A Comparative Study of Bisphenol-A, Hydantoin and Cyanuric Acid Based Epoxy Resins Using XRD1517

Figure 1. Hydantoin, showing the presence of 2N atoms in

its structure.

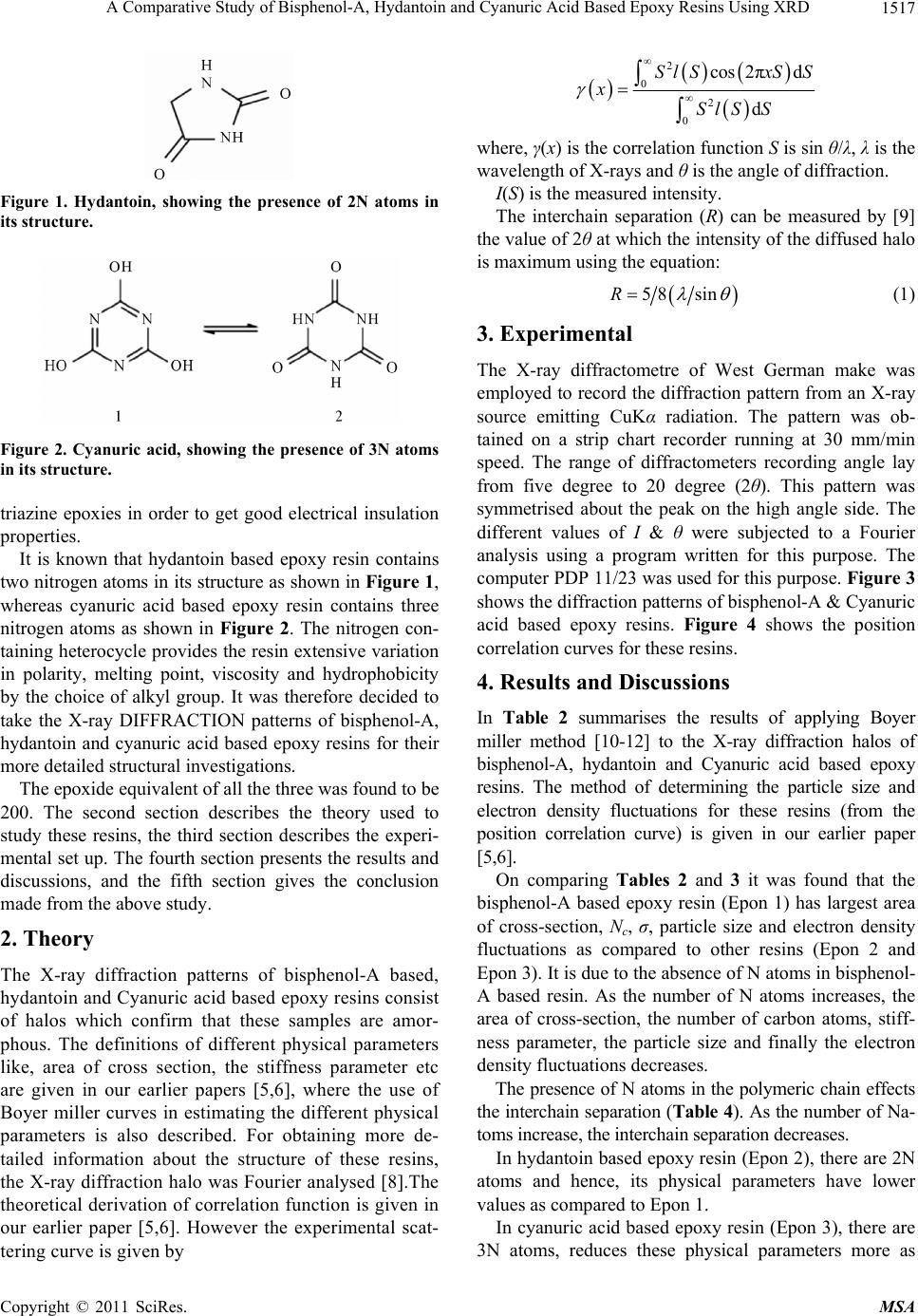

Figure 2. Cyanuric acid, showing the presence of 3N atoms

in its structure.

triazine epoxies in order to get good electrical insulation

properties.

It is known that hydantoin based epoxy resin contains

two nitrogen atoms in its structure as shown in Figure 1,

whereas cyanuric acid based epoxy resin contains three

nitrogen atoms as shown in Figure 2. The nitrogen con-

taining heterocycle provides the resin extensive variation

in polarity, melting point, viscosity and hydrophobicity

by the choice of alkyl group. It was therefore decided to

take the X-ray DIFFRACTION patterns of bisphenol-A,

hydantoin and cyanuric acid based epoxy resins for their

more detailed structural investigations.

The epoxide equivalent of all the three was found to be

200. The second section describes the theory used to

study these resins, the third section describes the experi-

mental set up. The fourth section presents the results and

discussions, and the fifth section gives the conclusion

made from the above study.

2. Theory

The X-ray diffraction patterns of bisphenol-A based,

hydantoin and Cyanuric acid based epoxy resins consist

of halos which confirm that these samples are amor-

phous. The definitions of different physical parameters

like, area of cross section, the stiffness parameter etc

are given in our earlier papers [5,6], where the use of

Boyer miller curves in estimating the different physical

parameters is also described. For obtaining more de-

tailed information about the structure of these resins,

the X-ray diffraction halo was Fourier analysed [8].The

theoretical derivation of correlation function is given in

our earlier paper [5,6]. However the experimental scat-

tering curve is given by

2

0

2

0

cos 2πd

d

Sl SxSS

x

Sl SS

where, γ(x) is the correlation function S is sin θ/λ, λ is the

wavelength of X-rays and θ is the angle of diffraction.

I(S) is the measured intensity.

The interchain separation (R) can be measured by [9]

the value of 2θ at which the intensity of the diffused halo

is maximum using the equation:

58 sinR

(1)

3. Experimental

The X-ray diffractometre of West German make was

employed to record the diffraction pattern from an X-ray

source emitting CuKα radiation. The pattern was ob-

tained on a strip chart recorder running at 30 mm/min

speed. The range of diffractometers recording angle lay

from five degree to 20 degree (2θ). This pattern was

symmetrised about the peak on the high angle side. The

different values of I & θ were subjected to a Fourier

analysis using a program written for this purpose. The

computer PDP 11/23 was used for this purpose. Figure 3

shows the diffraction patterns of bisphenol-A & Cyanuric

acid based epoxy resins. Figure 4 shows the position

correlation curves for these resins.

4. Results and Discussions

In Table 2 summarises the results of applying Boyer

miller method [10-12] to the X-ray diffraction halos of

bisphenol-A, hydantoin and Cyanuric acid based epoxy

resins. The method of determining the particle size and

electron density fluctuations for these resins (from the

position correlation curve) is given in our earlier paper

[5,6].

On comparing Tables 2 and 3 it was found that the

bisphenol-A based epoxy resin (Epon 1) has largest area

of cross-section, Nc, σ, particle size and electron density

fluctuations as compared to other resins (Epon 2 and

Epon 3). It is due to the absence of N atoms in bisphenol-

A based resin. As the number of N atoms increases, the

area of cross-section, the number of carbon atoms, stiff-

ness parameter, the particle size and finally the electron

density fluctuations decreases.

The presence of N atoms in the polymeric chain effects

the interchain separation (Table 4). As the number of Na-

toms increase, the interchain separation decreases.

In hydantoin based epoxy resin (Epon 2), there are 2N

atoms and hence, its physical parameters have lower

values as compared to Epon 1.

In cyanuric acid based epoxy resin (Epon 3), there are

3N atoms, reduces these physical parameters more as

Copyright © 2011 SciRes. MSA