Journal of Sustainable Bioenergy Systems

Vol.2 No.4(2012), Article ID:25882,4 pages DOI:10.4236/jsbs.2012.24016

Influence of Several Fermentation on Seaweed Waste of Feed

1School of Enviroment and Architecture, University of Shanghai for Science and Technology USST, Shanghai, China

2College of Science, University of Shanghai for Science and Technology USST, Shanghai, China

Email: tianshi819@126.com, *zhang_lucy9999@yahoo.com.cn

Received September 16, 2012; revised October 23, 2012; accepted November 1, 2012

Keywords: Seaweed Waste; Fermentation; Feed

ABSTRACT

This paper focuses on several factors on the effects of fermented seaweed feed, and obtains the optimal fermentation process through the analysis of nutrients. Through the experiment we can get, Seaweed waste fermented the best feed when adding 1% of microbial agents and 0.5% of corn powder, fermenting for 15 days.

1. Introduction

Recently, Renewable Fuels Agency reported that the grain to make bio-fuels has caused food prices at risk, but algae have the potential to produce bio-fuels that can alleviate the situation. So using algae to produce biodiesel and biomass oil, opening a new technology path for bio-energy especially for bio-diesel industry, can not only effectively solve the bottleneck of the bio-fuels industry, but also provide a healthy, stably, sustainable and new development for bio-fuel industry [1].

However, production of bio-fuels will lead to a large number of biological waster which is rich in organic matter and nutrients , they were discharged, which may results in eutrophication and red tide, effects and damages the fisheries economy and ecology ,wastes a lot of natural resources, brings a series of environmental pollution problems. However, the deep processing of seaweed wastemaking seaweed can not also reduce environmental pollution, but also alleviate the problem of feed shortage [2], and bring considerable economic benefits. Feed nutritional compositions are different with the different fermentation technology of seaweed waste .This experiment studied and analyzed these different nutritional compositions in order to provide certain data for animal feed made of fermentative seaweed .

2. Materials and Methods

2.1. Materials

Seaweed waste: it came from the seaweed industry such as algin, mannitol, iodine, fucoidan and other products .It must be shattered piece for partical size of 1 - 5 mm before fermentation.

Microbial agents and corn powder were both bought in the market. The potassium dihydrogen phosphate is analytical reagent.

2.2. Methods

1) Sample fermentation: Firstly put the microbial agents into the glucose solution whose concentration was less than 1%, and keep them for four hours at normal temperature. Secondly, mix 50% of dry seaweed waste, 5‰ of potassium dihydrogen phosphate [3,4] and other adjuvants. The solution was equably sprinkled to the mixture. Adjust the pH of the mixture for 4.5 - 6.0, the water for about 70%. It was better that the mixture gripped into the group didn’t dripped along the fingers and spread out when loosing the fist. Thirdly, they would be placed in a sealed bucket for anaerobic fermentation at a temperature of 25˚C - 30˚C. At last, the fermentative products would be dried at the natural temperature or at the temperature of 65 in the blast drier and shattered [5].

2) Sample fermentation: Samples which were reduced to 500 g through method of quartering were dried and shattered to 40 yards. Then they were narrowed 200 g through the same method and placed into sealed containers in a cool and dry place.

3) Quality identification a) Field assessment: Evaluate the samples in color, smell and quality after open the sealed containers [6].

b) Laboratory assessment: The method of determination of pH was to measure the supernatant which was made up 20 g of seaweed feed and 30 mL of water kept for five minutes with PHS-3 C precision acidity meter [7].

c) Determination of conventional nutrients was on the basis of national standards the determination of related substances:

Determination of crude protein (CP) referred to GB/T 6432-94.

Determination of crude fiber (CF) referred to GB/T 6434-94.

Determination of ether extract (EE) referred to GB/T 6433-94.

Determination of ash referred to GB/T 6438-92.

Determination of moisture referred to GB/T 6435-86.

3. Results and Analysis

The previously mentioned methods were used to determine the nutrients of different fermentation technology, such as CP, CF, EE, ash, moisture and nitrogen free extract (NFE).

3.1. Results of Experiments

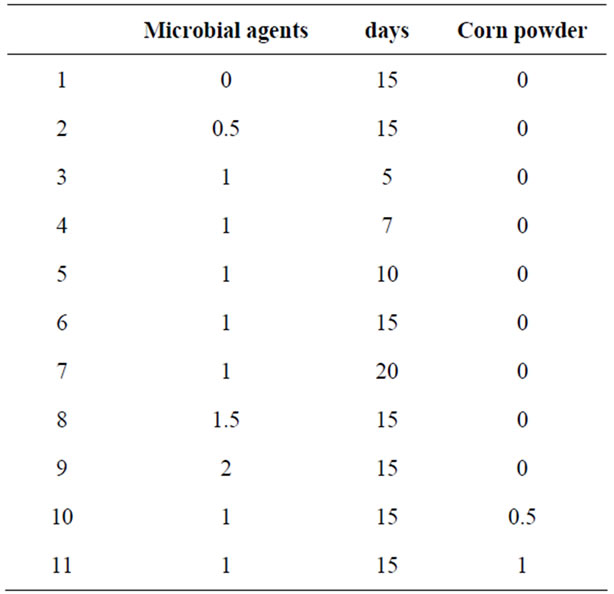

Table 1 showed different fermentation technology with different microbial agents added, fermentation days and corn powder added. Other factors didn’t change except the three factors mentioned previously. The temperature was 25˚C and water content was 70% [8]. In addition, it took four hours to make microbial agents activated. Seaweed waste materials, water and potassium dihydrogen phosphate were respectively for 1000 g, 1500 g and 5 g.

Table 2 showed the essential nutrients of different fermentation process.

Table 1. Fermentation technology (%, d, %)

3.2. Analysis of Results

1) Sensory effects: The seaweed waste unprocessed was coarser and drier. By contrast, the feed fermentated by seaweed felt softer, sound mellower and was brown.

2) Analysis of Nutrients: It could be found in these experiments that crude protein of seaweed feed significantly increased and crude fiber of them decreased. In other words, the crude fiber digested difficultly was degradated into the nutrients easily digested and digestive protein increased at the same time, which effectively improved the palatability of seaweed as feed.

a) The relationship between the number of days and fermentation effect:

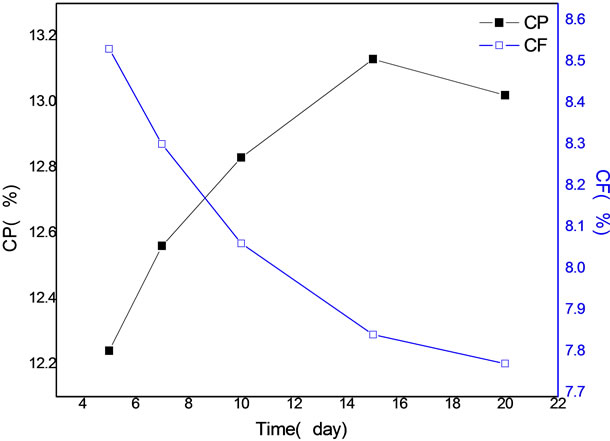

Figure 1 showed the relationships between the number of days and fermentation effect of 3-7 processes. It also

Table 2. The essential nutrients of different fermentation process.

Figure 1. The relationship between the number of days and fermentation effect Highlight all author and affiliation lines.

descripted that the crude protein had an increasing trend and the crude gradually decreasing with the fermentation days before the fifteenth day, which signified that fermentation effect was proportional to the fermentation time. In addition, the content of crude protein was highest for the fifteenth day and decreased later. Because the microorganisms in microbial agents were in a decline phase and the number of them began decreasing. Furthermore, nutrients had been insufficient to maintain microorganisms to survive so that microorganisms [9] consumed the nutrients in seaweed feed. In conclusion, fifteen days was most favorable for fermentation.

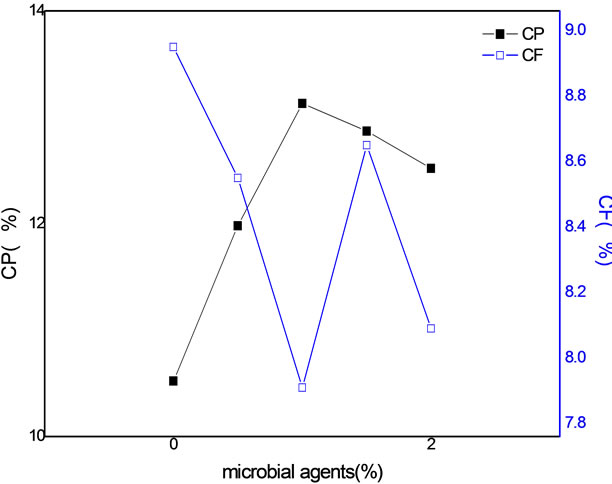

b) The relationship between the microbial agents added and fermentation effect:

Figure 2 showed the relationship between the microbial agents added and fermentation effect of processes 1, 2, 8 and 9.The content of crude protein was the most when the microbial agents were added by one percent. However, it was lower when the content of microbial agents was less than or more than one percent. It was because that the seaweed waste could not be fully decomposed by microorganisms with little agents, otherwise too many microbial agents competed each other was not conductive to fermentation of seaweed waste. In conclusion, fermentation effect was best when the agents’ addition was one percent.

c) The relationship between corn powder added and fermentation effect:

The addition of corn powder in processes 6, 10 and 11 were respectively 0%, 0.5% and 1%.What could be got from the data that the content of crude protein in process, 10 was increased by 12.92% than that in process 6, the content of crude protein in process 11 was increased by 0.22% than that in process 10. Why the second increase was not obvious was that C/N played an important part in microbial growth and was one of main factors improving

Figure 2. The relationship between the microbial agents added and fermentation effect.

the content of crude protein. The crude protein of seaweed feed increased with the addition of corn powder. What’s more, the more the corn powder was added, the more the cost of the fermentation was. So It was the most favorable to add 0.5% of corn powder.

4. Conclusions

In summary, the three factors contained fermentative days, agents, and corn powder had an impact on the fermentative effect. Experiments showed that seaweed feed was the best when adding 1% of microbial agents and 0.5% of corn powder, fermenting for 15 days, that was the tenth process. Compared with seaweed waste, the crude protein of seaweed feed increased by 34.56% and the crude fiber decreased by 10.72%.

In contrast to the conventional feed, such as corn straw, cassava cane, turnip leaf and wild grass, the seaweed feed is much richer in crude protein, crude fiber and minerals which are beneficial to the growth and reproduction of domestic animals. Also, the seaweed feed has less ether extract, that doesn’t easily lead to fat accumulation and meets the nutritional needs of modern people.

5. Acknowledgements

This work was financially supported by the Key Projects in the National Science & Technology Pillar Program during the Eleventh Five-year (2007BA62B04), Yangtze River Delta Joint research project (0939581140) and Shanghai international cooperation projects (073458014). This paper is supported by “Shanghai-Unilever Research & Development Fund” 08540750500, projects 09395811400, S2012C000005 and 11395803100.

REFERENCES

- R. G. Li, Y. X. Jiang, et al., “Comprehensive Technology of Macroalgae as Feed,” Scientific Fish, No. 10, 2009, pp. 64-65. (in Chinese)

- L. H. He and Y. Q. Gan, “Animal Feed Dedicated by the Oceans-Alage,” Feed Research, No. 8, 2004, pp. 22-24. (in Chinese)

- Gong Zhang, Rong Zheng, et al., “Study on Corn Straw Feed Fermentated with Multi-Strain,” Acta Agriculturae Boreali-Sinica, No. S1, 2000, pp. 175-177. (in Chinese)

- A. G. Ji and P. J. Gao, “A Preparative Method of Seaweed Organic Fertilizer,” Shandong University, Shandong, 2005. (in Chinese)

- H. Y. Yang, Z. J. Cui, et al., “Feed Addition Fermentated with Corn Straw and Its Research Progress,” Animal Husbandry & Veterinary Medicine, Vol. 37, No. 6, 2005, p. 5 (in Chinese)

- J. X. Liu, Z. H. Yang and J. A. Ye, “The Rational Allocation of Silage Feed and Feed Evaluation Standard,” Feed Industry, No. 4, 1999, pp. 3-5. (in Chinese)

- S. Yang, “Feed Analysis and Feed Quality Testing Technology,” China Agricultural University Press, Beijig, 1993. (in Chinese)

- L. J. Yu, “Fermentation Engineering Principles and Technology,” Chemical Industry Press, Beijig, 2006. (in Chinese)

- J. J. Lu, T. Y. Li and Y. Zhang, et al., “Study on Characteristic of Straw Feed Fermentated by Sporocytophaga, Bacillus Subtilis and Yeast,” Feed Resources, No. 41, pp. 47-49. (in Chinese)

NOTES

*Corresponding author. Shu-Ping Zhang: Ph.D., Professor of Physical Chemistry, Master Instructor, research mainly bio-electrochemical analysis, seaweed polysaccharides and colloid chemistry.