Facile Synthesis and Thermal Stability of Nanocrystalline Molybdenum Carbide1315

0100 200 300 400 500 600 700 800 900

-100

-90

-80

-70

-60

-50

-40

-30

-20

-10

0

Weight/%

Temperature/ oC

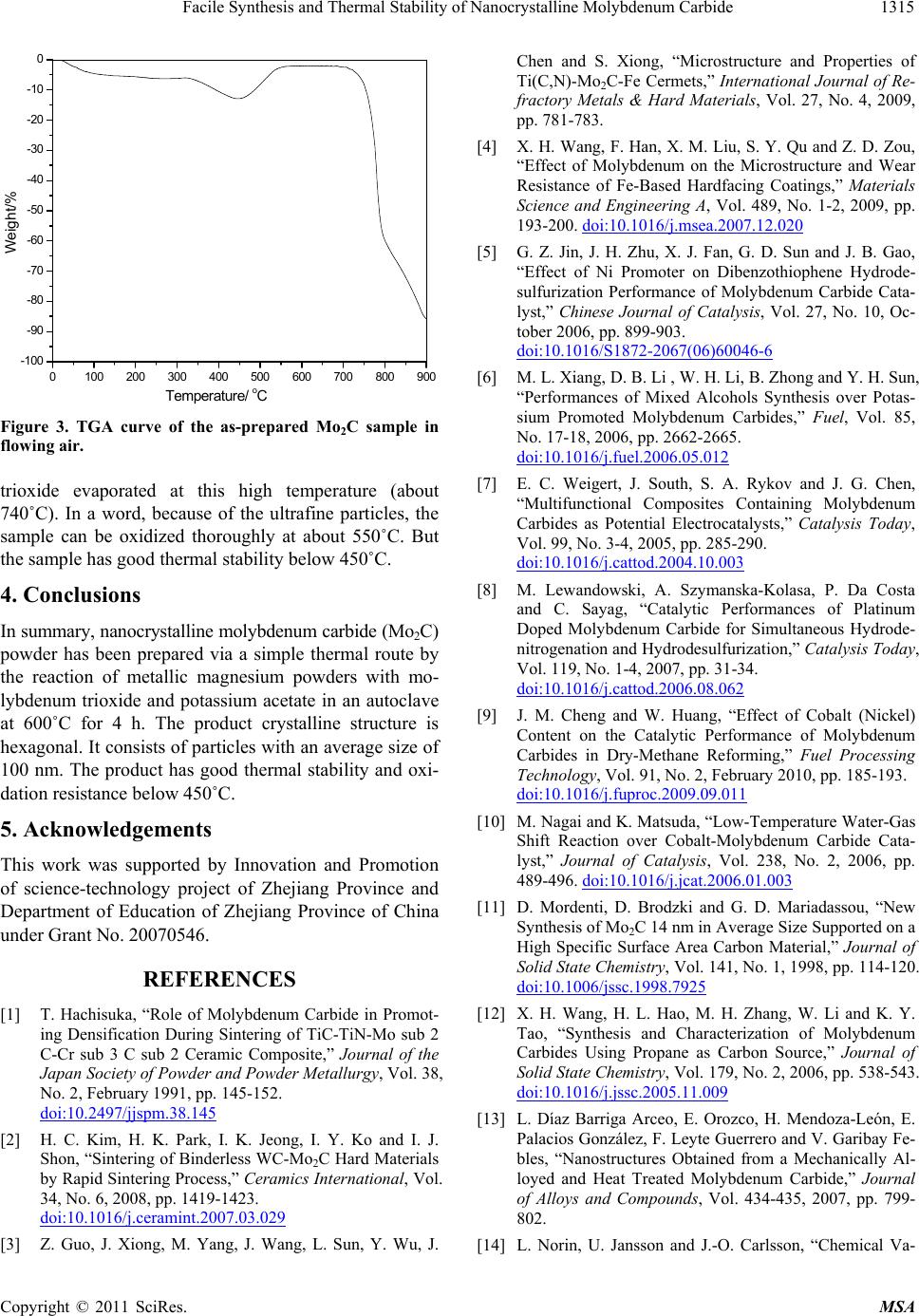

Figure 3. TGA curve of the as-prepared Mo2C sample in

flow ing air.

trioxide evaporated at this high temperature (about

740˚C). In a word, because of the ultrafine particles, the

sample can be oxidized thoroughly at about 550˚C. But

the sample has good thermal stability below 450˚C.

4. Conclusions

In summary, nanocrystalline molybdenum carbide (Mo2C)

powder has been prepared via a simple thermal route by

the reaction of metallic magnesium powders with mo-

lybdenum trioxide and potassium acetate in an autoclave

at 600˚C for 4 h. The product crystalline structure is

hexagonal. It consists of particles with an average size of

100 nm. The product has good thermal stability and oxi-

dation resistance below 450˚C.

5. Acknowledgements

This work was supported by Innovation and Promotion

of science-technology project of Zhejiang Province and

Department of Education of Zhejiang Province of China

under Grant No. 20070546.

REFERENCES

[1] T. Hachisuka, “Role of Molybdenum Carbide in Promot-

ing Densification During Sintering of TiC-TiN-Mo sub 2

C-Cr sub 3 C sub 2 Ceramic Composite,” Journal of the

Japan Society of Powder and Powder Metallurgy, Vol. 38,

No. 2, February 1991, pp. 145-152.

doi:10.2497/jjspm.38.145

[2] H. C. Kim, H. K. Park, I. K. Jeong, I. Y. Ko and I. J.

Shon, “Sintering of Binderless WC-Mo2C Hard Materials

by Rapid Sintering Process,” Ceramics International, Vol.

34, No. 6, 2008, pp. 1419-1423.

doi:10.1016/j.ceramint.2007.03.029

[3] Z. Guo, J. Xiong, M. Yang, J. Wang, L. Sun, Y. Wu, J.

Chen and S. Xiong, “Microstructure and Properties of

Ti(C,N)-Mo2C-Fe Cermets,” International Journal of Re-

fractory Metals & Hard Materials, Vol. 27, No. 4, 2009,

pp. 781-783.

[4] X. H. Wang, F. Han, X. M. Liu, S. Y. Qu and Z. D. Zou,

“Effect of Molybdenum on the Microstructure and Wear

Resistance of Fe-Based Hardfacing Coatings,” Materials

Science and Engineering A, Vol. 489, No. 1-2, 2009, pp.

193-200. doi:10.1016/j.msea.2007.12.020

[5] G. Z. Jin, J. H. Zhu, X. J. Fan, G. D. Sun and J. B. Gao,

“Effect of Ni Promoter on Dibenzothiophene Hydrode-

sulfurization Performance of Molybdenum Carbide Cata-

lyst,” Chinese Journal of Catalysis, Vol. 27, No. 10, Oc-

tober 2006, pp. 899-903.

doi:10.1016/S1872-2067(06)60046-6

[6] M. L. Xiang, D. B. Li , W. H. Li, B. Zhong and Y. H. Sun,

“Performances of Mixed Alcohols Synthesis over Potas-

sium Promoted Molybdenum Carbides,” Fuel, Vol. 85,

No. 17-18, 2006, pp. 2662-2665.

doi:10.1016/j.fuel.2006.05.012

[7] E. C. Weigert, J. South, S. A. Rykov and J. G. Chen,

“Multifunctional Composites Containing Molybdenum

Carbides as Potential Electrocatalysts,” Catalysis Today,

Vol. 99, No. 3-4, 2005, pp. 285-290.

doi:10.1016/j.cattod.2004.10.003

[8] M. Lewandowski, A. Szymanska-Kolasa, P. Da Costa

and C. Sayag, “Catalytic Performances of Platinum

Doped Molybdenum Carbide for Simultaneous Hydrode-

nitrogenation and Hydrodesulfurization,” Catalysis Today,

Vol. 119, No. 1-4, 2007, pp. 31-34.

doi:10.1016/j.cattod.2006.08.062

[9] J. M. Cheng and W. Huang, “Effect of Cobalt (Nickel)

Content on the Catalytic Performance of Molybdenum

Carbides in Dry-Methane Reforming,” Fuel Processing

Technology, Vol. 91, No. 2, February 2010, pp. 185-193.

doi:10.1016/j.fuproc.2009.09.011

[10] M. Nagai and K. Matsuda, “Low-Temperature Water-Gas

Shift Reaction over Cobalt-Molybdenum Carbide Cata-

lyst,” Journal of Catalysis, Vol. 238, No. 2, 2006, pp.

489-496. doi:10.1016/j.jcat.2006.01.003

[11] D. Mordenti, D. Brodzki and G. D. Mariadassou, “New

Synthesis of Mo2C 14 nm in Average Size Supported on a

High Specific Surface Area Carbon Material,” Journal of

Solid State Chemistry, Vol. 141, No. 1, 1998, pp. 114-120.

doi:10.1006/jssc.1998.7925

[12] X. H. Wang, H. L. Hao, M. H. Zhang, W. Li and K. Y.

Tao, “Synthesis and Characterization of Molybdenum

Carbides Using Propane as Carbon Source,” Journal of

Solid State Chemistry, Vol. 179, No. 2, 2006, pp. 538-543.

doi:10.1016/j.jssc.2005.11.009

[13] L. Díaz Barriga Arceo, E. Orozco, H. Mendoza-León, E.

Palacios González, F. Leyte Guerrero and V. Garibay Fe-

bles, “Nanostructures Obtained from a Mechanically Al-

loyed and Heat Treated Molybdenum Carbide,” Journal

of Alloys and Compounds, Vol. 434-435, 2007, pp. 799-

802.

[14] L. Norin, U. Jansson and J.-O. Carlsson, “Chemical Va-

Copyright © 2011 SciRes. MSA