Journal of Sustainable Bioenergy Systems

Vol.3 No.1(2013), Article ID:29082,9 pages DOI:10.4236/jsbs.2013.31006

Effect of Spacing on Growth, Biomass Yield and Quality of Leucaena (Leucaena leucocephala (Lam.) de Wit.) for Renewable Energy in Thailand

1Department of Agronomy, Faculty of Agriculture, Kasetsart University, Bangkok, Thailand

2PTT Research and Technology Institute, PTT Public Company Limited, Ayutthaya, Thailand

Email: *agrsat@ku.ac.th

Received January 25, 2013; revised February 27, 2013; accepted March 10, 2013

Keywords: Spacing; Diameter at Breast Height (DBH); Biomass; Renewable Energy

ABSTRACT

The present study was conducted to determine the effect of spacing on the growth, biomass production and wood quality of leucaena in order to be used as a fuel crop. Leucaena was grown in a field experiment at the Suwanvajokkasikit Research Station, Pak Chong, Nakhon Ratchasima, Thailand in 2006-2010. The experiment was arranged in a randomized complete block design with 4 replications. The treatment consisted of six spacings (1 × 0.25, 1 × 0.5, 1 × 1, 1 × 1.5, 2 × 0.5 and 2 × 1 m). The results showed that spacing had a significant effect on plant height, diameter at breast height, the number of coppice stumps and biomass yield. Wider spacings resulted in greater plant height. The widest spacing (2 × 1 m) exhibited the higher stem diameter and sprout number than the narrow spacing. The narrowest spacing of 1 × 0.25 m spacing produced the highest total dry weight of leaf, woody stem and biomass yield. The spacing did not have an influence on the heating value and the content of H, N, S, Mg, Cl and ash. However, some of the chemical compositions show significant different with different spacings such as C, O, P, K and Ca content.

1. Introduction

The use of biomass can reduce reliance on fossil fuels, to mitigate greenhouse gas (GHG) emissions and to increase energy resource diversification. Among the different renewable energy sources, biomass is one of the promising choices, which has the potential to be used as the raw material to generate electricity [1]. In Thailand, an agricultural-based country, there are many sources of agricultural residues [2] that in total amount of about 61 million ton per year [3], which are used as the main source of biomass energy for industry. However, there are limitations on biomass utilization in Thailand such as the problems of collection, transportation and storage, and availability. For these reasons, fast-growing tree farming for biomass production is likely to be a solution and the most sustainable method of fuel supply for biomass gasification electricity generation [4]. Leucaena is expected to become one of the biomass energy resources, because it is a fast growing tropical tree [5] and with a high yields of woody material [6]. Moreover, leucaena can be used for many purposes including forage, wood, shade, green manure, live fences and erosion control [7].

For energy utilization, information on the productivity related aspects and relative performance of leucaena is not available for large scale cultivation. In order to produce sufficient and sustainable quantities for electricity generation, plantation management must identify the important factors that have an influence on the long term growth and productivity after harvesting leucaena. Spacing is one of the most important factors influencing the growth of leucaena. High plant populations (10,000 - 20,000 trees∙ha−1) were reported to optimize fuelwood production in the Philippines [8]. Guevarra et al. [9] examined even higher plant populations (44,000 - 133,000 trees∙ha−1) were suitable for forage production. Spacing affects management options and the final product which the leucaena production for bioenergy may be optimized with the correct initial spacing [10]. To maximize potential yield, it is particularly important to establish stand densities per unit (spacings) that ensure the best utilisation of the site in long-term. In case of wood quality, leucaena need to evaluate the wood properties. Not only heating value is the most important parameter to characterize the chemical properties for combustion but the ultimate analysis as well. The ultimate analysis provided weight of percentage of C, H, O, N and S [11]. The ultimate analysis is ralated to thermal utilization of the wood [12] and can be also used to evaluate their heating values. Moreover, elemental analysis (P, K, Ca, Mg, Cl and Ash) can be used as the parameters to determine their impact on the environment that play an important role in sustaining energy production system. In addition, relatively little is known about the quality of leucaena wood at different spacings. Therefore, the present study aimed to assess the influence of spacing on the growth, biomass yield and wood quality of leucaena for fuelwood.

2. Materials and Methods

2.1. Site Description

The experiment was conducted at the Suwanvajokkasikit Research Station, Pak Chong district, Nakhon Ratchasima province, Thailand (14˚38'N, 101˚18'E, elevetion of 388 m above sea level). The soil was a sandy clay loam and with weak acidity (pH 6.5). The soil fertility was moderate in organic matter and in the availability of all the three major nutrients (0.11% N, 9.7 ppm P and 43.4 ppm K) in the top 15 cm soil layer. The climatic conditions of the site were recorded at the Suwanvajokkasikit Research Station.

2.2. Experiment Design

The experiment was arranged in a randomized complete block design (RCBD) with 4 replications. The treatments consisted of 6 spacings (1 × 0.25, 1 × 0.5, 1 × 1, 1 × 1.5, 2 × 0.5 and 2 × 1 m). The six spacings gave tree densities ranging from 5000 to 40,000 trees∙ha−1.

2.3. Establishment and Management

Leucaena was planted by direct seeding in December 2006. The area was ploughed and cultivated to produce a good seedbed before sowing. Leucaena leucocephala cultivar Taramba was selected for the study and leucaena seeds were scarified and inoculated with rhizobium strain 3126. A basal fertilizer was supplied consisting of double super phosphate (46% P2O5) at a rate of 187.5 kg∙ha−1∙ year−1 and potassium chloride (60% K2O) at a rate of 250 kg∙ha−1∙year−1. Following seedling emergence at 4 months, trees were thinned to one tree per hill. The present study was conducted under rainfed conditions and sowing was done at the start of the dry season. Therefore, the experiment was irrigated eight times by sprinkler at 25 mm∙ time−1 from December 2006 to February 2007.

2.4. Plant Measurement

The 1st year, leucaena was harvested in December 2007 after 12 months emergence and the 2nd, 3rd and 4th year were harvested after 12 months regrowth in December 2008, December 2009 and December 2010, respectively. The plant height and stem diameter at breast height (DBH) and number of coppice per stump were measured on six randomly selected trees in each treatment at 6 months and before each harvest (12 months); plant height was measured using a meter stick, stem diameter was measured at a height 1.3 m above ground level using a vernier caliper and the sprout number was measured the number of green sprout at main axis of stump. The trees were cut at 50 cm above ground level. Each tree was partitioned into leaf (including green stem), branch and stem. Fresh weight of every tree part was recorded immediately by using an electronic balance after harvesting. Dry weight of leaf, branch and woody stem were measured by hot air oven at 80˚C for 2 weeks and then woody stem were air dried again for about 3 months to measure dry weight. Woody stems were analyzed for carbon (C), hydrogen (H), oxygen (O), nitrogen (N) and sulfer (S) content (ultimate analysis) by an elemental analyzer (LECO CHNS-932). The determination of chemical compositions such as phosphorus (P), potassium (K), calcium (Ca), magnesium (Mg) and chlorine (Cl) contents were analyzed by the Association of Official Analytical Chemists (AOAC) method [13]. The ash content of the woody stem was measured by a proximate analysis method [13]. The heating value of the woody stem was measured using a standard bomb calorific combustion method [13].

2.5. Statistical Analysis

All data were subjected to analysis of variance (ANOVA) appropriate for a randomized complete block design (RCBD). The least significant difference at the 5% level was used to identify significant statistical differences.

3. Results

3.1. Climatic Condition

In the establishment year, there was no rainfall during the first 2 months (December 2006-January 2007) because of the dry season. In the 1st year, the rainy season started from February 2007 to the end of October 2007 (Table 1). Similar results were also observed in the 2nd year (2008). However, in May of the 3rd year (2009), there was little rainfall (94 mm) when compared with the first and second years (163 and 248 mm). Although there was rainfall of 57 mm for the first 2 months (December 2009- January 2010) after harvest in the 3rd year, rainfall decreased sharply to 3 and 7 mm in February and March 2010, respectively. However, the total amount of rainfall in the 4th year was more than in the other years resulting in the maximum monthly rainfall of 393 mm in October 2010.

Table 1. Monthly rainfall (mm) at suwanvajokkasikit research station, Pak chong, Nakhon ratchasima during the study period (2006-2010).

3.2. Plant Height, Stem Diameter and Number of Coppice Stumps

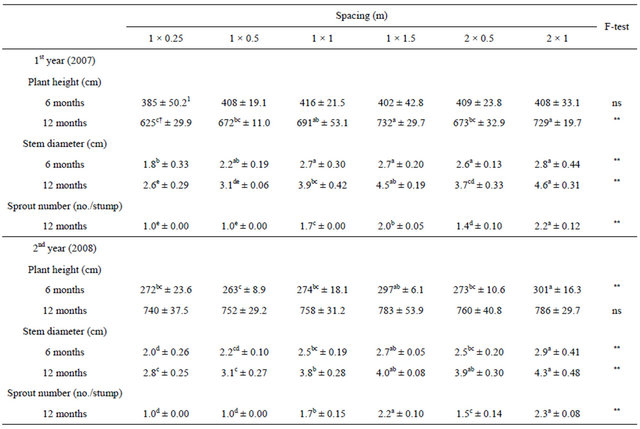

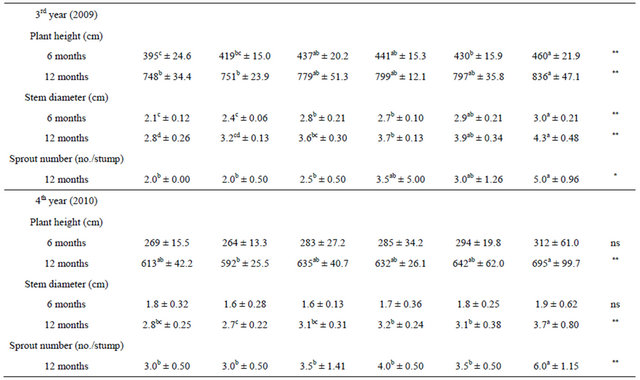

The wide spacing (2 × 1 and 1 × 1.5 m) resulted in the greatest plant heights (729 and 732 cm respectively), while the narrow spacing (1 × 0.25 and 1 × 0.5 m) recorded the lowest plant height (625 and 672 cm) in the 1st year (Table 2). There were no significant differences between spacing for plant height in the 2nd year. In the 3rd year, the 2 × 1 m gave significantly higher plant height than the narrow spacings of 1 × 0.25 and 1 × 0.5 m. The similar results were also found in the 4th year, where the widest spacing of 2 × 1 m gave a greater plant height than the narrow spacing of 1 × 0.5 m. The influence of spacing on stem diameter at harvest is shown in Table 2; the results showed that the widest spacing of 2 × 1 m had significantly larger stem diameter than the narrow spacing in the 1st year (Table 2). Similar results were also found in the 2nd and 3rd years, where the 2 × 1 m spacing exhibited the greatest stem diameter, while the smallest stem diameter was found in the narrowest spacing of 1 × 0.25 m. In the 4th year, the largest stem diameter was found in the widest spacing of 2 × 1 m (3.7 cm) and the smallest stem diameter was observed in the narrow spacing of 1 × 0.5 m (2.7 cm). The sprout number showed variation in their regrowth at different spacings (Table 2). The widest spacing of 2 × 1 m produced the highest sprout number at 12 months in the 1st and 2nd years (2.2 and 2.3 no./stump, respectively). In the 3rd year, the widest spacing of 2 × 1 m gave highest sprout number, but this was not significantly different from the results of the spacings 2 × 0.5 and 1 × 1.5 m. The widest spacing of 2 × 1 m exhibited a superior sprout number when compared with the other spacings in the 4th year.

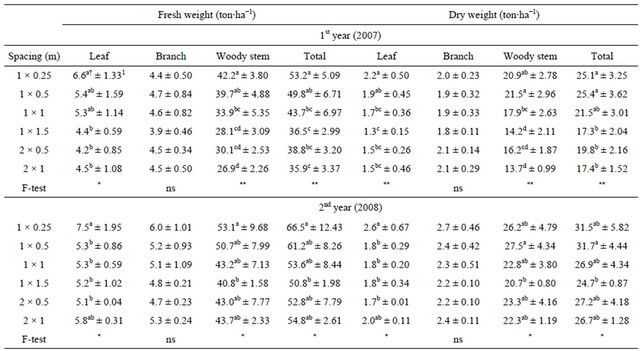

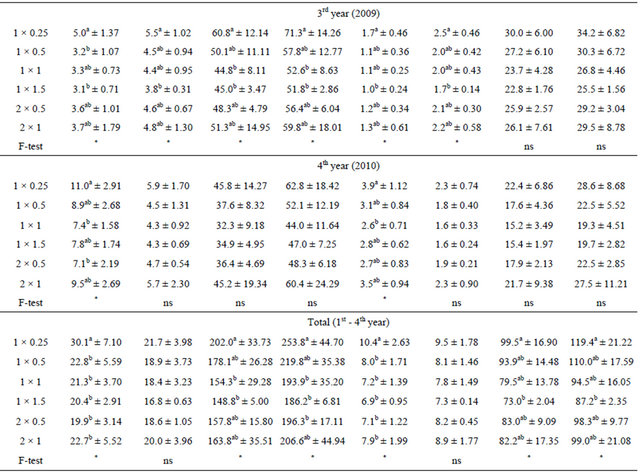

3.3. Leaf and Branch Production

The narrowest spacing of 1 × 0.25 m exhibited the highest leaf yield (2.2 ton/ha) but it was not significantly different from the 1 × 0.5 and 1 × 1 m in the 1st year (Table 3). In the 2nd year, leaf yield was the highest in the narrowest spacing of 1 × 0.25 m followed by the widest spacing of 2 × 1 m. There were little significant differences in leaf yield among the different spacings, although the narrowest spacing of 1 × 0.25 m tended to produce more leaf yield than the wide spacings in the 3rd and 4th years. The narrowest spacing of 1 × 0.25 m exhibited the highest total leaf yield (10.4 ton∙ha−1). Spacing did not affect branch yield in the 1st, 2nd and 4th years. However, the narrowest spacing of 1 × 0.25 m showed the lowest branch yield (1.7 ton∙ha−1) and it was significant difference from the 1 × 1.5 m spacing in the 3rd year. Spacing did not affect total branch yield in the 1st - 4th year.

3.4. Woody Stem Production

The narrow spacing of 1 × 0.5 m gave the highest woody stem yield in the 1st year (Table 3). However, the woody stem yield in the 1 × 0.5 m spacing was not significantly different from the woody stem yield produced by the 1 × 0.25 m spacing. In the 2nd year, the highest woody stem

Table 2. Plant height, stem diameters and sprout number of leucaena at 6 and 12 months after each cutting in 1st, 2nd, 3rd and 4th year of planting.

Note: *, ** = significant differences at the 0.05 and 0.01 probability levels, respectively. ns = non-significant difference. † = Means in the same row followed by the same lowercase letter are not different at P < 0.05, 1 = standard deviation.

Table 3. Biomass component yield of leucaena planted at different spacings over a 4-year period.

Note: *, ** = significant differences at the 0.05 and 0.01 probability levels, respectively. ns = non-significant difference. † = Means in the same column followed by the same lowercase letter are not different at P < 0.05. 1 = standard deviation.

yield was found in the narrow spacing of 1 × 0.5 m, but it was not significantly different from those observed in the spacings of 1 × 0.25, 1 × 1, 2 × 0.5 and 2 × 1 m. In both the 3rd and 4th years, spacing did not affect the woody stem yield.

The highest total woody stem yield (1st - 4th year) was produced by 1 × 0.25 m spacing (99.5 ton∙ha−1), but it was not significantly different from other spacings, except that of the wide spacing of 1 × 1.5 m (73 ton∙ha−1).

3.5. Total Biomass Production

The total biomass production was significantly influenced by spacing. In the 1st year, total biomass was the highest in the narrow spacing of 1 × 0.5 m (Table 3). However, total biomass in the 1 × 0.5 m spacing was not significantly different from those in the 1 × 0.25 and 1 × 1 m spacing. The narrow spacing of 1 × 0.5 m gave the highest total biomass, while the 1 × 1.5 m spacing exhibited the lowest total biomass in the 2nd year. Even though the narrowest spacing of 1 × 0.25 m produced the highest total biomass, the statistical comparison showed that there was no significant difference to the other spacings in the 3rd and 4th years. Total biomass over 4 years (1st - 4th year) showed that the narrowest spacing of 1 × 0.25 m exhibited the highest total biomass of 119.4 ton/ha but it was not significantly different from other spacings, except the wide spacing of 1 × 1.5 m (87.2 ton∙ha−1).

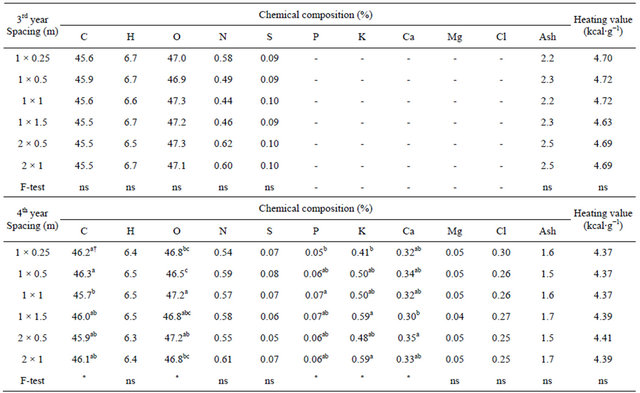

3.6. Chemical Composition and Heating Value

The results showed that the C content in woody stem of leucaena planted at the different spacings varied from 45.5% to 45.9% in the 3rd year, which show no signifycant differences (Table 4). In the 4th year, the narrow spacing of 1 × 0.25 and 1 × 0.5 m tended to exhibit higher C content than 1 × 1 m spacing. The O content was not significantly different among the different spacings (46.9% - 47.3%) in the 3rd year, while 1 × 1 m spacing showed higher O content than 2 × 1, 1 × 0.5 and 1 × 0.25 m spacings in the 4th year. In the 3rd and 4th years, there were no significant differences in the N content which varied from 0.44% to 0.60% and 0.54% to 0.61%, respectively. Both in the 3rd and 4th years, there were no significant differences in the H, N and S content under different spacings which varied from 6.3% to 6.7%, 0.44% to 0.62% and 0.05% to 0.10%, respectively. The narrowest spacing of 1 × 0.25 m gave lower P and K content (0.05% and 0.41%, respectively) than the other spacings. The 1 × 1.5 m spacing showed the lowest Ca content (0.30%), while Mg and Cl content ranged from 0.04% to 0.05% and 0.25% to 0.31%, respectively which

Table 4. Chemical composition and heating value in woody stem of leucaena planted under different spacings.

Note: * = significantly different at the 0.05 probability levels. ns = non-significant difference. † = Means in the same column followed by the same lowercase letter are not different at P < 0.05.

were not significantly different among the different spacings. The ash content of the woody stem showed no significant differences among the different spacings both in the 3rd and 4th years (2.2% - 2.5% and 1.5% - 1.7%, respectively). There were no significant differences in heating value (4.63 - 4.72 kcal∙g−1 of dry matter among the different spacings in the third year. Similar results were also found for heating value, which ranged from 4.37 to 4.41 kcal∙g−1 under different spacings in the 4th year.

4. Discussion

Plant height was relatively higher at the wide spacings and lower at the narrow spacings during the period of study. Differences in plant height due to spacing treatments were significantly different in the 1st, 3rd and 4th years. In the present study, leucaena height was significantly affected by competition which has been due to the extremely high planting densities [14]. The higher densities resulted in reduced plant height which was caused by the failure of sprouts to grow after emergence due to the lack of solar radiation. However, growth height of leucaena is more less affected by spacing than stem diameter.

Spacing had an enormous impact on stem diameter. Leucaena responded to wider spacing and lower competition by producing greater stem diameters with the widest spacing (2 × 1 m) produced the largest trees in every years, while the narrow spacing decreased stem diameter. At narrow spacing (≤1 × 0.5 m), diameter growth was suppressed at an early age. The stems were relatively bigger at the widest spacing, presumably because of the higher availability of soil, moisture and light resources [10]. The small-scale power plant of wood biomass in Thailand is mainly accomplished by using both log wood and wood chip.

The minimum size of log wood required for biomass gasification system is 2.5 cm [15]. Therefore, the stem diameter from the wider spacings of 1 × 1, 1 × 1.5, 2 × 0.5 and 2 × 1 m can be used after 6 months in the 1st year whereas the narrow spacings of 1 × 0.25 and 1 × 0.5 m required 12 months to gain a 2.5 cm of stem diameter. Similar results were also found in the 2nd and 3rd years (Table 2). However, stem diameters of all spacings at 6 months in the 4th year were smaller than those in the previous years, because plants received only 350 mm of rainfall during the 6 months after cutting in the 4th year compared to the 2nd and 3rd years (573 and 547 mm, respectively). Studies on other species have also reported an increase in density resulted in the decrease in stem diameter of trees such as eucalyptus [16] and poplar [17].

The sprout growing from the different spacings showed variations in their regrowth. The sprout number increased with the reduction in stand density and there were significantly differences in large-sized stumps. With small-sized stumps of narrow spacings could cause a decrease in sprouting from such stumps [10], because small area of stump resulted in low sprout number. The high sprout number of wide spacing resulted in no significantly differences in biomass yield in the 3rd and 4th years.

It is clearly that the spacing had an influence on the dry weight of woody stem yield. The spacing had distinctly difference dry weight of woody stem yield in the 1st year, when compared to the 2nd, 3rd and 4th years. The results showed that better performance contributed to a greater woody stem yield in the narrow spacings of 1 × 0.25 and 1 × 0.5 m as compared to that of the widest spacing of 2 × 1 m in the 1st year. In accordance with Proe et al. [18] stated that maximum yields are generally achieved early in dense plantations whereas the widest spacing may be suitable for harvesting cycle over one year in order to get high yield. However, compare to the 1st year, the widest spacing of 2 × 1 m increased the dry weight of woody stem more 60%, 91% and 58% and the woody stem of the narrowest spacing (1 × 0.25 m) increased 25%, 44% and 7% in the 2nd, 3rd and 4th year, respectively. The widest spacing of 2 × 1 m tended to produce the high woody stem yield and biomass yield in the last-three years. Similar results were also found in Mitchell [19] and Proe et al. [18], which reported that the wide spacing exhibited the highest biomass yield in long-term. Most of the spacings produced the higher dry weight of woody stem yield in the last-three years when compared with the 1st year, though the 4th year tended to decrease dry weight of woody stem yield. The abnormal distribution of precipitation resulted in lower woody stem yield and high leaf yield in the 4th year (Table 1).

Even though the maximum dry weight of biomass yield was in the narrowest spacing of 1 × 0.25 m, but the seed and planting costs of narrowest spacing were higher than widest spacing (8 times of widest spacing) in the leucaena plantation whereas the biomass yield was not significantly different between narrowest and widest spacing in the last-three years. For these reasons, the wider spacing would be more desirable, because it reduced a number of seeds and allows easier mechanized weed cultivation in terms of weed control [20]. However, the narrowest spacing is likely to decrease weed invasion by increasing the competitiveness of crop with weeds. Moreover, narrowest spacing resulted in higher leaf yield, but lower individual tree yields. The maximum leaf yield achieved at the narrowest spacing of 1 × 0.25 m throughout the experiment of period. In the present study, the leucaena is grown primarily for woody stem in biomass power plant, but the leucaena farmers can benefit from leaf yield, which could be a good additional income for them.

The results of ultimate analysis showed that the overall levels (as percent dry weight) of the five main elements were suitable for being used as fuel wood when compared to other biomass sources [21], The content of C, H and O are the main components of biomass fuel [22]. Leucaena wood tended to contain higher of oxygen content compared with carbon and hydrogen which reduced the energy value [12]. Jenkins et al. [23] reported that carbon content can also be correlated with heating values, with each 1% increase in carbon elevating the heating value by approximately 0.39 MJ/kg. The NOx is one of the main environmental impacts of solid biofuels combustion, which NOx emission increased with increasing N content above 0.6% [24]. Leucaena wood has higher nitrogen content than other plant varieties in many reports [11,12,21,24] because it can fix nitrogen from atmosphere. However, the N content of woody stem of leucaena planted at different spacings did not exceed the guiding value (0.6%) [24]. Generally the main elemental constituents of wood biomass are K, Ca and Mg, with smaller amounts of S and P. High amounts of S can cause problems regarding the emissions of SOx [24]. The S content of wood biomass forms mainly gaseous SO2. However, the S content of woody stem of leucaena planted at different spacings did not exceed the critical value (0.2%) according to Obernberger et al. [24]. Furthermore, the emission of SO2 is usually not significant for wood combustion due to their low concentrations of S content [12]. Moreover, high amounts of S can cause problems regarding deposit formation and corrosion. Together with Cl and K play a role in corrosion mechanisms [24]. An increased K content more than 7% leads to a decreased ash melting point, which can cause slag and hard deposit formation in the furnace and boiler [22]. The K content of the woody stem of leucaena planted at all spacings did not exceed the critical value (above 7%), but tended to increase at the wide spacing. Obernberger et al. [24] reported that PCDD/F (dioxins) emission related problems were to be expected for materials with Cl content above 0.3%. The Cl content of woody stem of leucaena planted at all spacings cannot cause the PCDD/ F (dioxins) emissions because Cl content did not exceed the guiding value of 0.3% according to Obernberger et al. [24]. However, not only Cl content is necessary for PCDD/F formation, but also carbon, oxygen and catalysts (Cu) [24]. In case of ash melting point, Obernberger et al. [24] stated that Ca and Mg usually increase the ash melting point, while K decreases it. The content of Ca increases the ash melting point ranging from 15% to 35% [22], while woody stem of leucaena planted at all spacings contained 0.30% - 0.35% Ca and 0.04% - 0.05% Mg. The P, K, Ca and Mg are identified as the most abundant ash-forming elements in biomass, all of which are essential plant nutrients and can be used in agriculture as fertilizers. None of the spacings produced the ash content in the woody stem more than 5%. McKendry [25] stated that the ash content above 5% resulted in the oxidation temperature to be above the melting point of the biomass ash, leading to the clinkering problems in the hearth and subsequent feed blockages. Thus, the ash content from biomass produced at all spacings should not have any adverse clinkering affect on gasification system. The heating values produced in the present study similar to those reported by other researchers [6,26]. All of the spacings produced higher the heating values than the guiding value (3.35 kcal∙g−1) [27].

5. Conclusion

The spacing for maximum yield in the first four-year for leucaena plantation should not exceed 1 × 0.5 m. It is clear from the present study that leucaena can be harvested when planted at a narrow spacing (1 × 0.25 and 1 × 0.5 m) in the relatively short period of four years. Moreover, they produced not only high stem yield, but also high leaf yield compared to the wider spacings. The chemical composition and heating value, resulted of the present study were similar to other researches so that biomass harvested from all spacings can be used as fuel crop. Therefore, these results when applied to biomass and energy production will enable leucaena to be evaluated as a renewable energy.

6. Acknowledgements

This research was partially supported by PTT Research and Technology Institute, PTT Public Company Limited and National Research Council of Thailand.

REFERENCES

- A. F. Kirkels and G. P. J. Verbong, “Biomass Gasification: Still Promising? A 30-Year Global Overview,” Renewable and Sustainable Energy Reviews, Vol. 15, No. 1, 2011, pp. 471-481. doi:10.1016/j.rser.2010.09.046

- M. Barz and M. K. Delivand, “Agricultural Residues as Promising Biofuels for Biomass Power Generation in Thailand,” Journal of Sustainable Energy & Environment, Special Issue, 2011, pp. 21-27.

- B. Sajjakulnukit and P. Verapong, “Sustainable Biomass Production for Energy in Thailand,” Biomass and Bioenergy, Vol. 25, No. 5, 2003, pp. 557-570. doi:10.1016/S0961-9534(03)00091-6

- H. Abe, A. Katayama, B. P. Sah, T. Toriu, S. Samy, P. Pheach, M. A. Adams and P. F. Grierson, “Potential for Rural Electrification Based on Biomass Gasification in Cambodia,” Biomass and Bioenergy, Vol. 31, No. 9, 2007, pp. 656-664. doi:10.1016/j.biombioe.2007.06.023

- S. K. Tewari, R. S. Katiyar, B. Ram and P. N. Misra, “Effect of Age and Season of Harvesting on the Growth, Coppicing Characteristics and Biomass Productivity of Leucaena leucocephala and Vitex negundo,” Biomass and Bioenergy, Vol. 26, No. 3, 2004, pp. 229-234. doi:10.1016/S0961-9534(03)00118-1

- K. Rengsirikul, A. Kanjanakuha, Y. Ishii, K. Kangvansaichl, P. Sripichitt, V. Punsuvon, P. Vaithanomsat, G. Nakamanee and S. Tudsri, “Potential Forage and Biomass Production of Newly Introduced Varieties of Leucaena Leucaena leucocephala (Lam.) de Wit.) in Thailand,” Grassland Science, Vol. 57, No. 2, 2011, pp. 94-100. doi:10.1111/j.1744-697X.2011.00213.x

- H. M. Shelton, C. M. Piggin and J. L. Brewbaker, “Leucaena-Opportunities and Limitations,” Proceedings of ACIAR, No. 57, 1995, pp. 16-23.

- R. J. Van den Beldt, “Effect of Spacing on Growth of Leucaena,” Proceedings of Leucaena Research in the AsianPacific Region, International Development Research Centre, Ottawa, 1983, pp. 103-108.

- A. B. Guevarra, A. S. Whitney and J. R. Thompson, “Influence of Intra-Row Spacing and Cutting Regimes on the Growth and Yield of Leucaena,” Agronomy Journal, Vol. 70, No. 6, 1978, pp. 1033-1037. doi:10.2134/agronj1978.00021962007000060034x

- J. V. N. S. Prasad, G. R. Korwar, K. V. Rao, U. K. Mandal, G. R. Rao, I. Srinivas, B. Venkateswarlu, S. N. Rao and H. D. Kulkarni, “Optimum Stand Density of Leucaena leucocephala for Wood Production in Andhra Pradesh, Southern India,” Biomass and Bioenergy, Vol. 35, No. 1, 2011, pp. 227-235. doi:10.1016/j.biombioe.2010.08.012

- K. W. Ragland, D. J. Aerts and A. J. Baker, “Properties of Wood for Combustion Analysis,” Bioresource Technology, Vol. 37, No. 2, 1991, pp. 161-168.

- C. Telmo, J. Lousada and N. Moreira, “Proximate Analysis, Backwards Stepwise Regression between Gross Calorific Value, Ultimate and Chemical Analysis of Wood,” Bioresource Technology, Vol. 101, No. 11, 2010, pp. 3808- 3815. doi:10.1016/j.biortech.2010.01.021

- Association of Official Analytical Chemists Inc., “Official Methods of Analysis of the Association of Official Analytical Chemists,” Association of Official Analytical Chemists Inc., Virginia, 1990.

- S. C. Verma and P. N. Misra, “Biomass and Energy Production in Coppice Stands of Vitex negundo L. in High Density Plantations on Marginal Lands,” Biomass, Vol. 19, No. 3, 1989, pp. 189-194. doi:10.1016/0144-4565(89)90092-9

- V. Arjhan, N. Kongkrapee, K. Rubsombut, P. Channaroke and T. Hin-Sui, “Study of a Small Scale Biomass Power Plant for Rural Communities,” Proceeding of the Demonstration Small Scale Biomass Power Plant for Rural Communities, National Research Council of Thailand, Nakhon Ratchasima, 2007, pp. 103-163.

- A. Bernando, L. Maria Reis, G. F. Geraldo Reis, G. R. Harrison and B. J. Deuseles Firme, “Effect of Spacing on Growth and Biomass Distribution in Eucalyptus camaldulensis, E. pellita, E. europhylla Plantations in Southeastern Brazil,” Forest Ecology and Management, Vol. 104, No. 1-3, 1998, pp. 1-13.

- A. Armstrong, C. Johns and I. Tubby, “Effects of Spacing and Cutting Cycle on the Yield of Poplar Grown as an Energy Crop,” Biomass and Bioenergy, Vol. 17, No. 4, 1999, pp. 305-314. doi:10.1016/S0961-9534(99)00054-9

- M. Proe, J. Craig and J. Griffiths, “Effects of Spacing, Species and Coppicing on Leaf Area, Light Interception and Photosynthesis in Short Rotation Forestry,” Biomass and Bioenergy, Vol. 23, No. 5, 2002, pp. 315-326. doi:10.1016/S0961-9534(02)00060-0

- C. P. Mitchell, “New Cultural Treatments and Yield Optimization,” Biomass and Bioenergy, Vol. 9, No. 1-5, 1995, pp. 11-34.

- G. N. Gathaara, E. L. Glumac and P. Felker, “Three-Year Growth Studies of Leucaena leucocephala (1094) and L. pulverulenta (1001) at Two Spacings in Texas,” Forest Ecology and Management, Vol. 40, No. 3-4, 1991, pp. 189-198.

- S. V. Vassilev, D. Baxter, L. K. Andersen and C. G. Vassileva, “An Overview of the Chemical Composition of Biomass,” Fuel, Vol. 89, No. 5, 2010, pp. 913-933. doi:10.1016/j.fuel.2009.10.022

- I. Obernberger and G. Thek, “Physical Characterization and Chemical Composition of Densilfied Biomass Fuels with Regard to Their Combustion Behavior,” Biomass and Bioenergy, Vol. 27, No. 6, 2004, pp. 653-669. doi:10.1016/j.biombioe.2003.07.006

- B. M. Jenkins, L. L. Baxter, T. R. Miles Jr. and T. R. Miles, “Combustion Properties of Biomass,” Fuel Processing Technology, Vol. 54, No. 1-3, 1998, pp. 17-46.

- I. Obernberger, T. Brunner and G. Bärnthaler, “Chemical Properties of Solid Biofuels Significance and Impact,” Biomass and Bioenergy, Vol, 30, No. 11, 2006, pp. 973- 982. doi:10.1016/j.biombioe.2006.06.011

- P. McKendry, “Energy Production from Biomass (Part 3): Gasification Technologies,” Bioresource Technology, Vol. 83, No. 1, 2002, pp. 55-63. doi:10.1016/S0960-8524(01)00120-1

- A. K. Rajvanshi and M. S. Joshi, “Development and Operational Experience with Topless Wood Gasifier Running a 3.75 kW Diesel Engine Pumpset,” Biomass, Vol. 19, No. 1-2, 1989, pp. 47-56. doi:10.1016/0144-4565(89)90005-X

- I. Lewandowski and A. Kicherer, “Combustion Quality of Biomass: Practical Relevance and Experiments to Modify the Biomass Quality of Miscanthus x giganteus,” European Journal of Agronomy, Vol. 6, No. 3-4, 1997, pp. 163- 177.

NOTES

*Corresponding author.