Optics and Photonics Journal

Vol.06 No.08(2016), Article ID:70305,8 pages

10.4236/opj.2016.68B013

An Experimental Study on the Temperature Characteristic of a 940 nm Semiconductor Laser Diode

Yiru Liao, Jianjun Li*, Guoxin Mi, Haikuo Wang, Yuancheng Wang, Jun Deng, Jun Han

Key Laboratory of Opto-Electronics Technology, Beijing University of Technology, Ministry of Education, Beijing, China

Received 27 May 2016; accepted 20 August 2016; published 25 August 2016

ABSTRACT

This paper is focused on a 940 nm edge type of semiconductor laser, which is made from 940 nm InGaAs double-quantum-well epitaxial wafer, produced by Metal Organic Chemical Vapor Deposition (MOCVD). In the absence of coating, the efficiency at the room temperature is 0.89 W/A, and the averaged threshold current is 0.307 A. The present study investigates the impact of temperature on the P-I curve, V-I curve and the centre wavelength, the temperature ranging from 286.15 - 333.15 K. It shows that the threshold current increases from 0.28 A to 0.41 A with the increasing temperature. The increase rate is 0.0027 A/K. With the temperature ranging from 286.15 - 333.15 K, the characteristic temperature is calculated to be 120 K. At driven current of 2 A, the output power decreases from 1.47 W to 1.27 W at a rate of 0.00425 W/K. At a constant voltage, the output current initially increases with the temperature within a certain range, beyond which the impact of the temperature is minimum. The ideal factor obtained from V-I curve by curve fitting is 1.076. The series resistance is 0.609 Ω. The centre wavelength shifts to a longer wavelength with the increasing temperature at a rate of 0.275288 nm/K.

Keywords:

940 nm Semiconductor Laser, Threshold Current, Characteristic Temperature

1. Introduction

High power 940 nm semiconductor quantum-well-structure laser diodes can be used as optical fiber amplifiers and to pump some solid state lasers. One of the most important applications is to pump Yb3 + doped fiber laser diodes [1]-[4]. The 940 nm semiconductor laser diodes have wide absorption band and high stability under wide-ranging working temperature. However, various factors can reduce their lifetime. In particular, temperature has a great influence on characteristic parameters of semiconductor laser diodes. With the changing temperature, the centre wavelength, threshold current and output power are affected, in addition to the instability caused by the mode of multimode laser. Those changes shift the laser diodes away from their optimized working conditions, which leads to permanent damages to the equipment in long-term. Hence it is necessary to analyze the impact of temperature on the semiconductor laser diodes.

The impact of temperature on semiconductor laser diodes of different wavelengths has attracted researchers’ attention globally. In 2001, Ma et al. [5] investigated the temperature sensitivity of 1.55μm InGaAs/InGaAsP compressive strain multi-quantum-well-structure laser diodes. In 2006, Shigeru Kanazawa et al. [6] studied the temperature sensitivity of 1.2 μm GaInAs/GaAs quantum-well-structure laser diodes working under high temperature. In 2012, Li et al. [7] reported the temperature sensitivity of 1.06 μm InGaAs/InGaAsP quantum-well structure semiconductor laser diodes. In 2013, Huang et al. [8] studied the temperature sensitivity of 850 nm taper semiconductor laser diodes. In 2013, Zhang et al. [9] performed analysis on 808 nm laser array vertical cavity surface. In 2016, Feng et al. [10] conducted a study on the temperature sensitivity on 808 nm. For 940 nm wavelength semiconductor laser research, in 2013, Li et al. [11] studied relaxation time in test of 940 nm semiconductor laser. However, there is less work on the impact of temperature on the 940 nm laser diodes.

This paper is focused on a 940 nm edge type of semiconductor laser diodes, which is made from 940 nm double-quantum-well quantum well epitaxial wafer, produced by Metal Organic Chemical Vapor Deposition (MOCVD). Without the use of coating, the efficiency at the room temperature is 0.89 W/A, and the averaged threshold current is 0.307 A. This paper reports the impact of temperature on the P-I curve, V-I curve, and the centre wavelength of the semiconductor laser diodes.

2. The Structure of the Laser Diode

In the present study, a 940 nm double-quantum-well semiconductor laser diode is produced by Metal Organic Chemical Vapor Deposition (MOCVD). The internal structure is made of a large asymmetric optical cavity. The internal structure is designed into asymmetric large optical cavity.

The semiconductor laser diode is a typical Fabry-Perot edge-emitting laser as shown in Figure 1. The device was built by the following processes: First, a 100-µm wide surface was fabricated using standard optical lithography in combination with various etching techniques for lateral structuring; Second, one layer of 200 nm thick SiO2 was made using PEVCD for insulation; Third, an 95-µm wide Lead hole window was produced with lithography; Fourth, TiAu layer was sprayed on the P-contact; Then the bottom surface on the N-contact was thinned to around 120 µm, which was followed by producing a AuGeNi/Au substrate on the N-contact; At last, the wafers were cleaved into single chip with a laser cavity length of L = 1000 µm , which was finalized with TO3.

3. Results and Discussions

The semiconductor laser diodes is tested with pulsed laser with a duty ratio of 0.5% and a frequency of 100 Hz. Using pulsed laser is to reduce the impact of internal cooling on the results. Six working temperatures are tested, including 286.15 K, 295.15 K, 303.15 K, 313.15 K, 323.15 K and 333.15 K. The following sections present analysis on the impact of temperature on the P-I curve, V-I curve, and the centre wavelength of the semiconductor laser diodes.

Figure 1. The structure of the semiconductor laser diode.

3.1. The Impact of Temperature on the P-I Curves

Figure 2 demonstrates the impact of temperature on the P-I curves with temperature ranging from 286.15 - 333.15 K. As is shown in Figure 2, with the increase of temperature, the threshold current gradually increases, the decrease of the output light power gradually.

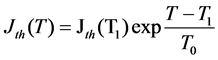

Figure 3 presents the threshold current as a function of temperature. It shows that the threshold current increases with the increasing temperature. Specifically, the threshold current increases from 0.28 A to 0.41 A at a rate of 0.0027 A/K. Previous studies found that the threshold current density at a given temperature Jth(T) can be calculated using the following equation [12]-[14]:

(1)

(1)

where Jth(T1) is the threshold current density at temperature of T1, in this experiment the T1 values set to 295.15 K, T0 represents the characteristic temperature [15]. The main underlying mechanisms for the changes in the threshold current density caused by the temperature [14] are as following: 1) Temperature changes the statistical distribution of the carrier, thereby affecting the light gain coefficient; 2) Temperature influences the internal loss existing in the semiconductor laser (auger recombination, surface composite, free carrier absorption; 3) Temperature affects heterojunction between the potential barrier heights, which in turn affects the hot carrier leakage. With the increase in the temperature, the internal wear of the semiconductor laser diodes increase, meanwhile both the internal and external quantum efficiency, external quantum efficiency drops. The potential barrier height increases with temperature, leading to the leakage of hot carriers, which results in a higher threshold current.

The characteristic temperature T0 is calculated by linear fitting the data points in Figure 3, which is 120 K. The characteristic temperature T0 is an important measure of the temperature sensitivity of semiconductor laser diodes. A bigger T0 indicates that the laser diode is less sensitive to temperature. The calculation shows that the semiconductor laser diode are sensitive to temperature, which implies a strong fluctuation in the performance of this particular laser diode with temperature ranging from 286.15 K to 333.15 K.

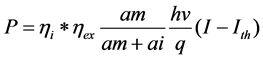

Figure 4 depicts the change in output power with temperature given an input current of 2 A. it shows that the output power decreases gradually with the increasing temperature, particularly, the output power decreases from 1.47 W to 1.27 W at a rate of 0.00425 W/K. Given a current higher than the threshold current, the output power can be expressed with the function below [12]-[14]:

(2)

(2)

where, ηi is the internal quantum efficiency, ηex is the external quantum efficiency, ai and am are internal loss and loss of end face. The internal loss increases, meanwhile the efficiency of internal quantum and external

Figure 2. P-I curves at various temperature.

Figure 3. Ith as a function of temperature.

Figure 4. P at various temperature.

quantum decreases as the temperature rises. In addition, the leakage of hot carriers increases, which increases the threshold current, thereby resulting in a reduced output power.

3.2. The Impact of Temperature on V-I Curves

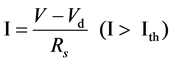

Plotted in Figure 5 is the V-I curves with temperature varying from 286.15 K to 333.15 K. At a given voltage, when temperature changes from 286.15 K to 295.15 K, current increases considerably. However, the change in the current is negligible with the temperature ranging from 295.15 K to 333.15 K as the rest curves overlap with each other. This can be explained by the relationship between voltage and current.

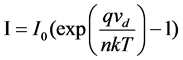

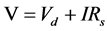

Analysis the reason, by the relationship between electric current and voltage and can know [12]:

(3)

(3)

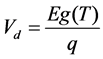

(4)

(4)

where V stands for the forward voltage imposed on the laser diode,  is the internal voltage,

is the internal voltage,  is the series resistance, Eg (T) is the forbidden bandwidth at a given temperature, The forbidden bandwidth narrows with the increasing temperature, which reduces

is the series resistance, Eg (T) is the forbidden bandwidth at a given temperature, The forbidden bandwidth narrows with the increasing temperature, which reduces , compared to the change in V and

, compared to the change in V and , the change in

, the change in  with

with

Figure 5. V-I curves at various temperature.

temperature can be ignored. Hence, current rises with temperature within a certain range. However, as the temperature continues to increase, the change in the conduction band and the valence band of Fermi level range reduces, leading to a smaller change in Eg, therefore there is minimum change in the current with temperature above 295.15 K.

The V-I function for other diodes is as following:

(5)

(5)

We obtain  from Equation (3), derivation Equation (5) gives us the value of

from Equation (3), derivation Equation (5) gives us the value of

When the change in current and voltage is small,

the threshold current, applying linear fitting to V-I curves with Equation (6), show in Figure 6 which gives an ideal factor of n = 1.076. Normally, the ideal factor for diodes ranges from 1 to 2, hence the calculated ideal factor in the present study is within the range. The series resistance is calculated to be 0.609 Ω.

3.3. The Impact of Temperature on the Centre Wavelength

Figure 7 shows the centre wavelength at different temperature while keeping the input current constant. It re-

veals that the centre wavelength increases as temperature rises. It is known that the material used in the semiconductor laser is direct band gap materials, and the centre wavelength is determined by Eg, which is a function of the temperature coefficient. The relationship between the output wavelength and forbidden bandwidth can be expressed as [12]-[14]:

Figure 6. Linear fitting of I(dV/dI)-I at T = 295 K.

Figure 7. The lasing spectrum at various temperature.

Figure 8 shows the centre wavelength and the forbidden bandwidth as a function of temperature. It demonstrates that the centre wavelength increases as the temperature rises. The increase rate of the centre wavelength is calculated to be 0.275288 nm/K. Compared to an increase rate of 0.37 nm/K for temperature characteristic of 1.06 μm InGaAs/InGaAsP quantum-well laser diode [7] in a previous study, this change is relatively small. At a given temperature, the forbidden bandwidth Eg is calculated from Equation (8) by substituting the centre wavelength at that particular temperature. Figure 8 reveals that the forbidden bandwidth is reduced when temperature is higher. This result agrees with the inversely proportional relationship between temperature and the forbidden bandwidth as shown in Equation (9). The decrease in the forbidden bandwidth is responsible for the increasing centre wavelength at a higher temperature.

4. Summary

This paper is focused on a 940 nm edge type of semiconductor laser, which is made from 940 nm InGaAs double-quantum-well epitaxial wafer, produced by Metal Organic Chemical Vapor Deposition (MOCVD). Without the use of coating, the efficiency at the room temperature is 0.89 W/A, and the averaged threshold current is 0.307 A. With the temperature ranging from 286.15 - 333.15 K, the present study investigates the impact of temperature on the P-I curve, V-I curve and the centre wavelength. The laser diode is tested with pulsed las-

Figure 8. The centre wavelength and forbidden width as a function of temperature.

ing with a duty ratio of 0.5%. Experimental results show that the threshold current increases from 0.28 A to 0.41 A at the increasing temperature. The increase rate is 0.0027 A/K. With the temperature ranging from 286.15 - 333.15 K, the characteristic temperature is calculated to be 120 K. The output power decreases from 1.47 W to 1.27 W at a rate of 0.00425 W/K. At a constant voltage, the output current initially increases with the temperature within a certain range, beyond which the impact of the temperature is minimum. The ideal factor obtained from V-I curve by curve fitting is 1.076. The series resistance is 0.609 Ω. The centre wavelength shifts to a longer wavelength with the increasing temperature at a rate of 0.275288 nm/K. The forbidden bandwidth decreases with the increasing temperature.

Acknowledgements

We thank the Beijing Municipal Education Commission for their financial support, which was provided as part of capacity improvement programs (PXM2016_014204_500026 andPXM2016_014204_500018).

Cite this paper

Yiru Liao,Jianjun Li,Guoxin Mi,Haikuo Wang,Yuancheng Wang,Jun Deng,Jun Han, (2016) An Experimental Study on the Temperature Characteristic of a 940 nm Semiconductor Laser Diode. Optics and Photonics Journal,06,75-82. doi: 10.4236/opj.2016.68B013

References

- 1. Dong, R.J., Yan, P.G., Zhang, G.L., Li, H.Q., Ruan, S.C., Wei, H.F. and Luo, J. (2013) Design of Seven-Core Photonic Crystal Fiber with Flat In-Phase Mode for Yb: Fiber Laser Pumping. Optics and Photonics Journal, 3, 197-201. http://dx.doi.org/10.4236/opj.2013.32B047

- 2. Belloui Bouzid. (2014) Erbium Doped Fiber Laser and Amplifier. Optics and Photonics Journal, 4, 189-193. http://dx.doi.org/10.4236/opj.2014.47019

- 3. Wang, Z.W., Du, S.T., Wang, Z.K., He, J., Wei, Y.R., Lou, Q.H. and Zhou, J. (2013) High Peak Power, Single-Pola- rized, Sub-Nanoseconds Pulses Generation of a Yb-Doped Rod-Type Photonic Crystal Fiber Amplifier. Optics and Photonics Journal, 3, 69-72.

- 4. Peng, C.H. (2012) Structural Properties and Two Photon Luminescence Study of Yb: YAG Single Crystal.

- 5. Ma, C., Guo, W. and Liu, S. (2001) High-Temperature Characteristics of 1.55-μm InGaAs/InGaAsP Strain-Compen- sated Multiple-Quantum-Well Lasers. International Symposium on Optoelectonics and Microelectronics, International Society for Optics and Photonics, 173-177.

- 6. Kanazawa, S., Takeda, K., Miyamoto, T., et al. (2006) High-Temperature Operation of a 1.2-μm Sin-gle-Trans- verse-Mode Highly Strained GaInAs/GaAs QW Laser. Asia-Pacific Optical Communications, International Society for Optics and Photonics, 63520L.

- 7. Li, Z.-J., Lu, P., Li, T., Qu, Y., Bo, B.-X., Liu, G.-J. and Ma, X.-H. (2012) Temperature Characteristic of 1.06 μm InGaAs/InGaAsP Quantum Well Laser Diode. Chinese Journal of Lu-minescence.

- 8. Huang, H.-H., Liu, Y. and Yang, Y. (2013) Temperature Characteristics of 850 nm Tapered Semi-conductor Lasers. Chinese Optics, 6, 201-207. http://dx.doi.org/10.3788/co.20130602.0201

- 9. Zhang, J.S., Ning, Y.Q., Zhang, J.L., et al. (2013) Temperature Characteristic Analysis of 808 nm Vertical Cavity Surface Emitting Laser Arrays. Chin. J. Lumin, 34, 1636. http://dx.doi.org/10.3788/fgxb20133412.1636

- 10. Feng, Y., Feng, D., Liu, P., et al. (2016) 808 nm VCSELs Temperature Characteristic Study. Wireless Communications, Networking and Applications, Springer, India, 799-805. http://dx.doi.org/10.1007/978-81-322-2580-5_72

- 11. Li, J.C., Li, J.J., Liu, T., Cui, B.F., Deng, J., Han, J., He, H.J. and Lin, S.J. (2013) The Study of Relaxation Time in Test of 940 nm. Journal of Computer and Communications, 1, 46-49. http://dx.doi.org/10.4236/jcc.2013.17011

- 12. Coldren, L.A. and Corzine, S.W. (Writers), Shi, H.X. (Translator) (2006) Diode Laser and Integrated Optics. Beijing University of Posts and Telecom-munications Press, Beijing.

- 13. Jiang, J.P. (2000) Semiconductor Laser. Electronic Industry Press, Beijing, 91-92.

- 14. Huang, D.X.and Liu, X.F. (1999) Semiconductor Laser and Its Applications. National Defence Industry Press.

- 15. Gao, X., Qu, Y., Bo, B.-X., Zhang, B.-S., Zhang, X.-D. (1999) 808 nm High Power Semiconductor Lasers with High Characteristic Temperature. Semiconductor Optoelectronics, 388-389.

NOTES

*Corresponding author.