mi- nute (cfm), while chemical oxidation costs around $8 per 105 cubic feet (all above prices in 1991 U.S. dollars) [1, 12]. However, other researchers and engineers implement- ing industrial-scale systems have preferred soil as longer- lasting and lower cost; and for particular applications lower-N and organic material media have demonstrated greater efficacy. Lower N and organic soil media pro- duce less biomass production which can contribute to shortened lifetimes and biofilter clogging [13]. 5. Mechanisms of Trace Gas Degradation in Soil Biofiltration Modeling has been done of the steps involved in the operation of a biofilter, e.g. Lynch [6]. Air pollutants are transported across a phase boundary from the solid parti- cles which operate as a type of filter to the moist, biolo- gically reactive biofilm layer where microorganisms can metabolically utilize and transform them. Oxygen is supplied from the incoming air flow and nutrients from the bed’s substrate. Degradation is accomplished prima- rily by heterotrophic organisms (bacteria, actinomycetes and fungi) while autotrophic bacteria (e.g. nitrifying bac- teria) are also involved depending on the composition of the waste gas. The biological reactions result in the pollutant gases being oxidized primarily to CO2 and water but with some sulfate, N2 or n itrate bein g produ ced The underlying mechanisms which enab le biofiltration to operate are quite similar to those operative in natural soil, but in the engineered system environmental conditions are controlled to try to optimize rates of reaction. Soil biofilters use soil, peat or compost as media utilizing their high porosity and sorption capability to begin the degradation process. Soils used typically have a porosity of some 40% - 50%, surface area from 1 - 100 sq·m/gram and are enriched to contain 1% - 5% soil organic matter (SOM). Compost has been preferred in many applications because it tends to have a somewhat higher porosity (50% - 80%) and far more partially  Soil-Based Biofiltration for Air Purification: Potentials for En vironmental and Space Life Suppo rt Application1087 if nitrogen and sulfur compounds are being treated [1] with an increase of microbial bio mass and energy u tiliza- tion occurring during the process. The biological degra- dation of pollutants can be limited by both biological activity of the microbiota or diffusion rates across the media to the biofilm at lower pollutant concentrations [6]. It is generally accepted that biofiltration follows first order kinetics. An exception is Ottengraf (cited in [9]) whose theoretical modeling of the processes of degra- dation assumes that degradation is independent of pollu- tant concentrations, i.e. zero order kinetics for concen- trations below a critical level for the compound. Brad- ford and Krishnamoorthy [14] point out that the reaction should be considered as WDR = KCw * Co * Cp * Cn where WDR is the waste destruction rate, K is the rea- ction rate constant, Cw is the concentration of the waste (pollutant gas), and Co, Cp and Cn represent concen- trations of oxygen, phosphorus and nitrogen in the soil beds. These latter three are key requirements for biolo- gical activity and are optimal at BOD:N:P ratios of about 100:5:1. If these are available and non-limiting, the reaction rate simplifies to WDR = KCw, a first order kinetic reaction [14]. Determinants of K, the reaction rate constant, include solubility of the pollutan t, ease of biological degradatio n, environmental parameters of the biofilter including tem- perature, nutrient status and oxygen availability, mois- ture content and pH. Solubility of the target pollutant and its biological degradation are primary factors determining whether soil biofiltration is a feasible technology for a particular application as all other factors can be manipulated and maintained at satisfactory levels if the system is p roperly designed. Low solubility will limit the transfer of the pollutant to the biofilm where it is exposed to biological activity. Trace gases also vary widely in the rate and ease with which they may be biologically metabolized. Nu- merous studies have shown that as a rule simple hydro- carbons are rapidly decomposed as are most simple structured inorganic technogenic gases. Retention time increases with increasing weight of the hydrocarbon and for equal carbon compounds adsorption increases with an increase in carbon chain branching and presence of unsaturated bonds [5] Water insoluble molecules were more readily adsorbed on water absorbent media such as soil organic matter than on the particles of mineral soils. While soil organic matter is the major adsorben t of orga- nic trace gases, clay soil particles are effective as well. But the interaction between soil organic matter and clay particles may limit adsorption of additional organic pollutants [5]. Biodegradability of air pollutants is generally high for alcohols, ethers, aldehydes, ketones, most common mo- nocyclic aromatics, amines and sulfides. But there are slower rates of reaction for complex chlorinated organics [9]. Bradford and Krishnamoorthy [14] report that rea- ction rates are low for polynuclear aromatic hydrocar- bons (PNAs) with four or more aromatic rings, as well as for halogenated compounds. But these latter are more susceptible to biological degradation in anaerobic con- ditions. The influence of co-metabo lism where the simu- ltaneous presence of two compounds will increase both their rates of microbial reaction, and also reported in- stances of inhibition due to the interaction of two trace gases further complicate predictive modeling of the efficacy of soil biofiltration [4,8]. For these reasons, most soil biofiltration applications are preceded by a pilot plant or bench scale trial where rates of reaction for the specific waste airstream can be determined prior to design and construction of the operational unit [1,8,9,14, 15]. 6. Engineering Parameters The final design of the engineered soil biofilter will reflect considerations unique to the airstream and desired level of contaminant removal but generally shares many features and operates in comparable ranges as a refle- ction of the need to optimize environmental conditions for the biota. Maintenance of adequate moisture is essential for the optimal transport of the pollutants to the biofilm and for microbial activity. Generally, moisture content is kept at 10% - 25% for soil ba sed filters and 20 % - 40% for com- post. Since dehydration from the incoming air stream is a potential problem, biofiltration systems frequently in- clude a humidifier on this stream and also include facili- ties for irrigation of the beds and drainage of excess water. Bohn reports that compost biofilters are more difficult to maintain at satisfactory moisture lev els, since they function more poorly when overly wet and being somewhat hydrophobic are harder to remoisten tho- roughly if allowed to dry out. For outdoor installations treating low flow rate air discharges natural rainfall is frequently sufficient for maintaining moisture in humid areas [1,14]. Oxygen must be maintained at adequate levels since it is required as an electron acceptor during the aerobic rea- ctions which generally predominate in current biofil- tration systems. This is usually not a problem as the beds are resupplied by the incoming air stream. But com- paction is avoided and mixing/turning and resupply of compost beds is required at periodic intervals due to the humidification/degradation of its original constituents [1,9]. There are conflicting reports of optimal operating Copyright © 2011 SciRes. JEP  Soil-Based Biofiltration for Air Purification: Potentials for En vironmental and Space Life Suppo rt Application 1088 temperature ranges. Bohn [1] indicates that there is little change in reaction rates between a wide range of temperature, 10 - 60 deg. C. At low temperatures, micro- bial activity is lessened, but this is compensated for by somewhat higher rates of adsorption. Upper temperature limits reflect a sharp decline in microbial activity above 65 deg C. [1]. In contrast, Leson and Winer [9] report a temperature range between 20 - 40 deg C. as optimal, citing decreased water solubility as well as a lessen ing of activity of mesophilic bacteria which are the primary class of responsible bacteria in biofiltration reactions at higher temperatures [9]. Still other accounts assert that overall bacterial activ ity slows above 32 deg C. although some thermophilic bacteria can survive up to 60 deg C [8]. In any case, performance characteristics can be determined at the pilot plant phase and is frequently engineered for cooling/heating of' incoming airstream or the system made larger to accommodate reaction rates at anticipated operating temperatures. pH levels are nor- mally maintained between 7 - 8. This is normally not a problem except in the case where inorganic gas degra- dation results in the formation of acids. In these cases, periodic liming of the biofilter is carried out to maintain higher pH levels [9]. One of the advantages of biofiltration is the flexibility of response to changing pollutant characteristics because of the wide variety of microbial metabolic pathways. The pollutants become “food” for the type of microbiota which can digest them. This means operationally that a period of “acclimatization” is often required for pollu- tants which are uncommon. During this period (often reported to be about ten days) populations of microbiota build up until a stable rate of reaction of the pollutant is reached. This has led to some experimentation with in- troduction of particular types of microbes to accelerate this process. There is no consensus on the necessity or long-term success of such introductions, as the intro- duced bacteria must compete with existing populations and most native bacteria will adapt to handle synthetic pollutants [1]. But this approach is used in a number of currently operating European systems [9]. An analogous concern is the v iability of microbial activity if the opera- tion of the biofilter is interrupted (e.g. because of inter- mittent releases from the source, or down-time during maintenance/repair operations). Indications are that pe- riods of up to two weeks can b e tolerated withou t decline in microbial populations and perhaps as long as two months as long as the filter con tains adequate alternative sources of nutrients [9]. Residence time is a key engineering system parameter and is dependent on flow pressure and rate, bed porosity, moisture content and size. Typically soil or compost beds are around 1 m deep and overall filter areas range from 10 - 2000 sq m, with air input rates between 1000 to 150,000 cu m/hr. An important safety consideration is to size beds so that “breakthrough” of discharge air does not occur during peak loading, and so that back pressures don’t become too high. Generally biofilters are designed with loads up to 300 cu m of incoming air per sq m per day of filter bed, although for mixtures with very good porosity (e.g. compost/bark) loads of up to 500 cu m/sq m/day have performed satisfactorily [9]. Recommended rule of thumb residence times are 30 seconds for 90 percent removal of organic pollutants in compost biofilters and one minute in soil biofilters (be- cause of their lower microbial populations) particularly if inorganic gases such as SO2 and NOx are to be treated as well [14]. An advantage of soil/compost media is that volatile gases tend to stay in contact with the bed for far longer periods than the transport air because of their partition out on the pore surfaces of the soil particles [1]. Most soil biofilters are constructed as a single bed, but in circumstances where space is limited a stacked bed configuration may be used. Since particle size and pore structure is key to maintaining desired flow rates and adsorption of pollutants, some engineered systems add porous clay or polystyrene spheres to increase surface area, reduce back pressure and increase lifetime of ma- terials. Others add activated carbon to reduce required system size and increase effectiveness and buffering capacity of the system especially if pollutant loading is intermittent [9]. Presence of pollutants toxic to the microbiota in the concentrations found in the discharge air will result in poor performance of the biofilter. Thus, chemical ana- lysis of the pollutant flow prior to system design is im- portant both to assess feasibility of soil biofiltration and to make necessary corrective steps such as a filtering of the particular toxic component, or dilution of its concen- tration in the inlet air. Biofilters tend to be especially effective and inexpensive for the treatment or low con- centrations of pollutants in discharge air, and as a rule are appropriate technologies where maximum VOC con- centration is below 3000 - 5000 ppm [9]. Another important advantage of biofiltration over competing air purification technologies is the ease and low cost of disposal of bed materials. In most cases, there is little residual pollutant and materials may be used for nursery, farm or garden soils or landfill covers. For this reason, careful screening of original soil or com- post materials to exclude the presence of hazardous ma- terials such as heavy metals, or pesticide residues is desirable since it will make disposal after use far less costly. Similarly, since drainage of water is occasionally required, proper maintenance of pH in the beds will not only result in better system performance, but also lessen C opyright © 2011 SciRes. JEP  Soil-Based Biofiltration for Air Purification: Potentials for En vironmental and Space Life Suppo rt Application1089 the problem of excessively acid discharge water which will be more difficult and costly to dispose [1,9]. Power consumption for biofiltration systems tend to be far lower than that required for alternative technologies. Average power requirements are from 1.8 - 2.5 kWhr per 1000 cu m of treated airflow. This is about 1/6 those required for chemical scrubbing [1,9,14]. Recent innovations in the field include use of innova- tive media, such as ceramic beads in the “trickle-bed” biofilter (Figure 2) to maximize porosity, airflow and reduce clogging, hybrid systems which use biofiltration as a preliminary step to conventional air purification to lower costs, automation to ensure moisture levels are maintained, and the development of fully enclosed bio- filters when applications need more control to ensure regulatory standards are met [16,17]. 7. Limitations of Soil Biofiltration In principle biofilter microbes can degrade/oxidize any compound that is thermodynamically unstable in air. The rule of thumb is that if it burns in air, it degrades in a biofilter. Polyhalogenated hydrocarbons are therefore un- treatable, and mono- and di-halogenated and aliphatic hydrocarbons degrade significantly only at slow flow rates through biofilters. The degradation rate increases with the number of double bonds and the O, N, and S content of th e molecule. The second rule of thumb is that the degradation rate increases with wat er solubility of t he m olecule. Biofilters are low-temperature catalytic oxidizers, the Fig ur e 2. Schematic of a ceramic bead biofilter for control of air-phase benzene which includes humidifier to ensure ade- quate moisture to the biofilter (A) Pump (B) Humidification unit (C) Liquid benzene (D) Air flow meter (E) U-tube ma- nometer (F) Mixing chamber (G) Benzene i nlet (H) Distribu- tor (I) Perforated support (J) Ceramic beads (K) Filter bed (L) Gas sampling ports (M) Treated air (N) Port for sprin- kling fresh media [18]. catalysts being of course the microbial enzymes. The low-cost and self-regenerative capability of these cata- lysts is somewhat offset by their molecular selectivity and their temperature dependence. The increase of enzy- matic rate with temperature is counterbalanced by the decreasing solubility of gases at increasing temperature. The net effect is that degradation rates change little over the range of 10 - 40 C, and degradation occurs over the range of 1 - 55 C. Freezing inactivates the microbes and 60+ C sterilizes all but a few thermophilic microbes. Hotter air must cool and dry air must be water saturated in order for biofiltration to be effective. 8. Air Cleaning Results for Soil Biofilters Experimental results generally show reaction rates of 10 - 100 g/cu m per hr for many common air pollutants. In European installations, pollutant reductions ranged from 50 - 94 percent for organic carbon compounds, with as- sociated odor reductions of 82 - 99 percent. In most faci- lities with proper system design, reductions of over 90 percent are obtainable. A wide range of industrial appli- cations have had effective use of soil biofiltration: adhe- sive production, coating operations, chemical manufac- turing, iron foundries, print shops, coffee roasting, to- bacco processing, fish frying and rendering, flavors and fragrances, pet food manufacture, slaughter houses, in- dustrial and residential wastewater treatment, gas extrac- tion, waste oi l processing. Sequential removal of pollutants by microbes has been observed evidently as a result of the varying structures and biodegradability of the compounds [8]. Bohn [1] reports results from installations where 100 mg of bu- tanol/kg of compost were removed per hour, an Arizona facility where rendering plant odors were 99% removed at 100% relative humidity, and a Texas installation de- pendent solely on incident rainfal1 where extremely odorous discharge air has 95% removal when bed is too wet, and 99% at moderate moisture levels. 9. Space Life Support Research: Combining Plants with Soil Biofiltration Bioregenerative life support systems face particularly acute concerns about the buildup of trace gases because they will inherently be tightly sealed to prevent loss of valuable atmosphere. This makes the problem, also seen in energy-conserving tightly sealed residences and of- fices, of what has come to be called “sick building syn- drome”. This lowered ventilation combined with the out gassing from synthetic materials (synthetic materials such as carpets, sealants, solvents, paints, electronic and electrical equipment etc.) creates an enhancement in con- centration of many volatile organic and inorganic com- pounds that can be up to one or two orders of magnitude Copyright © 2011 SciRes. JEP  Soil-Based Biofiltration for Air Purification: Potentials for En vironmental and Space Life Suppo rt Application 1090 greater than those in the outside environment [15]. Some researchers, especially Wolverton at the NASA Stennis Space Center, have demonstrated the efficacy of certain plants, e.g. spider plants, at removing technogenic and VOC trace gases [19]. These capacities are enhanced when coupled with soil biofiltration [15]. Biosphere 2 in southern Arizona, USA, is the largest closed ecological system ever built, with rainforest, sa- vannah, desert, marsh and ocean coral reef ecosystems as well as an agricultural area and workshops/laboratories built to support crews of 8 - 10 people [20-22]. In re- search during the facility’s development, a new system which integrates soil biofiltration with the growing of plants was developed. The intention was to provide a means of biological purification without the use of con- sumables. Preparatory research for Biosphere 2 con- ducted at the Environmental Research Laboratory at the University of Arizona confirmed both the efficacy of soil biofiltration for removal of potentially hazardous gases such as CO , CH4 an d ethylene and the compatibility with the soil also supporting food crop production. It was found that crop production was essentially unchanged with or without the operation of the underlying soil as a soil biofiltration. The slight increase in crop yields, dur- ing a long-term experiment with 72 one-meter diameter soil biofiltration planters was attributed to maintenance of good aerobic condition s in th e soils fro m the op eration of the air pumping system [23]. So the choice of running Biosphere 2’s agriculture with soil rather than hydroponics opened the way to a fundamental solution to one of the most vexing of space life support problems—the maintenance of air quality. The great diversity of out gassing products from anthro- pogenic, biogenic and technogenic sources combined with the small volumes and rapid cycling times of atmos- pheric components in tightly sealed closed systems cre- ate a significant hazard for toxic gas buildups [20]. In Apollo, Skylab and Space Shuttle cabins, for example, several hundred trace gases were identified in cabin air which raises concerns about unanticipated secondary reactions [24,25]. These air contamination concerns oc- curred in spite of flushing of the air volume through the carbon dioxide removal system, and other measures such as exclusion of certain materials known to be problem- atic for out gassing, equipment isolation, absorption tech- nologies using charcoal, and absorption of soluble sub- stances on the condensate in humidity-control devices. The conventional solutions to this problem include fil- tering methods using charcoal or catalytic oxidation which will require substantial energy costs and/or ex- pendable parts, such as filters, both of are very costly in off-planet application [26]. The Biosphere 2 research with soil biofiltration in- cluded testing in special closed chambers to simulate the proportions of open water (ocean and marsh), wilderness soils and agricultural soils as well as atmosphere. In such studies, the ability of the soil biofiltration technology to control a variety of potentially toxic gases was demon- strated. Special closed chambers were built for such stu- dies, and soil biofiltration was also studied in green- houses and in th e Biosphere 2 Test Module. Such studies confirmed that a period of “conditioning” (prior exposure to the trace gas in question) leads to greater control, pre- sumably through the increase in their metabolizers; that higher levels of organic matter increases efficacy; and that removal rates vary with moisture conten t of the soils and airflow rates. Another issue of concern is release of carbon dioxide: initially there is an net output of carbon dioxide from the flushing of the soil bed area as soils typically have far higher CO2 levels (typically 5 - 10 times greater) than the atmosphere, but over time carbon dioxide is n ot enhanced by operation of th e soil biofiltra- tion unit. Figure 3 shows rates of removal of some of the trace gases tested in preparation for Biosphere 2 [23]. After this preparatory research, the entire agricultural area of Biosphere 2 was outfitted with a piping system so that the internal atmosphere of the structure could be pumped from the basement up through the soil in a pe- riod of 24 hours (Figure 4). Biosphere 2, since it includes large soil beds in all the terrestrial biomes as well as the agricultural area, had a large amount of passive soil biofiltration occurring through normal atmospheric interactions with its soils. Biosphere 2 experien ced good co ntrol of tr ace gases w ith the one exception of nitrous oxide which is kept under control by processes that occur in the stratosphere of the global biosphere [21,22]. Since initial experiments with the soil biofilters included trials that showed net metabo- lism of nitrous oxide [23], this gas, which is increasing in Figure 3. Removal percentage as a function of airflow for selected trace gas compounds CO, carbon monoxide, CH4, methane, C2H4, ethane, C2H6, ethylene, C3H8, propane ) at the University of Arizona soil biofiltration testing facilities in preparation for the Biosphere 2 experimental facility [22, 23]. C opyright © 2011 SciRes. JEP  Soil-Based Biofiltration for Air Purification: Potentials for En vironmental and Space Life Suppo rt Application1091 Figure 4. Airflow patterns in the Biosphere 2 agricultural area. The entire soil was engineered to serve as a “soil bed reactor” so if pumps were activated in the technical base- ment below the farm, the internal air of Biosphere 2 could be pumped through the soils in 24 hours. the Earth’s biosphere, would be worthy of further de- tailed studies. The Biosphere 2 development and success with soil biofiltration should make the technology a candidate for inclusion in bioregenerative space life support systems. The integration of food crop production from the soils used makes it a multi-benefit addition, and the low en- ergy and non-use of consumables, increase its attractive- ness for volume and energy-limited space missions. The fact that soil biofiltration can adapt to whichever pollu- tants might otherwise build up make it a robust solution for the complexity of anthropogenic, biogenic and tech- nogenic gases likely to be found in tightly sealed space habitats. 10. Future Directions for Environmental Applications of Soil Biofiltration 10.1. Indoor Air Purification Combining soil biofiltration with plant growth opens the way for applications for home and office air purification through the use of indoor planters outfitted with air pumps to ensure active soil interaction with the ambient air. The low cost and maintenance of such technology makes it feasible for residential or office installation. In addition, the ability of soil microbiota to respond to a wide variety of pollutant gases means that such a system will acclimatize itself to the particular gases causing the sick building syndrome in that situation and become more proficient over time in reducing pollutant levels. Such a product, an attractive houseplant container with built-in air pump, was under development at Biosphere 2 before the change in project direction occurred in 1994 (Figure 5). Similarly, for larger applications like high-rise office Figure 5. Schematic of potential indoor soil biofiltration unit coupled with indoor plant container to be called an “airtron” which derived from research for Biosphere 2 (from proposed press release, Space Biospheres Ventures, Oracle, AZ, 1994). complexes, the addition of green atrium areas and indoor landscaping features could be greatly enhanced by engi- neering them so that their soil volumes also function as an active soil biofiltratio n unit by pumping th e indoor air through the so ils. 10.2. Industrial Odor Elimination and Air Purification Tightening of governmental regulations on emission standards have been contributing factors in the wide- spread adoption of soil biofiltration techno logy in Europe. Soil biofiltration is now considered Best Available Technology (BAT) for most applications where pollutant loading is in low concentration or in low volume dis- charge because of lower capital costs, lower operating costs and more fool-proof operation [9]. The unfamiliar- rity with the European literature and lack of similar air pollution legislation has slowed down the rate of soil biofiltration application in the U.S. In addition there may be an attitude among engineers that equates to: if it costs so little and is so simple, it can’t be any good [1]. But just as civil engineers have adapted to working with wastewater treatment which uses biological remediation that is so complex it is not necessarily fully understood nor under the control of the engineer as are the pumps Copyright © 2011 SciRes. JEP  Soil-Based Biofiltration for Air Purification: Potentials for En vironmental and Space Life Suppo rt Application Copyright © 2011 SciRes. JEP 1092 and stirrer which can be turned on or off, so they may learn to work with the microbial agents responsible for air purification. Even the apprehension of coming legis- lation, plus the appreciation of the goodwill that envi- ronmental responsibility bring s, led Johnson Wax to suc- cessfully install a soil biofiltration system for cleaning propane, isobutane and n-butane discharge from aerosol cans in Wisconsin. The engineers responsible reported reductions of over 90% of the hydrocarbons, using a re- sidence time of 15 minutes, operating temperatures of 12 - 24 deg C. They even had success with trichloroethane (TCE) a compound previously thought to be too unreac- tive to be handled b y a soil biofilter [15]. Tig htening U.S, standards since the 1980s stimulated research into whe- ther biofilters could be used for such p ollutants as VOCs and the development of newer designs with higher de- grees of monitoring, control and automation and using closed chambers to ensure consistent performance and regulatory compliance. These advances have resulted in better performance of biofilters for VOC control [27]. 10.3. Reduction of Global Warming Contributions from Methane (Biogas) Research has shown the effectiv eness of soil biofiltration as a method of reducing methane release from landfills (e.g. as illustrated in Figure 6) which represent a sig- nificant source of total methane production (e.g. in the U.S. it contributes 34% of all anthropogenic sources). The methanotrophic bacteria convert CH4 to CO2 which is a large improvement since methane is over 20 times as detrimental as carbon dioxide in its greenhouse effect. A number of researchers are investigating the optimization of the process. One such study compared the impact of nitrogen level in the soil, an d found th at low N soils were able to metabolize over 40% of the methane vs. 19% vs. soils with higher N [12]. 10.4. Prevention of Toxic Gas Release Accidents It has been proposed that soil bed reactors would be suc- cessfully applied in the prevention of accidental gas re- leases such as those from the Union Carbide plant in India which caused loss of life in surrounding neighbor- hoods. Tanks containing potentially dangerous gases could have their vents connected to soil b iofiltration beds, or valving to divert them to such systems in case of ac- cident. The adsorptive properties of the soil medium and responsiveness of soil bacteria make it ideal for such application in addition to their low cost. Such systems re- Figure 6. The schematic diagram of a landfill with composite plus biofilter for control of methane emissions; (a) Biofilter de- sign when the ratio of biofilter area to landfill area is much less than 1 and (b) Biofilter design when the ratio of biofilter area to landfill area is about 1 [28].  Soil-Based Biofiltration for Air Purification: Potentials for En vironmental and Space Life Suppo rt Application1093 quire virtually no energy, expendable chemicals and main- tenance requirements are minimal. They could also be economically effective in the removal of pollutants when storage tanks are filled [11]. Soil bed reactors may well become as commonplace in the 21st century as the smoke- stack industries were of the 19th and 20th. 11. Conclusions As previously noted, biofiltration is less suited to some of the applications where pollutant load is extremely concentrated, or to treat compounds such as complex, branched halogens where slower reaction times would require extreme residence times, and thus large volumes of material. But for a great many applications in industry, office, public utility and even indoor air cleanup, biofil- ters may prove to be cost-effective, reliable and easy to operate systems—a natural as well as best available tech- nology. REFERENCES [1] H. L. Bohn, “Consider Biofiltration for Decontaminating Gases,” Chemical Engineering Progress, Vol. 42, No. 4, April 1992, pp. 34-40. [2] W. J. Mitsch, “Ecological Engineering: The Roots and Rationale of a New Ecological Paradigm,” In: C. Etnier and B. Guterstam. Eds., Ecological Engineering for Wastewater Treatment, Bokskagen, Gothensburg, 1991, pp. 19-37. [3] M. Gandolla and M. Aragno, “The Importance of Micro- biology in Waste Management,” Experientia, Vol. 48, 1992, pp. 362-366. doi:10.1007/BF01923430 [4] D. A. Carlson and C. P. Leiser, “Soil Beds for the Control of Sewage Odors,” Journal of the Water Pollution Con- trol Federation, Vol. 38, No. 5, 1966, pp. 829-833. [5] H. L. Bohn, G. K. Prososki and J. G. Eckhardt, “Hy d ro ca r- bon Absorption by Soils as the Stationary Phase of Gas-Solid Chromatography,” Journal of Environmental Quality, Vol. 9, No. 4, 2008, pp. 563-565. doi:10.2134/jeq1980.00472425000900040005x [6] J. M. Lynch, “Soil Biotechnology: Microbiological Factors in Crop Productivity,” Blackwell Scientific Publications, Oxford, 1993. [7] C. Etnier and B, Guterstam, “Ecological Engineering for Wastewater Treatment,” Bokskagen, Gothensburg, 1991. [8] A. W. Busch, “Aerobic Biological Treatment of Waste Waters,” Oligodynamics Press, Houston, 1971. [9] G. Leson and A. M. Winer, “Biofiltration: An Innovative Air Pollution Control Technology for VOC Emissions,” Journal of the Air & Waste Management Association, Vol. 41, No. 8, 1991, pp. 1045-1054. [10] T. Godish, “Indoor Air Pollution Control,” Lewis Pu blishers, Chelsea, 1989. [11] D. Mathsen, “Evaluating Compost and Biofilter Aeration Performance,” Biocycle, Vol. 45, No. 6, 2004, pp. 20-25. [12] H. L. Bohn and R. K. Bohn, “Soil Bed Scrubbing of Fu- gitive Gas Releases,” Journal of Environmental Science and Health, Vol. A21, 1986, pp. 561-569. [13] J. Nikiema, L. Bideau and J. Lavoie, “Biogas: A Real Problem; Biofiltration: A Promising Solution,” In: J. S. Devinny, Ed., Proceedings 2004 Conference on Biofiltra- tion for Air Pollution Control, USC Center for Sustain- able Cities and Department of Civil and Environmental Engineering, Los Angeles, 2004, pp. 73-80. [14] M. L. Bradford and R. Krishnamoorthy, “Consider Bio- remediation for Waste Site Cleanup,” Chemical Engi- neering Progre ss, Vol. 87, No. 2, 1980, pp. 80-85. [15] D. H. Kampbell, J. T. Wilson, H. W. Read and T. T. Stocksdale, “Removal of Volatile Aliphatic Hydrocarbons in a Soil Bioreactor,” Journal of the Air & Waste Man- agement Association, Vol . 7, No. 10 , 19 8 7, pp. 1236 -1240. [16] C. Van Lith, G. Leson and R. Michelson, “Evaluating Design Options for Biofilters,” In: F. E. Reynolds, Ed., Proceedings 1996 Conference on Biofiltration, University of Southern California, The Reynolds Group, Tustin, 1996, pp. 102-127. [17] J. Devinny, “Topics for Research in Biofiltration,” In: D. S. Hodge and F. E. Reynolds, Eds., Proceedings 1995 Conference on Biofiltration, University of Southern California, The Reynolds Group, Tustin, 1995, pp. 6-13. [18] E. R. Rene, D. V. S. Murthy and T. Swaminathan, “Steady- and Transient-State Effects during the Biological Oxidation of Gas-Phase Benzene in a Continuously Oper- ated Biofilter,” Clean Technology and Environmental Policy, Published 2009 online. [19] B. C. Wolverton, “Foliage Plants for Removing Indoor Air Pollutants from Energy-Efficient Homes,” Economic Botany, Vol. 38, 1983, pp. 224-228. doi:10.1007/BF02858837 [20] M. Nelson, W. F. Dempster, N. Alvarez-Romo and T. MacCallum, “Atmospheric Dynamics and Bioregenerative Technologies in a Soil-Based Ecological Life Support System: Initial Results from Biosphere 2,” Advances in Space Research, Vol. 14, No. 11, 1994, pp. 417-426. doi:10.1016/0273-1177(94)90331-X [21] M. Nelson and W. F. Dempster, “Living in Space: Re- sults from Biosphere 2’s Initial Closure, an Early Testbed for Closed Ecological Systems on Mars,” In: C. R. Stoker and C. Emment, Eds., Strategies for Mars: A Guide to Human Exploration, AAS Publication, San Diego, Vol. 86, 1996, pp. 363-390. [22] J. P. Allen and M. Nelson, “Biospherics and Biosphere 2, Mission One (1991-1993),” Ecological Engineering, Vol. 13, 1999, pp. 15-29. doi:10.1016/S0925-8574(98)00089-5 [23] R. Frye and C. Hodges, “Soil Bed Reactor Work of the Environmental Research Laboratory of the University of Arizona in Support of the Biosphere 2 Project,” In: M. Nelson and G. Soffen, Eds., Biological Life Support Sys- tems, NASA Conference Proceedings 3094, Synergetic Press, Oracle, 1990, pp. 33-40. [24] A. Nicogossian and J. F. Parker, “Space Physiology and Copyright © 2011 SciRes. JEP  Soil-Based Biofiltration for Air Purification: Potentials for En vironmental and Space Life Suppo rt Application 1094 Medicine,” NASA SP-447, U.S. Government Printing Office, Washington DC, 1982, pp. 285-292. [25] W. J. Rippstein and H. J. Schneider, “Toxicological As- pects of the Skylab Program,” In: R. S. Johnston and L. F. Dietlin, Eds., Biomedical Results from Skylab, NASA SP-377, U.S. Government Printing Office, Washington DC, 1977. [26] R. M. Hord, “Handbook of Space Technology: Status and Projections,” CRC Press, Boca Raton, 1985. [27] G. Wu, J. C. Chabot, J. J. Caron and M. Heitz, “Biologi- cal Elimination of Volatile Organic Compounds from Waste Gases in a Biofilter,” Water, Air and Soil Pollution, Vol. 101, No. 1-4, 1998, pp. 69-78. doi:10.1023/A:1004914919615 [28] S. Y. Park, K. W. Brown and J. C. Thomas, “The Use of Biofilters to Reduce Atmospheric Methane Emissions from Landfills: Part 1, Biofilter Design,” Water, Soil and Air Pollution, Vol. 155, No. 1-4, 2004, pp. 63-85. doi:10.1023/B:WATE.0000026522.36984.42 C opyright © 2011 SciRes. JEP

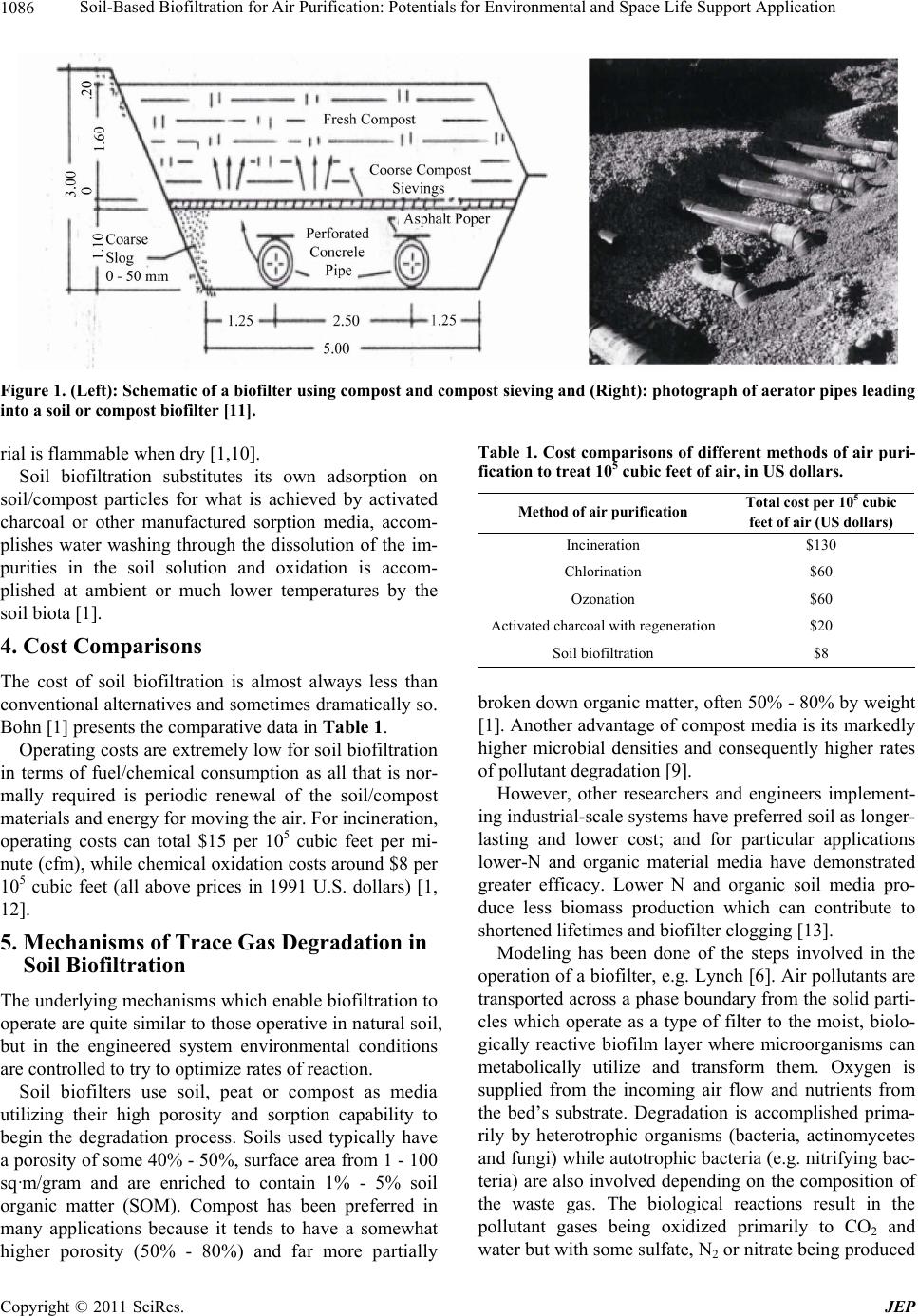

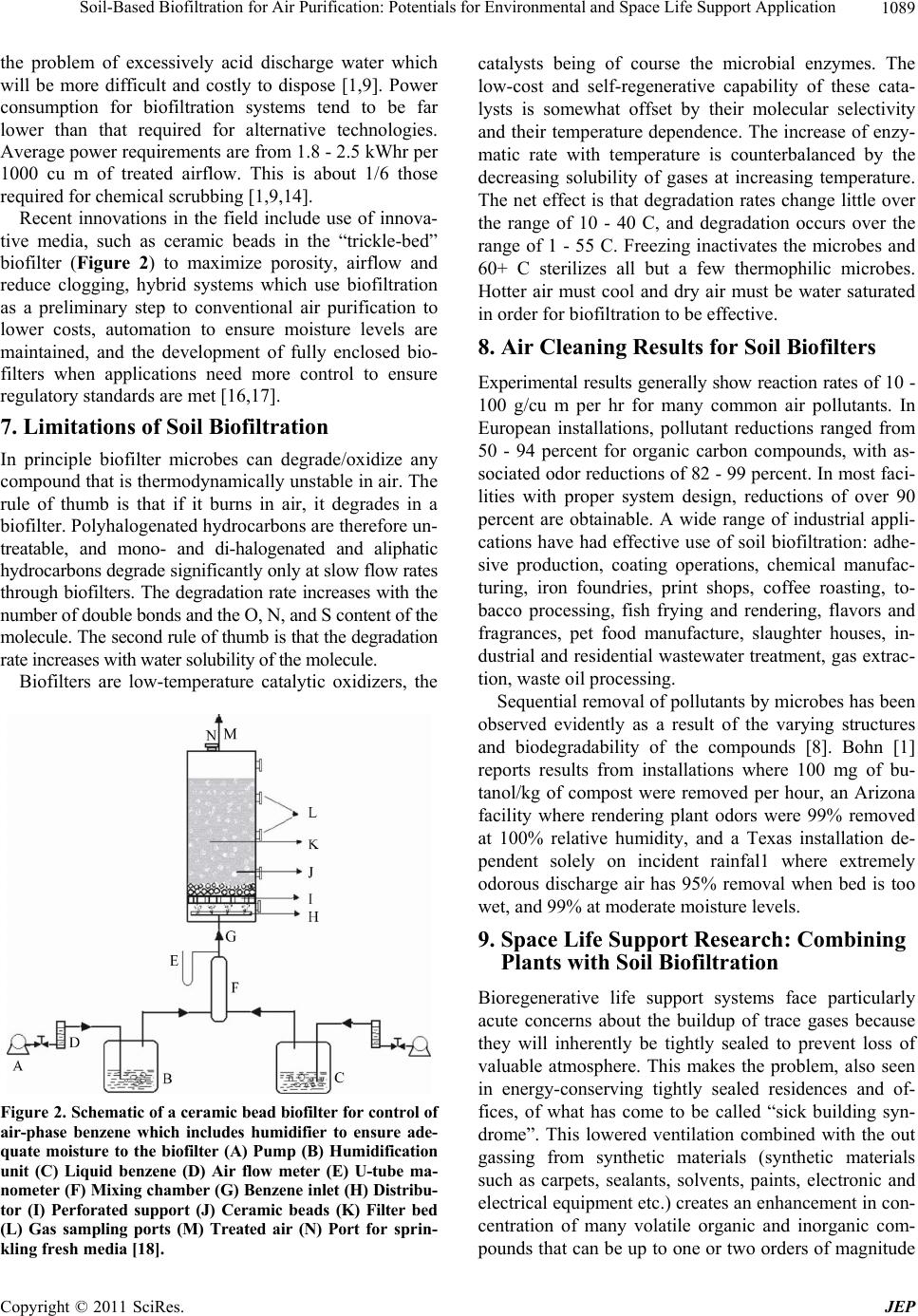

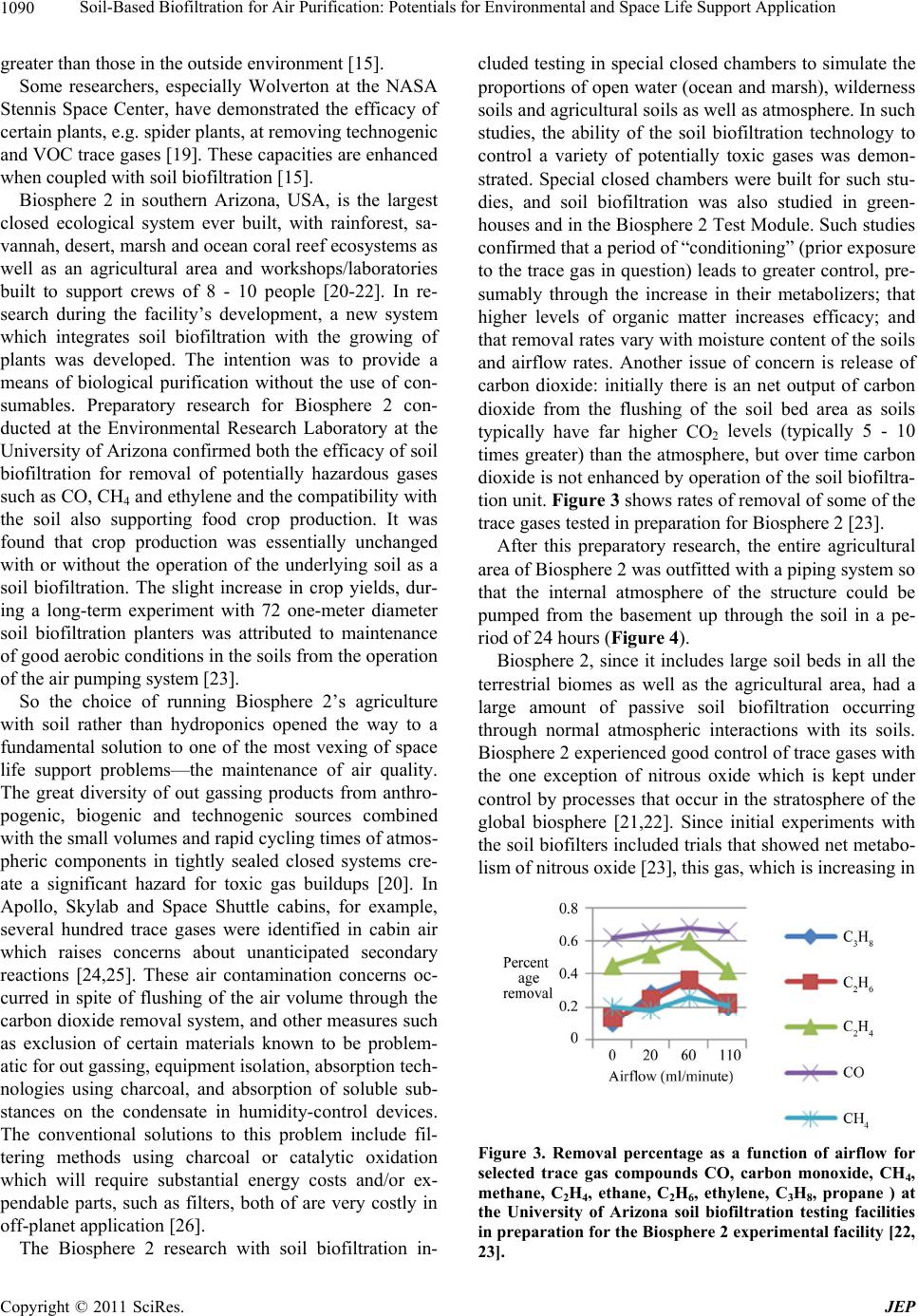

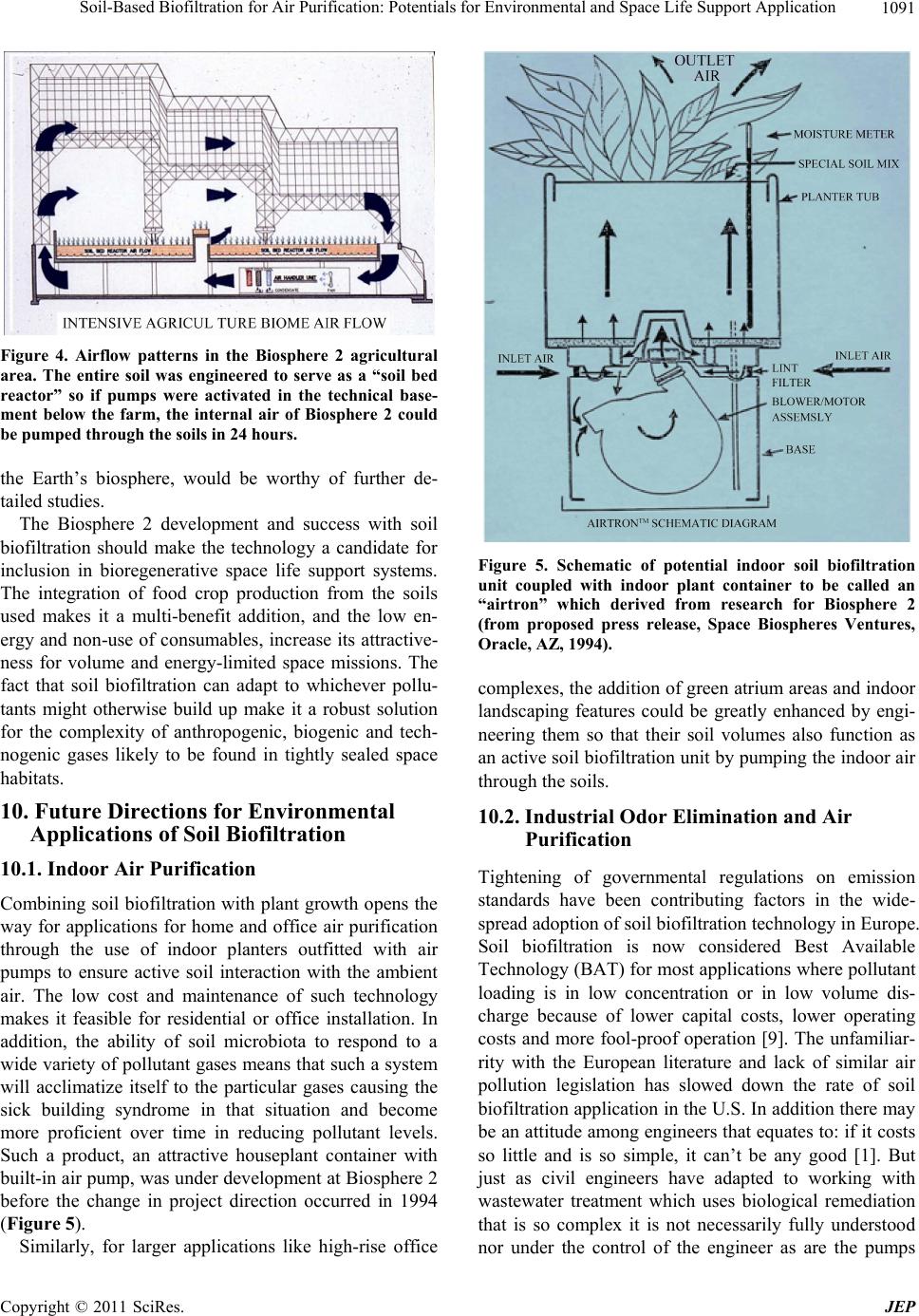

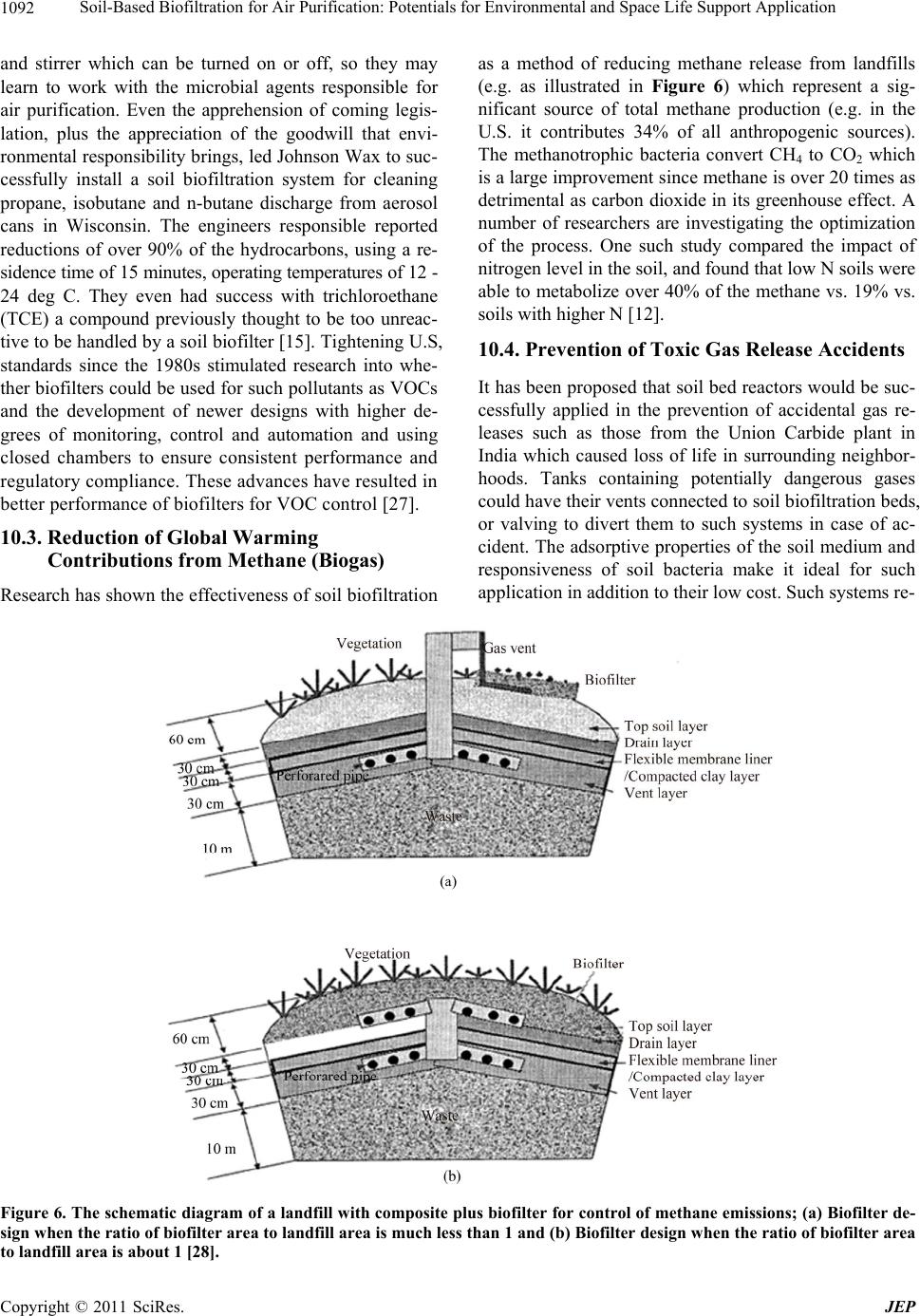

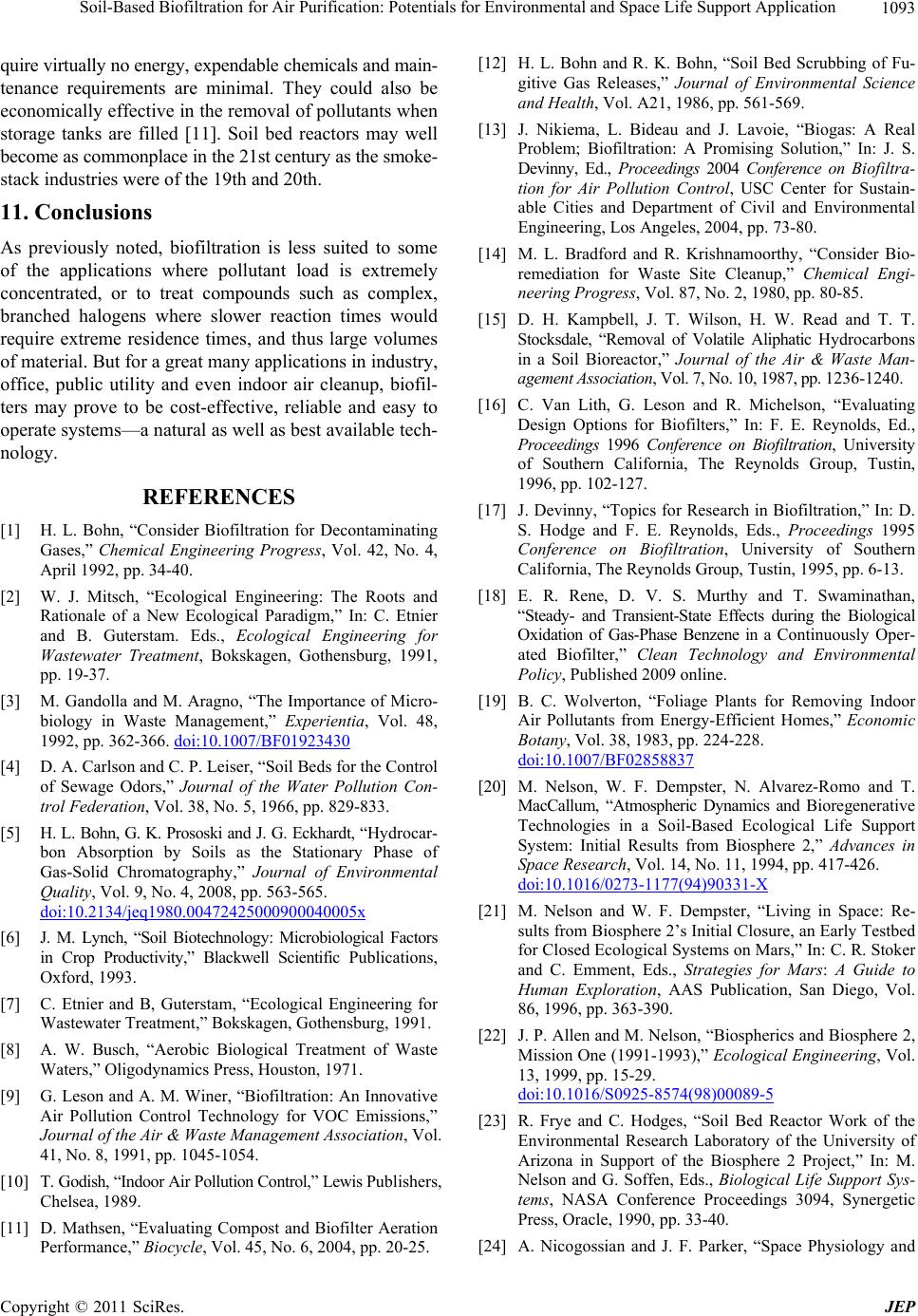

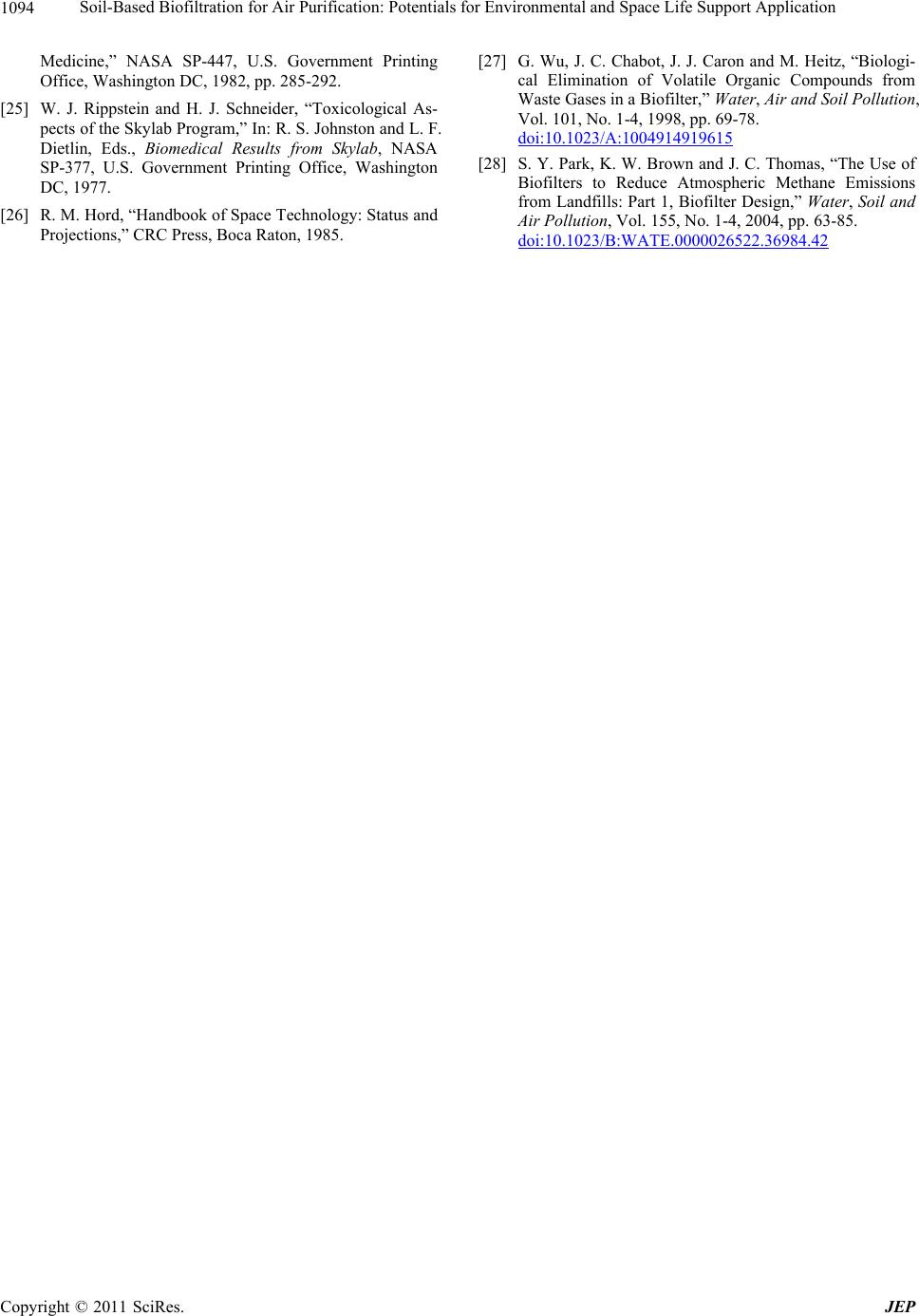

|