Eva lua t ion of Non Crystalline Phase in AZS Refracto r ies by XRD M ethods

Copyright © 2011 SciRes. NGJC

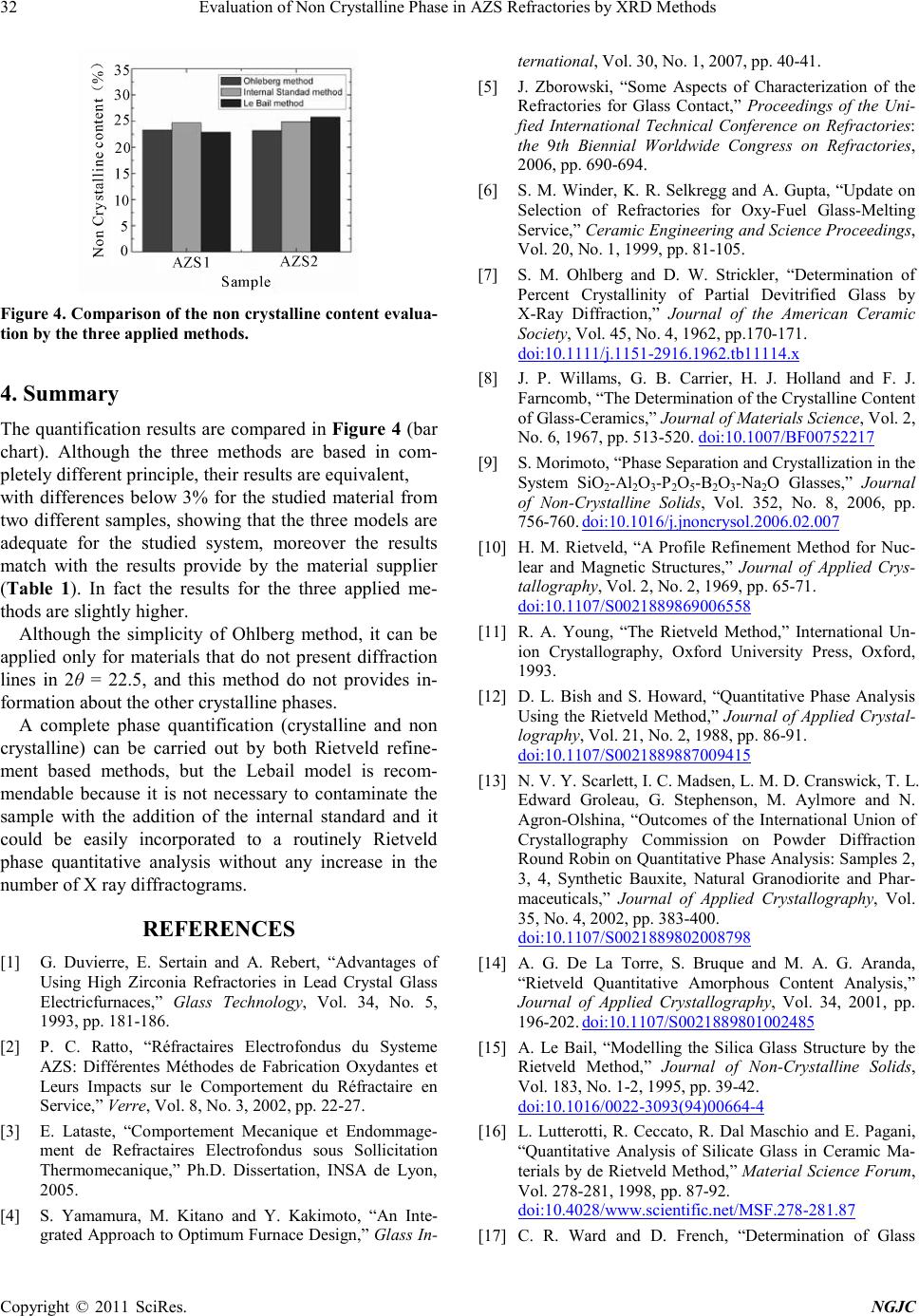

Figure 4. Co mpari so n of t he non cry st alli ne c ont ent eval ua-

tion by the three appl ied methods.

4. Summary

The quantification results are compared in Figure 4 (bar

chart). Although the three methods are based in com-

pletely different principle, their re sults are e quivalent,

with differences below 3% for the studied material from

two di fferent samples , showi ng that t he three models are

adequate for the studied system, moreover the results

match with the results provide by the material supplier

(Table 1). In fact the results for the three applied me-

thods are slightl y hi g her .

Although the simplicity of Ohlberg method, it can be

applied only for materials that do not present diffraction

lines in 2θ = 22.5, and this method do not provides in-

formation ab out the other crystalline phases.

A complete phase quantification (crystalline and non

crystalline) can be carried out by both Rietveld refine-

ment based methods, but the Lebail model is recom-

mendable because it is not necessary to contaminate the

sample with the addition of the internal standard and it

could be easily incorporated to a routinely Rietveld

phase quantitative analysis without any increase in the

number of X ray diffractograms.

REFERENCES

[1] G. Duvierre, E. Sertain and A. Rebert, “Advantages of

Using High Zirconia Refractories in Lead Crystal Glass

Electricfurnaces,” Glass Technology, Vol. 34, No. 5,

1993, pp . 181-186.

[2] P. C. Ratto, “Réfractaires Ele ctrofondus du Systeme

AZS: Différentes Méthodes de Fabrication Oxydantes et

Leurs Impacts sur le Comportement du Réfractaire en

Service,” Verre, Vol. 8, No. 3, 2002, pp. 22-27.

[3] E. Lataste, “Comportement Mecanique et Endommage-

ment de Refractaires Electrofondus sous Sollicitation

Thermomecanique,” Ph.D. Dissertation, INSA de Lyon,

2005.

[4] S. Yamamura, M. Kitano and Y. Kakimoto, “An Inte-

grated Approach to Optimum Furnace Design,” Glass In-

ternational, Vol. 30, No. 1, 2007, pp. 40-41.

[5] J. Zborowski, “Some Aspects of Characterization of the

Refractories for Glass Contact,” Proceedings of the Uni-

fied International Technical Conference on Refractories:

the 9th Biennial Worldwide Congress on Refractories,

2006, pp . 690-694.

[6] S. M. Winder, K. R. Selkregg an d A. Gupta, “Update on

Selection of Refractories for Oxy-Fuel Glass-Melting

Service,” Ceramic Engineering and Science Proceedings,

Vol. 2 0, No . 1, 1999, pp. 81-105.

[7] S. M. Ohlberg and D. W. Strickler, “Determination of

Percent Crystallinity of Partial Devitrified Glass by

X-Ray Diffraction,” Journal of the American Ceramic

Soci ety, Vol. 45, N o. 4, 1962, pp.170-171.

doi:10.1111/j.1151-2916.1962.tb11114.x

[8] J. P. Willams, G. B. Carrier, H. J. Holland and F. J.

Farnco mb, “The Determination of the Crystalline Content

of Gl a s s -Cer amics,” Journal of Materials Science, Vol. 2,

No. 6, 1967, pp. 513-520. doi:10.1007/BF00752217

[9] S. Morimoto, “Phase Separation and Crystallization in the

System SiO2-Al2O3-P2O5-B2O3-Na2O Glasses,” Journal

of Non-Crystalline Solids, Vol. 352, No. 8, 2006, pp.

756-760. doi:10.1016/j.jnoncrysol.2006.02.007

[10] H. M. Rietveld, “A Profile Refinement Method for Nuc-

lear and Magnetic Structures ,” Journal of Applied Crys-

tallography, Vol. 2, No. 2, 19 69 , pp. 65 -71.

doi:10.1107/S0021889869006558

[11] R. A. Young, “The Rietveld Method,” International Un-

ion Crystallography, Oxford University Press, Oxford,

1993.

[12] D. L. Bish and S. Howard, “Quantitative Phase Analysis

Using the Rietveld Method,” Journal of Applied Crystal-

lography, Vol. 21, No. 2, 1988, pp. 86-91.

doi:10.1107/S0021889887009415

[13] N. V. Y. S carlet t, I. C . Mads en, L. M. D. Cranswick, T. L.

Edward Groleau, G. Stephenson, M. Aylmore and N.

Agron -Ol shina, “Outcomes of the International Union of

Crystallography Commission on Powder Diffraction

Round Robin on Quantitative Phase Analysis: Samples 2,

3, 4, Synthetic Bauxite, Natural Granodiorite and Phar-

maceuticals,” Journal of Applied Crystallography, Vol.

35, No. 4, 20 02, pp. 38 3-400.

doi:10.1107/S0021889802008798

[14] A. G. De La Torre, S. Bruque and M. A. G. Aranda,

“Rietveld Quantitative Amorphous Content Analysis,”

Journal of Applied Crystallography, Vol. 34, 2001, pp.

196-202. doi:10.1107/S0021889801002485

[15] A. Le Bail, “Modelling the Silica Glass Structure by the

Rietveld Method ,” Journal of Non-Crystalline Solids,

Vol. 183, No. 1-2, 1995, pp. 39-42.

doi:10.1016/0022-3093(94 ) 00 66 4-4

[16] L. Lutterotti, R. Ceccato, R. Dal Maschio and E. Pagani,

“Quantitative Analysis of Silicate Glass in Ceramic Ma-

terials b y de Riet veld Met hod,” Material Science Forum,

Vol. 278-28 1, 19 98, pp. 87-92.

doi:10.4028/www.scientific.net/MSF.278-281.87

[17] C. R. Ward and D. French, “Determination of Glass