624 H. MORGNER

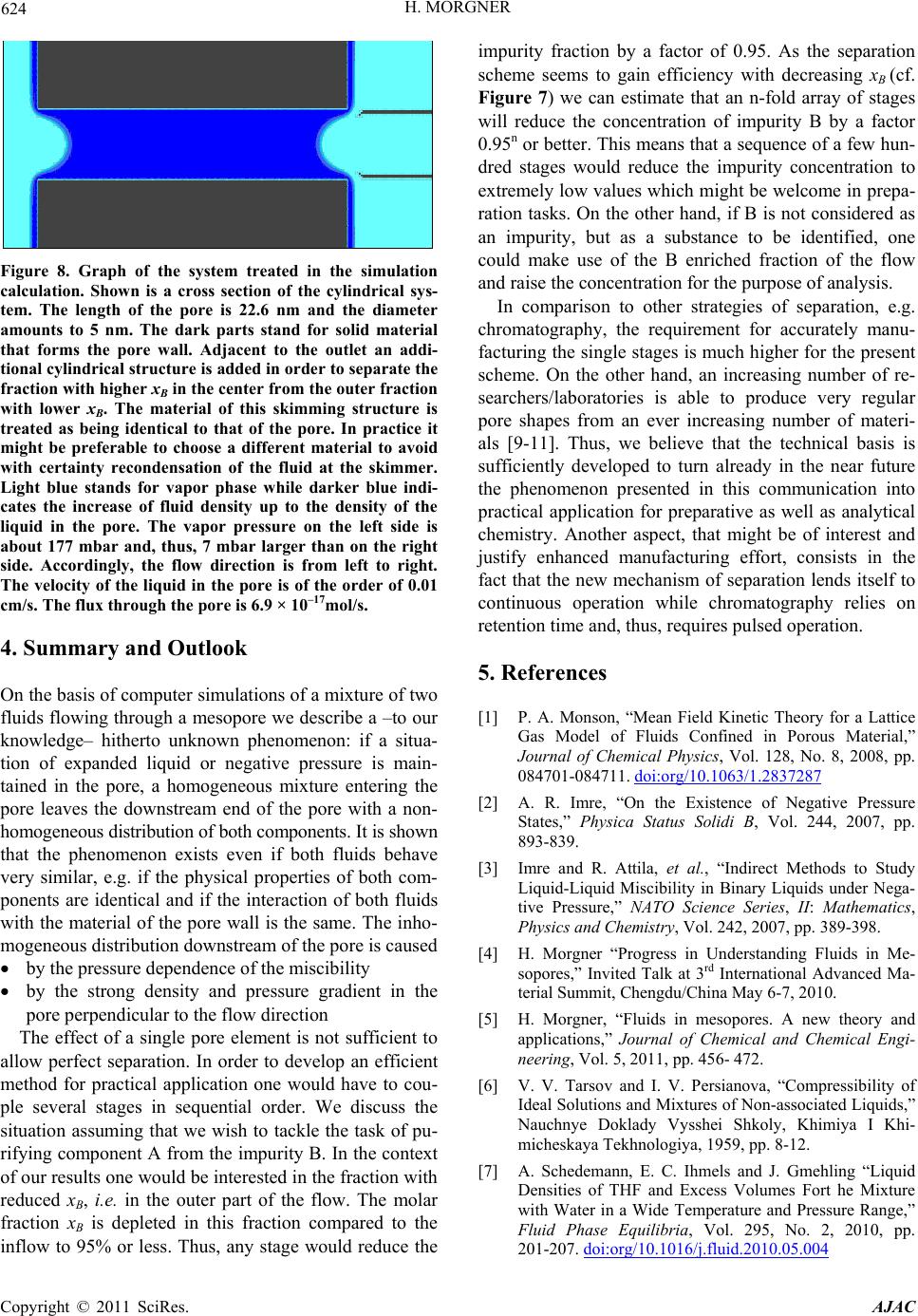

Figure 8. Graph of the system treated in the simulation

calculation. Shown is a cross section of the cylindrical sys-

tem. The length of the pore is 22.6 nm and the diameter

amounts to 5 nm. The dark parts stand for solid material

that forms the pore wall. Adjacent to the outlet an addi-

tional cylindrical structure is added in order to separate the

fraction with higher xB in the center from the outer fraction

with lower xB. The material of this skimming structure is

treated as being identical to that of the pore. In practice it

might be preferable to choose a different material to avoid

with certainty recondensation of the fluid at the skimmer.

Light blue stands for vapor phase while darker blue indi-

cates the increase of fluid density up to the density of the

liquid in the pore. The vapor pressure on the left side is

about 177 mbar and, thus, 7 mbar larger than on the right

side. Accordingly, the flow direction is from left to right.

The velocity of the liquid in the pore is of the order of 0.01

cm/s. The flux through the pore is 6.9 × 10–17mol/s.

4. Summary and Outlook

On the basis of computer simulations of a mixture of two

fluids flowing through a mesopore we describe a –to our

knowledge– hitherto unknown phenomenon: if a situa-

tion of expanded liquid or negative pressure is main-

tained in the pore, a homogeneous mixture entering the

pore leaves the downstream end of the pore with a non-

homogeneous distribution of both components. It is shown

that the phenomenon exists even if both fluids behave

very similar, e.g. if the physical properties of both com-

ponents are identical and if the interaction of both fluids

with the material of the pore wall is the same. The inho-

mogeneous distribution downstream of the pore is caused

by the pressure dependence of the miscibility

by the strong density and pressure gradient in the

pore perpendicular to the flow direction

The effect of a single pore element is not sufficient to

allow perfect separation. In order to develop an efficient

method for practical application one would have to cou-

ple several stages in sequential order. We discuss the

situation assuming that we wish to tackle the task of pu-

rifying component A from the impurity B. In the context

of our results one would be interested in the fraction with

reduced xB, i.e. in the outer part of the flow. The molar

fraction xB is depleted in this fraction compared to the

inflow to 95% or less. Thus, any stage would reduce the

impurity fraction by a factor of 0.95. As the separation

scheme seems to gain efficiency with decreasing xB (cf.

Figure 7) we can estimate that an n-fold array of stages

will reduce the concentration of impurity B by a factor

0.95n or better. This means that a sequence of a few hun-

dred stages would reduce the impurity concentration to

extremely low values which might be welcome in prepa-

ration tasks. On the other hand, if B is not considered as

an impurity, but as a substance to be identified, one

could make use of the B enriched fraction of the flow

and raise the concentration for the purpose of analysis.

In comparison to other strategies of separation, e.g.

chromatography, the requirement for accurately manu-

facturing the single stages is much higher for the present

scheme. On the other hand, an increasing number of re-

searchers/laboratories is able to produce very regular

pore shapes from an ever increasing number of materi-

als [9-11]. Thus, we believe that the technical basis is

sufficiently developed to turn already in the near future

the phenomenon presented in this communication into

practical application for preparative as well as analytical

chemistry. Another aspect, that might be of interest and

justify enhanced manufacturing effort, consists in the

fact that the new mechanism of separation lends itself to

continuous operation while chromatography relies on

retention time and, thus, requires pulsed operation.

5. References

[1] P. A. Monson, “Mean Field Kinetic Theory for a Lattice

Gas Model of Fluids Confined in Porous Material,”

Journal of Chemical Physics, Vol. 128, No. 8, 2008, pp.

084701-084711. doi:org/10.1063/1.2837287

[2] A. R. Imre, “On the Existence of Negative Pressure

States,” Physica Status Solidi B, Vol. 244, 2007, pp.

893-839.

[3] Imre and R. Attila, et al., “Indirect Methods to Study

Liquid-Liquid Miscibility in Binary Liquids under Nega-

tive Pressure,” NATO Science Series, II: Mathematics,

Physics and Chemistry, Vol. 242, 2007, pp. 389-398.

[4] H. Morgner “Progress in Understanding Fluids in Me-

sopores,” Invited Talk at 3rd International Advanced Ma-

terial Summit, Chengdu/China May 6-7, 2010.

[5] H. Morgner, “Fluids in mesopores. A new theory and

applications,” Journal of Chemical and Chemical Engi-

neering, Vol. 5, 2011, pp. 456- 472.

[6] V. V. Tarsov and I. V. Persianova, “Compressibility of

Ideal Solutions and Mixtures of Non-associated Liquids,”

Nauchnye Doklady Vysshei Shkoly, Khimiya I Khi-

micheskaya Tekhnologiya, 1959, pp. 8-12.

[7] A. Schedemann, E. C. Ihmels and J. Gmehling “Liquid

Densities of THF and Excess Volumes Fort he Mixture

with Water in a Wide Temperature and Pressure Range,”

Fluid Phase Equilibria, Vol. 295, No. 2, 2010, pp.

201-207. doi:org/10.1016/j.fluid.2010.05.004

Copyright © 2011 SciRes. AJAC