Product Maintainability Design Method and Support Tool Based on Feature Model

168

.2.2 Mean Preven ti ve Maintenance inspections,

3Time

Preventive maintenance activities such as

calibrations, and tuning keep equipment at a specified

performance level. The objective of a preventive main-

tenance program is to postpone the point at which the

equipment or any of its components wears out or breaks

down.

()()

k

mpi pti

i

mp k

pti

i

TF

T

F

(2)

Tmp is the mean preventive time. Tmpi is the elapsed time

Corrective Maintenance Time nting

for preventive maintenance task i, for i= 1,2,3 . . . . . k.Fpti

is the frequency of preventive maintenance task i, for i

=1, 2, 3 , . . . ,k. k is the number of preventive mainte-

nance tasks.

3.2.3 Median

Mean corrective time is a composite value represe

the arithmetic average of the individual maintenance cy-

cle times. Maintainability is the ability o f a product to be

maintained. Calculation of the median corrective main-

tenance time depends on the distribution describing time

to repair. The median corrective maintenance time for

lognormal distributed repair time is given by

2

/exp( )TT

med mttr

(3)

2

is the variance around the mean val

log

ive Maintenance Time tential

ue of the natural

arithm of repair time.

3.2.4 Maximum Correct

This measures the time required to complete all po

repair activities up to a given percentage, often the 90th

or 95th percentiles. The maximum corrective mainte-

nance time for lognormal distributed is

antilog(

mcm m

TTk)

(4)

Tmcm is th e maximum corrective maintenance time. Tm is

the mean of the logarithms of the repair times.

is the

standard deviation of the logarithms of repair ties. k is

equal to 1.28 or 1.65 for the 90th and 95th percentiles.

3.2.5 Mean Mai ntenance Downtime

m

restore equipment

(5)

Tmmd is the mean maintenance down

ad ld

repair, beginning at time t = 0, will be

aintainability function,

t is time.fr(t) is the probability density function of the

repair time.

ipment can be reached for service, replace-

important

of

ility can lead to

. For example, a

a

Accessibility Value

This is the total time needed either to

to a specified performance level or to maintain it at that

level of performance. Thus it includes active corrective

and preventive maintenance times, administrative and

logistic delay times.

mm

T

dmam adld

TTT

time. Tmam is the

mean active maintenance time, or mean time required to

conduct corrective and preventive maintenance related

tasks. T is the administrative delay time. T is the lo-

3.2.6 Maintenance Function

The maintainability functions are used to predict the

probability that a

gistic delay time.

accomplished in a time t. The m

m(t) for any distribution is expressed by

0

()

t

tr

mftdt (6)

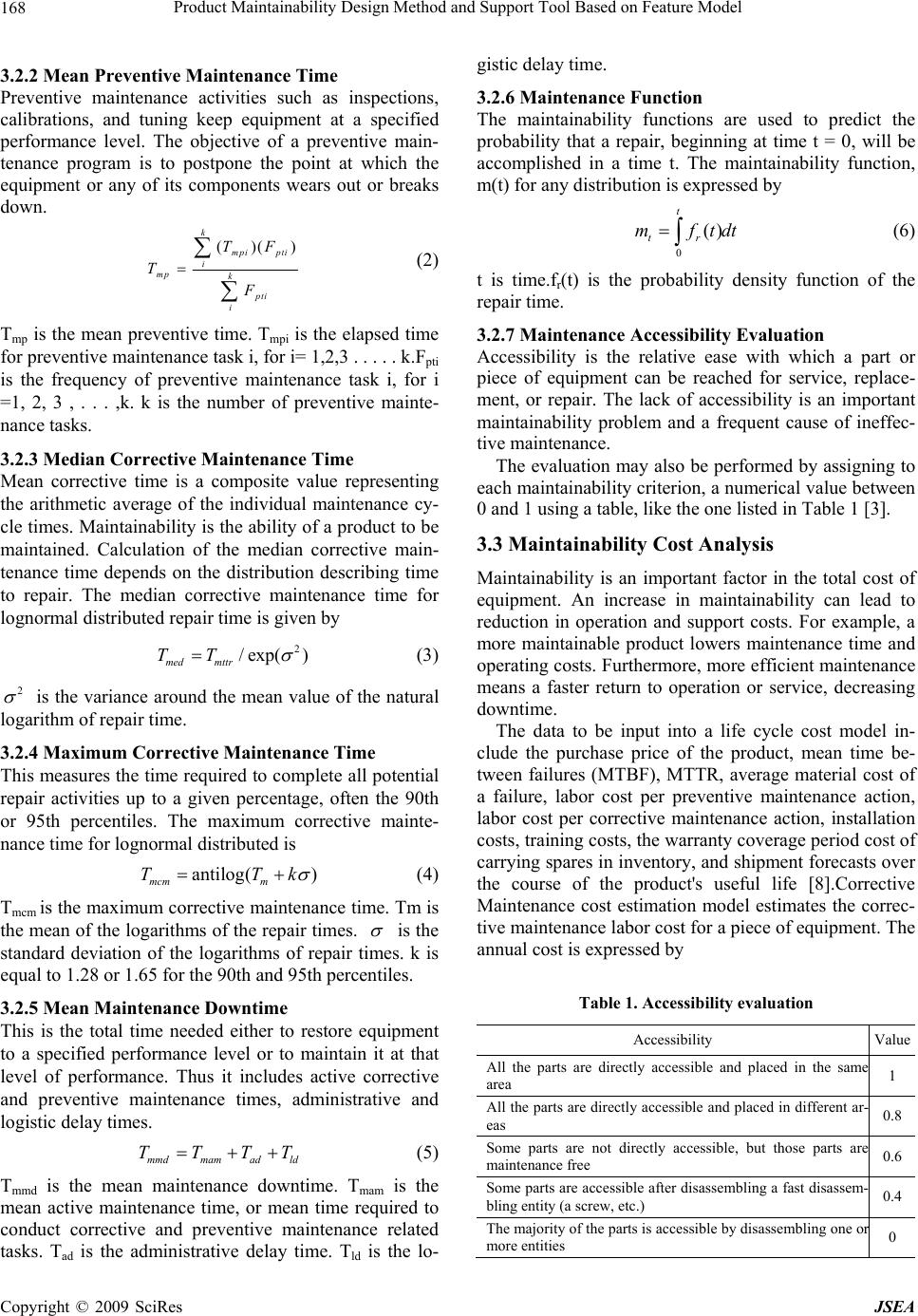

3.2.7 Maintenance Accessibili ty Eval u ation

Accessibility is the relative ease with which a part or

piece of equ

ment, or repair. The lack of accessibility is an

maintainability problem and a frequent cause of ineffec-

tive maintenance.

The evaluation may also be performed by assigning to

each maintainability criterion, a numerical value between

0 and 1 using a table, lik e the one listed in Table 1 [3].

3.3 Maintainability Cost Analysis

Maintainability is an important factor in the total cost

equipment. An increase in maintainab

reduction in operation and support costs

more maintainable product lowers maintenance time and

operating costs. Furthermore, more efficient maintenance

means a faster return to operation or service, decreasing

downtime.

The data to be input into a life cycle cost model in-

clude the purchase price of the product, mean time be-

tween failures (MTBF), MTTR, average material cost of

failure, labor cost per preventive maintenance action,

labor cost per corrective maintenance action, installation

costs, training costs, the warranty coverage period cost of

carrying spares in inventory, and shipment forecasts over

the course of the product's useful life [8].Corrective

Maintenance cost estimation model estimates the correc-

tive maintenance labor cost for a piece of equipment. The

annual cost is expressed by

Table 1. Accessibility evaluation

All the parts ae same

area 1

re directly accessible and placed in th

All the parts are directlerent ar-y accessible and placed in diff

eas 0.8

Some parts are not directly accessible, but those parts are

maintenance free 0.6

Some parts are accessible after disassembling a fast disassem-

bling entity (a screw, etc.) 0.4

The majority of the parts is accessible by disassembling one o

more entities 0

Copyright © 2009 SciRes JSEA