R. A. Joy et al. / Natural Science 3 (2011) 556-565

Copyright © 2011 SciRes. OPEN ACCESS

560

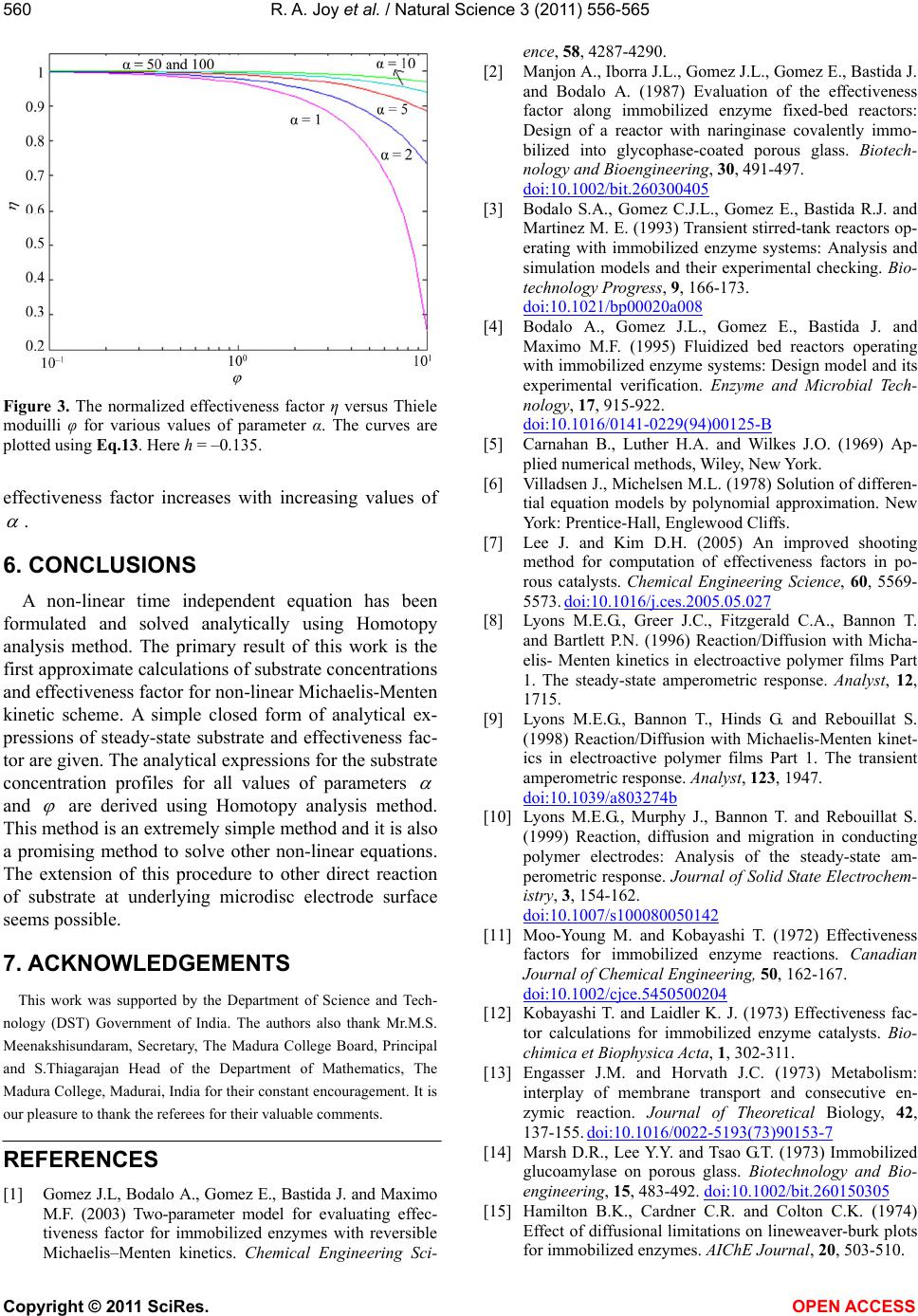

Figure 3. The normalized effectiveness factor η versus Thiele

moduilli φ for various values of parameter α. The curves are

plotted using Eq.13. Here h = –0.135.

effectiveness factor increases with increasing values of

.

6. CONCLUSIONS

A non-linear time independent equation has been

formulated and solved analytically using Homotopy

analysis method. The primary result of this work is the

first approximate calculations of substrate concentrations

and effectiveness factor for non-linear Michaelis-Menten

kinetic scheme. A simple closed form of analytical ex-

pressions of steady-state substrate and effectiveness fac-

tor are given. The analytical expressions for the substrate

concentration profiles for all values of parameters

and

are derived using Homotopy analysis method.

This method is an extremely simple method and it is also

a promising method to solve other non-linear equations.

The extension of this procedure to other direct reaction

of substrate at underlying microdisc electrode surface

seems possible.

7. ACKNOWLEDGEMENTS

This work was supported by the Department of Science and Tech-

nology (DST) Government of India. The authors also thank Mr.M.S.

Meenakshisundaram, Secretary, The Madura College Board, Principal

and S.Thiagarajan Head of the Department of Mathematics, The

Madura College, Madurai, India for their constant encouragement. It is

our pleasure to thank the referees for their valuable comments.

REFERENCES

[1] Gomez J.L, Bodalo A., Gomez E., Bastida J. and Maximo

M.F. (2003) Two-parameter model for evaluating effec-

tiveness factor for immobilized enzymes with reversible

Michaelis–Menten kinetics. Chemical Engineering Sci-

ence, 58, 4287-4290.

[2] Manjon A., Iborra J.L., Gomez J.L., Gomez E., Bastida J.

and Bodalo A. (1987) Evaluation of the effectiveness

factor along immobilized enzyme fixed-bed reactors:

Design of a reactor with naringinase covalently immo-

bilized into glycophase-coated porous glass. Biotech-

nology and Bioengineering, 30, 491-497.

doi:10.1002/bit.260300405

[3] Bodalo S.A., Gomez C.J.L., Gomez E., Bastida R.J. and

Martinez M. E. (1993) Transient stirred-tank reactors op-

erating with immobilized enzyme systems: Analysis and

simulation models and their experimental checking. Bio-

technology Progress, 9, 166-173.

doi:10.1021/bp00020a008

[4] Bodalo A., Gomez J.L., Gomez E., Bastida J. and

Maximo M.F. (1995) Fluidized bed reactors operating

with immobilized enzyme systems: Design model and its

experimental verification. Enzyme and Microbial Tech-

nology, 17, 915-922.

doi:10.1016/0141-0229(94)00125-B

[5] Carnahan B., Luther H.A. and Wilkes J.O. (1969) Ap-

plied numerical methods, Wiley, New York.

[6] Villadsen J., Michelsen M.L. (1978) Solution of differen-

tial equation models by polynomial approximation. New

York: Prentice-Hall, Englewood Cliffs.

[7] Lee J. and Kim D.H. (2005) An improved shooting

method for computation of effectiveness factors in po-

rous catalysts. Chemical Engineering Science, 60, 5569-

5573. doi:10.1016/j.ces.2005.05.027

[8] Lyons M.E.G., Greer J.C., Fitzgerald C.A., Bannon T.

and Bartlett P.N. (1996) Reaction/Diffusion with Micha-

elis- Menten kinetics in electroactive polymer films Part

1. The steady-state amperometric response. Analyst, 12,

1715.

[9] Lyons M.E.G., Bannon T., Hinds G. and Rebouillat S.

(1998) Reaction/Diffusion with Michaelis-Menten kinet-

ics in electroactive polymer films Part 1. The transient

amperometric response. Analyst, 123, 1947.

doi:10.1039/a803274b

[10] Lyons M.E.G., Murphy J., Bannon T. and Rebouillat S.

(1999) Reaction, diffusion and migration in conducting

polymer electrodes: Analysis of the steady-state am-

perometric response. Journal of Solid State Electrochem-

istry, 3, 154-162.

doi:10.1007/s100080050142

[11] Moo-Young M. and Kobayashi T. (1972) Effectiveness

factors for immobilized enzyme reactions. Canadian

Journal of Chemical Engineering, 50, 162-167.

doi:10.1002/cjce.5450500204

[12] Kobayashi T. and Laidler K. J. (1973) Effectiveness fac-

tor calculations for immobilized enzyme catalysts. Bio-

chimica et Biophysica Acta, 1, 302-311.

[13] Engasser J.M. and Horvath J.C. (1973) Metabolism:

interplay of membrane transport and consecutive en-

zymic reaction. Journal of Theoretical Biology, 42,

137-155. doi:10.1016/0022-5193(73)90153-7

[14] Marsh D.R., Lee Y.Y. and Tsao G.T. (1973) Immobilized

glucoamylase on porous glass. Biotechnology and Bio-

engineering, 15, 483-492. doi:10.1002/bit.260150305

[15] Hamilton B.K., Cardner C.R. and Colton C.K. (1974)

Effect of diffusional limitations on lineweaver-burk plots

for immobilized enzymes. AIChE Journal, 20, 503-510.