World Journal of Condensed Matter Physics

Vol.2 No.4(2012), Article ID:24652,5 pages DOI:10.4236/wjcmp.2012.24033

The Structure and Magnetic Properties of Co77Zr18W5 Melt-Spun Ribbons

![]()

1College of Science, Shenyang Aerospace University, Shenyang, China; 2College of Physics, Jilin University, Changchun, China.

Email: *wangwq@jlu.edu.cn

Received May 27th, 2012; revised June 28th, 2012; accepted July 8th, 2012

Keywords: Co-Zr Alloys; Co5Zr Phase; Coercivity; Melt-Spun; Permanent Magnets

ABSTRACT

Based on X-ray diffraction, microscopic and magnetic analysis, the structure and magnetic properties of Co77Zr18W5 melt-spun ribbons were studied in this paper. A new element to stabilize the metastable Co5Zr phase was found and the coercivity observed in Co-Zr alloys can be obviously enhanced by proper tungsten substitution. The Curie temperature of Co77Zr18W5 ribbons is 475˚C which suggests that W doped Co-Zr alloys may become an attractive candidate permanent magnets for practical applications in high temperature. Annealing of the Co77Zr18W5 ribbons results in a decrease of the coercivity which confirmed that the hard magnetic phase is Co5Zr phase in Co77Zr18W5 melt-spun ribbons.

1. Introduction

To enhance the thermal stability of permanent magnetic materials for high temperature applications, recent developments are largely concentrated on the non-rare-earth containing permanent magnets in the magnet society. One of the candidates for the new permanent magnetic materials is Co-Zr system alloys [1]. In recently years, a great deal of effort has been devoted to improve the magnetic properties of Co-Zr system alloys by doping or optimizing the annealing conditions of rapidly quenched ribbons [2-5]. The reported maximum values of energy products in Co-Zr-B(-Si) melt-spun ribbons are comparable to those of the hard ferrites [6,7]. According to previous reports, either Co5Zr phase or Co11Zr2 phase is the hard magnetic phase in Co-Zr system alloys [7-11]. To further improve the hard magnetic properties of Co-Zr system alloys, it is essential to determine the hard magnetic phase in Co-Zr system alloys.

Previous studies show that the rapidly quenched CoZr-based alloys with near 18 at% Zr concentration have a good hard magnetic property. To our knowledge, works on Co-Zr system alloys were mostly performed by small atomic radius elements additions, such as B, Si or C [5]. In this work, we will broaden the range of admixture by doping the relatively large atomic radius tungsten element to Co-Zr alloys and focus on the structure and magnetic properties of Co77Zr18W5 melt-spun ribbons. Moreover, we will try to identify the hard magnetic phase in Co-Zr system alloys.

2. Experiment

The ingot of Co77Zr18W5 was prepared by arc melting the constituent elements, Co and Zr of purity 99.99% and W of purity 99.95%, in an arc furnace under argon atmosphere. To ensure homogeneity, the melting was carried out six times and the weight loss after the final melting was less than 0.3%. Then, small amounts of the alloy ingot were placed in a quartz crucible with an orifice of 0.8 mm at the bottom. The alloy ingot was induction melted in an argon atmosphere and then ejected through the orifice with argon on to a copper wheel rotating at a surface velocity (Vs) of 40 m/s. The resultant melt-spun ribbons were typically 2 - 3 mm wide and 20 - 40 µm thick.

The phases of the ribbons were identified by X-ray diffraction (XRD) using CuKα radiation in a Rigaku D/ MAX2200PC diffractometer. The lattice parameters were evaluated by least-squares refinement from powder X-ray diffractograms. Thermomagnetic analysis (TMA) was performed in a magnetic balance in a field of 1 kOe. Magnetic properties of the ribbons were measured by a vibrating sample magnetometer (VSM) with a maximum applied field of 12 kOe. VSM was calibrated with a pure nickel flake. The microstructures of the specimens were examined by a scanning electron microscope (SEM).

3. Result and Discussion

Figure 1 shows the initial magnetization and roomtemperature hysteresis curves of Co77Zr18W5 melt-spun ribbons produced at a wheel speed of 40 m/s. The hysteresis curve is very smooth and the remanence ratio (Mr/Ms) exceeds 0.6, reflecting that an exchangecoupling effect might have occurred in these ribbons. The inset shows the hysteresis curves of Co77Zr18W5 ingot as a function of applied magnetic field. We can see that the as-cast alloy nearly has no coercivity, suggesting that the process of quenching change the phase in the ribbons. For the Co77Zr18W5 melt-spun ribbons, it has the coercive value of 4.3 kOe, which is higher than that of Co-Zr-B melt-spun ribbons (3.6 kOe) [7]. On the other hand, the large slope of magnetization at 12 kOe indicates that the specimens are not saturated. Much lager field is required to completely saturate the coercivity.

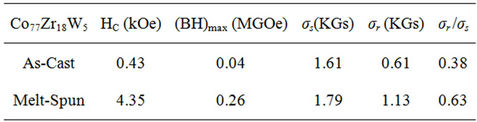

The magnetic properties of ingot and melt-spun ribbons are listed in Table 1. In the calculation of the maximum energy product (BH)max, the density of the melt-spun ribbons is assumed to be 8.82 g/cm3. The maximum value of coercive field HC were obtained under 12 kOe magnetic field. As can be seen, a much larger HC and (BH)max improvement are obtained for the Co77Zr18W5 ribbons than the ingot. This value of coercivity is also much larger than the value of the undoped Co82Zr18 meltspun ribbons and annealed samples. It can be considered that the magnetic performance in polycrystalline Co-Zr alloys can be improved by the substitutions of W for Co. This improvement can be understood based on the dependence of the crystal structure and microstructure.

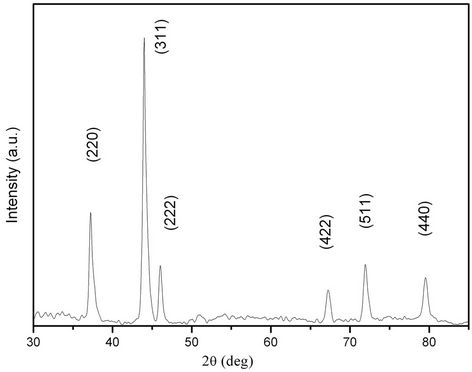

To understand the phases that exist in the studied ribbons, X-ray diffraction analysis was carried out. Figure 2 shows the X-ray diffraction pattern of Co77Zr18W5

Figure 1. Initial magnetization and hysteresis curves of Co77Zr18W5 melt-spun ribbons.

Table 1. Magnetic properties of the As-cast Co77Zr18W5 ingot and melt-spun ribbons.

melt-spun ribbons. From the X-ray diffraction analysis, only a single Co5Zr phase is found in the ribbons. The structure of the binary Co5Zr phase is of fcc type having a F43m or F23 space group with a = 0.67 nm. It has been reported that the XRD patterns of Co82Zr18 melt-spun ribbons (the surface velocity of 40 m/s) and of that annealed consist of Co11Zr2, Co2Zr, fcc-Co, Co23Zr6 and Co5Zr phase [5]. The XRD pattern suggests that W doping can decrease the amount of other phases. By leastsquares refinement from powder X-ray diffractograms we get that the substitution of Co by the relatively larger atomic radius W leads to an increase of the Co5Zr phase lattice constants of a = 0.6821 nm. We also detected the XRD of Co77Zr18W5 ingot and almost no Co5Zr phase was found. However, in the investigated Co77Zr18W5 melt-spun ribbons only the Co5Zr phase is detected. This indicates that the W additive plays an important role in stabilizing Co5Zr phase and W is an effective element to stabilize the metastable Co5Zr phase.

Figure 3 shows the thermomagnetic curve of Co77 Zr18W5 melt-spun ribbons. We can see that the thermomagnetic curve exhibits a single magnetic transition near 475˚C. It is clear that the Co77Zr18W5 melt-spun ribbons consist a single Co5Zr phase. The Curie temperature 475˚C is lower than that of the binary Co5Zr phase (TC = 500˚C) in Co-Zr-B alloys [5]. Similar results have been observed in Co-Zr-B-Si alloys [8]. As far as we know, the decreasing of Curie temperature is possibly due to the increasing of lattice constants by the size effect, because of the change of the 3d band structure resulting from the increasing of lattice constants [12]. Corresponding to the XRD studies above, the investigated specimens, consisting more Co5Zr phase, exhibits a higher coercivity. These results lead to the conclusion that Co5Zr phase is the hard magnetic phase in Co-Zr system alloys.

It is well known that annealing of rapidly solidified

Figure 2. XRD pattern of Co77Zr18W5 melt-spun ribbons. The peaks can be indexed according to the Co5Zr phase.

Figure 3. Thermomagnetic curve of Co77Zr18W5 melt-spun ribbons.

alloys results in the change in the grain size and the crystalline phase, which should give rise to the change in the magnetic properties. So the ribbons were annealed at temperatures between 550˚C and 750˚C for 20 min. Figure 4 shows the dependence of coercivity of Co77Zr18W5 melt-spun ribbons on the annealing temperature. We can find that the coercivity of the annealed melt-spun ribbons decreases initially with increasing the annealing temperature from 4.0 kOe at 550˚C to the minimum value 2.4 kOe at 700˚C, then gradually increasing from 2.4 kOe at 700˚C to 2.6 kOe at 750˚C. Virtually, all the annealed specimens have a lower coercivity value than the as melt-spun ribbons. Heat treatment of the Co77Zr18W5 melt-spun ribbons results in a decrease of the coercivity, as was also found in Co-Zr-M (M = Mo, C, Si, Al) melt-spun ribbons [3,13].

The corresponding XRD pattern of the Co77Zr18W5 ribbons annealed at 700˚C is shown in Figure 5. Three phases, namely, Co5Zr, Co23Zr6 and fcc Co phase, were found in the annealed Co77Zr18W5 ribbons. It is clear that the amount of Co5Zr phase in the annealed Co77Zr18W5 ribbons is less than that of the as-prepared ribbons. Obviously no detection of Co11Zr2 phase was found in both the as-prepared and annealed ribbons. This may be due to that the equilibrium Co11Zr2 should be a soft magnetic phase in Co-Zr system as reported [5].

The microstructures of the Co77Zr18W5 ribbons of before heat treatment and the Co77Zr18W5 ribbons annealed at 700˚C for 20 min were analyzed by SEM, as we can see in Figure 6. The grain size of Co77Zr18W5 melt-spun ribbons is too small to determine by SEM (less than 0.1 μm) and he ribbons annealed at 700˚C for 20 min have fine grains (about 2 μm). This suggests that heat treatment of the Co77Zr18W5 melt-spun ribbons results in the dramatic change in the grain size. According to the micro-structural studies, the change of the coercivity for the

Figure 4. Dependence of coercivity of melt-spun ribbons on the annealing temperature from 550˚C to 750˚C.

Figure 5. XRD patterns of the Co77Zr18W5 melt-spun ribbons annealed at 700˚C.

annealed specimens is considered to the change of the grain size of Co5Zr phase, that is, the annealing temperature. The same results have been found in Co-Zr alloys [11]. On the other hand, compared with the as-prepared ribbons, we can see that the decrease of the coercivity for the annealed specimens is suggested to originate from the decreasing of the amount of Co5Zr phase. These results further confirm that Co5Zr phase is the hard magnetic phase in Co-Zr system alloys.

We also measured the coercivity of the minor hysteresis loops of Co77Zr18W5 ribbons in dependence with the applied magnetic field. It was found that the coercivity of the ribbons increases drastically at the low applied field until the external field exceeds the coercivity value, whereupon it reaches the maximum value. Moreover, the lowfield susceptibility, determined by reversible displacement of the walls, is very large. Magnetic saturation is

Figure 6. SEM micrographs of Co77Zr18W5 melt-spun ribbons (a) and of the annealed at 700˚C (b).

obtained in comparatively low applied field. These behaviors indicate that the coercivity of the studied Co77Zr18W5 ribbons is mainly governed by the nucleation of the reversed domain [6,14]. The physical mechanism should be complex and detailed work for that is required in the future.

4. Conclusion

In conclusion a single metastable Co5Zr phase is obtained in the Co77Zr18W5 melt-spun ribbons. The high coercivity of 4.3 kOe is proved coming form the hard magnetic phase of Co5Zr. Substitution of Co by the relatively larger atomic radius W can lead to an increase of the Co5Zr phase lattice constants and exhibit a Curie temperature of about 475˚C. The coercivity of the annealed specimens decreases than the as-prepared ribbons because of the decrease of hard magnetic phase and the change of grain size. The excellent hard magnetic properties may make the Co-Zr alloys become very attractive candidate materials for permanent magnetic applications. The related physics is complex and require a further fundamental investigation.

5. Acknowledgements

This work was supported by the National Natural Science Foundation of China grant No. 11074092 and 51101105.

REFERENCES

- A. M. Gabay, Y. Zhang and G. C. Hadjipanayis, “CobaltRich Magnetic Phases in Zr-Co Alloys,” Journal of Magnetiam and Magnetic Materials, Vol. 236, No. 1-2, 2001, pp. 37-41. doi:10.1016/S0304-8853(01)00446-2

- B. G. Shen, L. Y. Yang, L. Cao and H. Q. Guo, “Hard Magnetic Properties in Melt-Spun Co82−xFexZr18 Alloys,” Journal of Applied Physics, Vol. 73, No. 10, 1993, pp. 5932-5934. doi:10.1063/1.353525

- J. B. Zhang, Q. W. Sun, W. Q. Wang and F. Su, “Effects of Mo Additive on Structure and Magnetic Properties of Co82Zr18 Alloy,” Journal of Alloys and Compounds, Vol. 474, No. 1-2, 2009, pp. 48-51. doi:10.1016/j.jallcom.2008.07.004

- G. C. Jeong and H. W. Kwon, “Study of Coercivity in Mechanically Alloyed Co-Zr System,” Journal of Magnetics, Vol. 67, No. 1, 2007, pp. 45-48. doi:10.4283/JMAG.2007.12.1.045

- T. Saito, Y. Kamagata and W. Q. Wang, “The Origin of High-Saturation Magnetization in Co-Zr-C Melt-Spun Ribbons,” IEEE Transactions on Magnetics, Vol. 41, No. 10, 2005, pp. 3787-3789. doi:10.1109/TMAG.2005.854690

- L. Y. Chen, H. W. Chang, C. H. Chiu, C. W. Chang and W. C. Chang, “Magnetic Properties, Phase Evolution, and Coercivity Mechanism of CoxZr98−xB2 (x = 74 86) Nanocomposites,” Journal of Applied Physics, Vol. 97, No. 10, 2005, Article ID: 10F307-3. doi:10.1063/1.1853275

- T. Saito, “High Performance Co-Zr-B Melt-Spun Ribbons,” Applied Physics Letters, Vol. 82, No. 14, 2003, pp. 2305-2307. doi:10.1063/1.1565694

- C. Gao, H. Wan and G. C. Hadjipanayis, “High Coercivity in Non-Rare-Earth Containing Alloys,” Journal of Alloys and Compounds, Vol. 67, No. 9, 1990, pp. 4960- 4962. doi:10.1063/1.344747

- T. Ishikawa and K. Ohmori, “Hard Magnetic Phase in Rapidly Quenched Zr-Co-B Alloys,” IEEE Transactions on Magnetics, Vol. 26, No. 5, 1990, pp. 1370-1372. doi:10.1109/20.104381

- G. V. Ivanova, N. N. Shchegoleva and A. M. Gabay, “Crystal Structure of Zr2Co11 Hare Magnetic Copound,” Journal of Alloys and Compounds, Vol. 432, No. 1-2, 2007, pp. 135-141. doi:10.1016/j.jallcom.2006.05.122

- T. Saito, “The Origin of the Coercivity in Co-Zr System Alloys,” IEEE Transactions on Magnetics, Vol. 39, No. 5, 2003, pp. 2890-2893. doi:10.1109/TMAG.2003.815738

- K. J. Strnat, G. Hoffer, J. C. Olson, W. Ostertag and J. J. Becker, “A Family of New Cobalt-Base Permanent Magnet Materials,” Journal of Applied Physics, Vol. 38, No. 3, 1967, pp. 1001-1002. doi:10.1063/1.1709459

- T. Saito, “Magnetization Process in Co-Zr-B PermanentMagnet Materials,” IEEE Transactions on Magneics, Vol. 124, No. 10, 2004, pp. 876-880. doi:10.1541/ieejfms.124.876

- J. J. becker, “Reversal Mechanism in Copper-Modified Cobalt-Rare-Earths,” IEEE Transactions on Magnetics, Vol. 12, No. 6, 1976, pp. 965-967. doi:10.1109/TMAG.1976.1059153

NOTES

*Corresponding author.