Food and Nutrition Sciences

Vol.06 No.16(2015), Article ID:61928,8 pages

10.4236/fns.2015.616158

Comparison between Hydroponic- and Soil-Grown Raspberries (Rubus idaeus): Viability and Sensory Traits

Chenin Treftz, Stanley T. Omaye

Agriculture, Nutrition and Veterinary Sciences Department, Environmental Sciences and Health Graduate Program, University of Nevada, Reno, USA

Copyright © 2015 by authors and Scientific Research Publishing Inc.

This work is licensed under the Creative Commons Attribution International License (CC BY).

Received 22 October 2015; accepted 13 December 2015; published 16 December 2015

ABSTRACT

Raspberries are known to have an abundant amount of the health promoting bioactive compounds, and increasing consumption has been associated with prevention of several chronic diseases. Growing fruits hydroponically compared to soil-grown has several environmental benefits and can be an option of sustainable food production in non-arable regions of the world. This research investigated the viability, unspecified sensory differences, ascorbic acid, tocopherol, total polyphenolic bioactive compounds and catechins of hydroponic raspberries compared to soil- grown raspberries. Overall, plant survival rate for hydroponic raspberries was 33% and for soil-grown raspberries, it was 66%. Fruit yield per plant was 10% higher in hydroponic raspberries compared to soil-grown. Sensory evaluation results by untrained participants illustrated that they were unable to differentiate between hydroponic and soil-grown raspberries. Nutritional analysis indicated similar values except for ascorbic acid, which was significantly higher in soil-grown raspberries. Growing raspberries hydroponically is feasible and sensory qualities are equal to soil-grown raspberries. Future research should investigate different methods of growing hydroponic raspberries for higher plant survival rates and eventually to determine if hydroponic raspberries may be grown on a commercial scale.

Keywords:

Hydroponic, Sensory Evaluation, Sustainable Foods, Raspberry, Greenhouse

1. Introduction

Growing food hydroponically, or without soil, has a positive connotation among consumers and producers because of the purported environmental benefits it can offer (i.e., less use of water, less pesticide use and higher yields) [1] . Growing hydroponic produce is being investigated to determine optimum environmental, nutritional and sensory attributes of the hydroponic product [2] -[6] . Optimizing growing systems, different types of crops, use of nutrient solution, lighting and other factors will be important when determining the crops that will be successful from environmental, economical, nutritional and sensory perspectives.

Raspberry fruits are a nutrient dense food, and high in vitamin C, manganese, fiber, and copper. Additionally, raspberries are high in bioactive compounds that have known antioxidant and anti-inflammatory benefits such as: anthocyanins, flavonols, flavanols, flavonoids, tannins, hydrobenzoic acids, hydroxycinnamic acids, and stilbenoids. The consumption of raspberry fruits are thought to play a role in obesity prevention, the management of blood sugar, and the prevention of cancer by reducing oxidative stress [7] [8] .

Previous literature has focused on various hypotheses of growing lettuce, tomatoes, carrots, peppers and strawberries hydroponically [6] [9] -[13] . With the hydroponic technology being used more frequently, it will be important to determine which crops are suitable to be grown in hydroponic systems. Research on growing hydroponic raspberries in the literature is scant. In addition to the viability of growing raspberries hydroponically, it will also be of interest to address the differences in taste between the hydroponic and soil-grown product since taste is one of the main drivers of consumption. For hydroponic food production to be effective, it must be equal or better to the soil-grown product in terms of environmental benefits, taste preferences and nutritional content. The goal of this one-year study was to investigate the viability, sensory and nutritional differences between hydroponic and soil-grown raspberries. Therefore, the differences between product yields, plant survival and mass of the fruit were studied. Additionally, sensory evaluation using an unspecified difference test between the hydroponically grown and soil-grown raspberries was assessed. The raspberries were also evaluated for differences in ascorbic acid, α-tocopherol, total polyphenolic bioactive compounds and catechins.

2. Methods

2.1. Growing Methods

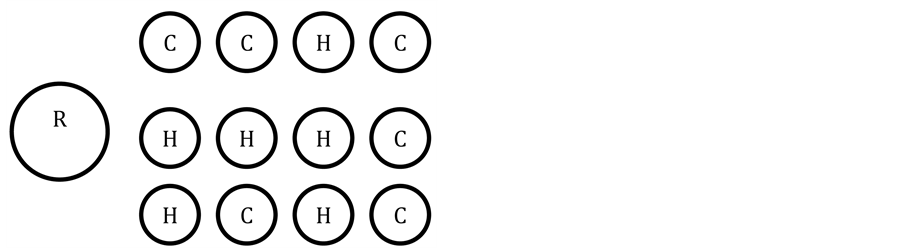

Growing methods have been described previously and are outlined in Figure 1 [3] . Hydroponic and soil-grown raspberries were grown at the University of Nevada, Reno (UNR) Experimental Station [3] . Both hydroponic and soil-grown plants were planted in the spring of 2015. Throughout the growing season, the temperature in the greenhouse was kept at 21˚C between 5:30 AM to 6:30 PM and 16˚C between 6:31 PM to 5:29 AM [3] . The relative humidity was 30%. Bare-root raspberry plants (“Heritage”, Rubus idaeus) were ordered from Stark Brothers Nurseries & Orchard Company (Louisiana, MO). Six raspberries plants were placed in soil conditions according to instructions provided by the nursery. The soil conditions consisted of 1:1 ratio of ratio of Miracle-Gro® potting soil (Marysville, OH) and Nevada topsoil [3] . The bare-root plants were placed in the soil mixture in 50-gallon barrels with drainage holes at the bottom. The raspberries were watered three times weekly for 20 minutes using a drip-irrigation system.

For the hydroponic system, bare-root plants were planted with hydroton (Reno, NV) and placed in 19-gallon buckets (United Solutions, Reno, NV). Water was pumped from the water reservoir using 500 gallon per hour Pro Pump (Hydrofarm, Denver, CO.) by means of polyvinyl chloride and the drip tubing then distributed water

Figure 1. Design for experimental treatments. Schematic illustrates the randomization of the hydroponic (H) and soil-grown (C) growing conditions. Water and nutrient reservoir is indicated by “R”.

over the hydroton. The 19-gallon buckets had holes drilled in the bottom and were placed on top of fifty-gallon barrels where the water could then drain back into the water reservoir. The pH and parts per million (ppm) was measured using Hanna Instruments 9813-6N waterproof pH/EC/TDS meter (Carrolton, TX). The pH of the water in the reservoir was kept in slightly acidic conditions, between 5.8 - 6.2 and adjusted triweekly [3] . The nutrient solution was General Hydroponic Flora Series (Sebastopol, CA) and the concentration averaged at 500 parts per million (ppm). To support the berries, a T-hedgerow system was constructed from polyvinyl chloride.

2.2. Pest Management

Pests are prevalent in greenhouse settings since the favorable growing climates provide optimum conditions for breeding and reproduction of the pests. In the UNR greenhouse, spider mites infected the plants. To generally manage the infestation, all plants were sprayed with water three times weekly to prevent dry, hot growing conditions spider mites thrive in. The spray solution was made with one teaspoon of dish soap mixed with one liter of water and sprayed on the plants. The solution was allowed to sit on the plants for 30 minutes, and then thoroughly rinsed with water. This method was used up to once per month and was marginally efficient at controlling the infection on the plants. For a more aggressive approach, PyGanic® (MGK, Minneapolis, MN) was used. PyGanic® is a pyrethrum containing, organic broad-spectrum contact insecticide, sprayed twice a month as spider mites were detected on and around the plants.

2.3. Sensory Analysis

Participants in the sensory analysis were undergraduate or graduate students at UNR. The study (project number: 583149-1) was approved by the Institutional Review Board. The participants were recruited using an approved recruitment script and asked to taste raspberries. Participant demographics are outlined in Table 1. Eighty percent of the students were female, 73% were between the ages of 17 - 29 years old. As noted from questionnaires, raspberry consumption of the participants varied between “once per day” and “rarely”. The majority (81%) of the participants were of White ethnicity. The unspecified tetrad test was used to determine if participants could differentiate between the hydroponic and soil-grown raspberries. This method has advantages compared to other discriminatory tests by increasing power and reducing variation among samples as explained by the Thurstonian theory [14] [15] . The analysis was conducted in the UNR sensory analysis laboratory on campus. The laboratory was designed according to American Society of Testing Materials standards. The raspberries used for evaluation were harvested on the same day they were sampled by participants. The raspberries were rinsed with tap water and served in a two ounce clear plastic cup coded with a random three digit number.

2.4. Nutritional Analysis

2.4.1. Materials and Equipment

The raspberries were stored at −70˚C Thermo Scientific TM Revco TM in a higher performance lab freezer (Thermo Fisher Scientific, Waltham, MA) until ready for nutrient analysis. Raspberries were randomly selected for analysis by hand. Raspberries were rinsed with deionized water to removed dirt residue and allowed to dry on a paper towel before analysis. For all assays and high performance liquid chromatography (HPLC) analysis, a Brinkmann Instruments Polyton homogenizer (Kinematica, Bohemia, NY) was used for homogenization of the raspberries. Chemicals purchased from Fischer Scientific (Fair Lawn, NJ) were: thiourea, copper sulfate, and 85% orthophosphoric acid. Chemicals purchased from Sigma-Aldrich Cooperation (St. Louis, MO) were: sulfuric acid, trichloroacetic acid, 2,4-dinitrophenylhydrazine, L-ascorbic acid, ferric chloride, xylene, bathophenanthroline, (±)α-tocopherol, Folin-Ciocalteu, catechin, methanol, hydrochloric acid and acetic acid. Absolute ethanol was purchased from pharmco-AAPER, Kentucky.

2.4.2. Ascorbic Acid and Tocopherol Analysis

Procedures have been described in detail previously [3] [16] . Briefly, 10 grams (g) of berries were homogenized with 10mL of cold 20% trichloroacetic acid (TCA). Activated carbon (0.1 grams) was added to the mixture to remove color intensity and the mixture was allowed to sit overnight and then filtered using Whatman no. 2 filter paper [17] . L-ascorbic acid was used to create a stock solution with 5% TCA between 0 - 120 μg/mL. The liquid after filtering was extracted into new test tubes containing 900 μg/mL 20% TCA and 1mL of a mixture of 2,4 dinitrophenyl-hydrazine (DNPH), thiourea, copper in the presence of sulfuric acid was added to all samples,

Table 1. Study participant demographics.

standards and blank. All tubes were incubated at 37˚C for three hours and then 1.5 mL of ice cold 65% sulfuric acid was added to all samples, standards and blank and allowed to sit for 30 minutes. The absorbance was read at 520 nm. The samples were compared to the linear regression created from the known standards and the reproducibility was measured added by adding a known amount of the sample to determine recovery, which was 113% ± 2.0%.

For the tocopherol analysis, 10 g of raspberries were homogenized with ethanol and then 1.2 mL of xylene was added. Samples were centrifuged at 7˚C for 20 minutes at 3500 rpm. The organic layer was removed and added to new test tubes with 400 µL of bathophanthroline. Ferric chloride (400 µL) was added to new tubes with 400 µL of orthophosphoric acid. Standards with α-tocopherol were made in a similar fashion between 0 - 50 μg/mL for the linear regression to compare the samples [3] . All samples, standards and blanks were read in triplicate at 530 nm [18] .

2.4.3. Total Polyphenolics

Ten grams of raspberries were homogenized with 10 mL ethanol. Deionized water (1.58) mL and Folin-Ciocal- teu reagent was added to all samples, standards and blank. Standards were made using the same method with gallic acid ranging from 0 - 300 mg GAE/L [3] . Sodium carbonate (25%) was added to all samples, standards and blank and was incubated at 40˚C for 15 minutes and measured at 690 nm [19] .

2.4.4. Catechin Analysis

Procedures for extraction and detection have been described previously [20] . Ten grams of raspberries were homogenized and extracted with ethanol, water and 0.12 M hydrochloric acid (70:29:1 ratio) for four hours. The extracts were centrifuged and the extracts were purified through a Sep Pak Plus C-18 cartridge (Alltech, Grace Davison, Baltimore, MD). The extract was then diluted in a 1:5 ratio with water and filtered though a 0.45 μm cellulose filter (Thermo Scientific, Waltham, MA) after it was washed with water and eluted with 2 mL of methanol. A reverse phase C18 column (Agilent 250 × 4.6 mm) was used for the HPLC system with a visible/UV detection (Agilent HPLC 1100). The data were processed using Chem Station A10.02 (Agilent Technologies, Folsom, CA) software package. The system was eluted with water, methanol, and acetic acid to detect the catechins with a flow rate of 0.8 mL・min−1 with a 20 μL injection volume. Samples were compared against the retention times of the standard and quantified by the linear regression equation created from the standards (R2 = 0.99).

3. Statistical Analysis

Data were analyzed using IBM SPSS Statistics®, version 23.0 (IBM, Armonk, New York, USA). Differences between masses and nutritional content of the raspberries were determined by the independent t-test. The tetrad test results were analyzed by calculating the d’ test statistic. Since d’ of 1 is considered the threshold for psychophysics, a d’ of less than 1 was considered a value where the majority of students could not tell the differences between the two products. Sample sizes for the tetrad test was calculated at α-level = 0.05 and power = 0.8 [21] .

4. Results

4.1. Viability of Raspberries

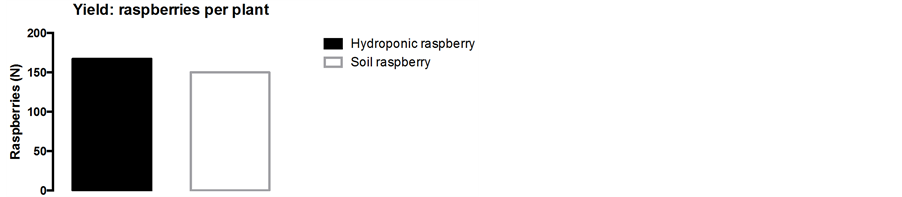

Plant survival rates are outlined in Table 2. Soil-grown raspberries had a much higher survival rate (66%) compared to hydroponic raspberries (33%). The raspberry yields and weights are outlined in Table 3. Both plants produced fruit during the months of August and September; however, the hydroponic plants started producing fruit two weeks prior to soil-grown plants. Both of the growing systems stopped producing fruit during the last week of September. During the month of August, the hydroponic raspberries and soil-grown raspberries had similar weights. During September, the hydroponic raspberries had a significantly higher mass compared to the soil-grown raspberries. The yield of raspberries was calculated per surviving plant. Results are shown in Figure 2. Hydroponic raspberries produced 10% more raspberries per plant compared to the soil-grown plant. Overall, the soil-grown plants produced more raspberries because of the higher plant survival rate.

4.2. Sensory Analysis

Results for the tetrad test are shown in Table 4. Findings indicate 42% of participants could correctly identify the unspecified differences between hydroponically and soil-grown raspberries. A d’ of 0.8 was calculated at the 5% level of significance. From this, it can be concluded that the majority of participants could not discriminate

Table 2. One-season plant survival rate.

Table 3. Mass distributions of hydroponic and soil-grown raspberries by month.

Figure 2. Number of raspberries produced per surviving plant.

Table 4. Unspecified tetrad test results.

between hydroponically and soil-grown raspberries.

4.3. Nutritional Analysis

The results of the nutrient analysis are outlined in Table 5. Ascorbic acid was the only nutrient that showed statistical differences, with the soil raspberry significantly higher amounts (p < 0.05). Tocopherol, total polyphenolic compounds and catechin content were similar in the hydroponic compared to the soil-grown raspberry.

5. Discussion

Growing produce by hydroponic methods is gaining momentum and more consumers are becoming aware of the plentiful advantages of soilless growing. This study showed that hydroponic raspberries yielded a higher number of berries compared to soil-grown plants. However, our overall plant survival rate for both soil and hydroponic conditions was less. Part of our low plant survival rate can be attributed to an aggressive spider mite infection. However, hydroponic plants are known for their pest resistance. Low plant survival rate of the hydroponic raspberry plants may be attributed to the growing system and the supports we provided for the plant, which was large and prone to maintenance technicality issues. For instance, the system was prone to leaks and not efficient at adjusting and monitoring pH and ppms because of using a single reservoir. If hydroponic raspberries could be grown with a high survival rate for several growing seasons, it may be possible to grow hydroponic raspberries on a commercial scale.

A previous study investigating nutritional quality of hydroponic compared to soil-grown raspberries indicated significant differences in sugars, ascorbic acid, and total polyphenolic compounds [3] . These study results were grown in a similar system but during a different growing season. The results in the previous year showed the soil-grown raspberries having higher amounts of ascorbic acid and total polyphenolic compounds. This study showed differences only with the ascorbic acid content and similar nutritional values among the other nutrients studied. Previous literature has indicated nutritional content variation across seasons and factors influencing nutritional composition of a product are multi-variant. Some of these factors include: weather, climate, geographical region, sunlight, and post-harvesting factors [22] . The differences in the current study compared to the nutritional value of the previous study can be attributed to the differences between the two growing years.

Among investigating differences in feasibility, determining the growing system which yields a higher or equal nutritional content compared to soil-grown produce will be important for the success of hydroponic farming. Along with determining nutritional factors, sensory ratings equal to or better than soil-grown produce will be essential, because taste is one of the most important factors a consumer will consider when purchasing and consuming a food product [23] . The participants contributing to the sensory panel for hydroponic compared to soil-grown raspberries were untrained, and study results showed that 42% could discriminate between the different raspberries. From these results, it can be concluded that in general, consumers are not able to differentiate between the two berries. However, more research should be done to confirm these findings. Although our panel sample size was somewhat small (N = 113), the tetrad test offers advantages of increased statistical power and

Table 5. Bioactive compounds in hydroponic and soil-grown raspberries (mg/100 g berries).

N = 3 with 3 replicates; *indicates p < 0.05.

requires a smaller sample size compared to the traditionally used triangle test to achieve statistical significance [14] [21] . The tetrad test has a psychometric function that is intermediate between two commonly used sensory tests (i.e., triangle and 3-alternative forced choice test) and because of this, it has been confirmed the tetrad test has a higher power compared to others [21] . The sample size this study was 113 participants and is large enough to confirm a d’ of 0.85 at a power of 0.8 [21] . This study is limited in that results cannot be confirmed until the next harvest season. Further, when the study is repeated, larger sample sizes with different demographics should be considered. Our panel was limited to students enrolled at the UNR, and the majority of the participants were female, aged 17 - 29 and White. Future research should use a larger sample size and a wider demographic to ensure results are generalizable.

6. Conclusion

Sensory evaluations results show that student volunteers may not be able to tell the taste differences between the hydroponic and soil-grown raspberries. The unspecified tetrad test shows that hydroponic raspberries may be comparable to soil-grown raspberries among the participants. This could be particularly advantageous in non- arable regions of the world, such as arid or urban regions to produce an attractive and flavorsome product to consumers. Although more research is warranted, growing fruits such as raspberries using hydroponic growing systems in greenhouses can complement sustainable local food production.

Acknowledgements

We thank Eric Horton for technical and maintenance assistance. We thank Fannie Zhang for laboratory assistance. We acknowledge the Nevada Agricultural Experiment Station, University of Nevada, Reno for the support of this study, HATCH #0745. The research was done and reported to partially fulfill dissertation requirement of C. Treftz.

Conflict of Interest

There are no conflicts of interest.

Cite this paper

CheninTreftz,Stanley T.Omaye, (2015) Comparison between Hydroponic- and Soil-Grown Raspberries (Rubus idaeus): Vi-ability and Sensory Traits. Food and Nutrition Sciences,06,1533-1540. doi: 10.4236/fns.2015.616158

References

- 1. Resh, H.M. and Howard, M. (2012) Hydroponic Food Production: A Definitive Guidebook for the Advanced Home Gardener and the Commercial Hydroponic Grower. CRC Press, Santa Barbara, California.

http://dx.doi.org/10.1201/b12500 - 2. Ferguson, S., Saliga III, R. and Omaye, S.T. (2014) Investigating the Effects of Hydroponic Media on Quality of Greenhouse Grown Leafy Greens. International Journal of Agricultural Extension, 2, 277-234.

- 3. Treftz, C. and Omaye, S.T. (2015) Nutrient Analysis of Soil and Soilless Strawberries and Raspberries Grown in A Greenhouse. Food and Nutrition Sciences, 6, 805-815.

http://dx.doi.org/10.4236/fns.2015.69084 - 4. Buchanan, D.N. and Omaye, S.T. (2013) Comparative Study of Ascorbic Acid and Tocopherol Concentrations in Hydroponic- and Soil-Grown Lettuces. Food and Nutrition Sciences, 4, 1047-1053.

http://dx.doi.org/10.4236/fns.2013.410136 - 5. Gichuhi, P.N., Mortley, D., Bromfield, E. and Bovell-Benjamin, A.C. (2009) Nutritional, Physical, and Sensory Evaluation of Hydroponic Carrots (Daucus carota L.) from Different Nutrient Delivery Systems. Journal of Food Science, 74, 403-412.

http://dx.doi.org/10.1111/j.1750-3841.2009.01338.x - 6. Arias, R., Lee, T.C., Specca, D. and Janes, H. (2000) Quality Comparison of Hydroponic Tomatoes (Lycopersicon esculentum) Ripened on and off Vine. Journal of Food Science, 65, 545-548.

http://dx.doi.org/10.1111/j.1365-2621.2000.tb16045.x - 7. Liu, M., Li, X.Q., Weber, C., Lee, C.Y., Brown, J. and Liu, R.H. (2002) Antioxidant and Antiproliferative Activities of Raspberries. Journal of Agricultural and Food Chemistry, 50, 2926-2930.

http://dx.doi.org/10.1021/jf0111209 - 8. Rao, A.V. and Snyder, D.M. (2010) Raspberries and Human Health: A Review. Journal of Agricultural and Food Chemistry, 58, 3871-3883.

http://dx.doi.org/10.1021/jf903484g - 9. Coolong, T. (2012) Hydroponic Lettuce. University of Kentucky Cooperative Extension Services, 1-4.

- 10. Lin, K.-H., Huang, M.-Y., Huang, W.-D., Hsu, M.-H., Yang, Z.-W. and Yang, C.-M. (2013) The Effects of Red, Blue, and White Light-Emitting Diodes on the Growth, Development, and Edible Quality of Hydroponically Grown Lettuce (Lactuca sativa L. Var. Capitata). Scientia Horticulturae (Amsterdam), 150, 86-91.

http://dx.doi.org/10.1016/j.scienta.2012.10.002 - 11. Benoit, F. and Ceustermans, N. (1987) Some Qualitative Aspects of Tomatoes Grown on NFT. Soilless Culture (Netherlands), 3, 3-7.

- 12. Sarooshi, R.A. and Cresswell, G.C. (1994) Effects of Hydroponic Solution Composition, Electrical Conductivity and Plant Spcing on Yield and Quality of Strawberries. Australian Journal of Experimental Agriculture, 34, 529-535.

http://dx.doi.org/10.1071/EA9940529 - 13. Paradikovic, N., Vinkovic, T., Vinkovic Vrcek, I., Zuntar, I., Bojic, M. and Medic-Saric, M. (2011) Effect of Natural Biostimulants on Yield and Nutritional Quality: An Example of Sweet Yellow Pepper (Capsicum annuum L.) Plants. Journal of the Science of Food and Agriculture, 91, 2146-2152.

- 14. Ennis, J.M. and Christensen, R. (2014) A Thurstonian Comparison of the Tetrad and Degree of Difference Tests. Food Quality and Preference, 40, 263-269.

http://dx.doi.org/10.1016/j.foodqual.2014.05.004 - 15. O’Mahony, M. (2013) The Tetrad Test: Looking Back, Looking Forward. Journal of Sensory Studies, 28, 259-263.

http://dx.doi.org/10.1111/joss.12045 - 16. Omaye, S.T., Turnbull, J.D. and Sauberlich, H.E. (1979) Selected Methods for the Determination of Ascorbic Acid in Animal Cells, Tissues, and Fluids. Methods in Enzymology, 62, 3-11.

http://dx.doi.org/10.1016/0076-6879(79)62181-X - 17. Duygu Ozsoy, H. and Van Leeuwen, J. (2010) Removal of Color from Fruit Candy Waste by Activated Carbon Adsorption. Journal of Food Engineering, 101, 106-112.

http://dx.doi.org/10.1016/j.jfoodeng.2010.06.018 - 18. Fabianek, J., Apak, E., Gunaydi, E. and Sogen, K. (1968) Micromethod for Tocopherol Determination in Blood Serum. Clinical Chemistry, 14, 456-462.

- 19. Heinonen, I., Lehtonen, P. and Hopia, A. (1998) Antioxidant Activity of Berry and Fruit Wines and Liquors. Journal of Agricultural and Food Chemistry, 46, 25-31.

http://dx.doi.org/10.1021/jf970489o - 20. Iacopini, P., Baldi, M., Storchi, P. and Sebastiani, L. (2008) Catechin, Epicatechin, Quercetin, Rutin and Resveratrol in Red Grape: Content, in Vitro Antioxidant Activity and Interactions. Journal of Food Composition and Analysis, 21, 589-598.

http://dx.doi.org/10.1016/j.jfca.2008.03.011 - 21. Ennis, J.M. and Jesionka, V. (2011) The Power of Sensory Discrimination Methods Revisited. Journal of Sensory Studies, 26, 371-382.

http://dx.doi.org/10.1111/j.1745-459X.2011.00353.x - 22. Wunderlich, S.M., Feldman, C., Kane, S. and Hazhin, T. (2008) Nutritional Quality of Organic, Conventional, and Seasonally Grown Broccoli Using Vitamin C as A Marker. International Journal of Food Sciences and Nutrition, 59, 34-45.

http://dx.doi.org/10.1080/09637480701453637 - 23. Glanz, K., Basil, M., Maibach, E., Goldberg, J. and Snyder, D. (1998) Why Americans Eat What They Do: Taste, Nutrition, Cost, Convenience, and Weight Control Concerns as Influences on Food Consumption. Journal of the American Dietetic Association, 98, 1118-1126.

http://dx.doi.org/10.1016/S0002-8223(98)00260-0