Intelligent Control and Automation, 2011, 2, 241-250 doi:10.4236/ica.2011.23029 Published Online August 2011 (http://www.SciRP.org/journal/ica) Copyright © 2011 SciRes. ICA Self-Structured Organizing Single-Input CMAC Control for De-icing Robot Manipulator Thanhquyen Ngo1,2, Yaonan Wang1, Youhui Chen1, Zan Xiao 1 1College of Electrical and Information Engineering, Hunan University, Changsha, China 2Faculty of Electrical Engineering, Ho Chi Minh City University of Industry, Ho Chi Minh, Vietnam E-mail: thanhquyenngo2000@ y ahoo.com, yaonan@hnu.cn Received June 1, 2011; revised June 22, 2011; accepted June 29, 20 1 1 Abstract This paper presents a self-structured organizing single-input control system based on differentiable cerebellar model articulation controller (CMAC) for an n-link robot manipulator to achieve the high-precision position tracking. In the proposed scheme, the single-input CMAC controller is solely used to control the plant, so the input space dimension of CMAC can be simplified and no conventional controller is needed. The structure of single-input CMAC will also be self-organized; that is, the layers of single-input CMAC will grow or prune systematically and their receptive functions can be automatically adjusted. The online tuning laws of sin- gle-input CMAC parameters are derived in gradient-descent learning method and the discrete-type Lyapunov function is applied to determine the learning rates of the proposed control system so that the stability of the system can be guaranteed. The simulation results of three-link De-icing robot manipulator are provided to verify the effectiveness of the proposed control methodology. Keywords: Cerebellar Model Articulation Controller (CMAC), De-icing Robot Manipulator, Gradient-Descent Method, Self-Organizing, Signed Distance 1. Introduction In general, robotic manipulators have to face various uncertainties in their dynamics, such as friction and ex- ternal disturbance. It is difficult to establish exactly mathematical model for the design of a model-based control system. In order to deal with this problem, the braches of current control theories are broad including classical control: neural networks (NNs) control [1-3], adaptive fuzzy logic control (FLCs) [4-6] or adaptive fuzzy-neural networks (FNNs) [7-9] etc. They are classi- fied as adaptive intellig ent control b ased on conven tional adaptive control techniques where fuzzy systems or neu- ral networks are utilized to approximate a nonlinear function of the dynamical systems. However, many adaptive approaches are rejected as being overly compu- tationally intensive because of the real-time parameter identification and requ ired control design. Fuzzy logic control (FLCs) has found extensive appli- cations for plants that are complex and ill-defined which is suitable for simple second order plants. However, in case of complex higher order plants, all process states are required as fuzzy input variables to implement state feedback FLCs. All the state variables must be used to represent contents of the rule antecedent. So, it requires a huge number of control rules and much effort to create. To address these issues, single-input Fuzzy Logic con- trollers (S-FLC) was proposed for the identification and control of complex dynamical systems [10-12]. As a re- sult, the number of fuzzy rules is greatly reduced com- pared to the ca se of t he conv enti onal F LCs, but i ts cont rol performance is almost the same as conventional FLCs. Neural networks (NNs) are a model-free approach, which can approximate a nonlinear function to arbitrary accuracy [1-3]. However, the learning speed of the NNs is slow. To deal with these issues, cerebellar model ar- ticulation controller (CMAC) was proposed by Albus in 1975 [13] for the identification and control of complex dynamical systems, due to its advantage of fast learning property, good generalization capability and ease of im- plementation by hardware [13-15]. The conventional CMACs, regarded as non-fully connected perceptron-like associative memory network with overlapping receptive fields which used constant binary or triangular functions. The disadvantage is that their derivative information is not preserved. For acquiring the derivative information of  T. NGO ET AL. 242 input and out put variables, C hiang and Lin [16] developed a CMAC network with a differentiable Gaussian recep- tive-field basis function and provided the convergence analysis for t his network. The advantages of using CMAC over neural network in many applications were well documented [17-21]. However, in the above CMAC lit- eratures, the structure of CMAC cannot be obtained automati cally. The am ount of m emory space is difficult to select, which will influence the learning and control schemes. Some self-organizing CMAC neural networks were proposed for structure adaptation [22-25]. In [22] and [23] a data clustering technique is used to reduce the memory size and a structural adaptation technique is developed in order to accommodate new data sets. However, only the structure growing mechanism is in- troduced and; the pruning mechanism was not discussed. In [24], a self-organizing hierarchical CMAC was intro- duced. The authors proposed a multilayer hierarchical CMAC model and used Shannon’s entropy measure and golden-section search method to determine the input space quantization. However, their approach is too com- plicated and lacks online real-time adaptation ability. Online adjusting suitable memory space of CMAC structure is our motivation. To address these issues, C. M. Lin, T. Y. Chen proposed self-organizing control system [25]. This control system does not require prior knowl- edge amount of memory space, the layers of CMAC will grow or prune systematically. However, the dimension of the input space of CMAC control system is reduced through a comb in ation of sliding con tro l mode l. Recently, to deal with the problem of the simplified input, B. J Choi, S. W. Kwak and B. K. Kim proposed the S-FLC [10-12] and its advantages which are mentioned above. Based on the S-FLC, several literatures developed sin- gle-input CMAC (S-CMAC) control system [26,27], which adopts two learning stages, namely, an offline learning stage and online learning stage. The disadvan- tage is that their derivative information is also not pre- served. So, M. F. Yeh and C. H. Tsai proposed differen- tiable standalone CMAC control system [28] to provided better system status in the learning control. In addition, the quantization of input space could be reduced while using the differentiable standalone CMAC. However, the disadvantages are that the structure of S-CMAC cannot be obtained automatic al l y . In this paper, we propose a novel self-structured orga- nizing single-input CMAC (SOSICM) control system for three-link De-icing robot manipulator to achieve the high-precision position tracking. This control system combines advantages of S-CMAC and it does not require prior knowledge of a certain amount of memory space, and the self-organizing approach demonstrates the prop- erties of generating and pruning the input layers auto- matically. The developed self-organizing rule of S-CMAC is clearly and easily used for real-time systems. More- over, the developed system is solely used to control the plant and no conventional or compensated controller. The online tuning laws of CMAC parameters are derived in gradient-descent method. This paper is organized as follows: System description is described in section 2. Section 3 presents SOSICM control system. Numerical simulation results of a three-link De-icing robot manipulator under the possible occurrence of uncertainties are provided to demonstrate the tracking control performance of the proposed SOSICM system in section 4. Finally, conclusions are drawn in section 5. 2. System Description In general, the dynamic of an n-link robot manipulator may be expressed in the Lagrange following form: ,MqqCqqqGq N (1) where are the joint position, velocity and acceleration vectors, respectively, ,, n qqq R nn qR denotes the inertia matrix, ,nxn CqqR 1nx NR expresses the matrix of centripetal and Coriolis forces, is the gravity vector, represents the vector of exter- nal disturbance , friction term 1nx Gq R l t q , and un-modeled dynamics, is the torque vectors exerting on joints. In this paper, a new three-link De-icing robot ma- nipulator, as shown in Figure 1, is utilized to verify dy- namic properties are given in section 4. 1mx R The control problem is to force , n i qt R 1, 2,im to track a given bounded reference input signal n R di qt . Let be the tracking error vector as follows: i et , 1,2, idii eq qim (2) and the system tracking error vector is defined as De-icing Robot Link 1Link 1 Link 2 Link 2 Link 3 Link 3 Link 2 Link 1 Power Line Figure 1. Architecture of three-link De-icing robot manipu- lator. Copyright © 2011 SciRes. ICA  T. NGO ET AL.243 1 2 1 1 12 1 12 00 00 00 0 00 , 1,2,, ii ii i n ni i n ii iinii n ii ni ke ke ke ke keke im (3) where nn ni R is the scaling factor matrix for the system tracking vector 1 [] nn iii i eeee R , . 1, 2,im Based on [10,11], the tracking error is trans- formed into a single variable, termed the signed distance which is the distance from an actual state to the switching line as shown in Figure 2 for a 2-D input. The switching line is defined as follows: n iR , m si dRn iR 12 121 0 nn iniii ee ee (4) where is a constant. Then, the signed dis- tance between the switching line and operating point can be expressed by the following equation: 1 1n nR n iR 12 1( 1)2211 222 121 1 nn ninn iii si n d (5) According to the standalone CMAC control system is shown in Figure 3. This control scheme provided better i i 0 si d 0 si d si d ),( ii Figure 2. Derivation of a signed distance. d/dt i si d i e + - di q i q i w i m i i2 i1 i q Signed Distance Adaptive Law Standalone Scheme 1 k 2 k i k 1 i k 2 S-CMAC Figure 3. Block diagram of standalone CMAC control sys- tem. control characteristics due to using the differentiable CMAC in the system. The advantage is that derivative information of input and output variables is preserved in learning process. In addition, the generalization error caused by quantization of input space could be reduced while using the differentiable CMAC. Based on the standalone CMAC control system, we propose the SOSICM control system as shown in Figure 4, which combines advantages of standalone CMAC and it does not require prior knowledge of a certain amount of memory space. The self-organizing approach demon- strates the properties of ge nerating and pruning the input layers automatically. The developed self-organizing rule of CMAC is clearly and easily used for real-time systems 3. Adaptive SOSICM Control System 3.1. Brief of the S-CMAC An S-CMAC is proposed and shown in Figure 5. It is composed of an input, association memory, weight and output spaces. The signal propagation and the basic function in each space are expressed as follows: 1) Input space D; assume that each input state vari- able i can be quantized into d i discrete states and that the information of a quantized state is regarded as region for each layer ki . Therefore, there exist si N nth 1N individual points on the i- axis. Figure 6 shows the case of si d 10N . Each activated state in each layer becomes a firing element, thus, the weight of each layer can be obtained. The Gaussian basic function for each layer is given as follows: d/dt si d i e + - di q i q i w i m i i 2 i1 i k 1 i k 2 i q Signed Distance S-CMAC Adaptive Law 2 k SOSICM Scheme Self-Organizing of S-CMAC Layers i ki ki v ki n 1 k Learning Rate Propagation Error Term d/dt i e i e pi wi P i P i k P 1 i k P 2 mi P wi mi i i1 i 2 Figure 4. Block diagram of proposed SOSICM control sys- tem. Copyright © 2011 SciRes. ICA  T. NGO ET AL. 244 k n w m o k n s D Input Space DsOutput Space O Weight Memory Space W Association Memory Space A Target + - Figure 5. Architecture of a single-input CMAC. d1d2d3d4d7d8d9d10 s1s2s3s4s5s7s8s9s10 dsi -10 +1 Knot State Layer 1 Layer 2 Layer nki d6 d5 s6 d0 Figure 6. Block divisio n of CMAC with Gaussian basic func- tion. 2 2 ()exp , 1,2,,, 1,2,, si ki ki siki ki dm d imk n (6) where ki represents the kth layer of the input i d w the mean ki m a the variance ki ith nd . 2) Output space O: The output of S-CMAC is the al- gebraic sum of the firing element with the weight mem- ory, and is expressed as 1 ki n ikikiki k aw d si n (7) where denotes the weight of the kth layer, is the index indicating whether the ith memory element is addressed by the state involving ki w si d , ki ki aa1, 2,ki k i. Since each state addressed exactly ki memory elements, only those addressed s are one, and the others are zero. d m, ki a The block diagram in Figure 3, in which only the S-CMAC plays a major role in the control process, thus to have a trade-off between the desired performance and the computation loading we must choose a reasonable number of layers. However, if the number of layers is chosen too small, the learning performance may be in- sufficient to achieve a desired performance. Otherwise, if the number of layers is chosen too large, the calculation process is too heavy, so it is not suitable for real-time applications. To deal with this problem, a self-structured organizing S-CMAC is proposed includes structure and parameter learning as shown in Figure 4. 3.2. Self-Structured Organizing S-CMAC In this section, structural learning is necessary to deter- mine whether to add a new layer in association memory A depends on the firing strength of each layer for each incoming data ki n ki R i. If the firing strength of each layer for new input data d ki n ki R i falls outside the bounds of the threshold, then, SOSICM will generate a new layer. The self-structured organizing S-CMAC can be summarized as follows: d 1) Calculate the firing strength of each layer for each input data ki n ki R i 2) Using Max-Min method is proposed for layer growin g . F ind d in (6). 1 ˆargmin, 1,2, ki ikisi kn kdk k n i (8) If ˆi i kdK gi (9) Here i is a threshold value of adaptation with 0K1 gi . In our case and a new layer is generated. 0.1 gi K This means that for a new input data, the exciting value of existing basic function is too small. In this case, number of layers increased as follows: 1 ki ki ntnt1 (10) where ki is the number of layers at time t. Thus, a new layer will be generated and then the corresponding pa- rameters in the new layer such as the initial mean and variance of Gaussian basic function in association mem- ory space and the weight memory space will be defined as n ki n mdsi (11) ˆ ki nki (12) 0 ki n w (13) Another self-structured organizing learning process is considered to determine whether to delete existing layer, which is inappropriate. A Max-Min method is proposed for layer pruning. Considering the output of SOSICM in (7), the ratio of the kth component of output is defined as Copyright © 2011 SciRes. ICA  T. NGO ET AL.245 , 1,2,, ki ki ki i v Mk n (14) where , kikiki wv Then, the minimum ratio of the kth component is defined as follows: 1 arg min ki i kn k ki MM (15) If ici k MK (16) Here ci is a predefined deleting threshold. In our case and the i layer will be deleted. This means that for an output data, if the minimum con- tribution of a layer is less than the deleting threshold, then this layer will be deleted. 0.03Kci kth 3.3. On-Line Learning Algorithm The central part of the learning algorithm for a SOSICM is how to choose the weight memory mean variance ki , ki w, ki m of the Gaussian basic function. ni Are the scaling factors of the error i e and the change of error i, which will significantly affect the performance of SOSICM. For achieving effective learning, an on-line learning algorithm, which is derived using the supervised gradient descent method, is introduced so that it can in real-time adjust the parameters of SOSICM. The energy function is defined as k e i E 22 1 22 idii Eqq e 1 i (17) According to the energy function (17) and the system structure in Figure 4, the error term to be propagated is given by iii pi i iii EEq e q i i q (18) where ii q represent the sensitivity of the plant with respect to its input. With the energy function the parameters updating law based on the normalized gradient descent method can be deri ved as follows , i E 1) The updating law for the weight memory can be derived according to kth ii ki wiwi kii ki kiwi pi kisi EE ww ad i w (19) where wi is positive learning rate for the output weight memory the connective weight can be up- dated according to the following equation: , ki w 1 kiki ki wtwt w (20) 2) The mean and variance of the Gaussian basic function can be also updated according to kth 2 2 2 iii ki miwi kiiki si ki kimi piki kisiki EE mmm dm awd (21) 2 3 2 iii ki iwi kii ki si ki kiipiki kisiki EE dm awd (22) where mi , i are positive learning rates for the mean and variance, respectively. The mean and variance can be updated as follows: 1 kikiki mtmt m (23) 1 kiki ki tt (24) 3) Finally, the updating law for scaling factors can be derived as follows: 2 1 1 222 121 2 1 ki iiisi ni nini niisi ni nsi ki nipikiki kisi kki n nni n EEd kkdk dm aw d e (25) where mi is the learning rate, and it can be updated by the following: 1 nini ni ktkt k (26) The plant sensitivity ii q in (18) can be calcu- lated if the plant model is exactly known. However, the plant model is unknown, so ii q can not obtained in advance. To deal with this problem, in [28], a simple approximation of the error term of the system can be use as follows: ii ee i (27) 3.4. Convergence Analysis The update laws of Equations (19), (21), (22) and (25) require a proper choice of the learning rates , wi mi , , i and ni in order to the convergence of the output error is guaranteed; however, this is not easy which de- pends on each person’s experience. To train the S-CMAC effectively, the variable learning rates which guarantee convergence of the output error are derived in the following. Defined a discrete-type Lyapunov function can be Copyright © 2011 SciRes. ICA  T. NGO ET AL. 246 given by 2 1 2 ii Vke k (28) Thus, the change of the Lyapunov due to the training process is obtained as 22 1 11 2 ii iii VkVkVke ke k (29) where is represented by [28] 1kei 1 T i iiii i ek ekekek ekP P i (30) where represents the in the learning process, i i eP denotes a change of an adjustable parameters. Using Equation (18), we have i ipiiii PeP ek and ipiii PEP ipi ii P , where i is the learning rate for the parameter Pi. Thus: 22 22 2 22 2 1 2 1 2 12 2 iii i pi pipi pi ii i ii ii pi ii pi pipi iii Vkekekek ek ek Pek P PekP (31) If the learning rate i is selected as: 2 2 02 ipii i ek P i (32) Then therefore 0, i Vk 1, ii Vk Vk the Lyapunov stability (system stability) and the conver- gence of the tracking error could be guaranteed. In addi- tion, the optimal learning rate can be found for achieving faster convergence by taking the differential equation (31) with respect to i and equals to zero. Finally, the op- timal learning rate can be determined as follows: 2 2 1 ipii i ek P i (33) where i P i for ,, ikiki Pwm ki and , it can be obtained as: ni k , i wiki ki ki Pk a w 2 2 iki i mikiki ki ki ki dm Pk aw m 2 3 2si ki i ikikiki ki ki dm Pk aw 2 1 1 222 121 2 1 ki ni nsiki i kkikikisi k ni ki n nni n dm Pkawd k e (34) 4. Simulation Results A three-link De-icing robot manipulator as shown in Figure 1 is utilized in this paper to verify the effective- ness of the proposed control scheme. The detailed system parameters of this robot manipulator are given as: link mass , lengths angular posi- tions and displacement position 123 ,,()mmmkg ,( )qqrad 12 ,ll m, 12 3 dm . The parameters for the equation of motion (1) can be represented as follow: 11 1213 21 2223 31 3233 MMM MqM MM MMM 22 11112212 111 22 322 2212 94 14 2 2 mlmcllllcs mcllcll 22 2222321 1 1443 2 ml mlml 2332322 Mmcl 33 3 m 12132131 0MMMM 11 1213 21 2223 31 3233 CC C CqC CC CCC 112 1 2111 22 2 2 2232 222122 8 122 2 Cmllcsq msclmsclsll q 22 212 2 2232 222121 122 2Cmsclmsclsll q d q 2232 23 Cmsl 2332 22 2Cmsl 3232 22 Cmslq 12133133 0CCCC 1211 2 2 122 222 3 3 12 12 cclcl mg Gqsslmclm g mg (35) where 3 qR and the shorthand notations 11 ,cqcos 22 cos ,cq 1 sin 1 qand Copyright © 2011 SciRes. ICA  T. NGO ET AL.247 2 sin 2 q 13( )mkg are used. For the convenience of the simulation, the nominal parameters of the robotic system are given as 2 2(),mkg32.5( ),mkg 1 2 and 0.14(),lm 0.32(),lm 2 9.8 ms 00,3 d 01, 2 q and the initial condi- tions 1 q 00, 100q, . The desired reference trajectories are 1d 200,q d qt 300 sin ,t2d cosqt ,t 2cos ,dt t d respectively. The most important parameters that affect the control performance of the robotic system are the external dis- turbance the friction term , l t q , which are injected into the robotic system, and their shapes are expressed as follows: l tt 5sin55sin55sin5T t t t (36) In addition, friction forces are also considered in this simulation and given as 112 33 20 0.8sgn42sgn 42sgnT 2 qqqqq dd (37) In order to exhibit the superior control performance of the proposed SOSICM control system, the control sys- tem standalone CMAC is introduced in Figure 3 and examined in the mean time [28]. They are applied to control three-link De-icing robot manipulator and the same setting of SOSICM and standalone CMAC control system are chosen as follows: The inputs space of S-CMAC are 1, d 2 d and 3 d, the mean and vari- ance of Gaussian basic functions are selected to cover the input space 11 kkk www 11 11 ; all initial weights are set to zero, i.e., 123 . The parameter 0,1,2,ki kn in the switching line is one. For re- cording respective control performance, the mean-square-error of the position-tracking response is defined as: 2 1 1, 1,2,3 T idii j mse q qjqj i T (38) where T is the total sampling instant, and iand di are the elements in the vector i and di q. In this paper, the numerical simulation results carried out by using Matlab software. q q Example 1: Consider the standalone CMAC control system is shown in Figure 3. For the standalone CMAC control system, the pa- rameters are chosen such as: 0.02, wi 0.02, mi 0.02 i , 0.02, ni 20.8 i m the initial value of Gaussian basic functions and scaling factors are defined as 11.0, i m ,30.6, i m 40.4, i m ,90.6 i m 50.2, i m 60.0, i m7 m0.2, 80.4 i m i 10 0.8, i mm11 1.0, iki 0.15, 10.5 i kand 20.2 i k for 1, 2,,11,k 1, 2, 3i . The simulation results of standalone CMAC system, the responses of joint position and MSE are depicted Figures 7(a)-(f), respectively. 0 246810 1214 16182020 22 20 -2 -1 0 1 Time Position link 1(rad) desired actual s (a) 0 2 46 810 121416 18 20 -2 0 2 Time(s) Position link 2 (r ad) desired actual (b) 0246810 1214161820 -2 0 2 Time s Distance link 3 (m) actual des ired (c) 0 2 46 810 12 1416 182020 0 0.2 0.4 0.6 0.8 11 Time(s) MSE Joint 1 (rad) (d) 0 246 810 1214 16 18 2020 0 0.2 0.4 0.6 0.8 11 Time s MSE Joint 2 (rad) (e) 0 2 46 810 12 1416 182020 0 0.2 0.4 0.6 0.8 1 Time s MSE Joint 3 (m) (f) Figure 7. Simulated position responses and MSE of the Standalone CMAC control system at joints 1, 2 and 3. Copyright © 2011 SciRes. ICA  T. NGO ET AL. 248 Example 2: Consider the proposed SOSICM control system is shown in Figure 4. For the proposed SOSICM control system, the pa- rameters are chose in the following: 2 2 1() pipi iii ek P ki for ,, ikiki Pwm and ni , and the initial values of system parameters are given as , the inputs of S-CMAC 1 k2 ki n d, 2 d and 3 d the mean and variance of Gaussian basic functions are selected to cover the input space 1111 11. The threshold value of i is set as 0.1; ci is set as 0.01 for . The simulation results of the pro- posed SOSICM system, the responses of joint position, MSE and layer number are depicted in Figures 8(a)-(f) and (g), (h) and (k) respectively. 1, 2, 3 i According to the simulation results as shown in Fig- ures 7 and 8, the joint-position tracking responses of the proposed SOSICM system can be controlled to more closely follow desired reference trajectories than the standalone CMAC as shown in Figure 7 and Figures 8(a)-(c). Our proposed control system for each joint shows that the MSE in Figures 8(d)-(f) is faster than the MSE in Figures 7(d)-(f) and finally converges to 0.009, 0.015 and 0,019. Meanwhile the MSE of standalone CMAC is 0.032, 0.031 and 0.036 and number of layers of S-CMACs converge to three layers as shown in Fig- ures 8(g), (h) and (k). 0 2 4681012 14 16 18 2020 -2 0 2 Time(s) Position link 1 (rad) desired actual (a) 0 2 4 6810 12 1416 18 2020 -2 0 2 Time(s) Position link 2 (rad) desired actual (b) 0 24 6810 12 14 16 18 2020 -2 0 2 Time(s) Distnce link 3 (m) desired actual (c) 0246810 12 14 1618 2020 0 0.2 0.4 0.6 0.8 11 Time s MSE Joint 1 (rad) (d) 0246810 121416 18 20 0 0.2 0.4 0.6 0.8 11 Time(s) MSE Joint 2 (rad) (e) 0246810 12 14 16 182020 0 0.2 0.4 0.6 0.8 1 1.21.2 Time(s) MSE Joint 3 ( m) (f) 02 46 810 12 1416 1820 0 2 4 6 8 1010 Time s Laye r Number CMAC (g) 0246810 12 14 16182020 0 2 4 6 8 10 Time(s) Layer Number CMAC2 (h) 0246810 12 1416182020 0 2 4 6 8 1010 Time(s) Layer number CMAC3 (k) Figure 8. Simulated position responses, MSEs and layer number of the SOSICM con trol system at joints 1, 2 and 3. 5. Conclusions In this paper, a SOSICM control system is proposed to Copyright © 2011 SciRes. ICA  T. NGO ET AL.249 control the joint position of a three-link De-icing robot manipulator. In the SOSICM system, dynamical system is completely unknown and auxiliary compensated con- trol is not required in the control process. The online tuning laws of S-CMAC parameters are derived in gra- dient-descent learning method and the discrete-type Lyapunov function is applied to determine the variable optimal learning rates so that the stability of the system can be guaranteed. This paper has successfully devel- oped the SOSICM control system for a three-link De-icing robot manipulator not only requires low mem- ory with online structure and parameters tuning algo- rithm, but also the input space can be reduced through the signed distance. The simulation results of the pro- posed SOSICM system can achieve favorable tracking performance for three-link De-icing robot manipulator. 6. Acknowledgments The authors would like to thank the editors and the re- viewers for their valuable comments. 7. References [1] A. Vemuri, M. M. Polycarpou and S. A. Diakourtis, “Neural Network Based Fault Detection in Robotic Ma- nipulators,” IEEE Robotics Automation, Vol. 14, No. 2, 1998, pp. 342-348. doi:10.1109/70.681254 [2] W. Z. Gao and R. R. Selmic, “Neural Network Control of a Class of Nonlinear Systems with Actuator Saturation,” American Control Conference, Boston, 2006, pp. 147- 156. [3] Y. Zou, Y. N. Wang and X. Z. Liu, “Neural Network Robust H∞Tracking Control Strategy for robot manipula- tors,” Applied Mathematical Modelling, Vol. 34, No. 7, 2010, pp. 1823-1838. doi:10.1016/j.apm.2009.09.026 [4] B.-S. Chen, H.-J. Uang and C.-S. Tseng, “Robust Track- ing Enhancement of Robot Systems Including Motor Dynamics: A Fuzzy-Based Dynamic Game Approach,” IEEE Transactions on Fuzzy Systems, Vol. 6, No. 4, 1998, pp. 538-552. doi:10.1109/91.728449 [5] H.-X. Li and S.-C. Tong, “A Hybrid Adaptive Fuzzy Control for a Class of Nonlinear MIMO Systems,” IEEE Transactions on Fuzzy Sysemstm, Vol. 11, No. 1, 2003, pp. 24-34. doi:10.1109/TFUZZ.2002.806314 [6] S. Labiod, M. S. Boucherit and T. M. Guerra, “Adaptive Fuzzy Control of a Class of MIMO Nonlinear Systems,” Fuzzy Set and Systems, Vol. 151, No. 1, 2005, pp. 59-77. doi:10.1016/j.fss.2004.10.009 [7] Y. G. Leu, W. Y. Wang, and T. T. Lee, “Observe Based Direct Adaptive Fuzzy Neural Control for Non-Affine Nonlinear Systems,” IEEE Transactions on Neural Net- works, Vol. 16, No. 4, 2005, pp. 853-861. doi:10.1109/TNN.2005.849824 [8] R. J. Wai and Z. W. Yang, “Adaptive Fuzzy Neural Net- work Control Design via a T-S Fuzzy Model for a Robot Manipulator Including Actuator Dynamics,” IEEE Trans- actions on Systems, Man and Cybernnetics, Vol. 38, No. 5, 2008, pp. 1326-1346. doi:10.1109/TSMCB.2008.925749 [9] C.-S. Chen, “Dynamic Structure Neural Fuzzy Networks for Robust Adaptive Control of Robot Manipulators,” IEEE Transactions on Industrial Electronics, Vol. 55, No. 9, 2008, pp. 3402-3414. doi:10.1109/TIE.2008.926778 [10] B. J. Choi, S. W. Kwak and B. K. Kim, “Design of Sin- gle-Input Fuzzy Logic Controller and Its Properties,” Fuzzy Sets and Systems, Vol. 106, No. 3, 1999, pp. 299-308. doi:10.1016/S0165-0114(97)00283-2 [11] B. J. Choi, S. W. Kwak and B. K. Kim, “Design and Sta- bility Analysis of Single-Input Fuzzy Logic Controller,” IEEE Transactions on Systems, Man and Cybernnetics, Vol. 30, No. 2, 2000, pp. 303-309. doi:10.1109/3477.836378 [12] K. Ishaque, S. S. Abdullah, S. M. Ayob and Z. Salam, “Single Input Fuzzy Logic Controller for Unmanned Un- derwater Vehicle,” Journal of Intelligent and Robotic Systems, Vol. 59, No. 3, 2010, pp. 87-100. doi:10.1007/s10846-010-9395-x [13] J. S. Albus, “A New Approach to Manipulator Control: The Cerebellar Model Articulation Controller,” Journal of Dynamic Systems Measurement and Control, Vol. 97, No. 3, 1975, pp. 220-227. doi:10.1115/1.3426922 [14] H. Shiraishi, S. L. Ipri and D. D. Cho, “CMAC Neural Network Controller for Fuel-Injection Systems,” IEEE Transactions on Control Systems Technology, Vol. 3, No. 1, 1995, pp. 32-38. doi:10.1115/1.3426922 [15] S. Jagannathan, S. Commuri and F. L. Lewis, “Feedback Linearization Using CMAC Neural Networks,” Auto- matica, Vol. 34, No. 3, 1998, pp. 547-557. doi:10.1016/S0005-1098(97)00206-9 [16] C. T. Chiang and C. S. Lin, “CMAC with General Basis Functions,” Journal of Neural Networks, Vol. 9, No. 7, 1996, pp. 1199-1211. doi:10.1016/S0005-1098(97)00206-9 [17] Y. H. Kim and F. L. Lewis, “Optimal Design of CMAC Neural-Network Controller for Robot Manipulators,” IEEE Transactions on Systems, Man and Cybernnetics, Vol. 30, No. 1, 2000, pp. 22-31. doi:10.1109/5326.827451 [18] C. M. Lin and Y. F. Peng, “Adaptive CMAC-Based Su- pervisory Control for Uncertain Nonlinear Systems,” IEEE Transactions on Systems, Man and Cybernnetics, Vol. 34, No. 2, 2004, pp. 1248–1260. doi:10.1109/TSMCB.2003.822281 [19] S. F. Su, T. Tao and T. H. Hung, “Credit Assigned CMAC and Its Application to Online Learning Robust Controllers,” IEEE Transactions on Systems, Man and Cybernnetics, Vol. 33, No. 2, 2003, pp. 202-213. doi:10.1109/TSMCB.2003.810447 [20] H.-C. Lu, C.-Y. Chuang and M.-F. Yeh, “Design of Hy- brid Adaptive CMAC with Supervisory Controller for a Class of Nonlinear System,” Neurocomputing, Vol. 72, No. 7-9, 2009, pp. 1920-1933. Copyright © 2011 SciRes. ICA  T. NGO ET AL. Copyright © 2011 SciRes. ICA 250 doi:10.1016/j.neucom.2008.07.004 [21] Y. F. Peng and C. M. Lin, “Intelligent Hybrid Control for Uncertain Nonlinear Systems Using a Recurrent Cerebel- lar Model Articulation Controller,” IEEE Proceedings Control Theory and Applications, Vol. 151, No. 5, 2004. pp. 589-600. doi:10.1049/ip-cta:20040903 [22] J. Hu and F. Pratt, “Self-Organizing CMAC Neural Net- works and Adaptive Dynamic Control,” IEEE Interna- tional Symposium on Intelligent Control/Intelligent Sys- tems and Semiotics, Cambridge, 1999, pp. 259-265. [23] H. C. Lu and C. Y. Chuang, “Robust Parametric CMAC with Self-Generating Design for Uncertain Nonlinear Systems,” Neurocomputing, Vol. 74, No. 4, 2011, pp. 549-562. doi:10.1016/j.neucom.2010.09.001 [24] H. M. Lee, C. M. Chen and Y. F. Lu, “A Self-Organizing HCMAC Neural-Network Classifier,” IEEE Transactions on Neural Networks, Vol. 14, No. 1, 2003, pp. 15-27. doi:10.1109/TNN.2002.806607 [25] C. M. Lin and T. Y. Chen, “Self-Organizing CMAC Con- trol for a Class of MIMO Uncertain Nonlinear Systems,” IEEE Transactions on Neural Networks, Vol. 20, No. 9, 2009, pp. 1377-1384. doi:10.1109/TNN.2009.2013852 [26] M.-F. Yeh, “Single-Input CMAC Control System,” Ne u - rocomputing, Vol. 70, No. 16-18, 2007, pp. 2638-2644. doi:10.1016/j.neucom.2006.05.019 [27] M.-F. Yeh, H.-C. Lu and J.-C. Chang, “Single-Input CMAC Control System with Direct Control Ability,” IEEE Transactions on Systems, Man and Cybernnetics, Vol. 3, No. 1, 2006, pp. 2602-2607. doi:10.1109/ICSMC.2006.385256 [28] M.-F. Yeh and C.-H. Tsai, “Standalone CMAC Control Systems with Online Learning Ability,” IEEE Transac- tions on Systems, Man and Cybernnetics, Vol. 40, No. 1, 2010, pp. 43-53. doi:10.1109/TSMCB.2009.2030334

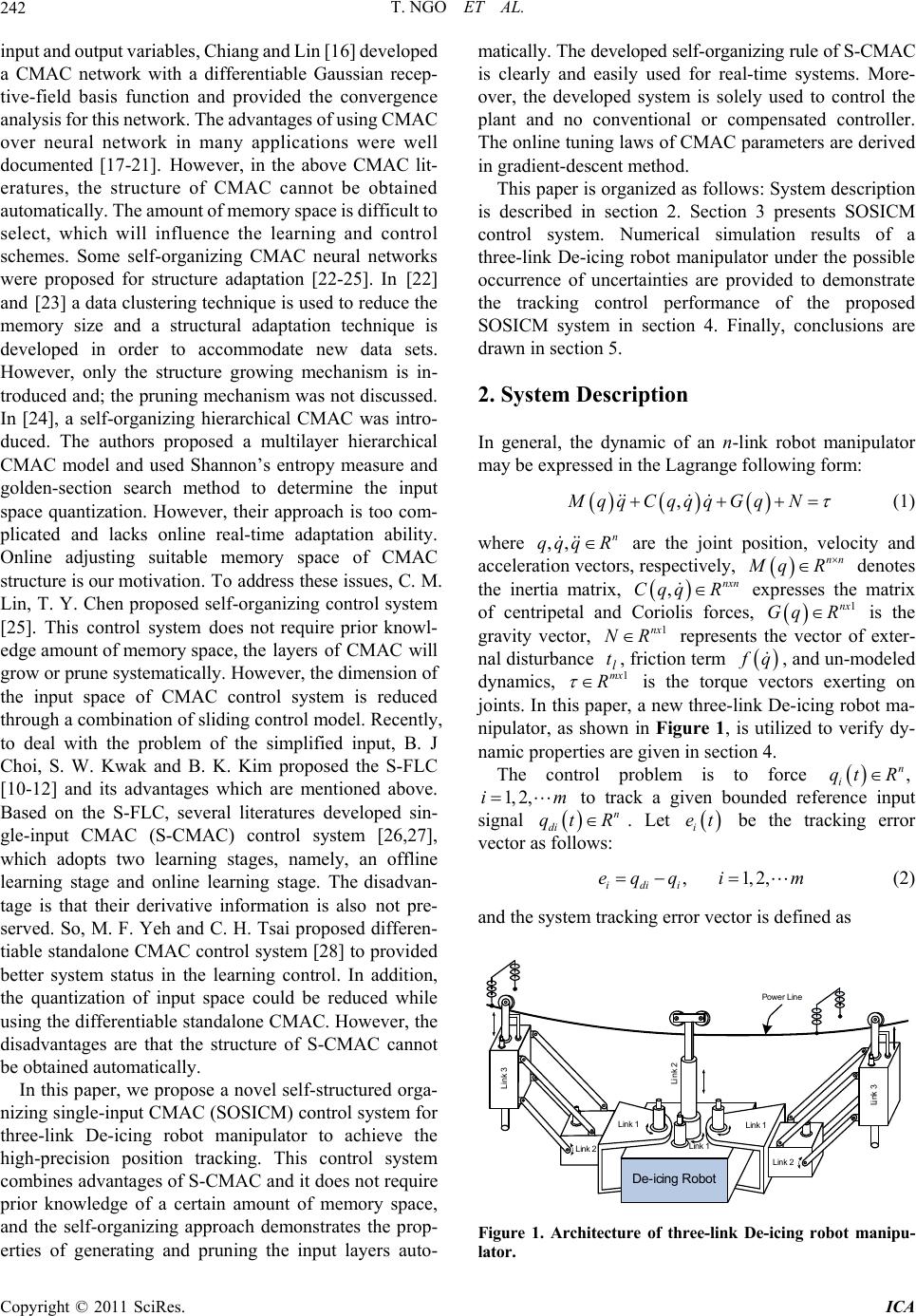

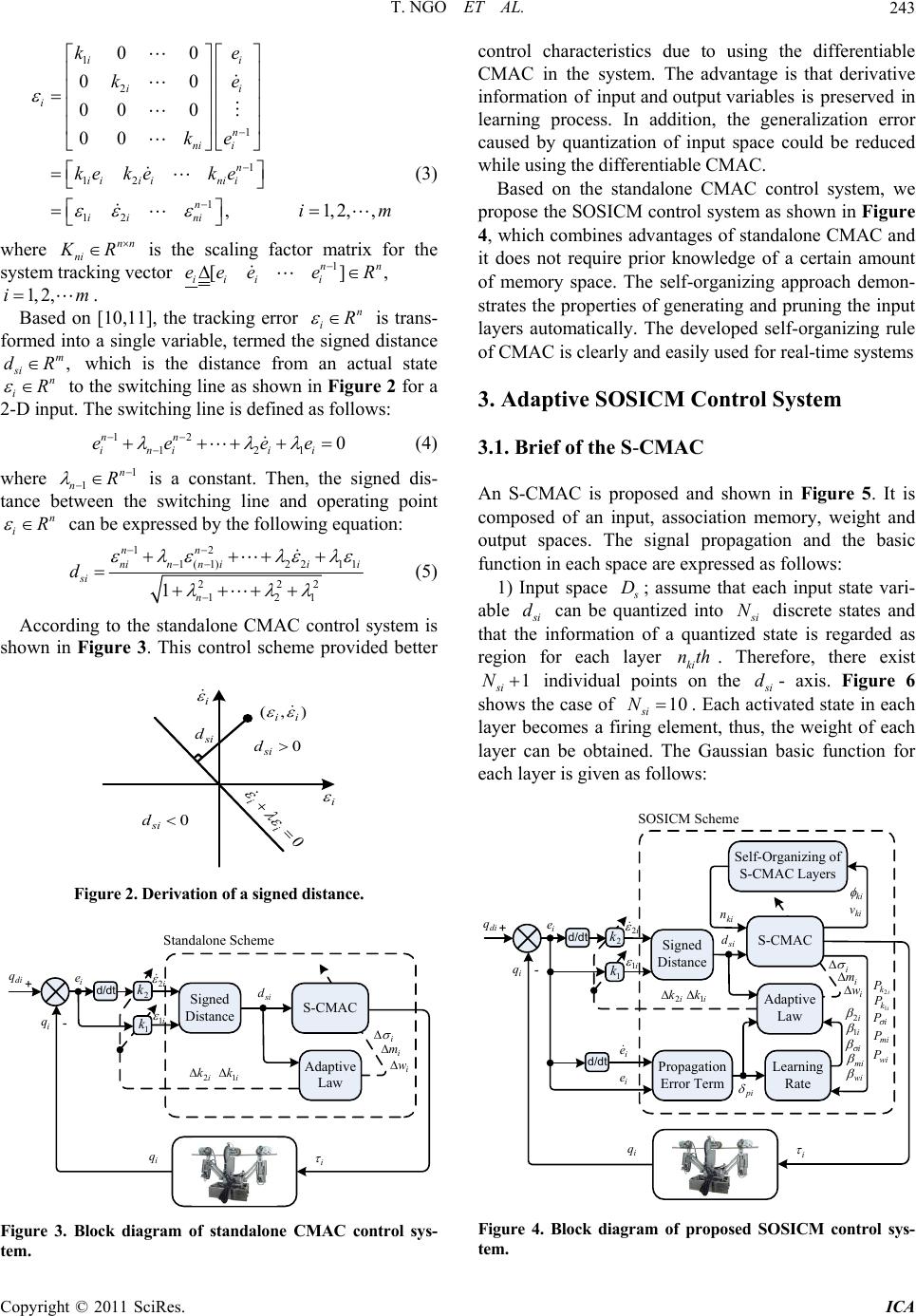

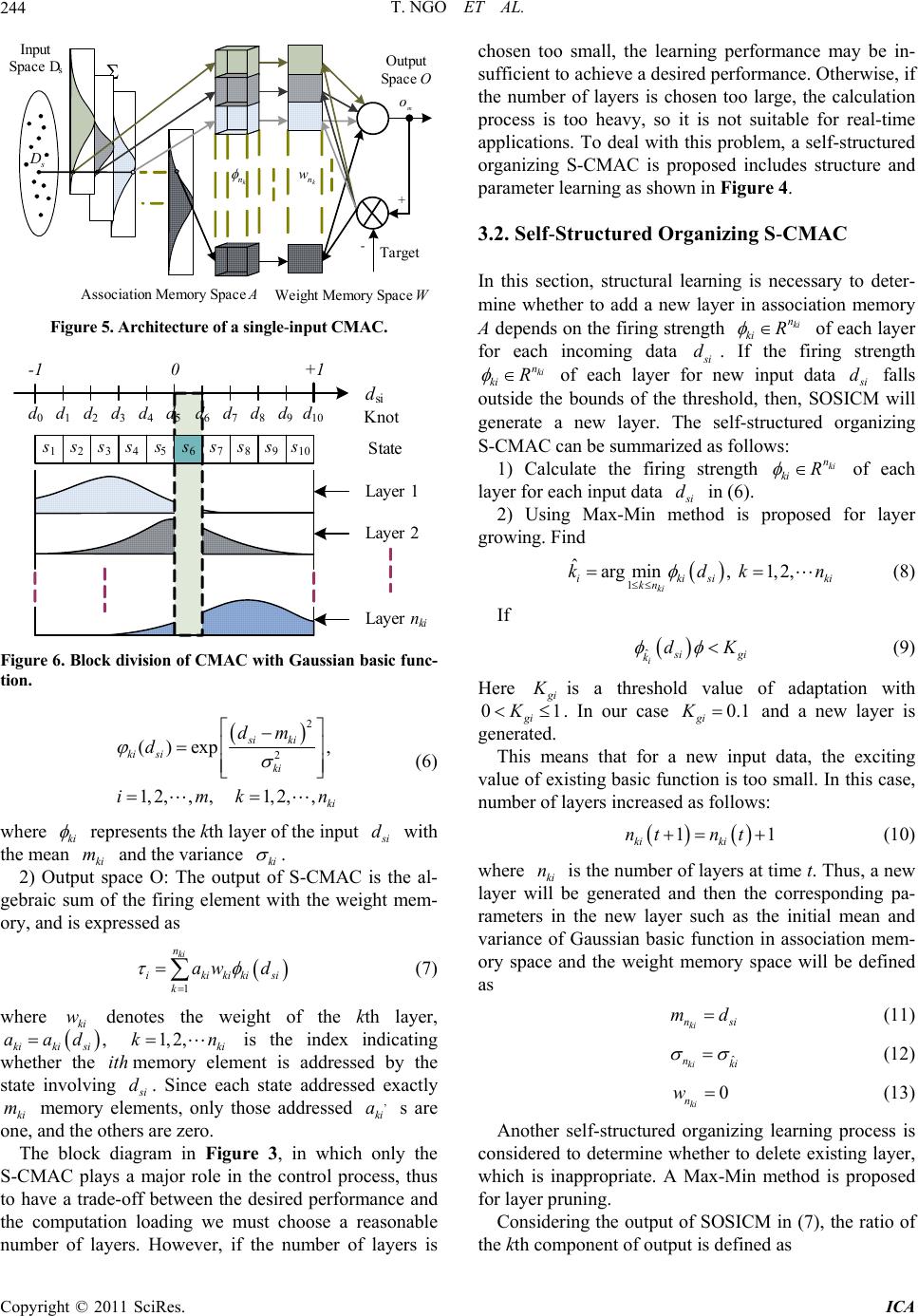

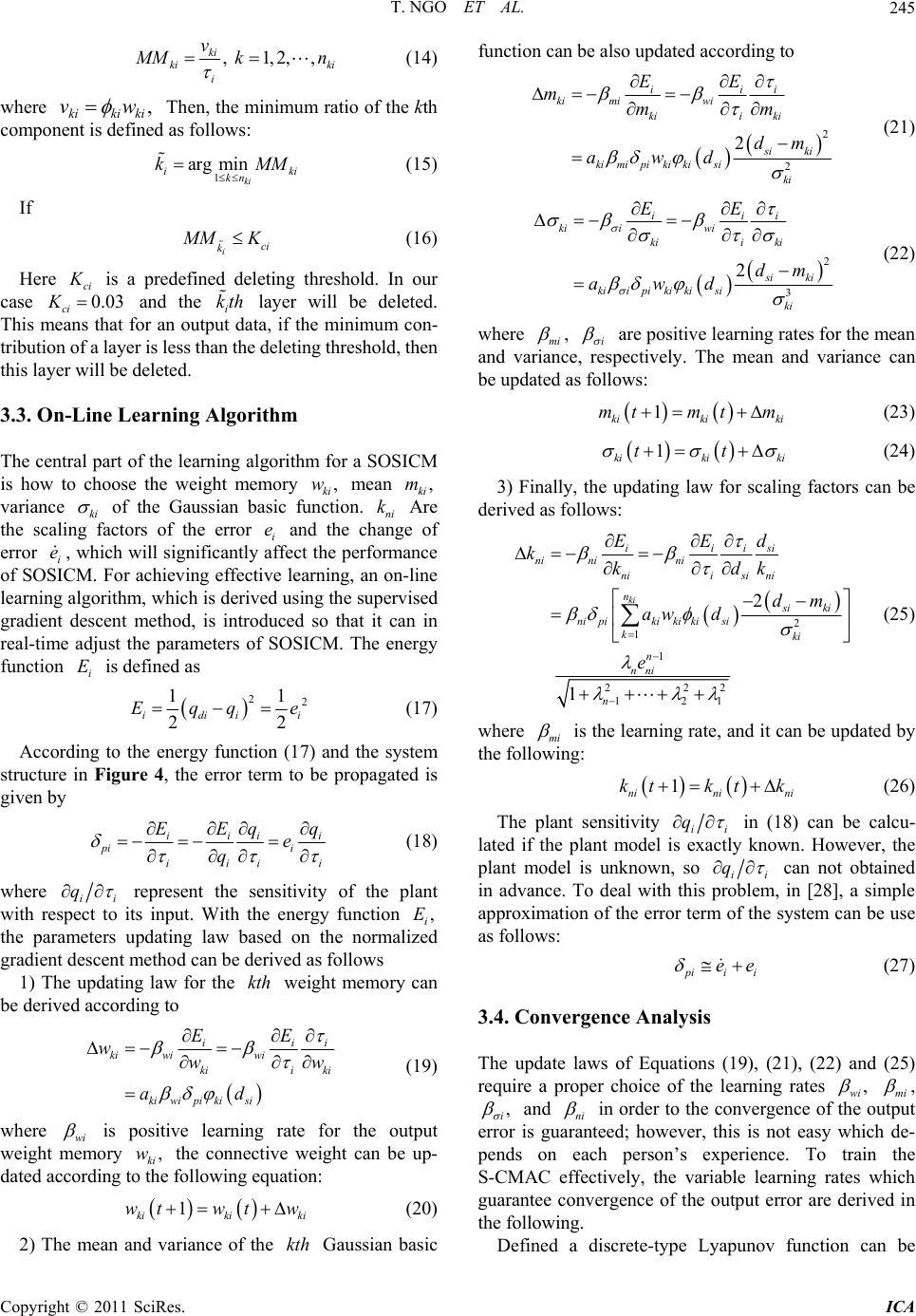

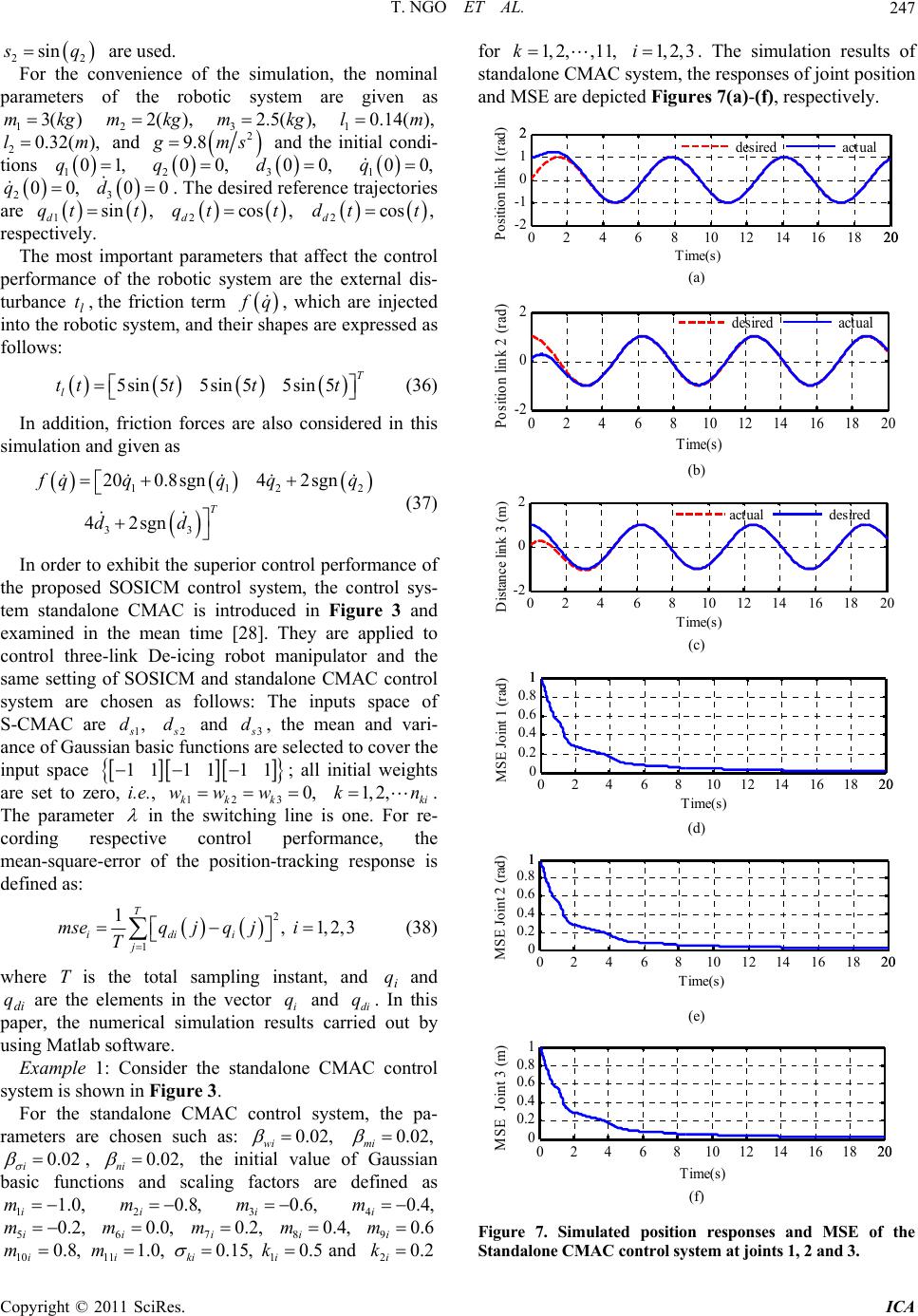

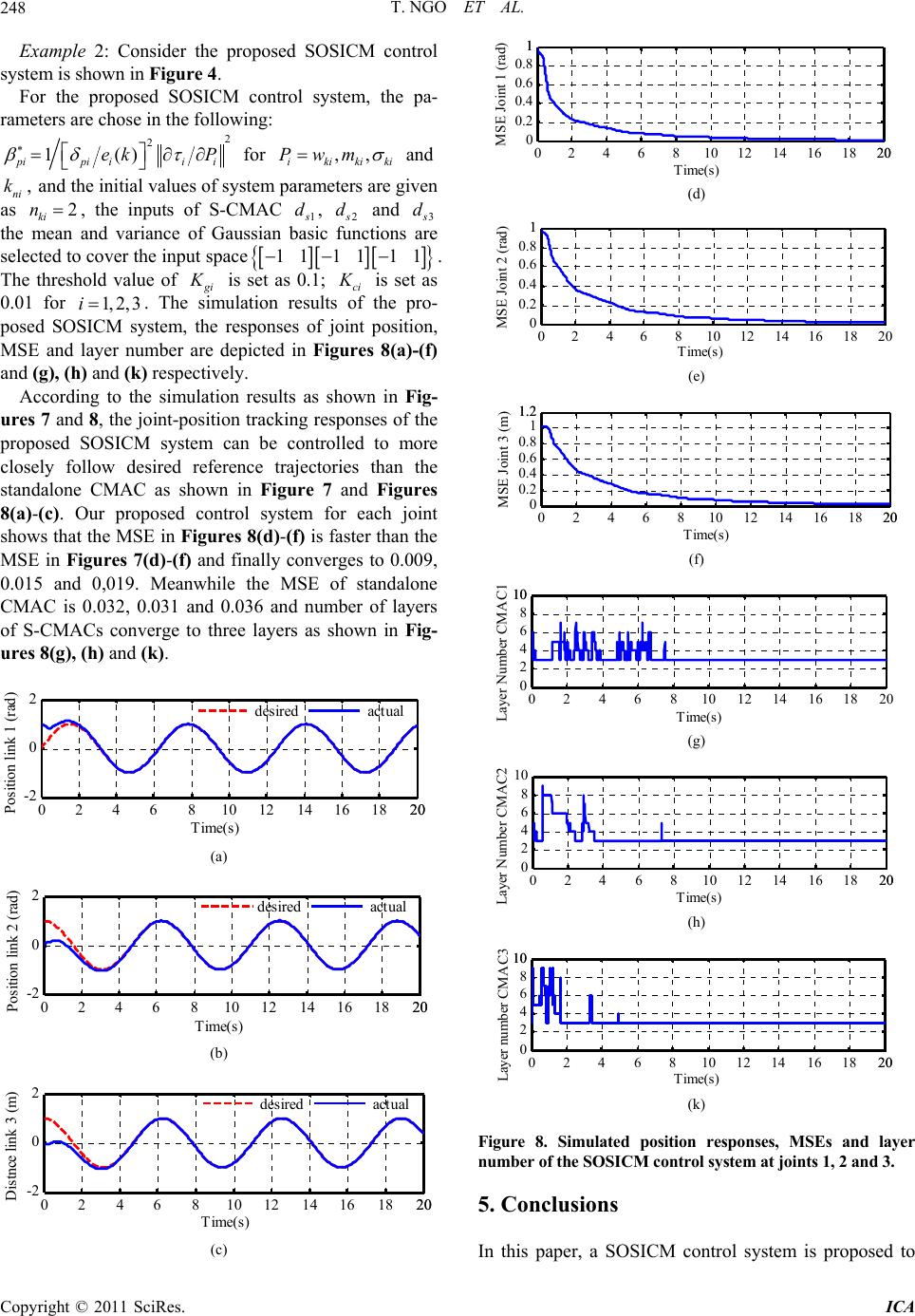

|