Paper Menu >>

Journal Menu >>

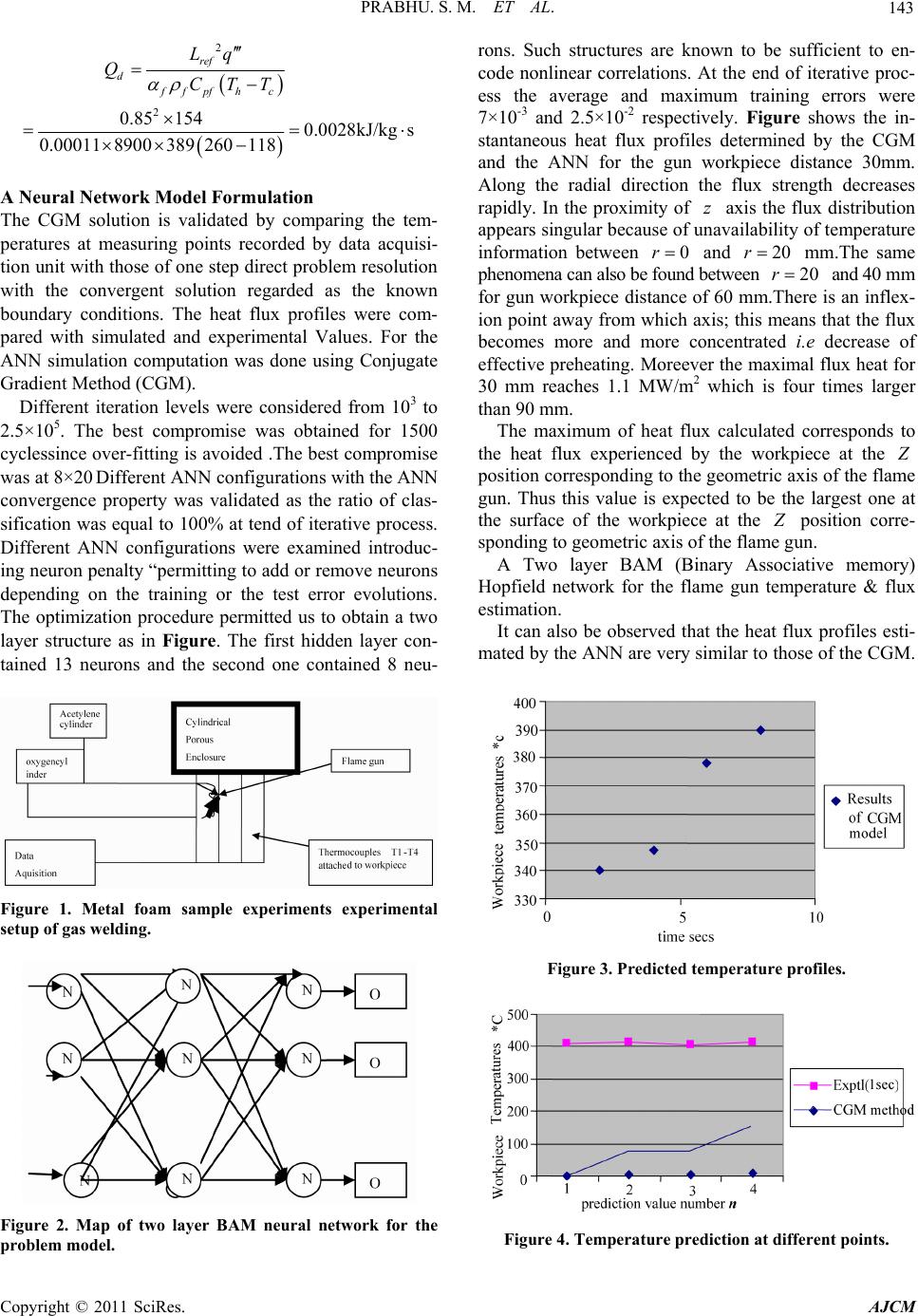

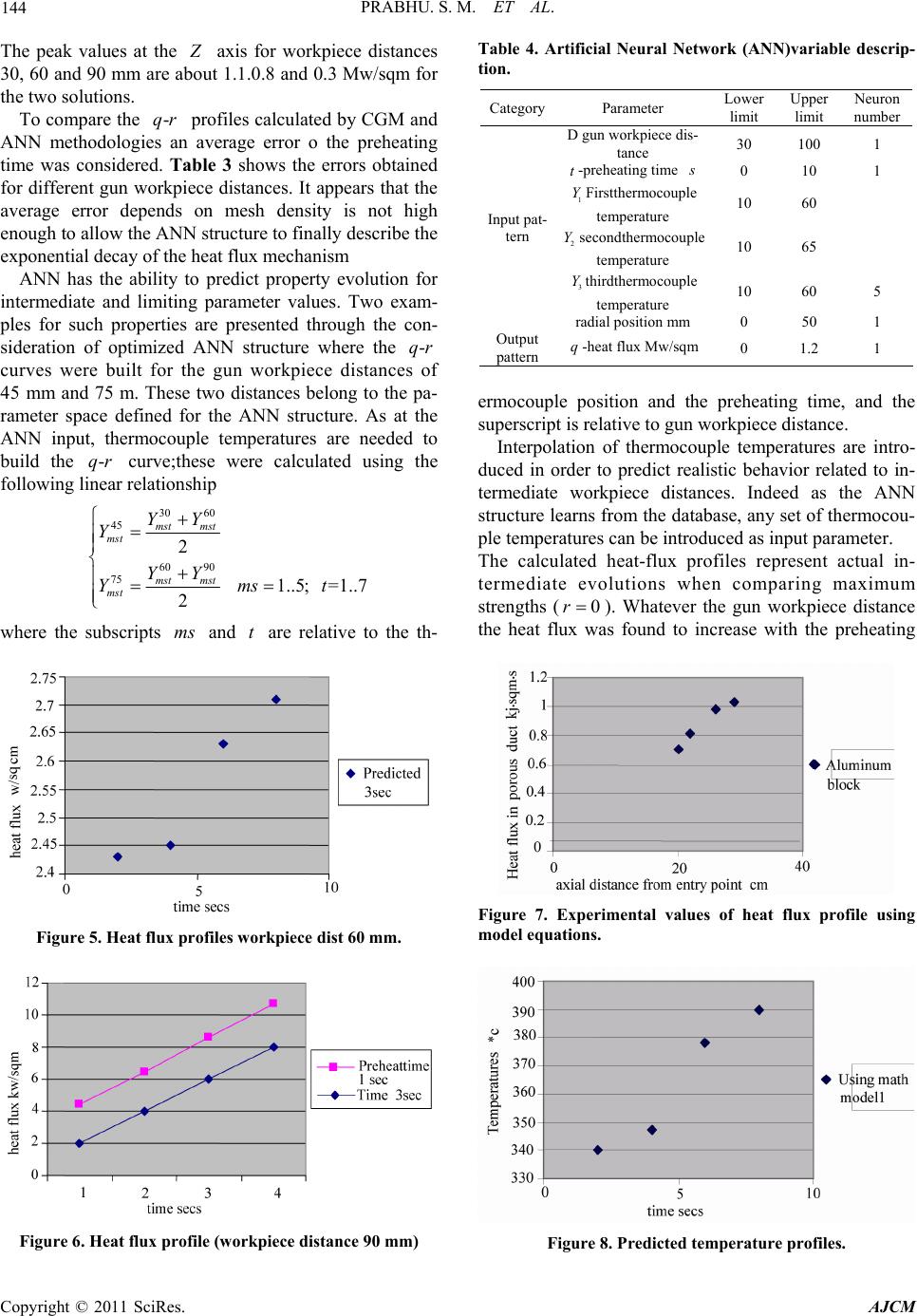

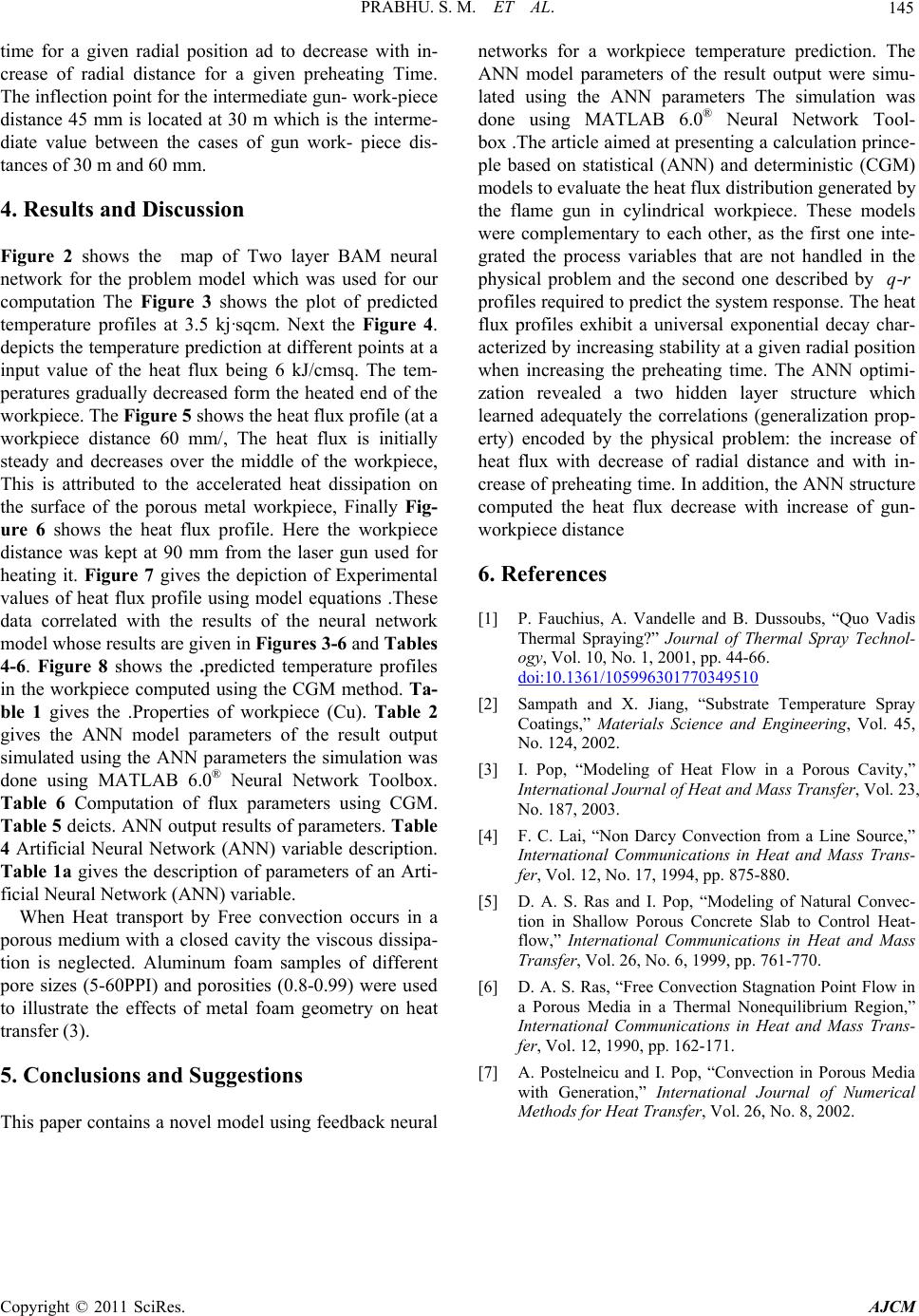

American Journal of Computational Mathematics, 2011, 1, 139-145 doi:10.4236/ajcm.2011.12015 Published Online June 2011 (http://www.scirp.org/journal/ajcm) Copyright © 2011 SciRes. AJCM Thermal and Mechanical Modeling of Fluid and Heat Flow in a Porous Metal Using Neural Networks for Application as TPS in Space Vehicles Prabhu. S. M.*, Abbas Soundarajan Mohadeen Jhon Bosco college of Engineering Tiruvallur 631203 Mamallan inst of technology Sriperumbudur E-mail: prabhusm2005@gmail.com, mamalan_princi@hotmail.com Received May 9, 2011; revised May 31, 2011; accepted June 5, 2011 Abstract This paper contains novel model using feedback neural networks for a work piece temperature prediction. The heat and mass transfer in a porous metal workpiece which is heated by a fire gun is studied. The heat flux distribution is determined by thermocouple connected on the workpiece at definite distances. The gun work piece distance were also change and the temperature distribution and heat flux were determined. The permeability’s were in range of 0.01 - 0.15. The ANN model parameters of the result output were simulated using the ANN parameters the simulation was done using MATLAB 6.0® Neural Network Toolbox. Keywords: Neyral Network, Porous Media, Prous Passages 1. Introduction The heat and mass transfer in a porous metal workpiece which is heated by a fire gun is studied. The heat flux distribution in a workpiece due to effect of thermal spray nozzle (uniform external heat source) causing high radia- tion conduction and convection transfer in the workpiece. The flame gun was kept at various distance and the effect of the source studied for the radiation and convection. This work mainly deals with the studies on heat flux and temperature prediction in a metal workpiece subjected to firing gun (fired using mixture of oxygen and acetylene gas) generally used for gas cutting and welding opera- tions Studies on Flow and transport at interface between a porous medium and clear fluid have been studied widely. Fauchius, Vandelle and others [1] studied the mecha- nisms and models for Thermal spraying. Sampath and Jiang [2] discussed the procedures for computing design parameters in Substrate temperature spray coatings. Pop [3] did studies on modeling of heat flow in a porous cav- ity. Lai [4] studied the effect of Non-Darcy Convection in the free surface of a porous media. In this paper a gener- alized treatment of convection force and the effect of free surface hydrodynamics on the heat transfer is dealt with. A novel model incorporating computation of local and average heat flux has been discussed. Ras [5,6] did studies on the free surface convection while others including Lai [4] studied the Forced convection on the surface of porous layer. Pop and Postelnicu [7] discu ssed on the effect of heat generation effect on the layers in porous media. Flow and transport at interface between a porous me- dium and clear fluid is of importance in heat transfer in porous enclosures and extended surfaces. The mecha- nisms that contribute to the enhanced heat transfer in- clude heat conduction in the metal foam matrix (whose conductivity is always higher by several orders of mag- nitude .The well known Darcy’s law is based on a bal- ance between the present gradient and the viscous forces and breaks down for high velocities when inertia terms are no longer negligible. Here we present numerical and experimental results for buoyancy induced flow in a high porosity metal foam The Associative Neural network (ASNN) is an extension of the ANN that goes beyond a simple/ weighted average of different models. Associative Neural network represents a combinatio n of an ensemble of feed-forward neural networks and the k-nearest nei- ghbor technique. It uses the correlation between ensem- ble responses as a measure of distance amid the analyzed cases for the ANN. This corrects the bias of the neural  PRABHU. S. M. ET AL. Copyright © 2011 SciRes. AJCM 140 network ensemble. An associative neural network has a memory that can coincide with the training set. If new data becomes available, the network instantly improves its predictive ability and provides data approximation (self-learn the data) without a need to retrain the en- semble. Another important feature of ASNN is the possibility to interpret neural network results by analysis of correlations between data cases in the space of models. BAM (binary associative memory) is the recurrent memory achieved by the exemplar on being trained by standard inputs prior to its deployment for modeling and simulation applications 2. Experimental Methods: The heat flux distribution is determined by thermocouple connected on the workpiece at definite distances. The gun work piece distance were also changed and the tem- perature distribution and heat flux were determined. Cu-Ni Thermocouples were attached on the surface of the workpiece. The flame was generated by acetylene and oxygen gasses as in gas welding process, the flame was kept at distances from 5 cm to 20 cm and the heat flux distrib ut i o n st udi ed. During a typical experimental run the powers were varied to achieve different base late temperature and hence Rayleigh numbers. Due to temperature constraints the parameters of the heat input were restricted to maxi- mum base plate temperature of 80*c a metal foam sam- ple heated from above . The foam sample is saturated with & surrounded by a fluid, which extends a distance 1 s in x direction and 2 s in y direction. The steady two dimensional equations for the fluid saturated porous medium & for the clear fluid region outside the metal foam are written separately as shown below. The Flow in a Square Pore cavity is modeled using the continuity and energy equations using a square computa- tional grid with velocity and temperatur e boundaries. The continuity and energy equations are given by 0 uv r (1) 2 222 1uu vvuT a rr r (2) where volumetric heat sources , , ryz represents the contribution of frictional heating. The parameters p C & e k may depend on y & z but remain independ- ent of r. More importantly the contribution of axial conduction deferred to the subsequent is neglected, hence Equation (4 ) red uces 22 22 22 p uvuv uva uv rr kc r (3) 0 1 TT uv rr TT Q rr (4) where the Heat generation number d Q is given by 2 0" () ref f fpf hc Lq QCTT (4a) The governing equations are scaled on basis of fluid Raleigh number as in the case of viscous fluid (inde- pendent of permeability) instead of modified Raleigh’s number. The scaling is introduced to study the effective change in values of individual matrix & fluid parameters (6). Finite element method is used for prediction of pa- rameters. A suitable grid scheme with iso-parametric, quadrilateral elements is used for stability of numerical solution, all the elements are containing 8 nodes, one at each corner and one at midpoint of each of the sides. All nodes are given velocity & temperature boundaries and corners of the grid pressure boundaries. This is an ac- cepted practice given by Taylor (2). For depicting the variation in pressure by the shape function i M of one order less than shape function i N defined for velocities and temperature. 2.1. Direct Problem: 2 pTTT Ckr rrrz (5) , t>0 0, kT qrtrR zH z (5a) 00 0. Tzr R n (5b) 0 0 at 0,TT trR (5c) 2.2. Sensitivity Problem 2 pTTT Ckr rrrz (6) , >0 0, = kT qrt trRzH z (7) 0, 0,0. Tzr R n (8)  PRABHU. S. M. ET AL. Copyright © 2011 SciRes. AJCM 141 2.3. Adjoint Problem 2 ,,; ms msms J qrTrztqYt (9) where (, , , ) ms ms Trztq is the temperature calculated at the measuring points (rms) through the direct problem Equations 5 & (5a)-(c), Yms(t) is measured temperature and the subscript ms denotes the thermocouple n umber. The adjoint problem is obtained by introducing the Lagrange multiplier , , rzt into the direct problem equations and by integrating over the spatial and then over the temporal domain as follows. For the region (0, )rR,(0, )zH 3 , , , at t>0 p w ms Tr Ck ttrz rr Trztq Ytzz (10) 0, 0, =0., z=0,zrR H n (11) 0 0., 0 f ttrRz H (12) where is the Dirac delta function. It is required for solving the adjoint equations with the end condition at time f tt, one should first proceed with variable change f tt , The adjoint problem becomes an ini- tial value problem in via the transformation. Step size and Gradient The iterative equation for determining , , qrzt can be given by 11 ,,(,) nn n qrtqrt Prt (13) where the superscript n denotes the iteration number and n is the search stepsize defined by 00 2 00 , , ; , , ; HHnmz msms n HRn mz ms Tr ztqYtdrdt rTrztq drdt (14) and the descendin g direct i o n n P is estimated by 1 , , , , nnnn p rztprzt (15) Where 1n, 10 . General definition of is given by 1 2 1 , n nnn n qqq q (16) where represents the norm and (.,.) the scalar prod- uct. Time stepsize and algorithm stop criterion The stopping criterion is satisfied when the Fourier Table 1. Properties of workpiece (Cu). Thermal conductivity k=396w/m·c p C389J/kg·c Density = 8900kg/m3 Table 1a. Artificial Neural Network (ANN) variable de- scription. CategoryParameter Lower limit Upper limit Neuron number D gun workpiece dis- tance 30 100 1 t-preheating time s 0 10 1 1 YFirstthermocouple temperature 10 60 3 2 Ysecondthermocouple temperature 10 65 2 3 Ythirdthermocouple temperature 10 60 5 Input pat- tern radial position mm 0 50 4 Output pattern q-heat flux Mw/sqm 0 1.2 1 number (o F ) satisfies the condition 0.05 optp kt FCH (17) where 0.028 o F , is the time step, and tp H is the location of thermocouples to the surface in front of the flame ,according to parameters listed in Table 1. Since the Fourier number satisfies Equation (17),the increase of measuring errors is weak and few obvious noisy signals can be captured. In this study, 0.5st has been considered for the time step according to the limit of data acquisition system. If the problem contains no noisy signals, the general stopping criterion condition is expressed by Jq (18) Where is specified stopping criterion. But the measurement precision of data acquisition is about 10-3. Hence it should not be reasonable to expect the functional Equation (9) to be equal to zero. A small value of 0.002 is chosen for above criterion Algorithm for CGM method The algorithm for Conjugate gradient method (CGM) is given belo w. 1) Select an initial guess , n qrt. generally equal to zero. 2) Calculate the direct problem, Equations (1)-(4), ob- tain the solution , , ; n ms ms Trztq . 3) Decide if the stopping criterion Equation (18) is satisfied. If yes go to step (6), otherwise continue. 4) Solve the adjoint problem. Equations (10)-(12) [note: 1 =(t )t in place of t], calculate the conjugate  PRABHU. S. M. ET AL. Copyright © 2011 SciRes. AJCM 142 Table 2. ANN output results of parameters. Time t secs r y p y t; E kl I D m 1 Y m 2 Y m 3 Y m Radial posn heat flux q MW/sqm 8 0.87 0.54 0.05 0.51 0.056 0.028 0.039 0.06 20 0.7 9 0.92 0.63 0.07 0.73 0.082 0.035 0.054 0.064 22 0.81 10 1.01 0.78 0.095 0.81 0.093 0.055 0.07 0.073 26 0.98 12 1.21 0.91 0.11 0.96 0.098 0.07 0.085 0.082 29 1.03 Table 3. Computation of flux parameters using CGM. Time t secs .n(cm) n Pr, z, t. n+1 qr, t f T T f =T T t o E . q o F d Q 2 1.83 0.628 340 280 60 0.15 1.5 2.43 0.185 0.003 4 1.84 0.651 347 284 63 0.173 1.48 2.45 0.21 0.0034 2 6 1.91 0.731 378 293 68 0.18 1.54 2.63 0.27 0.0041 2 1.41 0.78 390 297 72 0.21 1.64 2.71 0.32 0.0046 4 1.63 0.82 410 302 78 0.28 1.81 2.91 0.45 0.0047 4 6 1.73 0.87 412 308 81 0.32 1.92 3.12 0.51 0.0049 2 1.45 0.81 402 304 74 0.23 1.71 2.8 0.41 0.005 4 1.71 0.92 408 307 76.3 0.28 1.81 2.9 0.43 0.0051 6 6 1.81 1.02 415 308 77.4 0.41 1.93 3.2 0.48 0.0053 2 1.84 1.08 418 312 79 0.48 2.01 3.43 0.52 0.0054 4 1.86 1.13 421 315 81 0.51 2.11 3.51 0.58 0.0056 8 6 1.91 1.31 428 321 85 0.61 2.33 3.81 0.7 0.0058 coefficient n , Equation (19) and the direction of de- scendent n p Equa t i on (1 8). 5) Solve the sensitivity problem Equations (5)-(8), calculate the stepsize n from the nth to the (1n )st iteration, Equation (17) and calculate a new vector 1n q . Go to step 2. 6) The iteration is terminated. 3. A Neural Computational Procedure The heat flux calculated by solving the inverse problem was correlated to the workpiece temperature and other parameters with the aid of an artificial neural network (ANN). Such a structure considers three main categories. 1) The processing and the experiment design parame- ters with aid of an artificial neural network (ANN). Such a structure considers following types. 2) The processing and experiment design parameter as an input (1) pattern. These were the gun workpiece dis- tance, the preheating time, the thermocouple tempera- tures and radial position. 3) The heat flux as an output (O) unit calculated using CGM. 4) An intermediate structure called hidden layers, en- coding the corr elat i ons bet ween I/O patterns. Each of the ANN types is defined by a set of neurons playing role of simple processing elements as in Table 1a. A neuron has ability to receive a sum of numbers from other neurons and to emit a signal number toward other neurons accor ding to 11kijk ij I WO (19) where 1k I is input of neuron l from layer k, ij O is output of neuron j from layer; 1ijk W is called the weight relating neuron j and neuron 1 and this corresponds to neuron strength 1,,( , )2.351.450.628 nnn qrtqrt Prt from (16) 1 22 1 ,1.2 0.730.243 1.43 nnnn n qq q q 00.05 / 396 1.5 0.8850.05 8900389 0.0021 tp ptp kt FtH CH from (14) 1 , , , , 1.21.50.431.83 nnnn P rztPrzt from (4a) we h a ve  PRABHU. S. M. ET AL. Copyright © 2011 SciRes. AJCM 143 2 2 0.85 1540.0028kJ/kg s 0.000118900389 260118 ref dffpf hc Lq QCTT A Neural Networ k Mo del F ormulation The CGM solution is validated by comparing the tem- peratures at measuring points recorded by data acquisi- tion unit with those of one step direct problem resolution with the convergent solution regarded as the known boundary conditions. The heat flux profiles were com- pared with simulated and experimental Values. For the ANN simulation computation was done using Conjugate Gradient Method (CGM). Different iteration levels were considered from 103 to 2.5×105. The best compromise was obtained for 1500 cyclessince over-fitting is avoided .The best compromise was at 8×20 Different ANN configurations with the ANN convergence property was validated as the ratio of clas- sification was equal to 100% at tend of iterative process. Different ANN configurations were examined introduc- ing neuron penalty “permitting to add or remove neurons depending on the training or the test error evolutions. The optimization procedure permitted us to obtain a two layer structure as in Figure. The first hidden layer con- tained 13 neurons and the second one contained 8 neu- Figure 1. Metal foam sample experiments experimental setup of gas welding. Figure 2. Map of two layer BAM neural network for the problem model. rons. Such structures are known to be sufficient to en- code nonlinear correlations. At the end of iterative proc- ess the average and maximum training errors were 7×10-3 and 2.5×10-2 respectively. Figure shows the in- stantaneous heat flux profiles determined by the CGM and the ANN for the gun workpiece distance 30mm. Along the radial direction the flux strength decreases rapidly. In the proximity of z axis the flux distribution appears singular because of unavailab ility of temperature information between 0r and 20r mm.The same phenomena can also be found between 20r and 40 mm for gun workpiece distance of 60 mm.There is an inflex- ion point away from which axis; this means that th e flux becomes more and more concentrated i.e decrease of effective preheating. Moreever the maximal flux heat for 30 mm reaches 1.1 MW/m2 which is four times larger than 90 mm. The maximum of heat flux calculated corresponds to the heat flux experienced by the workpiece at the Z position corresp onding to the geometric axis of the flame gun. Thus this value is expected to be the largest one at the surface of the workpiece at the Z position corre- sponding to geometric axis of the flame gun. A Two layer BAM (Binary Associative memory) Hopfield network for the flame gun temperature & flux estimation. It can also be observed that the heat flux profiles esti- mated by the ANN are very similar to those of the CGM. Figure 3. Predicted temperature profiles. Figure 4. Temperature prediction at different points.  PRABHU. S. M. ET AL. Copyright © 2011 SciRes. AJCM 144 The peak values at the Z axis for workpiece distances 30, 60 and 90 mm are about 1.1.0.8 and 0.3 Mw/sqm for the two solution s . To compare the -qr profiles calculated by CGM and ANN methodologies an average error o the preheating time was considered. Table 3 shows the errors obtained for different gun workpiece distances. It appears that the average error depends on mesh density is not high enough to allow the ANN structure to finally describe the exponential decay of the heat flux m echanism ANN has the ability to predict property evolution for intermediate and limiting parameter values. Two exam- ples for such properties are presented through the con- sideration of optimized ANN structure where the -qr curves were built for the gun workpiece distances of 45 mm and 75 m. These two distances belong to the pa- rameter space defined for the ANN structure. As at the ANN input, thermocouple temperatures are needed to build the -qr curve;these were calculated using the following linear relationship 30 60 45 60 90 75 2 1..5; =1..7 2 mst mst mst mst mst mst YY Y YY Ymst where the subscripts ms and t are relative to the th- Figure 5. Heat flux profiles workpiece dist 60 mm. Figure 6. Heat flux profile (workpiece distance 90 mm) Table 4. Artificial Neural Network (ANN)variable descrip- tion. CategoryParameter Lower limit Upper limit Neuron number D gun workpiece dis- tance 30 100 1 t-preheating time s 0 10 1 1 YFirstthermocouple temperature 10 60 2 Ysecondthermocouple temperature 10 65 3 Ythirdthermocouple temperature 10 60 5 Input pat- tern radial position mm 0 50 1 Output pattern q-heat flux Mw/sqm 0 1.2 1 ermocouple position and the preheating time, and the superscript is relative to gun workpiece distance. Interpolation of thermocouple temperatures are intro- duced in order to predict realistic behavior related to in- termediate workpiece distances. Indeed as the ANN structure learns from the database, any set of thermocou- ple temperatures can be introduced as input parameter. The calculated heat-flux profiles represent actual in- termediate evolutions when comparing maximum strengths (0r ). Whatever the gun workpiece distance the heat flux was found to increase with the preheating Figure 7. Experimental values of heat flux profile using model equations. Figure 8. Predicted temperature profiles.  PRABHU. S. M. ET AL. Copyright © 2011 SciRes. AJCM 145 time for a given radial position ad to decrease with in- crease of radial distance for a given preheating Time. The inflection point for the intermediate gun- work-piece distance 45 mm is located at 30 m which is the interme- diate value between the cases of gun work- piece dis- tances of 30 m and 60 mm. 4. Results and Discussion Figure 2 shows the map of Two layer BAM neural network for the problem model which was used for our computation The Figure 3 shows the plot of predicted temperature profiles at 3.5 kj·sqcm. Next the Figure 4. depicts the temperature prediction at different points at a input value of the heat flux being 6 kJ/cmsq. The tem- peratures gradually decreased form the heated end of the workpiece. The Figure 5 shows the heat flux profile (at a workpiece distance 60 mm/, The heat flux is initially steady and decreases over the middle of the workpiece, This is attributed to the accelerated heat dissipation on the surface of the porous metal workpiece, Finally Fig- ure 6 shows the heat flux profile. Here the workpiece distance was kept at 90 mm from the laser gun used for heating it. Figure 7 gives the depiction of Experimental values of heat flux profile using model equations .These data correlated with the results of the neural network model whose results are given in Figures 3-6 and Tables 4-6. Figure 8 shows the .predicted temperature profiles in the workpiece computed using the CGM method. Ta- ble 1 gives the .Properties of workpiece (Cu). Table 2 gives the ANN model parameters of the result output simulated using the ANN parameters the simulation was done using MATLAB 6.0® Neural Network Toolbox. Table 6 Computation of flux parameters using CGM. Table 5 deicts. ANN output results of parameters. Table 4 Artificial Neural Network (ANN) variable description. Table 1a gives the description of parameters of an Arti- ficial Neural Network (ANN) variable. When Heat transport by Free convection occurs in a porous medium with a closed cavity the viscous dissipa- tion is neglected. Aluminum foam samples of different pore sizes (5-60PPI) and porosities (0.8-0.99) were used to illustrate the effects of metal foam geometry on heat transfer (3). 5. Conclusions and Suggestions This paper contains a novel model using feedback neural networks for a workpiece temperature prediction. The ANN model parameters of the result output were simu- lated using the ANN parameters The simulation was done using MATLAB 6.0® Neural Network Tool- box .The article aimed at presenting a calculation prince- ple based on statistical (ANN) and deterministic (CGM) models to evaluate the heat flux distribution generated by the flame gun in cylindrical workpiece. These models were complementary to each other, as the first one inte- grated the process variables that are not handled in the physical problem and the second one described by -qr profiles required to predict the system response. The heat flux profiles exhibit a universal exponential decay char- acterized by increasing stability at a given radial position when increasing the preheating time. The ANN optimi- zation revealed a two hidden layer structure which learned adequately the correlations (generalization prop- erty) encoded by the physical problem: the increase of heat flux with decrease of radial distance and with in- crease of preheating time. In addition , the ANN structure computed the heat flux decrease with increase of gun- workpiece distance 6. References [1] P. Fauchius, A. Vandelle and B. Dussoubs, “Quo Vadis Thermal Spraying?” Journal of Thermal Spray Technol- ogy, Vol. 10, No. 1, 2001, pp. 44-66. doi:10.1361/105996301770349510 [2] Sampath and X. Jiang, “Substrate Temperature Spray Coatings,” Materials Science and Engineering, Vol. 45, No. 124, 2002. [3] I. Pop, “Modeling of Heat Flow in a Porous Cavity,” International Journal of Heat and Mass Transfer, Vol. 23, No. 187, 2003. [4] F. C. Lai, “Non Darcy Convection from a Line Source,” International Communications in Heat and Mass Trans- fer, Vol. 12, No. 17, 1994, pp. 875-880. [5] D. A. S. Ras and I. Pop, “Modeling of Natural Convec- tion in Shallow Porous Concrete Slab to Control Heat- flow,” International Communications in Heat and Mass Transfer, Vol. 26, No. 6, 1999, pp. 761-770. [6] D. A. S. Ras, “Free Convection Stagnation Point Flow in a Porous Media in a Thermal Nonequilibrium Region,” International Communications in Heat and Mass Trans- fer, Vol. 12, 1990, pp. 162-171. [7] A. Postelneicu and I. Pop, “Convection in Porous Media with Generation,” International Journal of Numerical Methods for Heat Transfer, Vol. 26, No. 8, 2002. |