Paper Menu >>

Journal Menu >>

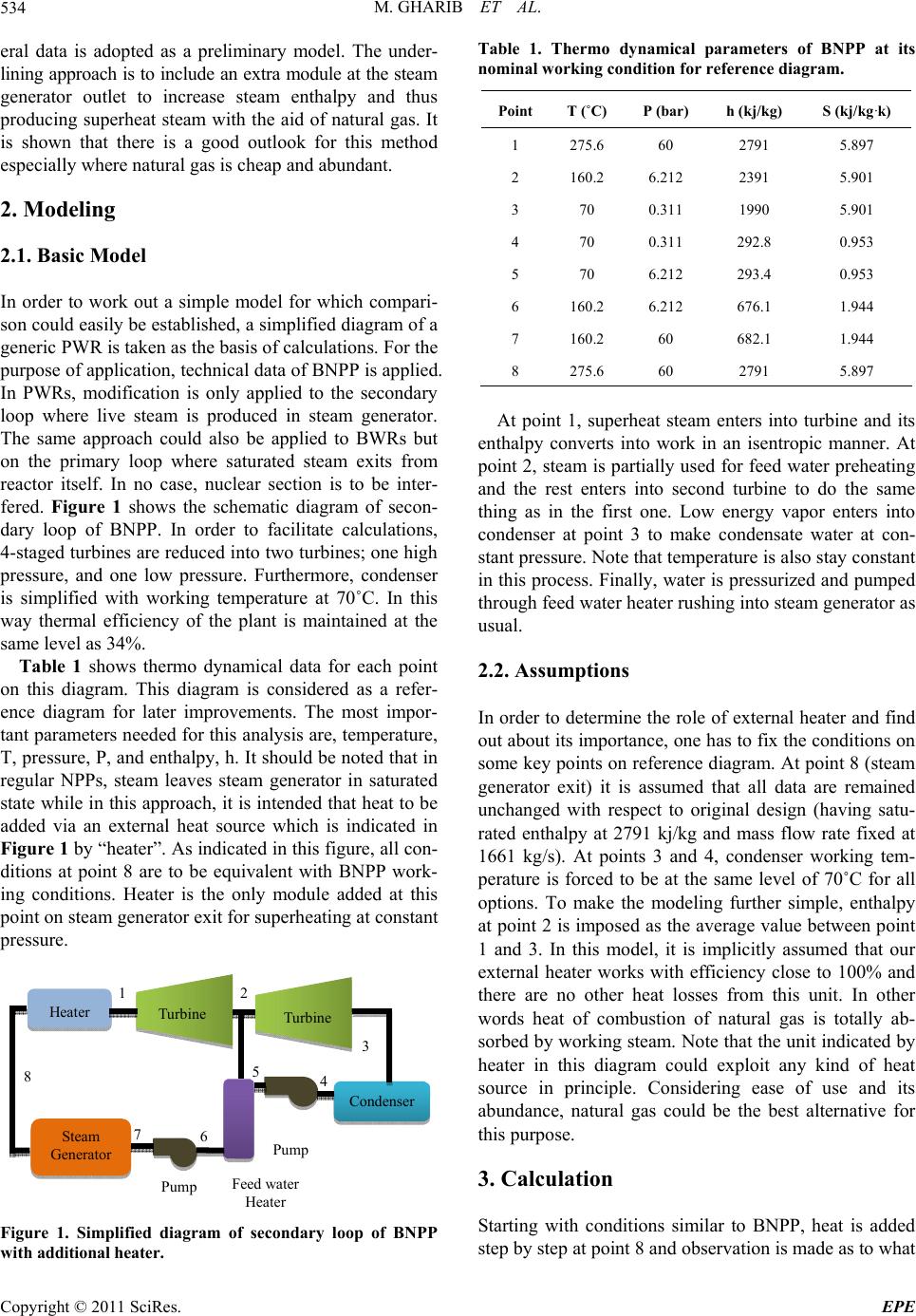

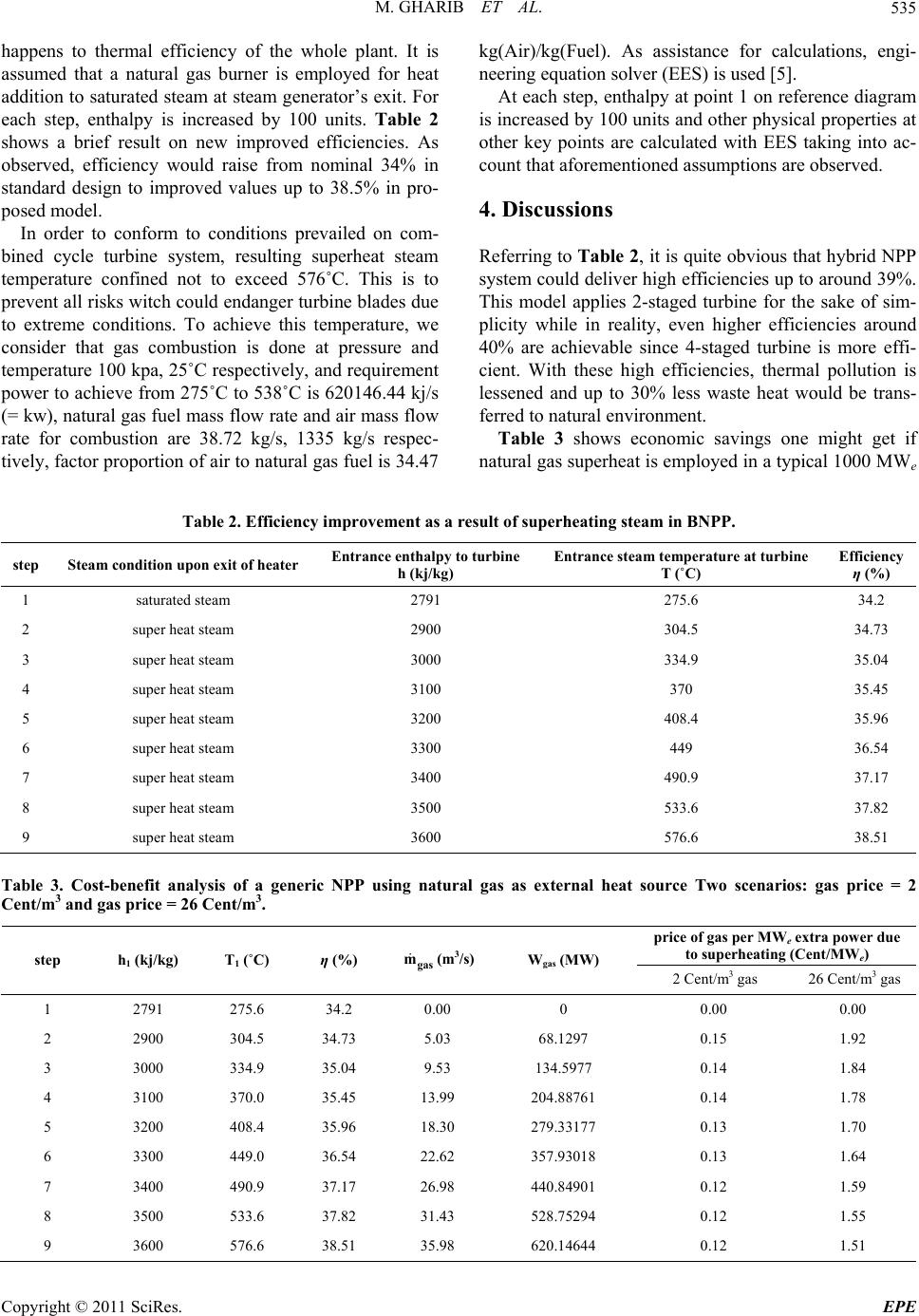

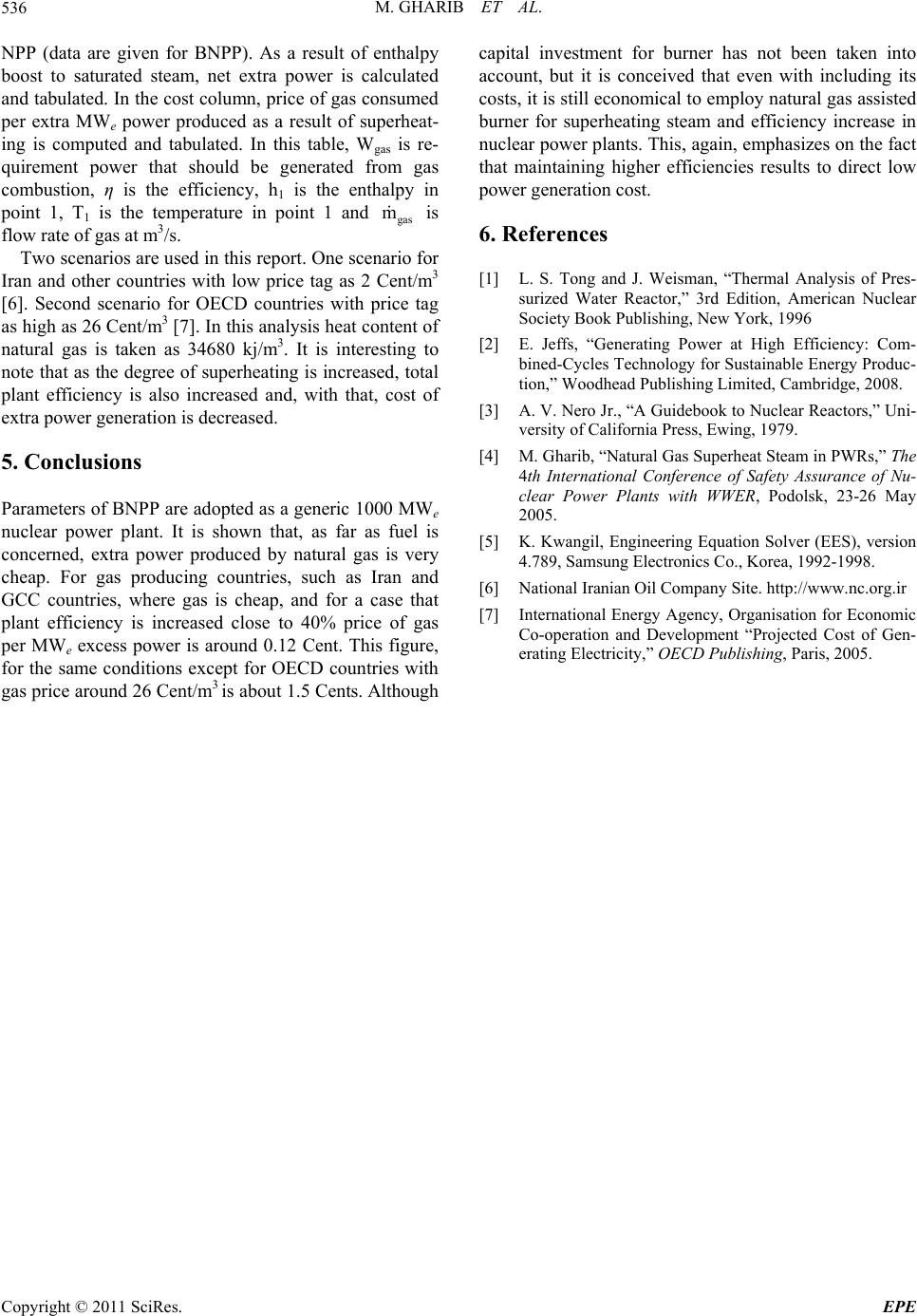

Energy and Power Engineering, 2011, 3, 533-536 doi:10.4236/epe.2011.34065 Published Online September 2011 (http://www.SciRP.org/journal/epe) Copyright © 2011 SciRes. EPE Efficiency Upgrade in PWRs Morteza Gharib1, Abdolazim Yaghooti1, Majid Oloomi Buygi2 1Amirkabir University of Technology, Tehran, Iran 2Ferdowsi University of Mashhad, Mashhad, Iran E-mail: {mgharib,ayaghooti}@aut.ac.ir Received April 25, 2011; revised May 28, 2011; accepted June 13, 2011 Abstract Most of the light water reactor power plants now operating or under construction use pressurized-water re- actor (PWR). They are suffering of relatively low thermal efficiency which is around 33%. This would not only have a negative impact economically but also incurs environmental burden in terms of thermal pollution. In this paper, nuclear steam supply system of a typical PWR has been taken into consideration using 1000 MWe Bushehr nuclear power plant (BNPP) data. It is shown thermal efficiency could conceivably be in- creased by superheating live steam with natural gas up to around 40%, competing with similar fossil-fueled power plants. It is further shown that fuel cost (natural gas) as low as 0.12 Cent/MWe, extra power generated is feasible. Keywords: Upgrade Efficiency, Nuclear Power Plant, PWR 1. Introduction Basic human needs can be met only through industrial growth, which depends to a great extent on energy sup- ply. The large increase in population during the last few decades and the spurt in industrial growth have placed tremendous burden on the electrical utility industry and process plants producing chemicals, petrochemicals, and other essential commodities, resulting in the need for additional capacity in the areas of power and steam gen- eration throughout the world. Steam is used in nearly every industry, and it is well known that steam genera- tors and heat recovery boilers are vital to power and process plants. It is no wonder that with rising fuel and energy costs engineers in these fields are working on innovative methods to generate electricity, improve en- ergy utilization in these plants, recover en ergy efficiently from various waste gas sources, and simultaneously minimize the impact these processes have on environ- mental pollution and the emission of harmful gases to the atmosphere. It is a common practice in fossil-fueled power plants to boost live steam entering turbine by superheating it. This would not only increase its thermal efficiency but also this reduces the problem of blade erosion and in- creases the turbine efficiency in actual cycles. Moreover, this means that less heat would be injected to an already thermally polluted environment [1,2]. Nuclear power plants (NPP), in contrast with fossil-fueled power plant, contribute their power to the working fluid through a solid substance known as nuclear fuel. This obviously prevents approach to high temperatures and thus high thermal efficiencies. Therefore approaching to a higher thermal efficiency for NPPs is very attractive. There are several approaches to accomplish this. One approach to achieve high temperatures, using gas cooled reactors which employing ceramic, but still solid, nuclear fuels such as dispersed UC fuels within graphite bed [3]. Therefore high operating temperatures is possible thanks to ceramic and graphite high melting points. Currently, light water reactors (LWR) are the most common type o f operational reactors in nuclear industry worldwide, among them pressurized water reactors (PWR) are most prominent [3]. Thus, for the time being, the easiest ap- proach is to improve existing reactors. Since fuel and other structural materials in these reactors are pushed at their extreme working conditions, therefore attention may only be restricted to the working fluid in PWRs. A chronic problem with PW Rs, as well as with boiling wa- ter reactors (BWR), is that steam production is in satu- rated state. Thus, the very first step on improving thermo dynamical cycle of such reactors is to boost live steam into a superheating state. This could be achieved by us- ing any form of external heat source economically available, including natural gas [4]. In the following, BNPP is taken as a generic 1000 MWe NPP and its gen-  M. GHARIB ET AL. 534 eral data is adopted as a preliminary model. The under- lining approach is to include an extra module at the steam generator outlet to increase steam enthalpy and thus producing superheat steam with the aid of natural gas. It is shown that there is a good outlook for this method especially where natural gas is cheap and abundant. 2. Modeling 2.1. Basic Model In order to work out a simple model for which compari- son could easily be established, a simplified diagram of a generic PWR is taken as the basis of calculations. For the purpose of application, technical data of BNPP is applied. In PWRs, modification is only applied to the secondary loop where live steam is produced in steam generator. The same approach could also be applied to BWRs but on the primary loop where saturated steam exits from reactor itself. In no case, nuclear section is to be inter- fered. Figure 1 shows the schematic diagram of secon- dary loop of BNPP. In order to facilitate calculations, 4-staged turbines are red uced into two turb ines; one high pressure, and one low pressure. Furthermore, condenser is simplified with working temperature at 70˚C. In this way thermal efficiency of the plant is maintained at the same level as 34%. Table 1 shows thermo dynamical data for each point on this diagram. This diagram is considered as a refer- ence diagram for later improvements. The most impor- tant parameters needed for this analysis are, temperature, T, pressure, P, and enthalpy, h. It should be noted that in regular NPPs, steam leaves steam generator in saturated state while in this approach, it is intended that heat to be added via an external heat source which is indicated in Figure 1 by “heater”. As indicated in this figure, all con- ditions at point 8 are to be equivalent with BNPP work- ing conditions. Heater is the only module added at this point on steam generator exit for superheating at constant pressure. Condenser Turbine Steam Generator Heater Pump Pump Feed water Heater 4 7 Turbine 6 5 3 2 1 8 Figure 1. Simplified diagram of secondary loop of BNPP with additional heater. Table 1. Thermo dynamical parameters of BNPP at its nominal working condition for reference diagram. Point T (˚C) P (bar) h (kj/kg) S (kj/kg·k) 1 275.6 60 2791 5.897 2 160.2 6.212 2391 5.901 3 70 0.311 1990 5.901 4 70 0.311 292.8 0.953 5 70 6.212 293.4 0.953 6 160.2 6.212 676.1 1.944 7 160.2 60 682.1 1.944 8 275.6 60 2791 5.897 At point 1, superheat steam enters into turbine and its enthalpy converts into work in an isentropic manner. At point 2, steam is partially used for feed water preheating and the rest enters into second turbine to do the same thing as in the first one. Low energy vapor enters into condenser at point 3 to make condensate water at con- stant pressure. Note that temperature is also stay constant in this process. Finally, water is pressurized and pumped through feed water heater rushing in to steam generator as usual. 2.2. Assumptions In order to determine the role of external heater and find out about its importance, one has to fix the conditions on some key points on reference diagram. At point 8 (steam generator exit) it is assumed that all data are remained unchanged with respect to original design (having satu- rated enthalpy at 2791 kj/kg and mass flow rate fixed at 1661 kg/s). At points 3 and 4, condenser working tem- perature is forced to be at the same level of 70˚C for all options. To make the modeling further simple, enthalpy at point 2 is imposed as the average value between point 1 and 3. In this model, it is implicitly assumed that our external heater works with efficiency close to 100% and there are no other heat losses from this unit. In other words heat of combustion of natural gas is totally ab- sorbed by w orking steam. Note that the unit indicated by heater in this diagram could exploit any kind of heat source in principle. Considering ease of use and its abundance, natural gas could be the best alternative for this purpose. 3. Calculation Starting with conditions similar to BNPP, heat is added step by step at point 8 and observation is made as to what Copyright © 2011 SciRes. EPE  M. GHARIB ET AL. Copyright © 2011 SciRes. EPE 535 happens to thermal efficiency of the whole plant. It is assumed that a natural gas burner is employed for heat addition to satu rated steam at steam generator’s exit. For each step, enthalpy is increased by 100 units. Table 2 shows a brief result on new improved efficiencies. As observed, efficiency would raise from nominal 34% in standard design to improved values up to 38.5% in pro- posed model. In order to conform to conditions prevailed on com- bined cycle turbine system, resulting superheat steam temperature confined not to exceed 576˚C. This is to prevent all risks witch could endanger turbine blades due to extreme conditions. To achieve this temperature, we consider that gas combustion is done at pressure and temperature 100 kpa, 25˚C respectively, and requirement power to achieve from 275˚C to 538˚C is 620146.4 4 kj/s (= kw), natural gas fuel mass flow rate and air mass flow rate for combustion are 38.72 kg/s, 1335 kg/s respec- tively, factor propor tion of air to natural g as fuel is 34.47 kg(Air)/kg(Fuel). As assistance for calculations, engi- neering equation solver (EES) is used [5]. At each step, enthalpy at point 1 on reference diagram is increased by 100 units and other physical properties at other key points are calculated with EES taking into ac- count that aforementioned assumptions are observed. 4. Discussions Referring to Table 2, it is quite obvious that hybrid NPP system could deliver high ef ficiencies up to around 39%. This model applies 2-staged turbine for the sake of sim- plicity while in reality, even higher efficiencies around 40% are achievable since 4-staged turbine is more effi- cient. With these high efficiencies, thermal pollution is lessened and up to 30% less waste heat would be trans- ferred to natural environment. Table 3 shows economic savings one might get if natural gas superheat is employed in a typical 1000 MWe Table 2. Efficiency improvement as a result of superheating steam in BNPP. step Steam condition upon exit of heater Entrance enthalpy to turbine h (kj/kg) Entrance steam temperature at turbine T (˚C) Efficiency η (%) 1 saturated steam 2791 275.6 34.2 2 super heat steam 2900 304.5 34.73 3 super heat steam 3000 334.9 35.04 4 super heat steam 3100 370 35.45 5 super heat steam 3200 408.4 35.96 6 super heat steam 3300 449 36.54 7 super heat steam 3400 490.9 37.17 8 super heat steam 3500 533.6 37.82 9 super heat steam 3600 576.6 38.51 Table 3. Cost-benefit analysis of a generic NPP using natural gas as external heat source Two scenarios: gas price = 2 Cent/m3 and gas price = 26 Cent/m3. price of gas per MWe extra power due to superheating (Cent/MWe) step h1 (kj/kg) T1 (˚C) η (%) gas m(m3/s) Wgas (MW) 2 Cent/m3 ga s 26 Cent/m3 gas 1 2791 275.6 34.2 0.00 0 0.00 0.00 2 2900 304.5 34.73 5.03 68.1297 0.15 1.92 3 3000 334.9 35.04 9.53 134.5977 0.14 1.84 4 3100 370.0 35.45 13.99 204.88761 0.14 1.78 5 3200 408.4 35.96 18.30 279.33177 0.13 1.70 6 3300 449.0 36.54 22.62 357.93018 0.13 1.64 7 3400 490.9 37.17 26.98 440.84901 0.12 1.59 8 3500 533.6 37.82 31.43 528.75294 0.12 1.55 9 3600 576.6 38.51 35.98 620.14644 0.12 1.51  M. GHARIB ET AL. Copyright © 2011 SciRes. EPE 536 NPP (data are given for BNPP). As a result of enthalpy boost to saturated steam, net extra power is calculated and tabulated. In the cost column, price of gas consumed per extra MWe power produced as a result of superheat- ing is computed and tabulated. In this table, Wgas is re- quirement power that should be generated from gas combustion, η is the efficiency, h1 is the enthalpy in point 1, T1 is the temperature in point 1 and is flow rate of gas at m3/s. gas m Two scenarios are used in this report. One scenario for Iran and other countries with low price tag as 2 Cent/m3 [6]. Second scenario for OECD countries with price tag as high as 26 Cent/m3 [7]. In this analysis heat content of natural gas is taken as 34680 kj/m3. It is interesting to note that as the degree of superheating is increased, total plant efficiency is also increased and, with that, cost of extra power ge ner atio n is decreased. 5. Conclusions Parameters of BNPP are adopted as a generic 1000 MWe nuclear power plant. It is shown that, as far as fuel is concerned, extra power produced by natural gas is very cheap. For gas producing countries, such as Iran and GCC countries, where gas is cheap, and for a case that plant efficiency is increased close to 40% price of gas per MWe excess power is around 0.12 Cent. This figure, for the same conditions except for OECD countries with gas price around 26 Cent/m3 is a bou t 1. 5 Ce nts. Although capital investment for burner has not been taken into account, but it is conceived that even with including its costs, it is still economical to employ natural gas assisted burner for superheating steam and efficiency increase in nuclear power plants. This, again, emphasizes on the fact that maintaining higher efficiencies results to direct low power gene rat i on cos t . 6. References [1] L. S. Tong and J. Weisman, “Thermal Analysis of Pres- surized Water Reactor,” 3rd Edition, American Nuclear Society Book Publishing, New York, 1996 [2] E. Jeffs, “Generating Power at High Efficiency: Com- bined-Cycles Technology for Sustainable Energy Produc- tion,” Woodhead Publishing Limited, Cambridge, 2008. [3] A. V. Nero Jr., “A Guidebook to Nuclear Reactors,” Uni- versity of California Press, Ewing, 1979. [4] M. Gharib, “Natural Gas Superheat Steam in PWRs,” The 4th International Conference of Safety Assurance of Nu- clear Power Plants with WWER, Podolsk, 23-26 May 2005. [5] K. Kwangil, Engineering Equation Solver (EES), version 4.789, Samsung Electronics Co., Korea, 1992-1998. [6] National Iranian Oil Company Site. http://www.nc.org.ir [7] International Energy Agency, Organisation for Economic Co-operation and Development “Projected Cost of Gen- erating Electricity,” OECD Publishing, Paris, 2005. |