Development of the Biopolymeric Optical Planar Waveguide with Nanopatter n

Copyright © 2011 SciRes. JSEMAT

where

,

,

and k0 ≈ ω/c = 2π/λ. Given a set of

refractive indices n1, n2, and n3 and the waveguide thick-

ness, tg, of the planar waveguide, and the source wave-

length,

λ

, Equation (1) in general yields a number of so-

lutions for the propagation constant, βs. However, the

source wavelength and the waveguide thickness are re-

stricted in the present study such that only one propaga-

tion mode is supported, and therefore Equation (1) has

only one solution of interest. As a result, the effective

index of the planar waveguide is given by neff = βsλ/2π.

The corrugated structure into the waveguide leads to a

corresponding periodic perturbation of the refractive in-

dex distribution. Each groove of the grating acts like a

weak mirror, and the cumulative effect of all of the weak

reflectors results in a very strong combined reflection

centered on what i s kno wn as the B ragg wave le ngth. The

Bragg wavelength is related to the effective index calcu-

lated above and the grating period, Λ, by [6]

(2)

which when expressed in terms of the propagation con-

stant is given by

(3)

where λb is the Bragg wavelength and λ is the central

wavel ength of t he optical sour ce.

3. Experiment

3.1. The Production of Biopolymer through

Blending of Chitosan and Gelatin

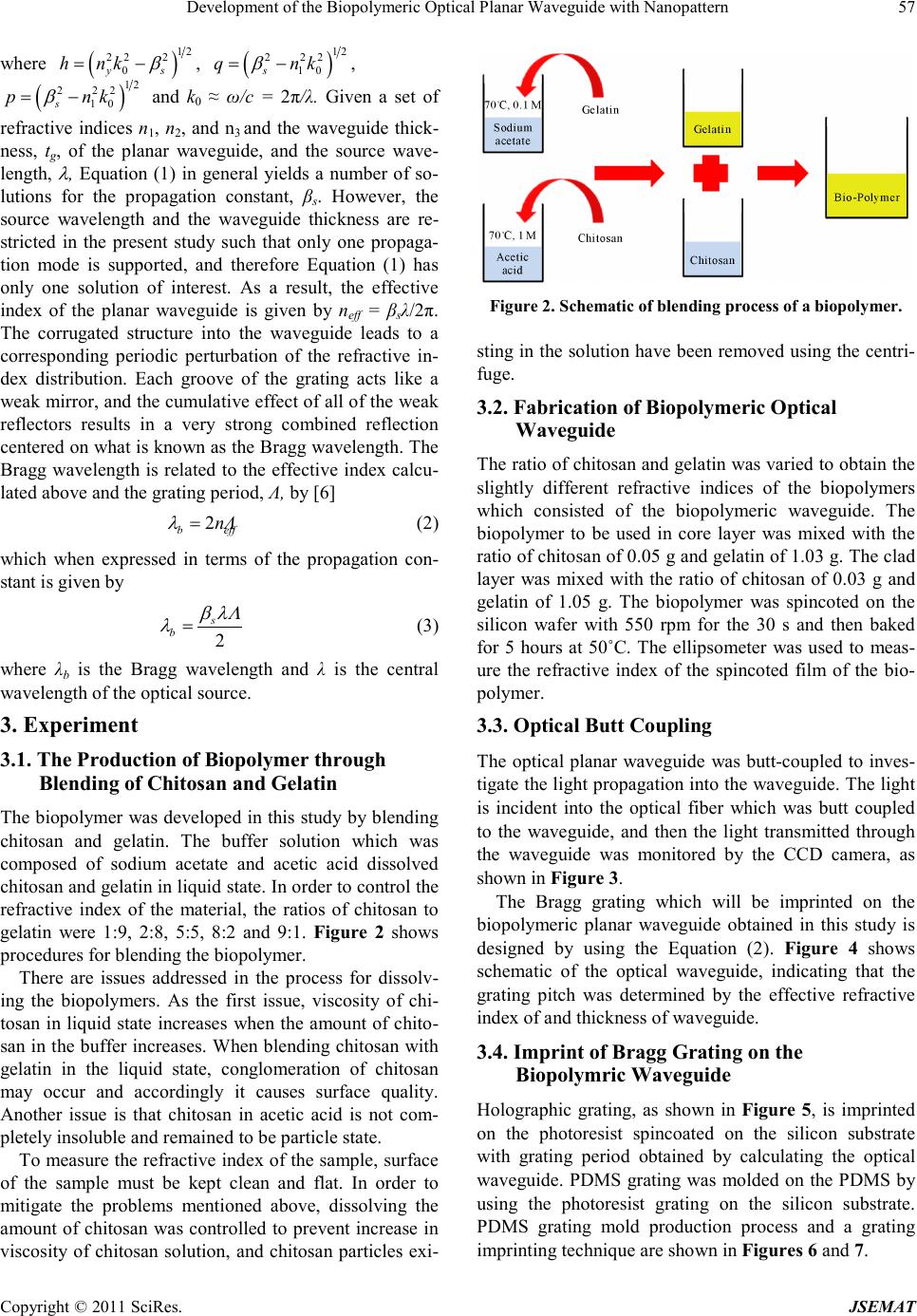

The biopolyme r was de veloped in this stud y by ble nding

chitosan and gelatin. The buffer solution which was

composed of sodium acetate and acetic acid dissolved

chitosan and gelati n in liquid state. In ord er to co ntrol the

refractive index of the material, the ratios of chitosan to

gelatin were 1:9, 2:8, 5:5, 8:2 and 9:1. Figure 2 shows

procedures for blending the biopolymer.

There are issues addressed in the process for dissolv-

ing the biopolymers. As the first issue, viscosity of chi-

tosan in liq uid state increase s when the amount of chito-

san i n the buf fer incre ases. W hen ble nding c hitosa n with

gelatin in the liquid state, conglomeration of chitosan

may occur and accordingly it causes surface quality.

Another issue is that chitosan in acetic acid is not com-

pletely insoluble and remained to b e par tic le state .

To measure the refractive index of the sample, surface

of the sample must be kept clean and flat. In order to

mitigate the problems mentioned above, dissolving the

amount of chitosan was controlled to prevent increase in

viscosity of chitosan solution, and chitosan particles exi-

Figure 2. Schematic of blending process of a biopo lymer.

sting in the solution have b een removed using the centri-

fuge .

3.2. Fabrication of Biopolymeric Optical

Waveguide

The ratio of chitosan and gela tin was varied to ob tain the

slightly different refractive indices of the biopolymers

which consisted of the biopolymeric waveguide. The

biopolymer to be used in core layer was mixed with the

ratio of chitosan of 0.05 g and ge lati n of 1 .03 g. The clad

layer was mixed with the ratio of chitosan of 0.03 g and

gelatin of 1.05 g. The biopolymer was spincoted on the

silicon wafer with 550 rpm for the 30 s and then baked

for 5 hours at 50˚C. The ellipsometer was used to meas-

ure the refractive index of the spincoted film of the bio-

polymer.

3.3. Optical Butt Coupling

The optical planar waveguide was butt-coupled to inves -

tigate the light p ropagation into the waveguide. T he light

is incident into the optical fiber which was butt coupled

to the waveguide, and then the light transmitted through

the waveguide was monitored by the CCD camera, as

sho wn in Figure 3.

The Bragg grating which will be imprinted on the

biopolymeric planar waveguide obtained in this study is

designed by using the Equation (2). Figure 4 shows

schematic of the optical waveguide, indicating that the

grating pitch was determined by the effective refractive

index of and thick ness of waveguide.

3.4. Imprint of Bragg Grating on the

Biopolymric Waveguide

Holographic grating, as shown in Figure 5, is imprinted

on the photoresist spincoated on the silicon substrate

with grating period obtained by calculating the optical

waveguide. PDMS grating was molded on the PDMS by

using the photoresist grating on the silicon substrate.

PDMS grating mold production process and a grating

impr i ntin g tec hni que are shown in F igures 6 and 7.