580 N. MARIE ET AL.

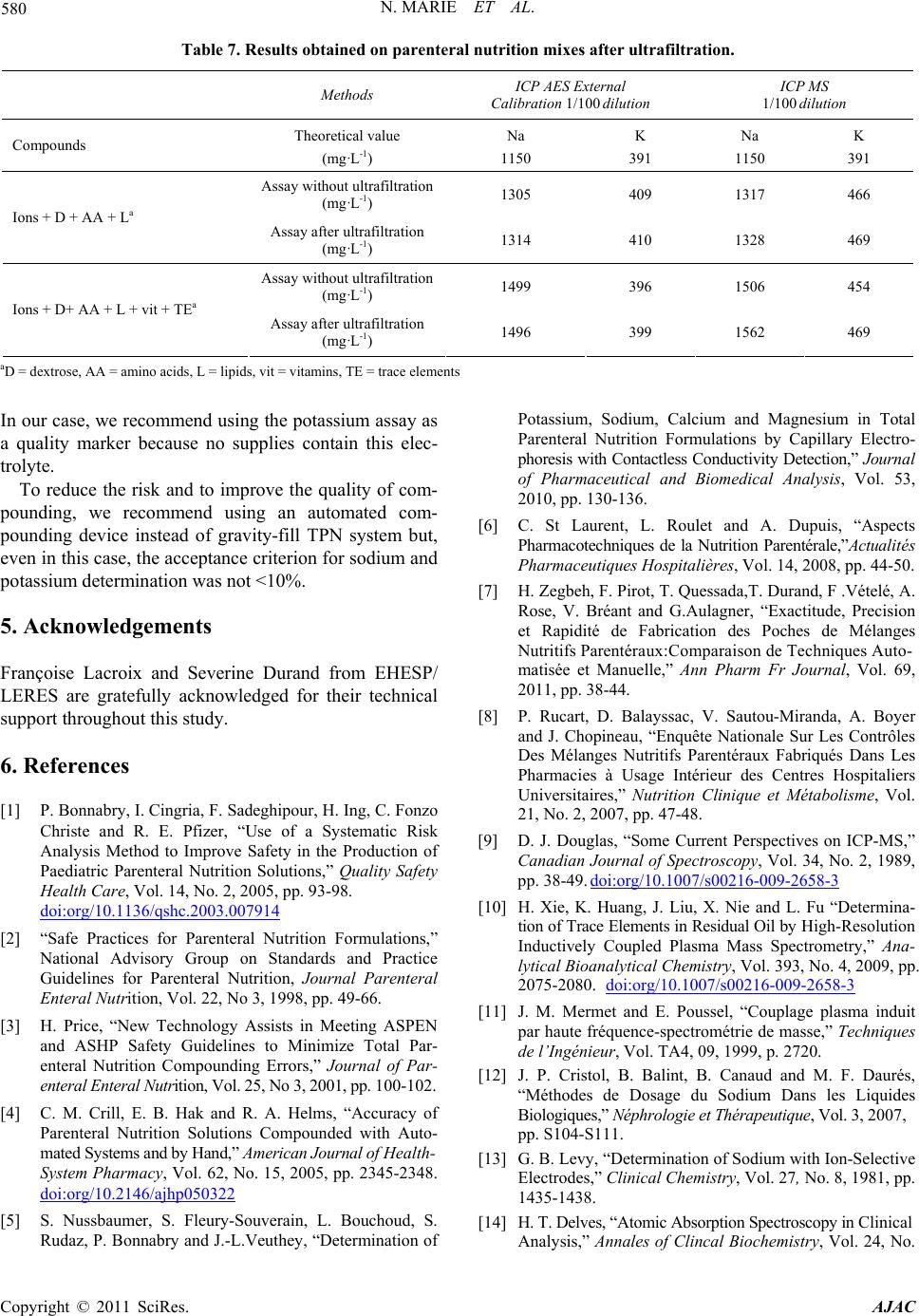

Table 7. Results obtained on parenteral nutrition mixes after ultrafiltration.

Methods ICP AES External

Calibration 1/100 dilution ICP MS

1/100 dilution

Compounds Theoretical value

(mg·L-1)

Na

1150

K

391

Na

1150

K

391

Assay without ultrafiltration

(mg·L-1) 1305 409 1317 466

Ions + D + AA + La Assay after ultrafiltration

(mg·L-1) 1314 410 1328 469

Assay without ultrafiltration

(mg·L-1) 1499 396 1506 454

Ions + D+ AA + L + vit + TEa Assay after ultrafiltration

(mg·L-1) 1496 399 1562 469

aD = dextrose, AA = amino acids, L = lipids, vit = vitamins, TE = trace elements

In our case, we recommend using the potassium assay as

a quality marker because no supplies contain this elec-

trolyte.

To reduce the risk and to improve the quality of com-

pounding, we recommend using an automated com-

pounding device instead of gravity-fill TPN system but,

even in this case, the acceptance criterion for sodium and

potassium determination was not <10%.

5. Acknowledgements

Françoise Lacroix and Severine Durand from EHESP/

LERES are gratefully acknowledged for their technical

support throughou t this study.

6. References

[1] P. Bonnabry, I. Cingria, F. Sadeghipour, H. Ing, C. Fonzo

Christe and R. E. Pfizer, “Use of a Systematic Risk

Analysis Method to Improve Safety in the Production of

Paediatric Parenteral Nutrition Solutions,” Quality Safety

Health Care, Vol. 14, No. 2, 2005, pp. 93-98.

doi:org/10.1136/qshc.2003.007914

[2] “Safe Practices for Parenteral Nutrition Formulations,”

National Advisory Group on Standards and Practice

Guidelines for Parenteral Nutrition, Journal Parenteral

Enteral Nutrition, Vol. 22, No 3, 1998, pp. 49-66.

[3] H. Price, “New Technology Assists in Meeting ASPEN

and ASHP Safety Guidelines to Minimize Total Par-

enteral Nutrition Compounding Errors,” Journal of Par-

enteral Enteral Nutrit i o n, V ol . 2 5, No 3 , 2001, pp. 100-102.

[4] C. M. Crill, E. B. Hak and R. A. Helms, “Accuracy of

Parenteral Nutrition Solutions Compounded with Auto-

mated Systems and by Hand,” American Journal of Health-

System Pharmacy, Vol. 62, No. 15, 2005, pp. 2345-2348.

doi:org/10.2146/ajhp050322

[5] S. Nussbaumer, S. Fleury-Souverain, L. Bouchoud, S.

Rudaz, P. Bonnabry and J.-L.Veuthey, “Determination of

Potassium, Sodium, Calcium and Magnesium in Total

Parenteral Nutrition Formulations by Capillary Electro-

phoresis with Contactless Conduc tivity Detection,” Journal

of Pharmaceutical and Biomedical Analysis, Vol. 53,

2010, pp. 130-136.

[6] C. St Laurent, L. Roulet and A. Dupuis, “Aspects

Pharmacotechniques de la Nutrition Parentérale,”Actualités

Pharmaceutiques Hospitalières, Vol. 14, 2008, pp. 44-50.

[7] H. Zegbeh, F. Pirot, T. Quessada,T. Durand, F .Vételé, A.

Rose, V. Bréant and G.Aulagner, “Exactitude, Precision

et Rapidité de Fabrication des Poches de Mélanges

Nutritifs Parentéraux :C omp a rai so n de Te ch ni que s Aut o -

matisée et Manuelle,” Ann Pharm Fr Journal, Vol. 69,

2011, pp. 38-44.

[8] P. Rucart, D. Balayssac, V. Sautou-Miranda, A. Boyer

and J. Chopineau, “Enquête Nationale Sur Les Contrôles

Des Mélanges Nutritifs Parentéraux Fabriqués Dans Les

Pharmacies à Usage Intérieur des Centres Hospitaliers

Universitaires,” Nutrition Clinique et Métabolisme, Vol.

21, No. 2, 2007, pp. 47-48.

[9] D. J. Douglas, “Some Current Perspectives on ICP-MS,”

Canadian Journal of Spectroscopy, Vol. 34, No. 2, 1989,

pp. 38-49. doi:org/10.1007/s00216-009-2658-3

[10] H. Xie, K. Huang, J. Liu, X. Nie and L. Fu “Determina-

tion of Trace Elements in Re sidual Oil by H i g h- R e so l u ti o n

Inductively Coupled Plasma Mass Spectrometry,” Ana-

lytical Bioanalytical Chemistry, Vol. 393, No. 4, 2009, pp.

2075-2080. doi:org/10.1007/s00216-009-2658-3

[11] J. M. Mermet and E. Poussel, “Couplage plasma induit

par haute fréquence-spectrométrie de masse,” Techniques

de l’Ingénieur, Vol. TA4, 09, 1999, p. 2720.

[12] J. P. Cristol, B. Balint, B. Canaud and M. F. Daurés,

“Méthodes de Dosage du Sodium Dans les Liquides

Biologiques,” Néphrologie et Thérapeutique, V ol . 3, 2007,

pp. S104-S111.

[13] G. B. Levy, “Determination of Sodium with Ion-Selective

Electrodes,” Clinical Chemistry, Vol. 27, No. 8, 1981, pp.

1435-1438.

[14] H. T. Delves, “Atomic Absorption Spectroscopy in Clinical

Analysis,” Annales of Clincal Biochemistry, Vol. 24, No.

Copyright © 2011 SciRes. AJAC