Paper Menu >>

Journal Menu >>

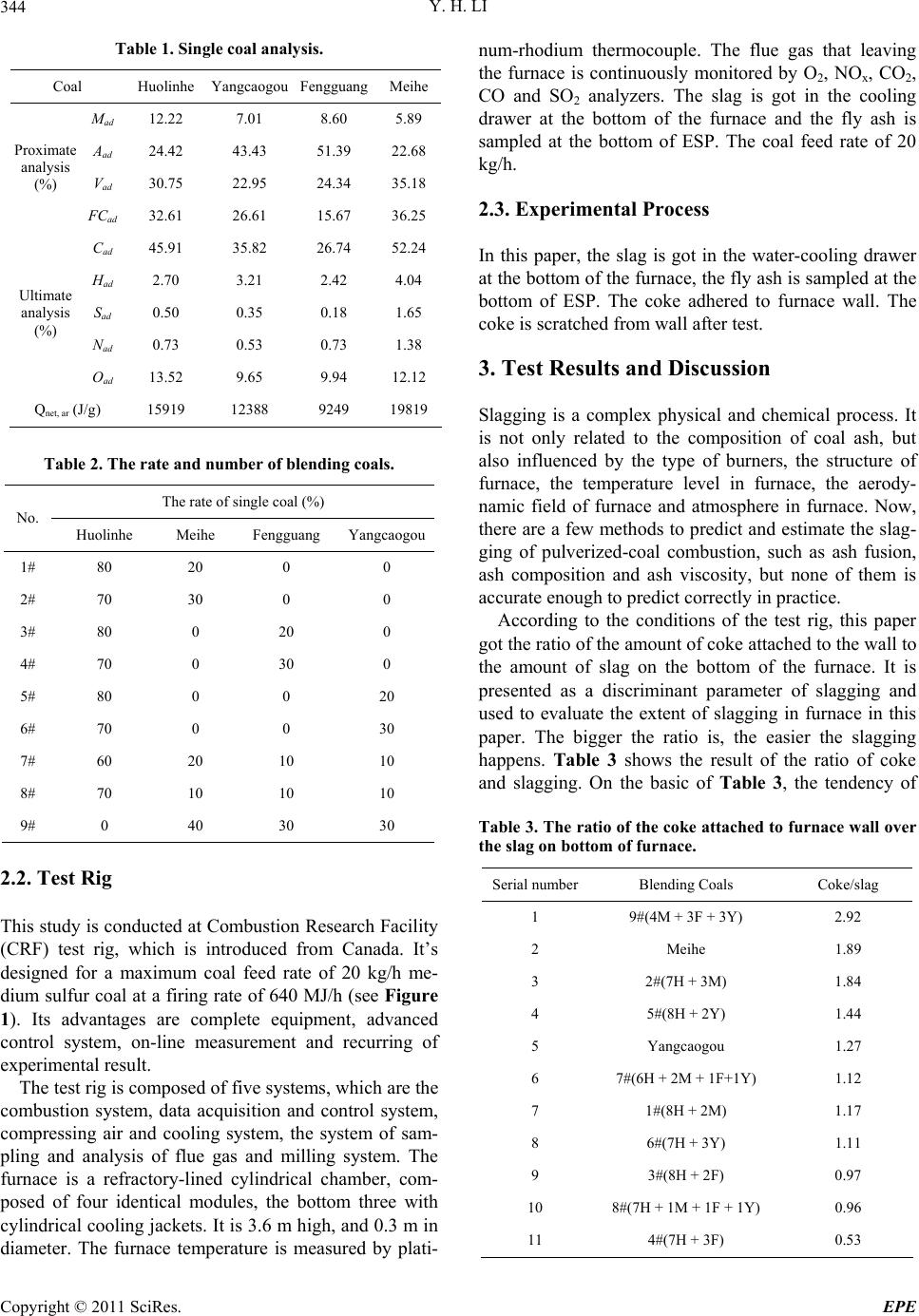

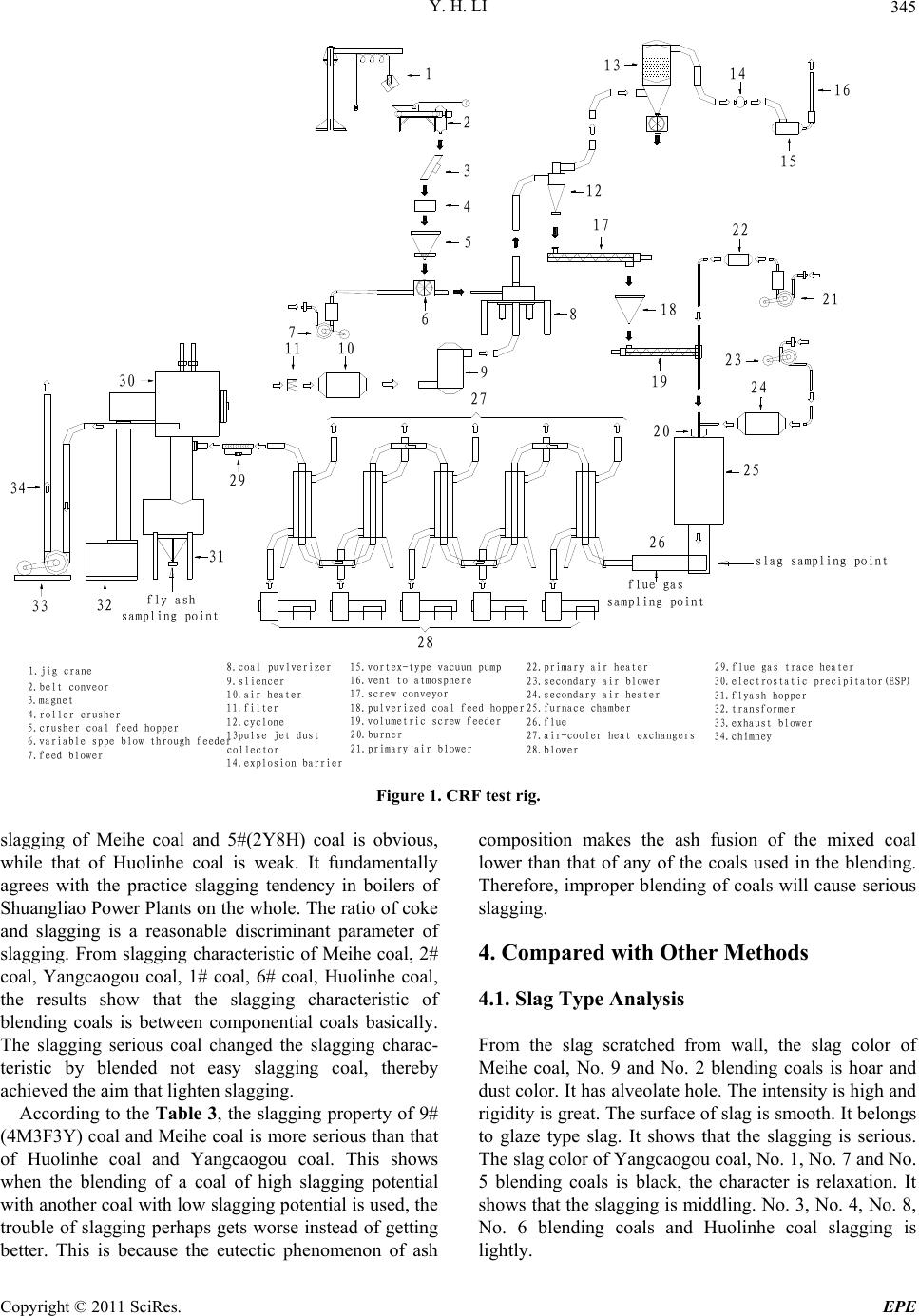

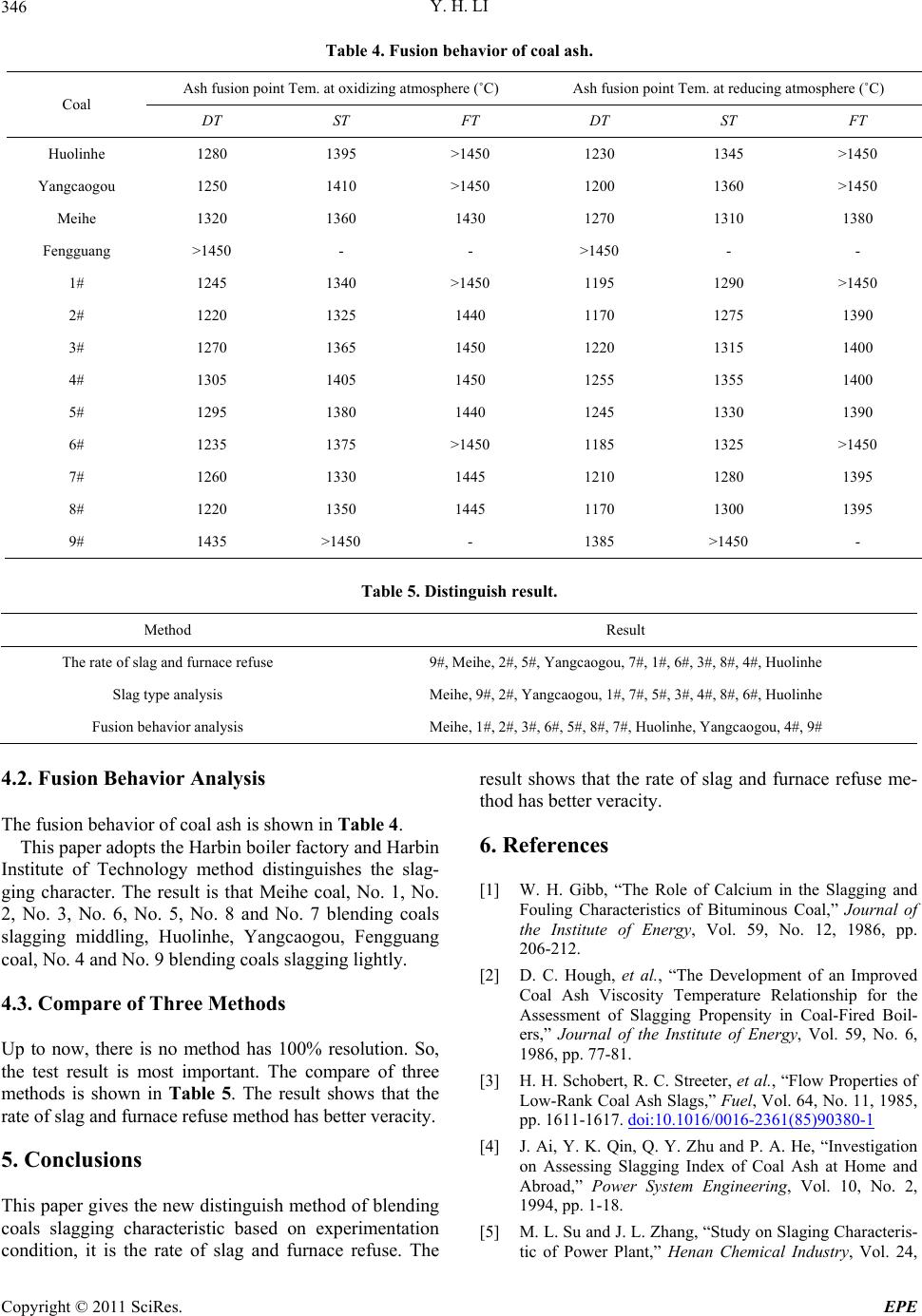

Energy and Power En gi neering, 2011, 3, 343-347 doi:10.4236/epe.2011.33043 Published Online July 2011 (http://www.SciRP.org/journal/epe) Copyright © 2011 SciRes. EPE A New Distinguish Method of Blending Coals Slagging Characteristic Yonghua Li North China Electric Power University, Baoding, China E-mail: liyonghua68@yahoo.com.cn Received December 27, 2010; revised February 15, 2011; accepted Marc h 2, 2011 Abstract The slagging characteristic of coal effects the safe operation of boiler unit directly, the study on coal slagging is paid more and more attention by scholars of the world. Because of the complexity of coal characteristic, the blending coals slagging characteristic is more complex than single coal. The study method of blending coals characteristic is the same as the single coal method, but the simple method can’t distinguish the blend- ing coals slagging characteristic well and truly. This paper gives the new distinguish method of blending coals slagging characteristic based on experimentation condition, it is the rate of slag and furnace refuse. The rate of slagging on furnace wall and the refuse on furnace bottom has utilized to distinguish the slagging characteristic of coal. The result shows that the rate of slag and furnace refuse method has better veracity. Keywords: Slagging, Blending Coals, Distinguish Method 1. Introduction The slagging characteristic of coal effects the safe opera- tion of boiler unit directly. So, scholars of the world at- tach importance to th e study of coal slagging. At present, the study of slagging characteristics of blending coals is depended on the study of single coal. The fuel character, boiler structure and operation mode are the factors of deciding boiler slagging. The fuel character is the basic of boiler design and operation. So, the study on fuel slagg ing characteristic is important. The study on distinguish slagging character is paid more and more attention by scholars. There are many distinguish methods and index of single coal slagging characteristics. The most of the methods are ash melting temperature slagging index method, ash element slagging index method, ash viscosity slagging index method, special type method and in tegrative distinguish method [1-3]. In USA, every slagging distinguish method are studied in 130,300 MW and upwards units. Th e results sho w that no method can forecast slagging trend complete accu- rately. The resolution of the softening temperature and silicon aluminum ratio is the highest. Harbin complete institute distinguishes the slagging trend of 250 kinds of Chinese coal; the resolution is 65%. Harbin boiler fac- tory and Harbin Institute of Technology study on lignite slagging trend, the results show th at the resolution of the softening temperature an d silicon aluminum ratio is 74% [4]. Some scholars adopt ash element slagging index method and ash liquation index [5], ash melting tem- perature [6], supporting vector machine [7], base/acid and silica/alumina [8], to study coal slagging char acteris- tic. Many scholars study on blending coals slagging char- acteristics [9,10]. They consider that the slagging char- acter of blending coals is more complex than single coal because of the complex of single coal slagging character. The blending coals research method is the same as single coal research method, but it can’t distinguish blending coals slagging trend by single coal slagging trend. It means that the difference of slagging character between blending coals and singles coal is great. This paper gives the new distinguish method of blending coals slagging characteristic based on experi- mentation condition, it is the rate of slag and furnace refuse. The rate of slagging on furnace wall and the re- fuse on furnace bottom has utilized to distinguish the slagging characteristic of coal. 2. Test Rig and Experimental Process [11] 2.1. Coal Analysis The single coal analysis and the rate and numbers of blending coals are shown in Table 1 and Table 2.  Y. H. LI 344 Table 1. Single coal analysis. Coal Huolinhe Yangcaogou FengguangMeihe Mad 12.22 7.01 8.60 5.89 Aad 24.42 43.43 51.39 22.68 Vad 30.75 22.95 24.34 35.18 Proximate analysis (%) FCad 32.61 26.61 15.67 36.25 Cad 45.91 35.82 26.74 52.24 Had 2.70 3.21 2.42 4.04 Sad 0.50 0.35 0.18 1.65 Nad 0.73 0.53 0.73 1.38 Ultimate analysis (%) Oad 13.52 9.65 9.94 12.12 Qnet, ar (J/g) 15919 12388 9249 19819 Table 2. The rate and number of blending coals. The rate of single coal (%) No. Huolinhe Meihe Fengguang Yangcaogou 1# 80 20 0 0 2# 70 30 0 0 3# 80 0 20 0 4# 70 0 30 0 5# 80 0 0 20 6# 70 0 0 30 7# 60 20 10 10 8# 70 10 10 10 9# 0 40 30 30 2.2. Test Rig This study is conducted at Combustion Research Facility (CRF) test rig, which is introduced from Canada. It’s designed for a maximum coal feed rate of 20 kg/h me- dium sulfur coal at a firing rate of 640 MJ/h (see Figure 1). Its advantages are complete equipment, advanced control system, on-line measurement and recurring of experimental result. The test rig is composed of five systems, which are the combustion system, data acquisition and control system, compressing air and cooling system, the system of sam- pling and analysis of flue gas and milling system. The furnace is a refractory-lined cylindrical chamber, com- posed of four identical modules, the bottom three with cylindrical cooling jackets. It is 3.6 m high, and 0.3 m in diameter. The furnace temperature is measured by plati- num-rhodium thermocouple. The flue gas that leaving the furnace is continuously monitored by O2, NOx, CO2, CO and SO2 analyzers. The slag is got in the cooling drawer at the bottom of the furnace and the fly ash is sampled at the bottom of ESP. The coal feed rate of 20 kg/h. 2.3. Experimental Process In this paper, the slag is got in the water-cooling drawer at the bottom of the furnace, the fly ash is sampled at the bottom of ESP. The coke adhered to furnace wall. The coke is scratched from wall after test. 3. Test Results and Discussion Slagging is a complex physical and chemical process. It is not only related to the composition of coal ash, but also influenced by the type of burners, the structure of furnace, the temperature level in furnace, the aerody- namic field of furnace and atmosphere in furnace. Now, there are a few methods to predict and estimate the slag- ging of pulverized-coal combustion, such as ash fusion, ash composition and ash viscosity, but none of them is accurate enough to predict correctly in practice. According to the conditions of the test rig, this paper got the ratio of the amount of coke attached to the wall to the amount of slag on the bottom of the furnace. It is presented as a discriminant parameter of slagging and used to evaluate the extent of slagging in furnace in this paper. The bigger the ratio is, the easier the slagging happens. Table 3 shows the result of the ratio of coke and slagging. On the basic of Table 3, the tendency of Table 3. The ratio of the coke attached to furnace wall over the slag on bottom of furnace. Serial numberBlending Coals Coke/slag 1 9#(4M + 3F + 3Y) 2.92 2 Meihe 1.89 3 2#(7H + 3M) 1.84 4 5#(8H + 2Y) 1.44 5 Yangcaogou 1.27 6 7#(6H + 2M + 1F+1Y) 1.12 7 1#(8H + 2M) 1.17 8 6#(7H + 3Y) 1.11 9 3#(8H + 2F) 0.97 10 8#(7H + 1M + 1F + 1Y) 0.96 11 4#(7H + 3F) 0.53 Copyright © 2011 SciRes. EPE  Y. H. LI Copyright © 2011 SciRes. EPE 345 23 34 33 31 32 30 29 28 27 9 20 25 19 24 10 7 11 5 68 3 4 2 17 12 22 18 21 15 113 14 16 15.vortex-type vacuum pump 16.vent to atmosphere 17.screw conveyor 18.pulverized coal feed hopper 19.volumetric screw feeder 20.burner 21.primary air blower 8.coal puvlverizer 9.sliencer 10.air heater 11.filter 12.cyclone 13pulse jet dust collector 14.explosion barrier 2.belt conveor 3.magnet 4.roller crusher 5.crusher coal feed hopper 6.variable sppe blow through feeder 7.feed blower 1.jig crane29.flue gas trace heater 30.electrostatic precipitator(ESP) 31.flyash hopper 32.transformer 33.exhaust blower 34.chimney 22.primary air heater 23.secondary air blower 24.secondary air heater 25.furnace chamber 26.flue 27.air-cooler heat exchangers 28.blower slag sampling point 26 flue gas sampling point fly ash sampling point Figure 1. CRF test rig. slagging of Meihe coal and 5#(2Y8H) coal is obvious, while that of Huolinhe coal is weak. It fundamentally agrees with the practice slagging tendency in boilers of Shuangliao Power Plants on the whole. Th e ratio of coke and slagging is a reasonable discriminant parameter of slagging. From slagging characteristic of Meihe coal, 2# coal, Yangcaogou coal, 1# coal, 6# coal, Huolinhe coal, the results show that the slagging characteristic of blending coals is between componential coals basically. The slagging serious coal changed the slagging charac- teristic by blended not easy slagging coal, thereby achieved the aim that lighten slagging. According to the Table 3, the slagging property of 9# (4M3F3Y) coal and Meihe coal is more serious than that of Huolinhe coal and Yangcaogou coal. This shows when the blending of a coal of high slagging potential with another co al with low slagging potential is u sed, the trouble of slagging perhaps gets worse instead of getting better. This is because the eutectic phenomenon of ash composition makes the ash fusion of the mixed coal lower than that of any of the coals used in the blending. Therefore, improper blending of coals will cause serious slagging. 4. Compared with Other Methods 4.1. Slag Type Analysis From the slag scratched from wall, the slag color of Meihe coal, No. 9 and No. 2 blending coals is hoar and dust color. It has alveo late hole. The intensity is high and rigidity is great. The surface of slag is smooth. It belongs to glaze type slag. It shows that the slagging is serious. The slag color of Yangcaogou coal, No. 1, No. 7 and No. 5 blending coals is black, the character is relaxation. It shows that the slagging is middling. No. 3, No. 4, No. 8, No. 6 blending coals and Huolinhe coal slagging is ightly. l  Y. H. LI Copyright © 2011 SciRes. EPE 346 Table 4. Fusion behavior of coal ash. Ash fusion point Tem. at oxidizing atmosphere (˚C) Ash fusion point Tem. at reducing atmosphere (˚C) Coal DT ST FT DT ST FT Huolinhe 1280 1395 >1450 1230 1345 >1450 Yangcaogou 1250 1410 >1450 1200 1360 >1450 Meihe 1320 1360 1430 1270 1310 1380 Fengguang >1450 - - >1450 - - 1# 1245 1340 >1450 1195 1290 >1450 2# 1220 1325 1440 1170 1275 1390 3# 1270 1365 1450 1220 1315 1400 4# 1305 1405 1450 1255 1355 1400 5# 1295 1380 1440 1245 1330 1390 6# 1235 1375 >1450 1185 1325 >1450 7# 1260 1330 1445 1210 1280 1395 8# 1220 1350 1445 1170 1300 1395 9# 1435 >1450 - 1385 >1450 - Table 5. Distinguish result. Method Result The rate of slag and furnace refuse 9#, Meihe, 2#, 5#, Yangcaogou, 7#, 1#, 6#, 3#, 8#, 4#, Huolinhe Slag type analysi s Meihe, 9#, 2#, Yangcaogou, 1#, 7#, 5#, 3#, 4#, 8#, 6 # , Huolinhe Fusion behavior analysis Meihe, 1#, 2#, 3#, 6#, 5#, 8#, 7#, Huolinhe, Yangcaogou, 4#, 9# 4.2. Fusion Behavior Analysis The fusion behavior of coal ash is shown in Table 4. This paper adopts the Harbin boiler factor y an d Harbin Institute of Technology method distinguishes the slag- ging character. The result is that Meihe coal, No. 1, No. 2, No. 3, No. 6, No. 5, No. 8 and No. 7 blending coals slagging middling, Huolinhe, Yangcaogou, Fengguang coal, No. 4 and No. 9 blending coals slagging lightly. 4.3. Compare of Three Methods Up to now, there is no method has 100% resolution. So, the test result is most important. The compare of three methods is shown in Table 5. The result shows that the rate of slag and furnace refuse method has bett er veracity. 5. Conclusions This paper gives the new distinguish method of blending coals slagging characteristic based on experimentation condition, it is the rate of slag and furnace refuse. The result shows that the rate of slag and furnace refuse me- thod has better veracity. 6. References [1] W. H. Gibb, “The Role of Calcium in the Slagging and Fouling Characteristics of Bituminous Coal,” Journal of the Institute of Energy, Vol. 59, No. 12, 1986, pp. 206-212. [2] D. C. Hough, et al., “The Development of an Improved Coal Ash Viscosity Temperature Relationship for the Assessment of Slagging Propensity in Coal-Fired Boil- ers,” Journal of the Institute of Energy, Vol. 59, No. 6, 1986, pp. 77-81. [3] H. H. Schobert, R. C. Streeter, et al., “Flow Properties of Low-Rank Coal Ash Slags,” Fuel, Vol. 64, No. 11, 1985, pp. 1611-1617. doi:10.1016/0016-2361(85)90380-1 [4] J. Ai, Y. K. Qin, Q. Y. Zhu and P. A. He, “Investigation on Assessing Slagging Index of Coal Ash at Home and Abroad,” Power System Engineering, Vol. 10, No. 2, 1994, pp. 1-18. [5] M. L. Su and J. L. Zhang, “Study on Slaging Characteris- tic of Power Plant,” Henan Chemical Industry, Vol. 24,  Y. H. LI347 No. 2, 2007, pp. 23-25. [6] Q. G. Fan and P. Pan, “The Correlativity on Chemistry Component Melting Temperature and Coal Ash Melting Temperature,” Boiler Technology, Vol. 38, No. 6, 2007, pp. 10-14. [7] G. S. Xue, W. M. Ding and L. Cheng, “Based on Sup- porting Vector Machine for Boiler Slag Characteristics Evaluation,” Energy Research and Utilization, No. 6, 2008, pp. 13-15. [8] Q. J. Huang, “The Product of Base/Acid and Sil- ica/Alumina of Ash in Steal Coal—An Index to Ash Slagging Tendency,” Power Engineering, Vol. 24, No. 3, 2004, pp. 340-344. [9] L. L. Baxter, “Boiler Performance with Blends of Eastern and Western Coals,” Proceedings of the 3rd EPRI Con- ference on the Effects of Coal Quality on Power Plants, San Diego, 25 August 1992, pp. 54-61. [10] D. I. Barnes, W. Lewittm and D. G. Richards, “The Slag- ging Behaviour of Blends of Power Station Coals,” Pro- ceedings of the 3rd EPRI Conference on the Effects of Coal Quality on Power Plants, San Diego, 25 August 1992, pp. 75-79. [11] Y. H. Li, “Study on the High Efficiency and Low Pollu- tion Combustion Characteristic of Blending Coals,” PhD Thesis, North China Electric Power University, Baoding, 2000. Copyright © 2011 SciRes. EPE |