H. GULDEMIR405

00.002 0.004 0.006 0.008 0.01

0

t (s)

Vo (Volt)

2

4

6

8

10

12

4

8

12

16

20

24

E

E (V o lt)

V

o

(Volt)

00.002 0.004 0.006 0.0080.01

0

0.05

0.1

0.15

0.2

0.25

0.3

0.35

t (s)

I

(A)

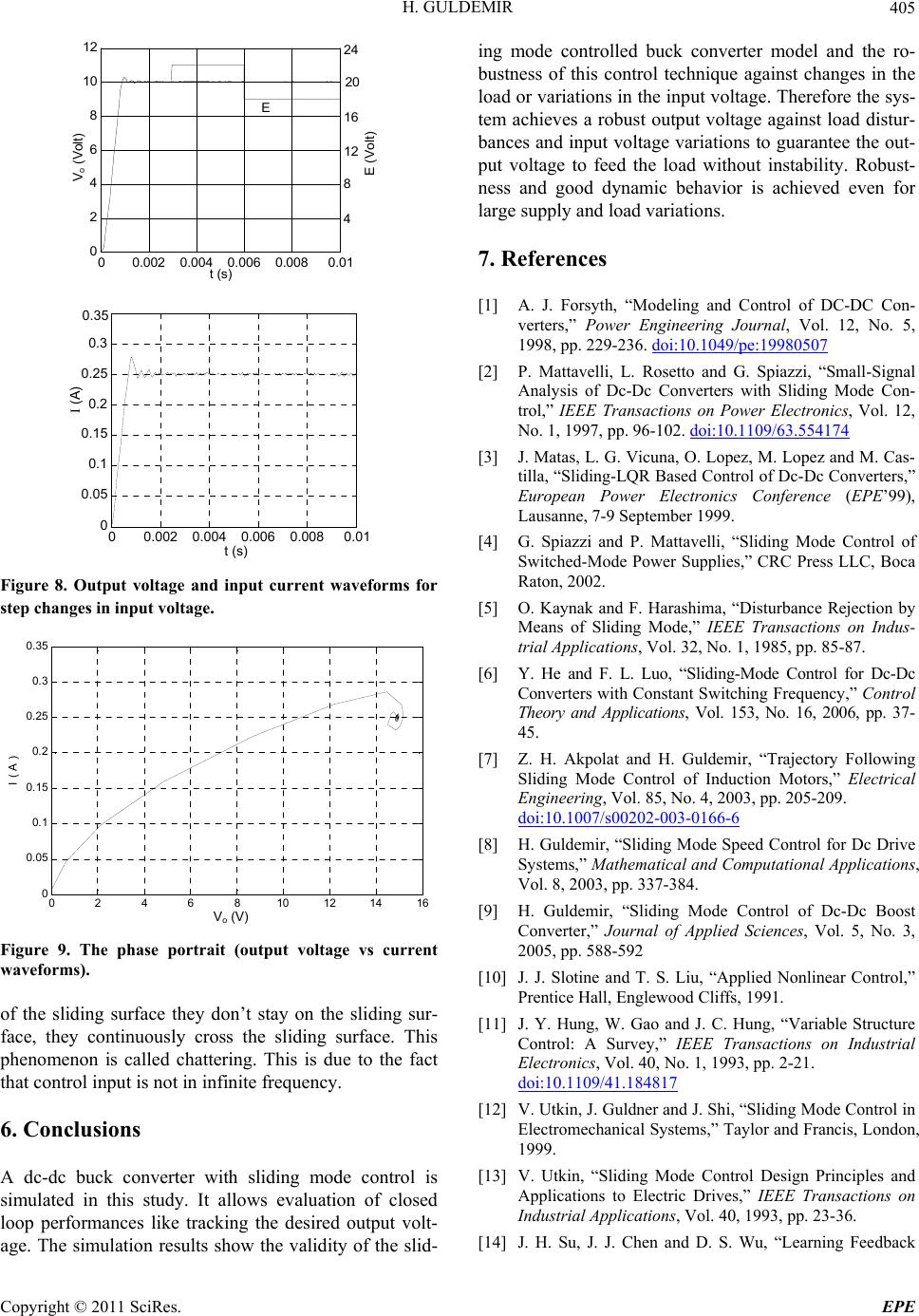

Figure 8. Output voltage and input current waveforms for

step changes in input voltage.

02 46 810 1214 16

0

0.05

0. 1

0.15

0. 2

0.25

0. 3

0.35

Vo ( V )

I ( A )

V

o

(V)

Figure 9. The phase portrait (output voltage vs current

waveforms).

of the sliding surface they don’t stay on the sliding sur-

face, they continuously cross the sliding surface. This

phenomenon is called chattering. This is due to the fact

that control input is not in infinite frequency.

6. Conclusions

A dc-dc buck converter with sliding mode control is

simulated in this study. It allows evaluation of closed

loop performances like tracking the desired output volt-

age. The simulation results show the validity of the slid-

ing mode controlled buck converter model and the ro-

bustness of this control technique against changes in the

load or variations in the input voltage. Therefore the sys-

tem achieves a robust output voltage against load distur-

bances and input voltage variations to guarantee the out-

put voltage to feed the load without instability. Robust-

ness and good dynamic behavior is achieved even for

large supply and load variations.

7. References

[1] A. J. Forsyth, “Modeling and Control of DC-DC Con-

verters,” Power Engineering Journal, Vol. 12, No. 5,

1998, pp. 229-236. doi:10.1049/pe:19980507

[2] P. Mattavelli, L. Rosetto and G. Spiazzi, “Small-Signal

Analysis of Dc-Dc Converters with Sliding Mode Con-

trol,” IEEE Transactions on Power Electronics, Vol. 12,

No. 1, 1997, pp. 96-102. doi:10.1109/63.554174

[3] J. Matas, L. G. Vicuna, O. Lopez, M. Lopez and M. Cas-

tilla, “Sliding-LQR Based Control of Dc-Dc Converters,”

European Power Electronics Conference (EPE’99),

Lausanne, 7-9 September 1999.

[4] G. Spiazzi and P. Mattavelli, “Sliding Mode Control of

Switched-Mode Power Supplies,” CRC Press LLC, Boca

Raton, 2002.

[5] O. Kaynak and F. Harashima, “Disturbance Rejection by

Means of Sliding Mode,” IEEE Transactions on Indus-

trial Applications, Vol. 32, No. 1, 1985, pp. 85-87.

[6] Y. He and F. L. Luo, “Sliding-Mode Control for Dc-Dc

Converters with Constant Switching Frequency,” Control

Theory and Applications, Vol. 153, No. 16, 2006, pp. 37-

45.

[7] Z. H. Akpolat and H. Guldemir, “Trajectory Following

Sliding Mode Control of Induction Motors,” Electrical

Engineering, Vol. 85, No. 4, 2003, pp. 205-209.

doi:10.1007/s00202-003-0166-6

[8] H. Guldemir, “Sliding Mode Speed Control for Dc Drive

Systems,” Mathematical and Computational Applications,

Vol. 8, 2003, pp. 337-384.

[9] H. Guldemir, “Sliding Mode Control of Dc-Dc Boost

Converter,” Journal of Applied Sciences, Vol. 5, No. 3,

2005, pp. 588-592

[10] J. J. Slotine and T. S. Liu, “Applied Nonlinear Control,”

Prentice Hall, Englewood Cliffs, 1991.

[11] J. Y. Hung, W. Gao and J. C. Hung, “Variable Structure

Control: A Survey,” IEEE Transactions on Industrial

Electronics, Vol. 40, No. 1, 1993, pp. 2-21.

doi:10.1109/41.184817

[12] V. Utkin, J. Guldner and J. Shi, “Sliding Mode Control in

Electromechanical Systems,” Taylor and Francis, London,

1999.

[13] V. Utkin, “Sliding Mode Control Design Principles and

Applications to Electric Drives,” IEEE Transactions on

Industrial Applications, Vol. 40, 1993, pp. 23-36.

[14] J. H. Su, J. J. Chen and D. S. Wu, “Learning Feedback

Copyright © 2011 SciRes. EPE