Effect of Nitriding on Wear Behavior of Graphite Reinforced Aluminum Alloy Composites

Copyright © 2011 SciRes. JSEMAT

motes easy shear bet ween the la mellar plane s of graphite.

The buildup of the fi lm i s a significant feature of graphite

tribology. Gra phite has a hexa gona l la yere d str uct ure a nd

the bonds between the parallel layers are relatively weak

(van der Walls type). The key to graphite’s value as a

self-lubricating solid lies in its layered lattice structure

and its ability to form strong chemical bonds with gases

such as water vapour. The adsorption of water vapour

and other gases from the environment ont o the cr ys t alline

edges weakens the interlayer bonding forces, resulting in

easy shear and transfer of the crystalline platelets on to

the mating surfaces. Graphite also performs well under

boundary lubrication conditions because of its affinity fro

hydrocarbon lubricants [10].

Hence it can be concluded that the ability of the

sheared reinforcement layers to adhere to the sliding sur-

face decides the effectiveness of the graphite particles in

reducing the wear rate of the composite materials.

3.3. Effect of Nitriding on Wear Rate

Nitriding is a surface treatment process where nitroge n i s

supplied into the chamber of specialized equipment at

relatively high temperature. A nitrided thin layer on the

surface will be formed containing aluminum alloy based

phases. The addition of graphite to the base alloy signif-

icantly improves the wear resistance. This is further im-

proved by several folds in the case of nirtided compo-

sites. The hardness of the nitrided composites increases

quite significantly as shown in the Ta ble 2. T he primary

cause for the increase in hardness and hence wear resis-

tance is the presence of AlN and nitrogen enriched alu-

minum at the surface. The presence of the phases is

sho wn by the XRD a na l ysi s whic h is p r esented i n Figure

2(a).

3.4. SEM Analysis

In view of brevity and convenience, the SEM micro-

graphs of only 7% composites at speed of 1.87 m/s have

been presented. However, the explanation holds good

even for the composites with 3 and 5% reinforcement as

well. The SEM micrographs of a typical worn surface of

the 7% graphite reinforced composites are presented in

Figure 6(a), (b) and (c) which shows the wear track

morphology of the specimens tested at various loads.

It can be seen that a lot of parallel, continuous and

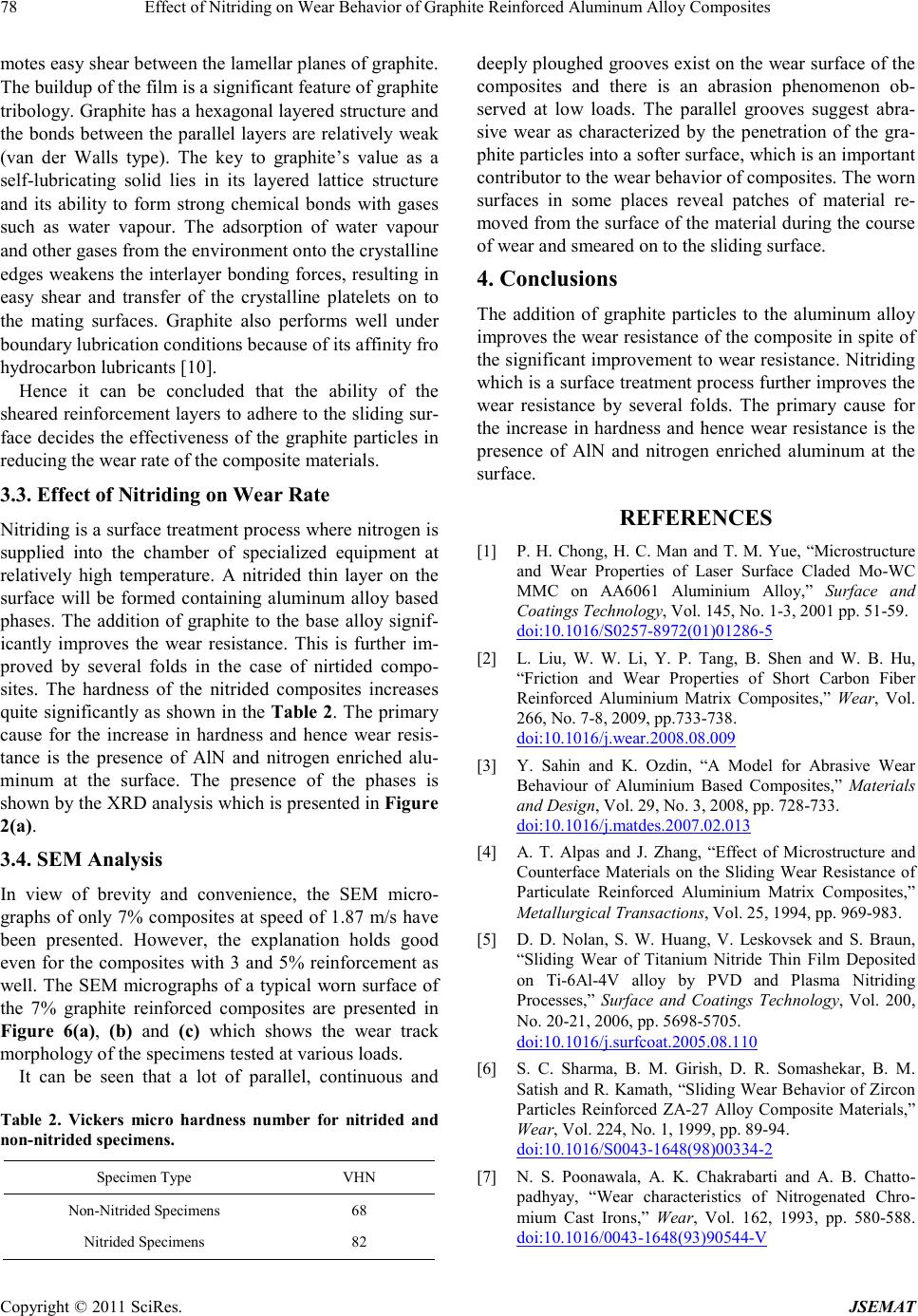

Table 2. Vickers micro hardness number for nitrided and

non-nitrided specimens.

Specimen Type VHN

Non-Nitrided Specimens 68

Nitrided Specimens 82

deeply ploughed grooves exist on the wear surface of the

composites and there is an abrasion phenomenon ob-

served at low loads. The parallel grooves suggest abra-

sive wear as characterized by the penetration of the gra-

phite particle s into a so fter sur face, which is an i mportant

contributor to the wear behavior of composites. The worn

surfaces in some places reveal patches of material re-

moved from the surface of the material during the c ours e

of wear and smeared on to the sliding surface.

4. Conclusions

The addition of graphite particles to the aluminum alloy

improves the wear resistance of the composite in spite of

the s ignifi cant i mpro vement to wear resi stance. Nitridin g

whi ch is a s urface treatment process further improves the

wear resistance by several folds. The primary cause for

the increase in hardness and hence wear resistance is the

presence of AlN and nitrogen enriched aluminum at the

surface.

REFERENCES

[1] P. H. Chong, H. C. Man and T. M. Yue, “Microstructure

and Wear Properties of Laser Surface Claded Mo-WC

MMC on AA6061 Aluminium Alloy,” Surface and

Coatings Technology, Vol. 145, No. 1-3, 2001 pp. 51-59.

doi:10.1016/S0257-8972(01)01286-5

[2] L. Liu, W. W. Li, Y. P. Tang, B. Shen and W. B. Hu ,

“Friction and Wear Properties of Short Carbon Fiber

Reinforced Aluminium Matrix Composites,” Wear, Vol.

266, No. 7-8, 2009, pp.733-738.

doi:10.1016/j.wear.2008.08.009

[3] Y. Sahin and K. Ozdin, “A Model for Abrasive Wear

Behaviour of Aluminium Based Composites,” Materials

and Design, Vol. 29, No. 3, 2008, pp. 728-733.

doi:10.1016/j.matdes.2007.02.013

[4] A. T. Alpas and J. Zhang, “Effect of Microstructure and

Counterface Materials on the Sliding Wear Resistance of

Particulate Reinforced Aluminium Matrix Composites,”

Metallurgical Transactions, Vol. 25, 1994 , pp. 96 9-983.

[5] D. D. Nolan, S. W. Huang, V. Leskovsek and S. Braun,

“Sliding Wear of Titanium Nitride Thin Film Deposited

on Ti-6Al-4V alloy by PVD and Plasma Nitriding

Processes,” Surface and Coatings Technology, Vol. 200,

No. 20-21, 2006, pp. 5698-5705.

doi:10.1016/j.surfcoat.2005.08.110

[6] S. C. Sharma, B. M. Girish, D. R. Somashekar, B. M.

Satish and R. Kamath, “Sliding Wear Beh avior o f Zircon

Particles Reinforced ZA-27 Alloy Composite Materials,”

Wear, Vol. 224, No. 1, 199 9, pp. 89-94.

doi:10.1016/S0043-1648(98)00334-2

[7] N. S. Poonawala, A. K. Chakrabarti and A. B. Chatto-

padhyay, “Wear characteristics of Nitrogenated Chro-

mium Cast Irons,” Wear, Vol. 162, 1993, pp. 580-588.

doi:10.1016/0043-1648(93)90544-V