Journal of Water Resource and Protection

Vol. 5 No. 3 (2013) , Article ID: 28909 , 6 pages DOI:10.4236/jwarp.2013.53031

Research Progress of Brackish Water Desalination by Reverse Osmosis*

1Energy and Environmental Research Center, North China Electric Power University, Beijing, China

2Nuclear Institute, North China Electric Power University, Beijing, China

Email: zhangpan8632@hotmail.com

Received December 9, 2012; revised January 23, 2013; accepted February 1, 2013

Keywords: Brackish Water; Reverse Osmosis; Desalination; New Energy

ABSTRACT

Brackish water (BW) desalination is a primary path to relieve the shortage of water. As one of the BW desalination methods, reverse osmosis (RO) technology has advantage for both technology and process procedure. The expounding of this research studied or reviewed recent years, reverse osmosis membrane, energy recovery, new energy and application technology in BW desalination of RO at home and abroad. Wind power and solar energy can be combined with energy recovery device for RO. The research also explains that BW desalination by RO is practical and feasible in some areas in China.

1. Introduction

Water is the necessary resource for human survival, is indispensable in daily life. According to researches, s severe shortage of water resource in China will reach 60 billion cubic meters by 2030. BW is extensive in China, especially in the Northwest China, North China and Yellow sea area. High salt concentration and high fluorine content limit the uses of water resources. BW has obvious peculiar smell and taste, which can cause cancer, calculus, cirrhosis and other diseases. High salinity in BW, especially the sulfate and organic humic acid, is the main reason for these diseases. BW with the degree of mineralization of more than 1000 mg/L, fluoride content than 1.0 mg/L and can’t be used directly [1]. In recent years, BW desalination has always been the research focus. Both the primitive distillation and emerging electrodialysis method can desalt BW, however, they both have difficulties to overcome shortcomings. Because of its advantage, better output water quality and excellent cost performance, RO has been widely adopted.

2. Reverse Osmosis System Composition

Selecting a Template

The RO method is to use the permselectivity of reverse osmosis membrane to intercept ion material. When pressure to the reverse osmosis membrane salt water pressure side is greater than infiltration pressure, the water from the salt side will flow into the pure water side. So RO method is to make full use of the pressure at the salt side under the conditions of the migration phenomenon and is the opposite process of penetration phenomena. RO can remove more than 90% soluble salts and 99% colloid microbial and organic matter from the water. It can also remove the inorganic ions, bacteria and viruses, and then high quality pure water can be obtained. So to deal high conductivity BW with RO can completely meet the requirements from theory. The sea water desalination is to solve the lack of fresh water in the coastal city, while the BW desalination by RO can solve the lack of fresh water in Northwest China. And more and more cities in west utilize RO method [2].

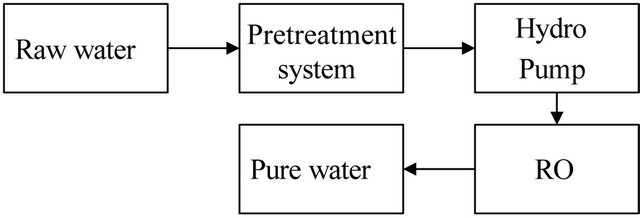

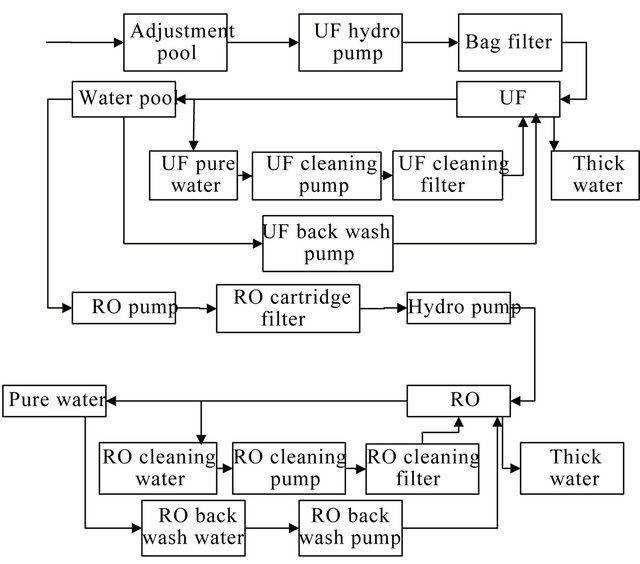

There are some parts in RO system including water pretreatment system, RO device system, water post-treatment system, cleaning system and electric control system. The feed water before RO device needs high quality, so the key of the process is to make the feed water meet the RO membrane requirement. The technological process of the conventional method is:

For the BW, the technological process is more complicated:

This process is widely adopted at home [3]. Because of the distinct BW, high fluorine BW or high arsenic BW should choose the corresponding treatment according to its characteristic.

3. Reverse Osmosis Desalination Technology of BW

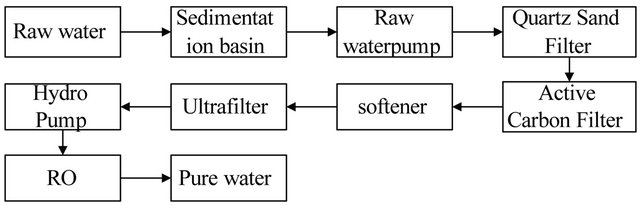

The development of RO technology of BW at home starts later than European and American countries. Most of the RO membrane needs to be imported at present. However, researches in China are becoming more, especially in the Northwest and North China. And the water supply by RO has been increasingly mature. Table 1 is the compositions of BW somewhere [2].

A large number of monatomic and bivalent ions is contained, especially iron, sodium, sulfate and chloride which are far more than the standards for drinking water. High turbidity, high hardness and high conductivity are the characteristic of BW. A lot of pretreatment work should be done for treating high turbidity and the existence of the massive ions led to high conductivity. Only RO can achieve the purposes. High hardness could lead to RO membrane pollution, but adding inhibitor and washing membrane will prolong the membrane life.

3.1. The Pretreatment of RO Method for Treating BW

Pretreatment is the indispensable part in RO technology process. The raw water must be disposed before enter RO membrane module and the quality should achieve a certain standard, otherwise it will greatly reduce the life of membrane and influence the outlet water. The traditional processes include coagulation, medium filtering and filter filtering can achieve water requirements, but can’t completely remove colloid and suspended material, and the quality of outlet water will fluctuate. The new pretreatment technologies contain micro filter, ultrafiltration, nanofiltration, which have higher reliability and lower sensitive of raw water quality, lower operation cost and commercialization component device features [4]. Yu et al. proposed that the pretreatment should be different according to the different sources of BW. The pretreatment of groundwater focuses on how to ease or prevent the precipitation of undissolved salt; the surface water in addition to prevent inorganic salt structure formulating upon membrane surface, still colloid and organic pollution [5]. Therefore, the different water should have different pretreatment methods. Sun et al. [6] used ultrafiltration as parts of the pretreatment and put ultrafiltration membrane and RO membrane together for the desalination with salt content of 4000 - 4500 mg/L. The ultrafiltration membrane could remove the suspend mucus, chroma, microbial, colloid and polymer organic matter. It provided experiment basis for ultrafiltration and RO. Wang et al. [7] put forward a viewpoint that the requirement of PH, chlorine, temperature, bacteria, the stability of certain chemicals of membrane should be considered in the process of the pretreatment. The inflow of RO must meet the water supply quality index, including SDI, PH, alkalinity, temperature, iron and manganese content, sulfate, hardness, residual chlorine, total organic carbon and so on. Zhang et al. [8] came up with the pretreatment process of pipeline coagulation, more filter medium and secondary filter according to the high turbidity, high salinity and high hardness of BW in Lop Nor area, Sinkiang province. The results showed that the pretreatment system could completely control suspended solids, turbidity and TDS, and the outlet water could meet the needs of the power plant supplied water.

The right choice of pretreatment system can ensure the next process. All the pretreatment such as coagulation precipitate, quartz sand filter, activated carbon filter, ultrafiltration, nanofiltration, softener, ultrafilter should be chosen according to the different RO membrane and the composition of BW.

Table 1. Compositions of BW somewhere.

3.2. RO Membrane in the Application of Technology of BW

In China RO membrane materials development relies mainly on the independent researches. Although it has made great progresses in recent years, there is a large gap compared with foreign countries. The main disadvantages are less in materials, the backward membrane process, and some research results still stay in the laboratory period which is not at the stage of industrialization, and new membrane materials research is limited [9]. There are three membranes for the use of pure water RO, roll type cellulose acetate membrane, hollow fiber membrane amine exception together and new type composite film roll. RO membrane should be chosen according to the quality of BW, because different RO membranes have different features. FT-BW4040 and FT-BW8040 are the general public RO membrane in the design process.

Shang et al. [10] used 8040 membrane for desalting BW of airport in Xianyang, Shanxi Province. After two months’ testing, TDS, hardness, chloride, nutrients, fluoride, hexavalent chromium have high removal rate, with obvious purifying effect. He et al. [11] desalted BW of a mine in Shanxi Province using CPA2-8040 type aromatic polyamide composite film of the United States Hydranautics company. It was useful for the removal of calcium, magnesium, chloride, sulfate and hardness. Feature of effluent from RO was satisfying the national standards for drinking water.

Brackish Water Reverse Osmosis (BWRO) and Sea Water Reverse Osmosis (SWRO) are different membranes. Because of their different features, even inlet water are same, effluent will be different. Zhou et al. [12] compared the trimesoyl chloride (TMC) membrane with metaphenylene diamine (MPD) membrane at different salinities. In the low salt concentration chloride desalination is similar; while the chloride using TMC membrane is lower than using MPD membrane in high salt concentration. So putting both of the membranes together will be able to achieve better effect. Almulla [13] constituted a membrane module system with SWRO membrane and BWRO membrane. BWRO membrane is in the first stage and SWRO membrane is in the second stage. The water recovery rate increased from 73% to 83%. Gluechstem [14] showed that the SWRO membrane of RO can remove boron ion in BW through the experiment results.

3.3. New Energy and Energy Recovery Technology Utilized Research

Using new energy sources such as wind and solar power in BWRO desalination is a hot spot. BWRO motive power from new energy has appropriate proportions, with wind power occupied 19% and solar energy accounted for 32%. Some of the island nation, especially in Europe, sea water desalination is usually adopting these two energies [15]. Although China has used wind and solar for BWRO desalination and some projects has been put into operation, they are smaller scale and the nature of the main research still stays in demonstration stage.

Zhang et al. manufactured a small photovoltaic solar reverse osmosis desalination system, which combined solar panels, batteries, solar controller and the RO device together. DC motor of high pressure pumps provides motivation. But this kind of device only was applied in the family unit, which had not reached the point of mass production yet [16]. Zhang et al. used solar energy collector to improve water temperature for RO. In the pressure of 0.9MPa, inlet water temperature from 18˚C to 38˚C, the water yield increased from 6.5 L/min to 8.8 L/min which improved by 35.5%. The conductivity from 2.8 us/cm rose to 3.1 us/cm and the hardness kept in 0mol/L, but the outlet water can also meet the low pressure steam boiler requirement [17]. Hazim Qiblawey et al. treated BW concentration in 1700 mg/L using photovoltaic technology in the RO process. They recorded the meteorological data such as sunshine time, temperature, light intensity which could affect the system and also discussed with the changes of recovery and desalting rate from the operating pressure and temperature [18]. G. E. Ahmad et al. made use of the solar energy resources in Egypt for BWRO experiments, and the small photovoltaic solar RO system could make the water cost at 3.73 $/m3. The cause of the high cost is that the power generating system can only run in the daytime, so solar cells can’t support the night operation [19]. Stewart Dallas et al. could only need 120 W photovoltaic power for their RO system which can deal with 400 L/d·BW [20].

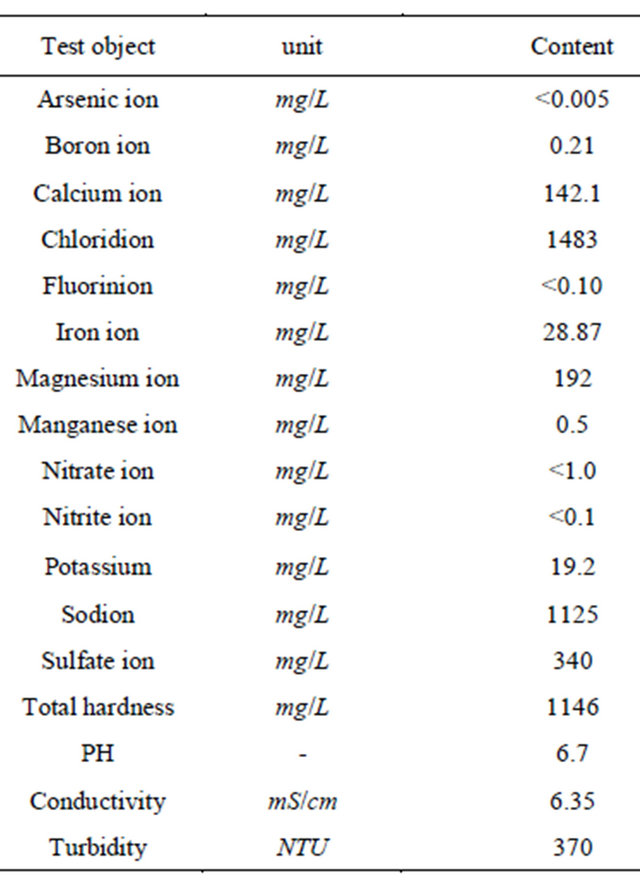

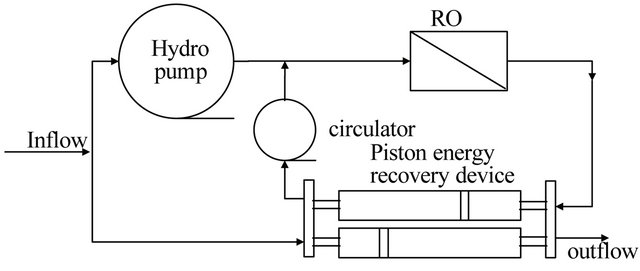

The wind energy for BW desalination is mainly used in direct and indirect ways (Figure 1). The direct way is that wind energy is utilized as mechanical energy for the BWRO; while the indirect way is to make the wind energy into electrical energy. The general application is the indirect way in the practices.

Zhu et al. proposed a wind power-sea water desalination coupling system. The key technology of the coupling system is the combination of wind power measurement, storage technology, HP thermal logic technology which

Figure 1. Ways of wind power as RO power.

controls RO starting or stopping, adjustable technology which keeps the water yield of RO [21]. Park et al. showed that using wind power could desalt the concentration of 2750 - 5500 mg/L BW and the wind power is used in the direct way. The effluent concentration is less than 1000 mg/L when the wind speed is 7.0 m/s or higher. The whole system can operate at high water inflow, but this system maybe can’t operate so well for the intermittent water or higher concentration BW [22].

Energy recovery is an energy consumption reducing process which uses energy recovery technology such as hydraulic turbine type and positive displacement type energy recovery device to put the high pressure of thick water for the raw water. The researches at home and aboard about RO energy recovery are much more. Many researches focus on turbine, hydraulic turbine type and piston (Figure 2) [23]. Piston energy recovery device puts stiff piston into the piston cylinder which could prevent liquid mixing. Through the piston, it can make high pressure fluid providing pressure for low pressure fluid. Because the piston resistance is very small, energy transfer efficiency is nearly 100%. But because of the pipeline loss and other reasons, transfer efficiency is commonly 80% - 90%. RO energy recovery device has been widely used in SW desalination. Energy consumption is less than 4.346 kWh/m3 in Singapore new spring desalination plant. Even if the flow is lower, the energy consumption is 4.2 kWh/m3. The Swiss company Calder AG, according to the different external conditions, developed two different energy recovery devices: DWEER and ERT. Both of them have their advantages and disadvantages. In order to be able to control the relationship between the overflow and mixing flow, company Desal designed the different DWEER device with LinX sliding steering valves. LinX valves could switch quickly and keep the process reliability between supercharging and decompression of the energy recovery device.

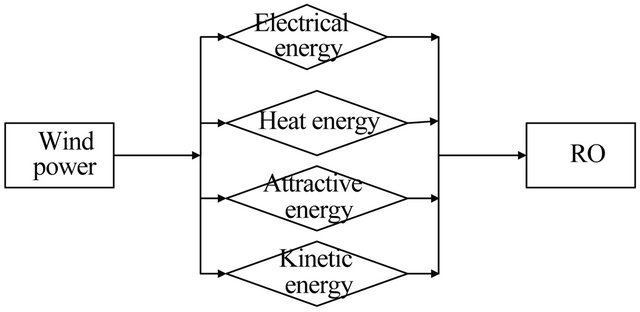

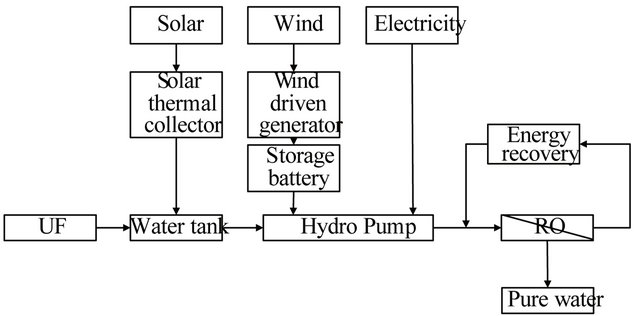

3.4. The Application of BWRO Desalination Driven by Combined Wind and Solar Power

Introducing the solar and wind power into the BWRO is an innovation in the process (Figure 3). Using solar energy as the high-pressure pump power directly is not stable in practical applications. The reason is that photo-

Figure 2. Piston energy recovery device.

Figure 3. New energy and energy recovery in BWRO.

voltaic energy is discontinuous and can’t keep continuous power. In the design solar power is not the motive power for hydro pump while it will improve water temperature. That is to say, solar auxiliary system is for heating inlet water of RO. According to experience rules, temperature rise 1˚C and water production will increase 3%. So the load of hydro pump will reduce when the water temperature improves at the condition of water production in constant. Wind power directly is same as the hydro pump power also could be not stability, so transforming the wind power into electrical energy is the way for hydro pump power. When the wind battery can’t keep enough power, alternating current will ensure continued operation of the hydro pump. Solar power, wind power and energy recovery device can maximum limit reduce the energy consumption.

4. The Application of BWRO

Because the existence of BW is located in water shortage area, the pure water of BWRO is usually used for drinking water. In China, the desalination of RO has been widely applied in Northwest and North China. The largest RO bitter salty water desalination project is the water plant in Qingyang city, Gansu province (Figure 4). The advanced treatment is RO system which put the outlet water with V type filter water. The design could make water recovery achieve above 85%, and the effluent water quality complies with the standards and forms 38,000 m3/d of scale [24]. Wang et al. showed that the RO membrane for treating high fluoride content of BW plays a remarkable role. At the pressure of 1.3 MPa, the recovery of 50% and the water temperature of 25˚C, the desalination rate can achieve 98%. Sulfate, chloride ion and other ions removal rate could reach 80% [25]. G. R. Lashkaripour et al. use small RO device desalination for BW in Iran. After some experiments the 2697 mg/L of bitter salty groundwater can be desalted for drinking water. And it could reach the standard of the world health organization. Energy consumption is low and the water making cost is only 0.5 - 1.3 $/t [26]. Chen et al. showed that the double membrane method for the water plant in Hangzhou bay is successful. The actual operation proved that the process could remove the chloride of BW [27].

The significant BWRO desalination examples are the drinking water project in Alxa Right Banner, Inner Mongolia, the city water supply project in Ningcheng, Gansu province, and the water supple project in Northwest University for Nationalities. So BWRO technology is mature and gradually develops to more large-scale regional.

Using RO desalination in power plant water supplying is little. Cangzhou power plant is the birthplace of RO device of China. According to the character of the underwater of the plant, deploying RO process in the desalting step before the ion exchange system, desalination rate and water recovery rate meet or exceed the standards of supply water.

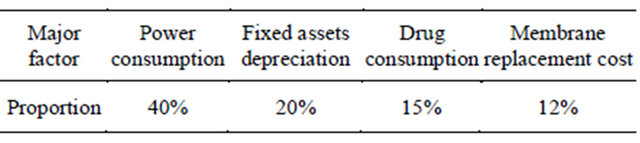

5. Expenses Study of BWRO

In addition to achieving the lowest energy consumption comparing with distillation and electroosmosis, the operation of RO is the most convenient, the realization of automation of the easiest, and it is easy to make small RO device [28]. The mainly cost of RO is consisted with three parts: the equipment investment cost, energy consumption cost and operation cost. And the operation cost mainly includes power consumption, fixed assets depreciation, drug consumption and membrane replacement cost (Table 2).

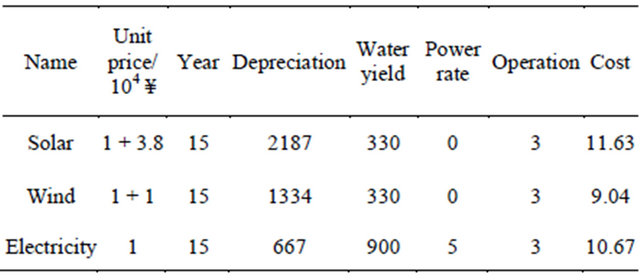

Although the domestic RO membranes are relatively cheap, the quality and stability is poorer. So many domestic operation membranes are imported. With the membrane demand growing, domestic membrane quality and the price will have a big change. The proportion of the membrane consumption will be gradually reduced. Comparing three kinds of different devices with solar energy, wind energy and electric energy power respec-

Figure 4. UF + RO in Hangzhou bay.

tively, wind power is the best and the solar power is a bit poorer (Table 3) [29].

The salt content is closely linked with water making cost. Generally the more the salt content, the higher the water making cost (Table 4).

6. Problems in RO Desalination

Whether in the design or operation, there are some problems which should be paid attention in RO desalination. Accurate water quality data could ensure the design of RO system and the pretreatment security. Because of the cold weather in winter in the Northwest China, the water temperature is low, so the inlet water should be heated. The water should be added acid to adjust the water PH value for the moderate and high BW.

In the operation process, SDI should be tested. If the SDI is too high, it will cause the membrane module ireversible pollution. If the recovery rate is too high, the membrane will scale. The pressure on the surface of the membrane is low in the early time. If the pressure increases rapidly, it shows that the membrane could scale. The changes of water yield and desalination rate should be very important.

7. Conclusion

According to the pretreatment of BWRO and choosing the RO membrane properly, it is feasible to use RO system for brackish water. RO system for brackish water is on top of a better methods considering both price or quality. Renewable energy such as solar and wind could guarantee the RO running and the energy recovery sys

Table 2. The cost analysis of BWRO.

Table 3. Compare of different device.

Table 4. The relationship of salinity and water making cost.

tem could achieve the purpose of saving energy and reducing consumption.

REFERENCES

- J. Wang. X.-Z. MENG, L. Chen and J.-F. Zhao, “Advances in Causes of Brackish Water and Desalination Technology,” Gansu Agricultural Science and Technology, Vol. 7, 2010, pp. 39-42.

- X.-C. An, W.-Z. Wang and J.-W. Lei, “Reverse Osmosis Desalination Technology of Brackish Water in the Western Area,” Desalination and Water Reuse Lake Forum, Hangzhou, 2006, pp. 205-215.

- B. Li, “The Choice of Reverse Osmosis Process,” Ning Xia Machinery, Vol. 3, No. 29, 2003.

- W. Zhang, “Study on RO Pretreatment and Silt Density Index Influence Factors,” Tianjin University, Tianjin, 2007.

- R. Yu, B. Dong and F. Y. Hao, “Study on the Reverse Osmosis Pretreatment for Brackish Water,” Petrochemical Industry Application, Vol. 26, No. 2, 2007, pp. 28-31.

- W. Sun, X.-W. Zhang, H.-L. Luo and H.-Q. Ding, “Treatment of Brackish Water with Ultrafiltration Membrane and Reverse Osmosis Membrane,” Liaoning Chemical Industry, Vol. 36, No. 3, 2007, pp. 187-189.

- L.-X. Wang, Y.-W. Guo and X.-M. Wang, “Study on Brackish Water Desalination Technology,” Safety and Environmental Engineering, Vol. 13, No. 1, 2006, pp. 66-69.

- G. Zhang and X.-W. He, “Study of Brackish Water Treatment Technology in High Salt Mine Area,” Energy Environmental Protection, Vol. 5, 2009, pp. 43-45.

- J. L. Chen, “A Survey of Materials Research of Reverse Osmosis (RO) Membrane at Home,” Water Purification Technology, Vol. 30, No. 3, 2011, pp. 34-37.

- T. C. Shang, “The Application of Reverse Osmosis in Brackish Water Desalination,” Industrial Water Treatment, Vol. 18, No. 2, 1998, pp. 33-36.

- L.-X. He, J. Yang and X.-W. He, “Experiments and Applied Research about Mine Brackish Water Reverse Osmosis Desalination,” Coal Engineering, Vol. 5, 2006, pp. 61-63.

- Y. Zhou and C. J. Gao, “Comparison between BWRO Membrane and SWRO Membrane,” CIESC Journal, Vol. 10, 2010, pp. 2590-2595.

- A. Almulla, M. Eid, P. Cote and J. Coburn, “Development in High Recovery Brackish Water Desalination Plants as Part of the Solution to Water Quantity Problems,” Desalination, Vol. 153, No. 1-3, 2002, pp. 237- 243. doi:10.1016/S0011-9164(02)01142-6

- P. Glueckstern and M. Priel, “Boron Removal in Brackish Water Desalination Systems,” Desalination, Vol. 205, No. 1-3, 2007, pp. 178-184. doi:10.1016/j.desal.2006.02.054

- Q. F. Ma and H. Lu, “Wind Energy Technologies Integrated with Desalination Systems: Review and State-ofthe-Art,” Desalination, Vol. 277, 2011, pp. 274-280. doi:10.1016/j.desal.2011.04.041

- X.-J. Zhang, B. Tan and H. Y. Chen, “Small-Scale Photovoltaic Solar Plant Development of Reverse Osmosis Desalination,” Desalination and Water Reuse Lake Forum, Hangzhou, 2006, pp. 178-183.

- X. Q. Zhang, M. X. Du, Y. Zhang and L. Yang, “Reverse Osmosis Watertreatment Employing Solar Energy,” Acta Energiae Solaris Sinica, Vol. 31, No. 11, 2010, pp. 1419- 1422.

- H. Qiblawey, F. Banat and Q. Al-Nasser, “Performance of Reverse Osmosis Pilot Plant Powered by Photovolatic in Jordan,” Renewable Energy, Vol. 36, No. 12, 2011, pp. 3452-3460. doi:10.1016/j.renene.2011.05.026

- G. E. Ahmad and J. Schmid, “Feasibility Study of Brackish Water Desalination in the Egyptian Deserts and Rural Regions Using PV Systems,” Energy Conversion and Management, Vol. 43, No. 18, 2002, pp. 2641-2649. doi:10.1016/S0196-8904(01)00189-3

- S. Dallas, N. Sumiyoshi, J. Kirk, K. Mathew and N. Wilmot, “Efficiency Analysis of the Solarflow: An Innovative Solar-Powered Desalination Unit for Treating Brackish Water,” Renewable Energy, Vol. 34, No. 2, 2009, pp. 397-400. doi:10.1016/j.renene.2008.05.016

- F.-J. Zhu and P.-F. Du, “New Wind Energy Desalination Coupled Systems,” China Rural Water and Hydropower, Vol. 7, 2010, pp. 70-71.

- G. L. Park, A. I. Schafer and B. S. Richards, “Renewable Energy Powered Membrane Technology: The Effect of Wind Speed Fluctuations on the Performance of a WindPowered Membrane System for Brackish Water Desalination,” Journal of Membrane Science, Vol. 370, No. 1-2, 2011, pp. 34-44. doi:10.1016/j.memsci.2010.12.003

- Y. Wang, “A Study on Valve-Controlled Energy Recovery Device for Reverse Osmosis Desalination Process,” Tianjin Unversity, Tianjin, 2004.

- Y.-P. Wang, J.-W. Lei and G.-L. Jiao, “Reverse Osmosis Brackish Water Desalination Project in Qingyang City,” Water & Wastewater Engineering, Vol. 4, 2010, pp. 26- 29.

- S. N. Wang, S. X. Hou, J. J. Chen and J. M. Wan, “Study on the Test of RO Desalinating Brackish Water with High Contains of Fluorine,” Journal of Hebei Institute of Architecture and Civil Engineering, Vol. 25, No. 1, 2007, pp. 49-51.

- G. R. Lashkaripour and M. Zivdar, “Desalination of Brackish Groundwater in Zahedan City in Iran,” Desalination, Vol. 177, No. 1-3, 2005, pp. 1-5. doi:10.1016/j.desal.2004.12.002

- X.-A. Chen and X.-H. Wang, “Application of Membrane Treatment Technology in Advanced Treatment of Brackish Water,” China Water & Wastewater, Vol. 16, 2009, pp. 41-43.

- L.-N. Ma, “The Technical Specifications of Brackish Water Reverse Osmosis for Water Plant,” Electric Power Stardardization & Measurement, Vol. 2, 2002, p. 5.

- H.-M. Liu, Z.-X. Guo, W.-B. Liu and Y. Zha, “The Features and Cost Analysis of Brackish Water Reverse Osmosis Desalination Technology,” Inner Mongolia Water Resourcas, Vol. 4, 2002, pp. 49-50.

NOTES

*The Fundamental Research Fun for the Central Universities.