A. Pazirandeh, L. Shirmohammadi

minerals are abundantly available in man y countries including, Austra lia , India, …

Accelerator Driven Thorium Reactor (ADTR) has some special properties that make it different from classic

reactors. All AD systems consist of three main components: a Subcritical Core (SC), a spallation targets (ST)

and an accelerator coupled with SC. Physics of AD reactors, in both structure and operation method, is quite

different from other reactors. No control rod is used in these systems; instead, a proton beam from the accelera-

tor coupled with SC controls and handles the core. This implies that the safety of the ADS basically depends on

the fu nction of the accelerator [2]-[4].

2. Accelerator Driven Subcritical Core Simulation by MCNPX Code [5]

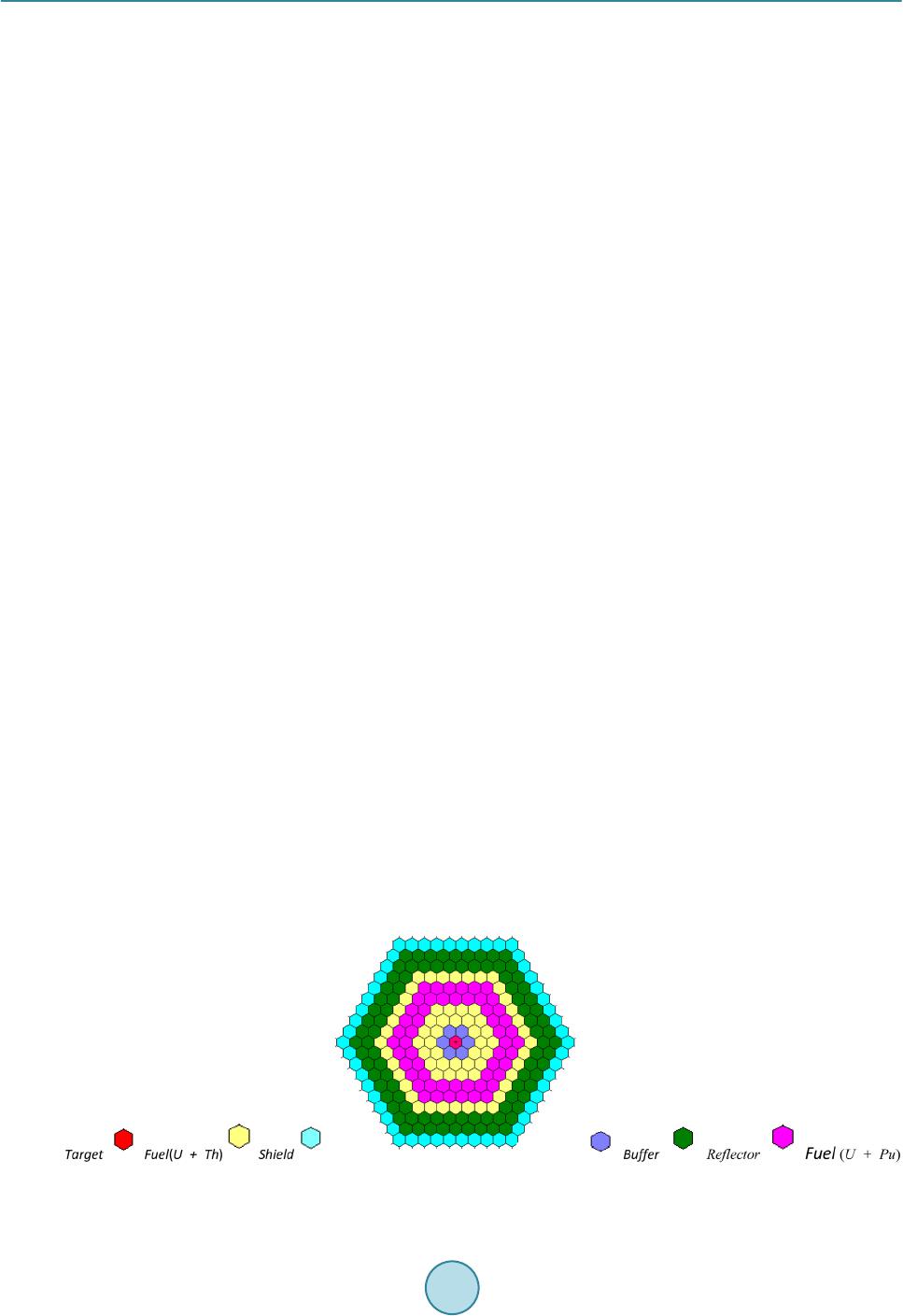

The subcritical system adopts a hexagonal fuel array in order to compact the core and to achieve hard neutron

energy spectrum by minimizing neutron moderation. The core is simulated using Monte Carlo code MCNPX

2.4.0. The core includes a cylindrical accelerator driven subcritical system loaded with (85% T hO2 + 15% UO2)

and MOX (U-Pu) fuel assemblies. The MOX (U-Pu) n uc lide s c an b e d i sc ha rge d fr om hig hl y b ur nt -up spent fuel

assemblies of a PWR. The core consists of 66 hexagonal (85% T hO 2 + 15% UO2) fuel assemblies, 54 MOX

(U-Pu) fuel assemblies, 90 reflector assemblies and 54 shield assemblies (see Figure 1). Each assembly com-

prises 37 rods. The radius of accelerator tube is 2.5 cm and 32.6 cm below the top of subcritical core. There is

no control rod in the core. The subcritical core is generally driven by external neutrons emerged from the spalla-

tion target that is bombarded by charged particles accelerated and collimated in a high-power accelerator. Here,

the system is driven b y 1 GeV proton beam aimed to LBE (Lead-Bismuth Eutectic) target. The structure walls

and beam window are made of stainless-steel (HT-9). Owing to its outstanding nuclear properties, liquid lead-

bismuth (44.5% Pb + 55.5% Bi) is employed as both coolant and spallation target. Low melting point, high

boiling point and very low vapor pressure of LBE make it proper to operate within a wide range of temperature

that implies a n extraor dinary natur al conve ction a nd coo ling melti ng point, high bo iling p oint and ve ry lo w va-

por pressure of LBE make it proper to operate within a wide range of temperature that implies an extraordinary

natural convection and cooling capability leading to an enhanced passive safety. Because of its low neutron

capture cross section, LBE is transparent to neutrons, allowing much relaxed core design. The configuration of

the core is illustra te d in Figure 1.

The shield is made of B4C. Fig ure 2 shows a cro s s -sectio nal vie w of a single assembly. The structural assem-

bly walls are made of stainle ss-steel (HT -9). No separate target is included in the core. As depicted in Figure 1,

the buffer region is between LBE target and the core. The buffer zone flattens the power distribution. Figure 3

demonstrates the array of assemblies in the core simulated by MCNPX2.4.0.

3. The Neutronic Performance Calculation and Results for Simulated ADS Core

The calculation of neutron multiplication factor for ADS was performed by MCNPX code using KCODE option.

In an ADS, keff must be between 0.95 and 0.98 indicating that ADS is a subcritical system. ADS reactors, as a

matter of fact, ar e s ubcritica l in all co ndit ions a nd power leve ls. T he syste m was firs t si mula ted with onl y (Th -U)

fuel asse mblies loaded and the multiplication factor was calculated. This being the case, keff was muc h less tha n

0.9 5, implyin g that the c ore would not run. T hen the MOX (U-Pu) fuel assemblies were loaded into the core as

shown in Figure 1 and the multiplication factor increased to 0.966 where the chain reaction could sustain. The

Figure 1. Cutaway of simulated ADS core.