Journal of Applied Mathematics and Physics

Vol.04 No.01(2016), Article ID:62629,7 pages

10.4236/jamp.2016.41004

Unrelated Parallel-Machine Scheduling Problems with General Truncated Job-Dependent Learning Effect

Jibo Wang1, Chou-Jung Hsu2*

1School of Science, Shenyang Aerospace University, Shenyang, China

2Department of Industrial Management, Nan Kai University of Technology, Taiwan

Received 22 November 2015; accepted 5 January 2016; published 12 January 2016

ABSTRACT

In this paper, we consider scheduling problems with general truncated job-dependent learning effect on unrelated parallel-machine. The objective functions are to minimize total machine load, total completion (waiting) time, total absolute differences in completion (waiting) times respectively. If the number of machines is fixed, these problems can be solved in  time respectively, where m is the number of machines and n is the number of jobs.

time respectively, where m is the number of machines and n is the number of jobs.

Keywords:

Scheduling, Unrelated Parallel Machines, Truncated Job-Dependent Learning

1. Introduction

In modern planning and scheduling problems, there are many real situations where the processing time of jobs may be subject to change due to learning effect. An extensive survey of different scheduling models and problems with learning effects could be found in Biskup [1]. More recently, Janiak et al. [2] studied a single processor problem with a S-shaped learning model. They proved that the makespan minimization problem is strongly NP-hard. Lee [3] considered scheduling jobs with general position-based learning curves. For some single machine and a two-machine flowshop scheduling problems, they presented the optimal solution respectively. Lee [4] considered single-machine scheduling jobs with general learning effect and past-sequence-dependent setup time. For some single machine scheduling problems, they presented the optimal solution respectively. Lee and Wu [5], and Wu and Lee [6] considered scheduling jobs with learning effects. They proved that some single machine and flowshop scheduling problems can be solved in polynomial time respectively. Lee et al. [7] considered a single-machine scheduling problem with release times and learning effect. Lee et al. [8] considered a makespan minimization uniform parallel-machine scheduling problem with position-based learning curves. Lee and Chung [9], Sun et al. [10] [11], and Wang et al. [12] considered flow shop scheduling with learning effects. Wu et al. [13], Wu et al. [14], Wu et al. [15] and Wang et al. [16] considered scheduling problems with the truncated learning effect.

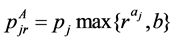

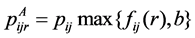

Recently, Wang et al. [17] considered several scheduling problems on a single machine with truncated job-dependent learning effect, i.e., the actual processing time of job  is

is  if it is sche-

if it is sche-

duled in the rth position of a sequence, where  is the job-dependent learning index of job

is the job-dependent learning index of job , and b is a truncation parameter with

, and b is a truncation parameter with . In this paper, we study scheduling problems with general truncated job- dependent learning effect on unrelated parallel-machine. The objective is to minimize total machine load, total completion (waiting) time, total absolute differences in completion (waiting) times respectively.

. In this paper, we study scheduling problems with general truncated job- dependent learning effect on unrelated parallel-machine. The objective is to minimize total machine load, total completion (waiting) time, total absolute differences in completion (waiting) times respectively.

2. Problems Description

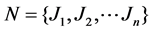

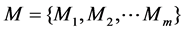

There are n independent jobs  to be processed on m unrelated paralle-machine

to be processed on m unrelated paralle-machine  . Let

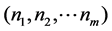

. Let  denote a job-allocation vector, where

denote a job-allocation vector, where  denotes the number of jobs assigned to machine

denotes the number of jobs assigned to machine , and

, and . In this paper, we assume that the actual processing time of job

. In this paper, we assume that the actual processing time of job  scheduled on machine

scheduled on machine  is

is

,

, (1)

(1)

where  denotes the normal (basic) processing time of job

denotes the normal (basic) processing time of job

Let

dule so that the following objective functions is to be minimized: the total machine load

3. Main Results

Let

Lemma 1. For a given permutation

If the vector

where

Now, the question is how many vectors

Theorem 1. For a given constant

Proof. As discussed above, to solve the problem

Note that if the number of machines

Algorithm 1

Step 1. For each possible vector

Step 2. The optimal solution for the problem is the one with the minimum value of the objective function

The following example illustrates the working of Algorithm 1 to find the optimal solution for the problem

Example 1. There are

Solution. When

When

Table 1. The

Table 2. The

(2)-(5) to obtain that the optimal schedule on machine

When

When

When

When

Table 3. The

Table 4. The

Table 5. The

Table 6. The

Hence, the optimal schedule on machine

Acknowledgements

Hsu was supported by the Ministry Science and Technology of Taiwan under Grant MOST 104-2221-E-252- 002-MY2.

Cite this paper

Jibo Wang,Chou-Jung Hsu, (2016) Unrelated Parallel-Machine Scheduling Problems with General Truncated Job-Dependent Learning Effect. Journal of Applied Mathematics and Physics,04,21-27. doi: 10.4236/jamp.2016.41004

References

- 1. Biskup, D. (2008) A State-of-the-Art Review on Scheduling with Learning Effects. European Journal of Operational Research, 188, 315-329. http://www.sciencedirect.com/science/article/pii/S0377221707005280 http://dx.doi.org/10.1016/j.ejor.2007.05.040

- 2. Janiak, A., Janiak, W., Rudek, R. and Wielgus, A. (2009) Solution Algorithms for the Makespan Minimization Problem with the General Learning Model. Computers and Industrial Engineering, 56, 1301-1308. http://www.sciencedirect.com/science/article/pii/S0360835208001654 http://dx.doi.org/10.1016/j.cie.2008.07.019

- 3. Lee, W.-C. (2011) Scheduling with General Position-Based Learning Curves. Information Sciences, 181, 5515-5522. http://www.sciencedirect.com/science/article/pii/S0020025511004130 http://dx.doi.org/10.1016/j.ins.2011.07.051

- 4. Lee, W.-C. (2011) A note on Single-Machine Scheduling with General Learning Effect and Past-Sequence-Dependent Setup Time. Computers and Mathematics with Applications, 62, 2095-2100. http://www.sciencedirect.com/science/article/pii/S0898122111005384 http://dx.doi.org/10.1016/j.camwa.2011.06.057

- 5. Lee, W.-C. and Wu, C.-C. (2009) Some Single-Machine and m-Machine Flowshop Scheduling Problems with Learning Considerations. Information Sciences, 179, 3885-3892. http://www.sciencedirect.com/science/article/pii/S0020025509003235 http://dx.doi.org/10.1016/j.ins.2009.07.011

- 6. Wu, C.-C. and Lee, W.-C. (2009) Single-Machine and Flowshop Scheduling with a General Learning Effect Model. Computers & Industrial Engineering, 56, 1553-1558. http://www.sciencedirect.com/science/article/pii/S036083520800260X http://dx.doi.org/10.1016/j.cie.2008.10.002

- 7. Lee, W.-C., Wu, C.-C. and Hsu, P.-H. (2010) A Single-Machine Learning Effect Scheduling Problem with Release Times. Omega—The International Journal of Management Science, 38, 3-11. http://www.sciencedirect.com/science/article/pii/S0305048309000024 http://dx.doi.org/10.1016/j.omega.2009.01.001

- 8. Lee, W.-C., Yeh, W.-C. and Chuang, M.C. (2012) Uniform Parallel-Machine Scheduling to Minimize Makespan with Position-Based Learning Curves. Computers & Industrial Engineering, 63, 813-818. http://www.sciencedirect.com/science/article/pii/S0360835212001283 http://dx.doi.org/10.1016/j.cie.2012.05.003

- 9. Lee, W.-C. and Chung, Y.-H. (2013) Permutation Flowshop Scheduling to Minimize the Total Tardiness with Learning Effects. International Journal of Production Economics, 141, 327-334. http://www.sciencedirect.com/science/article/pii/S0925527312003623 http://dx.doi.org/10.1016/j.ijpe.2012.08.014

- 10. Sun, L.-H., Cui, K., Chen, J.-H., Wang, J. and He, X.-C. (2013) Research on Permutation Flow Shop Scheduling Problems with General Position-Dependent Learning Effects. Annals of Operations Research, 211, 473-480. http://link.springer.com/article/10.1007/s10479-013-1481-6 http://dx.doi.org/10.1007/s10479-013-1481-6

- 11. Sun, L.-H., Cui, K., Chen, J.-H., Wang, J. and He, X.-C. (2013) Some Results of the Worst-Case Analysis for Flow Shop Scheduling with a Learning Effect. Annals of Operations Re-search, 211, 481-490. http://link.springer.com/article/10.1007/s10479-013-1368-6 http://dx.doi.org/10.1007/s10479-013-1368-6

- 12. Wang, X.-Y., Zhou, Z., Zhang, X., Ji, P. and Wang, J.-B. (2013) Several Flow Shop Scheduling Problems with Truncated Position-Based Learning Effect. Computers & Operations Research, 40, 2906-2929. http://www.sciencedirect.com/science/article/pii/S0305054813001743 http://dx.doi.org/10.1016/j.cor.2013.07.001

- 13. Wu, C.-C., Yin, Y. and Cheng, S.-R. (2011) Some Single-Machine Scheduling Problems with a Truncation Learning Effect. Computers & Industrial Engineering, 60, 790-795. http://www.sciencedirect.com/science/article/pii/S0360835211000362 http://dx.doi.org/10.1016/j.cie.2011.01.016

- 14. Wu, C.-C., Yin, Y. and Cheng, S.-R. (2013) Single-Machine and Two-Machine Flowshop Scheduling Problems with Truncated Position-Based Learning Functions. Journal of the Operation Research Society, 64, 147-156. http://www.palgrave-journals.com/jors/journal/v64/n1/abs/jors201246a.html http://dx.doi.org/10.1057/jors.2012.46

- 15. Wu, C.-C., Yin, Y., Wu, W.-H. and Cheng, S.-R. (2012) Some Polynomial Solvable Single-Machine Scheduling Problems with a Truncation Sum-of-Processing-Times Based Learning Effect. European Journal of Industrial Engineering, 6, 441-453. http://www.inderscienceonline.com/doi/abs/10.1504/EJIE.2012.047665 http://dx.doi.org/10.1504/ejie.2012.047665

- 16. Wang, J.-B., Wang, X.-Y., Sun, L.-H. and Sun, L.-Y. (2013) Scheduling Jobs with Truncated Exponential Learning Functions. Optimization Letters, 7, 1857-1873. http://link.springer.com/article/10.1007/s11590-011-0433-9 http://dx.doi.org/10.1007/s11590-011-0433-9

- 17. Wang, X.-R., Wang, J.-B., Jin, J. and Ji, P. (2014) Single Machine Scheduling with Truncated Job-Dependent Learning Effect. Optimization Letters, 8, 669-677. http://link.springer.com/article/10.1007/s11590-012-0579-0 http://dx.doi.org/10.1007/s11590-012-0579-0

- 18. Graham, R.L., Lawler, E.L., Lenstra, J.K. and Rinnooy Kan, A.H.G. (1979) Optimization and Approximation in Deterministic Sequencing and Scheduling: A Survey. Annals of Discrete Mathematics, 5, 287-326. http://www.sciencedirect.com/science/article/pii/S016750600870356X http://dx.doi.org/10.1016/S0167-5060(08)70356-X

- 19. Kanet, J.J. (1981) Minimizing Variation of Flow Time in Single Machine Systems. Management Science, 27, 1453- 1459. http://pubsonline.informs.org/doi/abs/10.1287/mnsc.27.12.1453 http://dx.doi.org/10.1287/mnsc.27.12.1453

- 20. Bagchi, U.B. (1989) Simultaneous Minimization of Mean and Variation of Flow-Time and Waiting Time in Single Machine Systems. Operations Research, 37, 118-125. http://pubsonline.informs.org/doi/abs/10.1287/opre.37.1.118 http://dx.doi.org/10.1287/opre.37.1.118

NOTES

*Corresponding author.