M. N. BAGDE ET AL.245

the stresses, which they experienced earlier. The best

studied memory effects are the memory effect in AE,

known as Kaiser Effect, and the deformation memory

effects, or memory effects in strain, which make a phy-

sical basis of the Deformation Rate Analysis (DRA)

stress measurement method. Both kinds of effects take

place while the rock is cyclically loaded to stress levels,

increasing from cycle to cycle [15]. Both deformation

and acoustic emission memory effects are due to the de-

velopment of irreversible micro-fractures in rock sub-

jected to cyclic loading [9,18]. According to Filimonov

et al., [15] this leads to the absence of crack growth and

sliding processes (dislocation movements) at stress val-

ues smaller than the maximum previously applied stress.

As soon as this “memorized” stress value is attained,

crack propagation is again initiated, which is accompa-

nied with AE pulses and non-linear inelastic strain de-

velopment. Memory effects are related to irreversible,

stress-induced changes in the rock’s structure occurring

in the first cycle loading. Therefore, the elastic limit pre-

sents a natural threshold for memory formation. This is

confirmed by the tests in which the first stage cycle axial

stress was smaller than the elastic limit for the given

loading condition. In second stage cycle stress and defor-

mation of such specimen were similar to those of “fresh”

specimen, which did not undergo any first cycle loading.

This was due to the absence of micro-fracture damage

below the elastic limit, which could form a stress mem-

ory. Distinct memory effects in the third stage cycle took

place where the maximum axial stress exceeded the elas-

tic limit took place in the second stage cycle. From the

Figure 7, it can be seen that in final stage of cycling and

loading, rock has followed the same path experienced in

stage II and III loading path. A more detailed study of

the stress memory effect under dynamic cyclic loading

could be carried out in the future.

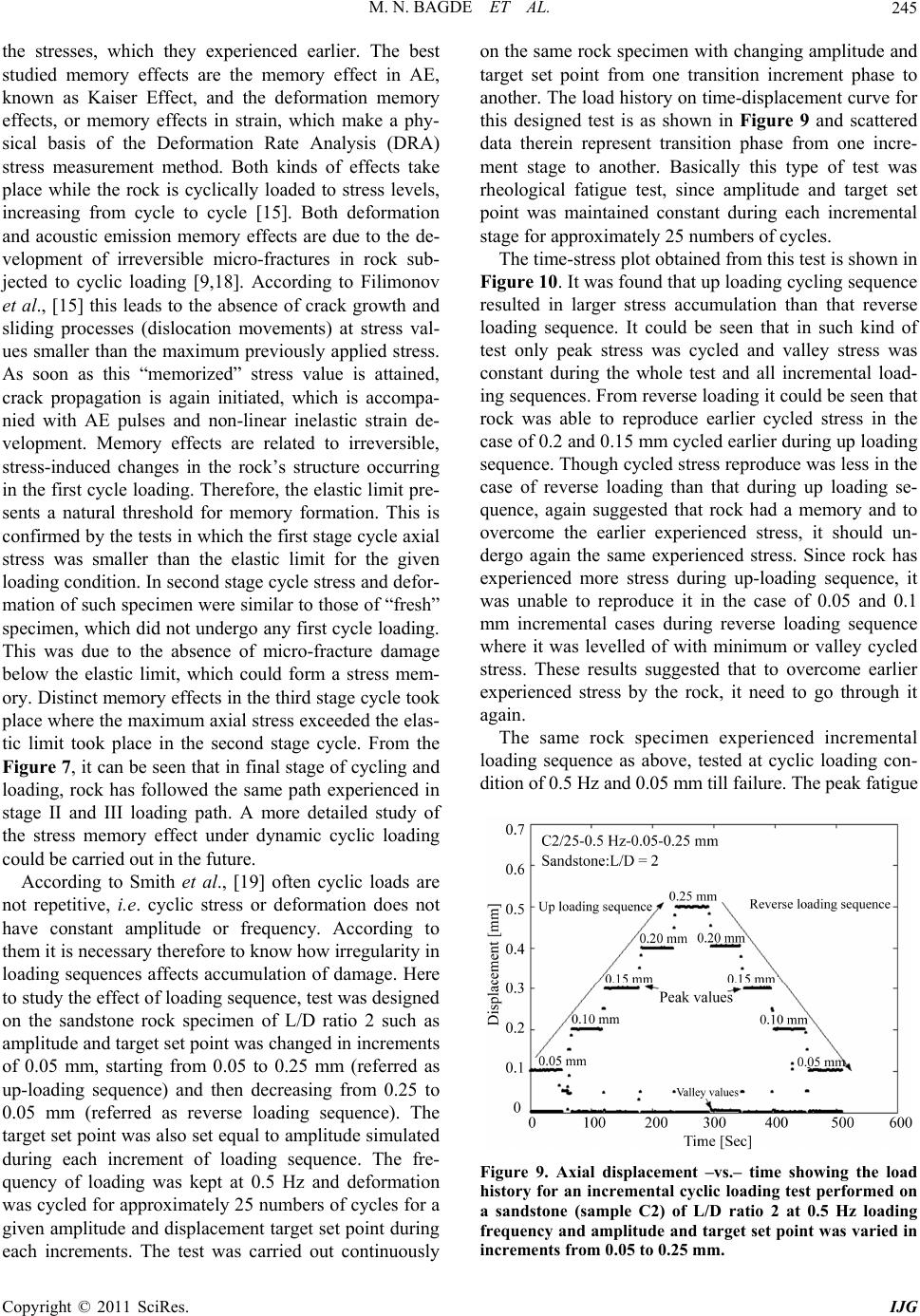

According to Smith et al., [19] often cyclic loads are

not repetitive, i.e. cyclic stress or deformation does not

have constant amplitude or frequency. According to

them it is necessary therefore to know how irregularity in

loading sequences affects accumulation of damage. Here

to study the effect of loading sequence, test was designed

on the sandstone rock specimen of L/D ratio 2 such as

amplitude and target set point was changed in increments

of 0.05 mm, starting from 0.05 to 0.25 mm (referred as

up-loading sequence) and then decreasing from 0.25 to

0.05 mm (referred as reverse loading sequence). The

target set point was also set equal to amplitude simulated

during each increment of loading sequence. The fre-

quency of loading was kept at 0.5 Hz and deformation

was cycled for approximately 25 numbers of cycles for a

given amplitude and displacement target set point during

each increments. The test was carried out continuously

on the same rock specimen with changing amplitude and

target set point from one transition increment phase to

another. The load history on time-displacement curve for

this designed test is as shown in Figure 9 and scattered

data therein represent transition phase from one incre-

ment stage to another. Basically this type of test was

rheological fatigue test, since amplitude and target set

point was maintained constant during each incremental

stage for approximately 25 numbers of cycles.

The time-stress plot obtained from this test is shown in

Figure 10. It was found that up loading cycling sequence

resulted in larger stress accumulation than that reverse

loading sequence. It could be seen that in such kind of

test only peak stress was cycled and valley stress was

constant during the whole test and all incremental load-

ing sequences. From reverse loading it could be seen that

rock was able to reproduce earlier cycled stress in the

case of 0.2 and 0.15 mm cycled earlier during up loading

sequence. Though cycled stress reproduce was less in the

case of reverse loading than that during up loading se-

quence, again suggested that rock had a memory and to

overcome the earlier experienced stress, it should un-

dergo again the same experienced stress. Since rock has

experienced more stress during up-loading sequence, it

was unable to reproduce it in the case of 0.05 and 0.1

mm incremental cases during reverse loading sequence

where it was levelled of with minimum or valley cycled

stress. These results suggested that to overcome earlier

experienced stress by the rock, it need to go through it

again.

The same rock specimen experienced incremental

loading sequence as above, tested at cyclic loading con-

dition of 0.5 Hz and 0.05 mm till failure. The peak fatigue

Figure 9. Axial displacement –vs.– time showing the load

history for an incremental cyclic loading test performed on

a sandstone (sample C2) of L/D ratio 2 at 0.5 Hz loading

frequency and amplitude and target set point was varied in

increments from 0.05 to 0.25 mm.

Copyright © 2011 SciRes. IJG