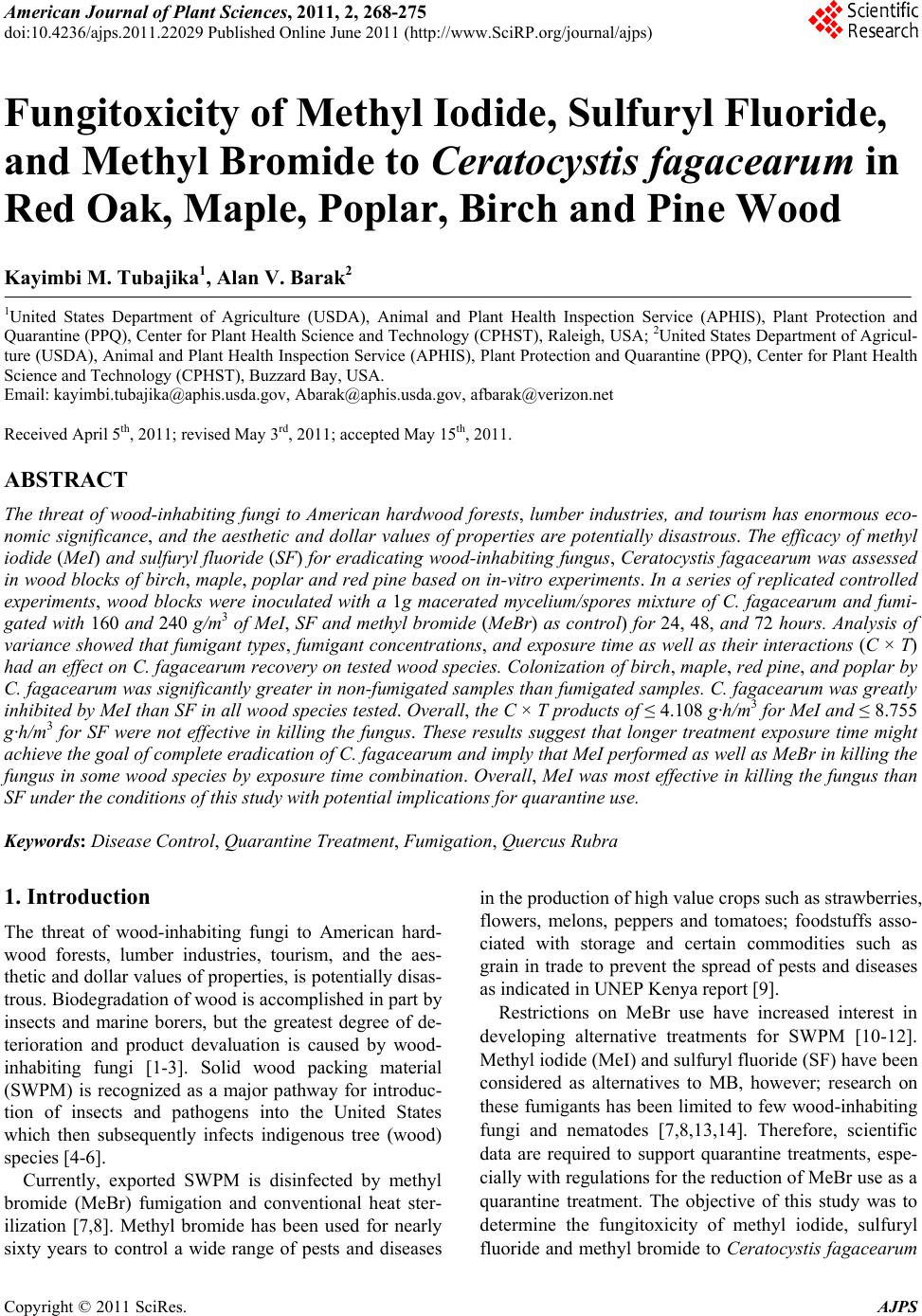

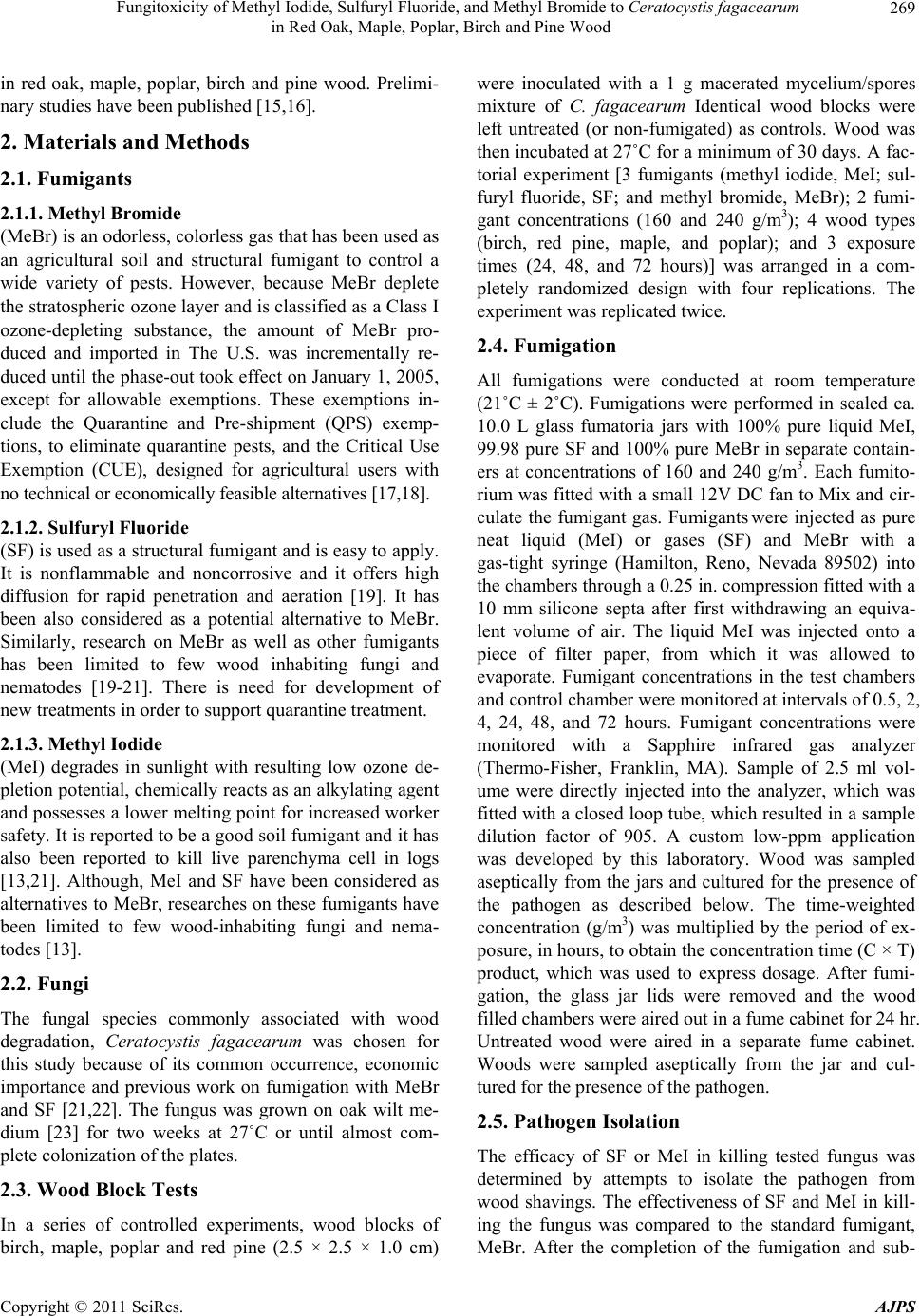

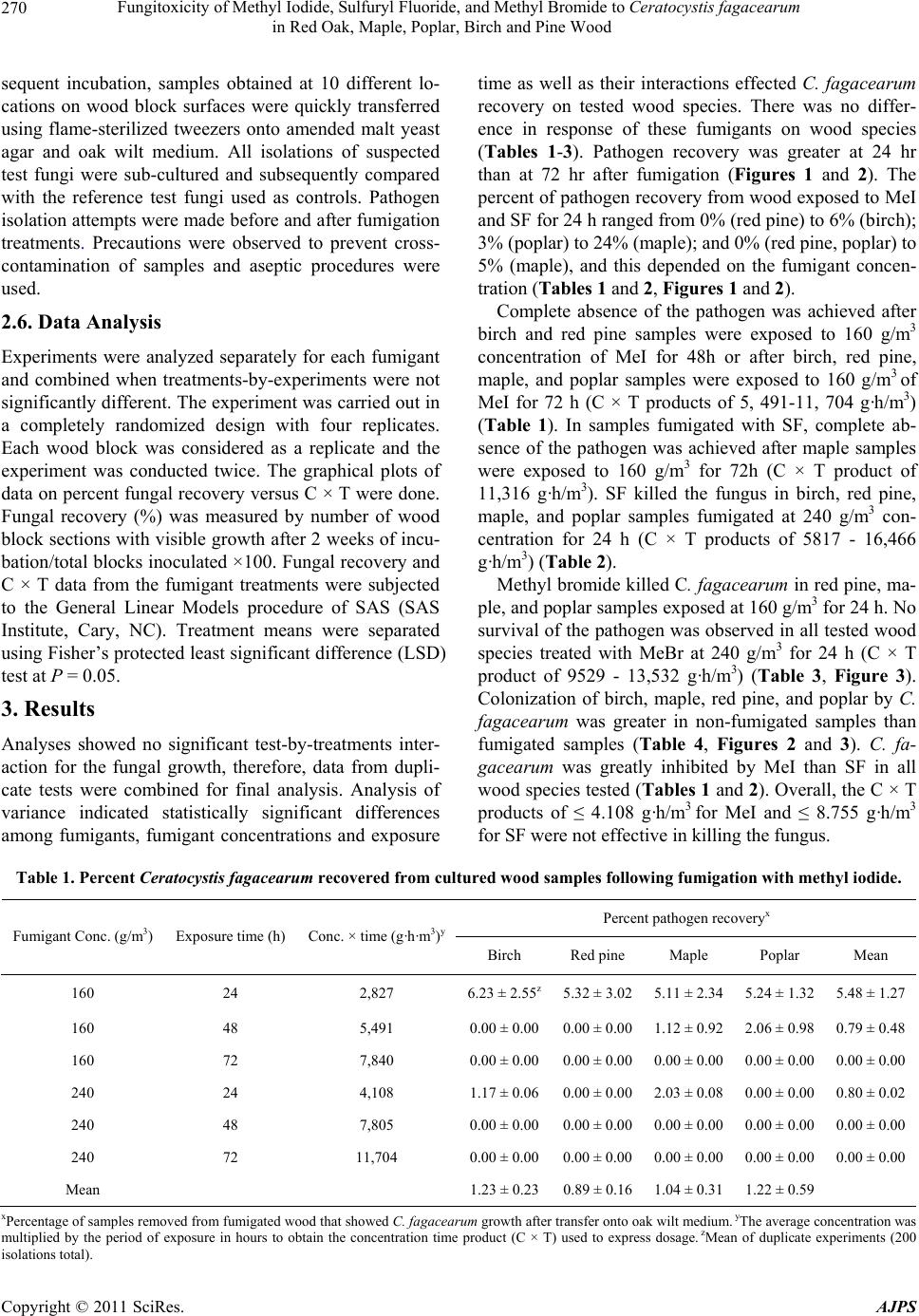

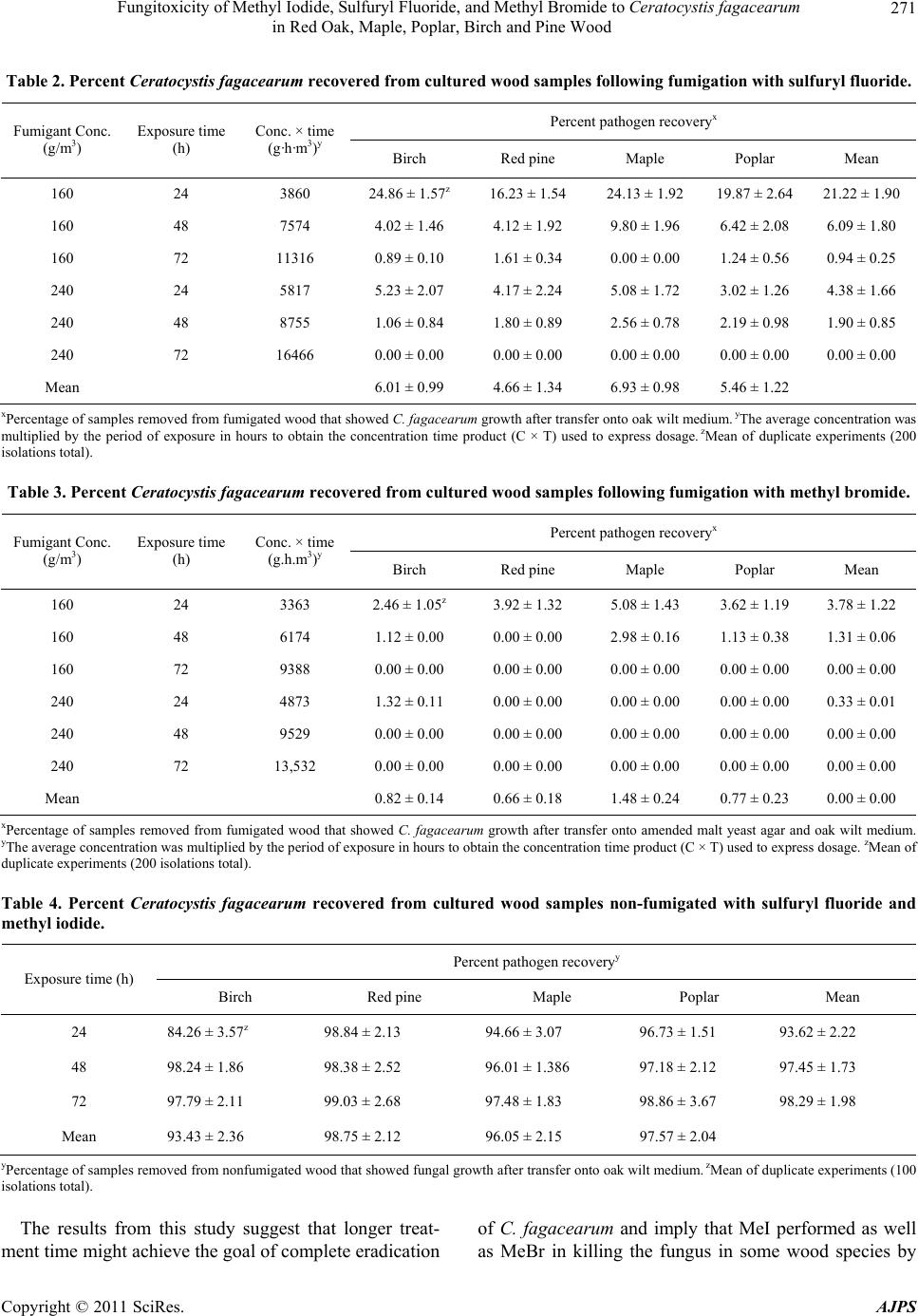

American Journal of Plant Sciences, 2011, 2, 268-275 doi:10.4236/ajps.2011.22029 Published Online June 2011 (http://www.SciRP.org/journal/ajps) Copyright © 2011 SciRes. AJPS Fungitoxicity of Methyl Iodide, Sulfuryl Fluoride, and Methyl Bromide to Ceratocystis fagacearum in Red Oak, Maple, Poplar, Birch and Pine Wood Kayimbi M. Tubajika1, Alan V. Barak2 1United States Department of Agriculture (USDA), Animal and Plant Health Inspection Service (APHIS), Plant Protection and Quarantine (PPQ), Center for Plant Health Science and Technology (CPHST), Raleigh, USA; 2United States Department of Agricul- ture (USDA), Animal and Plant Health Inspection Service (APHIS), Plant Protection and Quarantine (PPQ), Center for Plant Health Science and Technology (CPHST), Buzzard Bay, USA. Email: kayimbi.tubajika@aphis.usda.gov, Abarak@aphis.usda.gov, afbarak@verizon.net Received April 5th, 2011; revised May 3rd, 2011; accepted May 15th, 2011. ABSTRACT The threat of wood-inhabiting fungi to American hardwood forests, lumber industries, and tourism has enormous eco- nomic significance, and the aesthetic and dollar values of properties are potentially disastrous. The efficacy of methyl iodide (MeI) and sulfu ryl fluoride (SF) for eradicating wood-inhabiting fungus, Ceratocystis fag acearum was assessed in wood blocks of birch, maple, poplar and red pine based o n in-vitro experiments. In a series of replicated controlled experiments, wood blocks were inoculated with a 1g macerated mycelium/spores mixture of C. fagacearum and fumi- gated with 160 and 240 g/m3 of MeI, SF and methyl bromide (MeBr) as control) for 24, 48, and 72 hours. Analysis of variance showed that fumigant types, fumigant concentrations, and exposure time as well as their interactions (C × T) had an effect on C. fagacearum recovery on tested wood species. Colonization of birch , maple, red pine, and poplar by C. fagacearum was significantly g reater in non-fumigated samp les than fumigated samples. C. fagacearu m was greatly inhibited by MeI than SF in all wood species tested. Overall, the C × T products of ≤ 4.108 g·h/m3 for MeI and ≤ 8.755 g·h/m3 for SF were not effective in killing the fungus. These results suggest that longer treatment exposure time might achieve the goal of complete eradication of C. fagacearum and imp ly that MeI performed as well as MeBr in killing the fungus in some wood species by exposure time combination. Overall, MeI was most effective in killing the fungus than SF under the conditions of this study with potential implications for quarantine use. Keywords: Dis e ase Cont rol, Quarant ine Treatment, Fumigation, Quercus Rubra 1. Introduction The threat of wood-inhabiting fungi to American hard- wood forests, lumber industries, tourism, and the aes- thetic and dollar values of properties, is potentially disas- trous. Biodegradation of wood is accomplished in part by insects and marine borers, but the greatest degree of de- terioration and product devaluation is caused by wood- inhabiting fungi [1-3]. Solid wood packing material (SWPM) is recognized as a major pathway for introduc- tion of insects and pathogens into the United States which then subsequently infects indigenous tree (wood) species [4-6]. Currently, exported SWPM is disinfected by methyl bromide (MeBr) fumigation and conventional heat ster- ilization [7,8]. Methyl bromide has been used for nearly sixty years to control a wide range of pests and diseases in the production of high value crops such as strawberries, flowers, melons, peppers and tomatoes; foodstuffs asso- ciated with storage and certain commodities such as grain in trade to prevent the spread of pests and diseases as indicated in UNEP Kenya report [9]. Restrictions on MeBr use have increased interest in developing alternative treatments for SWPM [10-12]. Methyl iodide (MeI) and sulfuryl fluoride (SF) have been considered as alternatives to MB, however; research on these fumigants has been limited to few wood-inhabiting fungi and nematodes [7,8,13,14]. Therefore, scientific data are required to support quarantine treatments, espe- cially with regulations for the reduction of MeBr use as a quarantine treatment. The objective of this study was to determine the fungitoxicity of methyl iodide, sulfuryl fluoride and methyl bromide to Ceratocystis fagacearum  Fungitoxicity of Methyl Iodide, Sulfuryl Fluoride, and Methyl Bromide to Ceratocystis fagacearum 269 in Red Oak, Maple, Poplar, Birch and Pine Wood in red oak, maple, poplar, birch and pine wood. Prelimi- nary studies have been published [15,16]. 2. Materials and Methods 2.1. Fumigants 2.1.1. Methyl B r o mi d e (MeBr) is an odorless, colorless gas that has been used as an agricultural soil and structural fumigant to control a wide variety of pests. However, because MeBr deplete the stratospheric ozone layer and is classified as a Class I ozone-depleting substance, the amount of MeBr pro- duced and imported in The U.S. was incrementally re- duced until the phase-out took effect on January 1, 2005, except for allowable exemptions. These exemptions in- clude the Quarantine and Pre-shipment (QPS) exemp- tions, to eliminate quarantine pests, and the Critical Use Exemption (CUE), designed for agricultural users with no technical or economically feasible alternatives [17,18]. 2.1.2. Sulfuryl Fluoride (SF) is used as a structural fumigant and is easy to apply. It is nonflammable and noncorrosive and it offers high diffusion for rapid penetration and aeration [19]. It has been also considered as a potential alternative to MeBr. Similarly, research on MeBr as well as other fumigants has been limited to few wood inhabiting fungi and nematodes [19-21]. There is need for development of new treatments in order to support quarantine treatment. 2.1.3. Methyl Iodide (MeI) degrades in sunlight with resulting low ozone de- pletion potential, chemically reacts as an alkylating agent and possesses a lower melting point for increased worker safety. It is reported to be a good soil fumigant and it has also been reported to kill live parenchyma cell in logs [13,21]. Although, MeI and SF have been considered as alternatives to MeBr, researches on these fumigants have been limited to few wood-inhabiting fungi and nema- todes [13]. 2.2. Fungi The fungal species commonly associated with wood degradation, Ceratocystis fagacearum was chosen for this study because of its common occurrence, economic importance and previous work on fumigation with MeBr and SF [21,22]. The fungus was grown on oak wilt me- dium [23] for two weeks at 27˚C or until almost com- plete colonization of the plates. 2.3. Wood Block Tests In a series of controlled experiments, wood blocks of birch, maple, poplar and red pine (2.5 × 2.5 × 1.0 cm) were inoculated with a 1 g macerated mycelium/spores mixture of C. fagacearum Identical wood blocks were left untreated (or non-fumigated) as controls. Wood was then incubated at 27˚C for a minimum of 30 days. A fac- torial experiment [3 fumigants (methyl iodide, MeI; sul- furyl fluoride, SF; and methyl bromide, MeBr); 2 fumi- gant concentrations (160 and 240 g/m3); 4 wood types (birch, red pine, maple, and poplar); and 3 exposure times (24, 48, and 72 hours)] was arranged in a com- pletely randomized design with four replications. The experiment was replicated twice. 2.4. Fumigation All fumigations were conducted at room temperature (21˚C ± 2˚C). Fumigations were performed in sealed ca. 10.0 L glass fumatoria jars with 100% pure liquid MeI, 99.98 pure SF and 100% pure MeBr in separate contain- ers at concentrations of 160 and 240 g/m3. Each fumito- rium was fitted with a small 12V DC fan to Mix and cir- culate the fumigant gas. Fumigants were injected as pure neat liquid (MeI) or gases (SF) and MeBr with a gas-tight syringe (Hamilton, Reno, Nevada 89502) into the chambers through a 0.25 in. compression fitted with a 10 mm silicone septa after first withdrawing an equiva- lent volume of air. The liquid MeI was injected onto a piece of filter paper, from which it was allowed to evaporate. Fumigant concentrations in the test chambers and control chamber were monitored at intervals of 0.5, 2, 4, 24, 48, and 72 hours. Fumigant concentrations were monitored with a Sapphire infrared gas analyzer (Thermo-Fisher, Franklin, MA). Sample of 2.5 ml vol- ume were directly injected into the analyzer, which was fitted with a closed loop tube, which resulted in a sample dilution factor of 905. A custom low-ppm application was developed by this laboratory. Wood was sampled aseptically from the jars and cultured for the presence of the pathogen as described below. The time-weighted concentration (g/m3) was multiplied by the period of ex- posure, in hours, to obtain the concentration time (C × T) product, which was used to express dosage. After fumi- gation, the glass jar lids were removed and the wood filled chambers were aired out in a fume cabinet for 24 hr. Untreated wood were aired in a separate fume cabinet. Woods were sampled aseptically from the jar and cul- tured for the presence of the pathogen. 2.5. Pathogen Isolation The efficacy of SF or MeI in killing tested fungus was determined by attempts to isolate the pathogen from wood shavings. The effectiveness of SF and MeI in kill- ing the fungus was compared to the standard fumigant, MeBr. After the completion of the fumigation and sub- Copyright © 2011 SciRes. AJPS  Fungitoxicity of Methyl Iodide, Sulfuryl Fluoride, and Methyl Bromide to Ceratocystis fagacearum in Red Oak, Maple, Poplar, Birch and Pine Wood Copyright © 2011 SciRes. AJPS 270 sequent incubation, samples obtained at 10 different lo- cations on wood block surfaces were quickly transferred using flame-sterilized tweezers onto amended malt yeast agar and oak wilt medium. All isolations of suspected test fungi were sub-cultured and subsequently compared with the reference test fungi used as controls. Pathogen isolation attempts were made before and after fumigation treatments. Precautions were observed to prevent cross- contamination of samples and aseptic procedures were used. 2.6. Data Analysis Experiments were analyzed separately for each fumigant and combined when treatments-by-experiments were not significantly different. The experiment was carried out in a completely randomized design with four replicates. Each wood block was considered as a replicate and the experiment was conducted twice. The graphical plots of data on percent fungal recovery versus C × T were done. Fungal recovery (%) was measured by number of wood block sections with visible growth after 2 weeks of incu- bation/total blocks inoculated ×100. Fungal recovery and C × T data from the fumigant treatments were subjected to the General Linear Models procedure of SAS (SAS Institute, Cary, NC). Treatment means were separated using Fisher’s protected least significant difference (LSD) test at P = 0.05. 3. Results Analyses showed no significant test-by-treatments inter- action for the fungal growth, therefore, data from dupli- cate tests were combined for final analysis. Analysis of variance indicated statistically significant differences among fumigants, fumigant concentrations and exposure time as well as their interactions effected C. fagacearum recovery on tested wood species. There was no differ- ence in response of these fumigants on wood species (Tables 1-3). Pathogen recovery was greater at 24 hr than at 72 hr after fumigation (Figures 1 and 2). The percent of pathogen recovery from wood exposed to MeI and SF for 24 h ranged from 0% (red pine) to 6% (birch); 3% (poplar) to 24% (maple); and 0% (red pine, poplar) to 5% (maple), and this depended on the fumigant concen- tration (Tables 1 and 2, Figures 1 and 2). Complete absence of the pathogen was achieved after birch and red pine samples were exposed to 160 g/m3 concentration of MeI for 48h or after birch, red pine, maple, and poplar samples were exposed to 160 g/m3 of MeI for 72 h (C × T products of 5, 491-11, 704 g·h/m3) (Table 1). In samples fumigated with SF, complete ab- sence of the pathogen was achieved after maple samples were exposed to 160 g/m3 for 72h (C × T product of 11,316 g·h/m3). SF killed the fungus in birch, red pine, maple, and poplar samples fumigated at 240 g/m3 con- centration for 24 h (C × T products of 5817 - 16,466 g·h/m3) (Table 2). Methyl bromide killed C. fagacearum in red pine, ma- ple, and poplar samples exposed at 160 g/m3 for 24 h. No survival of the pathogen was observed in all tested wood species treated with MeBr at 240 g/m3 for 24 h (C × T product of 9529 - 13,532 g·h/m3) (Table 3, Figure 3). Colonization of birch, maple, red pine, and poplar by C. fagacearum was greater in non-fumigated samples than fumigated samples (Table 4, Figures 2 and 3). C. fa- gacearum was greatly inhibited by MeI than SF in all wood species tested (Table s 1 and 2). Overall, the C × T products of ≤ 4.108 g·h/m3 for MeI and ≤ 8.755 g·h/m3 for SF were not effective in killing the fungus. Table 1. Percent Ceratocystis fagacearum recovered from cultured wood samples following fumigation with methyl iodide. Percent pathogen recoveryx Fumigant Conc. (g/m3) Exposure time (h) Conc. × time (g·h·m3)y Birch Red pine Maple Poplar Mean 160 24 2,827 6.23 ± 2.55z5.32 ± 3.025.11 ± 2.34 5.24 ± 1.32 5.48 ± 1.27 160 48 5,491 0.00 ± 0.000.00 ± 0.001.12 ± 0.92 2.06 ± 0.98 0.79 ± 0.48 160 72 7,840 0.00 ± 0.000.00 ± 0.000.00 ± 0.00 0.00 ± 0.00 0.00 ± 0.00 240 24 4,108 1.17 ± 0.060.00 ± 0.002.03 ± 0.08 0.00 ± 0.00 0.80 ± 0.02 240 48 7,805 0.00 ± 0.000.00 ± 0.000.00 ± 0.00 0.00 ± 0.00 0.00 ± 0.00 240 72 11,704 0.00 ± 0.000.00 ± 0.000.00 ± 0.00 0.00 ± 0.00 0.00 ± 0.00 Mean 1.23 ± 0.230.89 ± 0.161.04 ± 0.31 1.22 ± 0.59 xPercentage of samples removed from fumigated wood that showed C. fagacearum growth after transfer onto oak wilt medium. yThe average concentration was multiplied by the period of exposure in hours to obtain the concentration time product (C × T) used to express dosage. zMean of duplicate experiments (200 isolations total).  Fungitoxicity of Methyl Iodide, Sulfuryl Fluoride, and Methyl Bromide to Ceratocystis fagacearum 271 in Red Oak, Maple, Poplar, Birch and Pine Wood Table 2. Percent Ceratocystis fagacearum recovered from cultured wood samples following fumigation with sulfuryl fluoride. Percent pathogen recoveryx Fumigant Conc. (g/m3) Exposure time (h) Conc. × time (g·h·m3)y Birch Red pine Maple Poplar Mean 160 24 3860 24.86 ± 1.57z 16.23 ± 1.54 24.13 ± 1.92 19.87 ± 2.64 21.22 ± 1.90 160 48 7574 4.02 ± 1.46 4.12 ± 1.92 9.80 ± 1.96 6.42 ± 2.08 6.09 ± 1.80 160 72 11316 0.89 ± 0.10 1.61 ± 0.34 0.00 ± 0.00 1.24 ± 0.56 0.94 ± 0.25 240 24 5817 5.23 ± 2.07 4.17 ± 2.24 5.08 ± 1.72 3.02 ± 1.26 4.38 ± 1.66 240 48 8755 1.06 ± 0.84 1.80 ± 0.89 2.56 ± 0.78 2.19 ± 0.98 1.90 ± 0.85 240 72 16466 0.00 ± 0.00 0.00 ± 0.00 0.00 ± 0.00 0.00 ± 0.00 0.00 ± 0.00 Mean 6.01 ± 0.99 4.66 ± 1.34 6.93 ± 0.98 5.46 ± 1.22 xPercentage of samples removed from fumigated wood that showed C. fagacearum growth after transfer onto oak wilt medium. yThe average concentration was multiplied by the period of exposure in hours to obtain the concentration time product (C × T) used to express dosage. zMean of duplicate experiments (200 isolations total). Table 3. Percent Ceratocystis fagacearum recovered from cultured wood samples following fumigation with methyl bromide. Percent pathogen recoveryx Fumigant Conc. (g/m3) Exposure time (h) Conc. × time (g.h.m3)y Birch Red pine Maple Poplar Mean 160 24 3363 2.46 ± 1.05z 3.92 ± 1.32 5.08 ± 1.43 3.62 ± 1.19 3.78 ± 1.22 160 48 6174 1.12 ± 0.00 0.00 ± 0.00 2.98 ± 0.16 1.13 ± 0.38 1.31 ± 0.06 160 72 9388 0.00 ± 0.00 0.00 ± 0.00 0.00 ± 0.00 0.00 ± 0.00 0.00 ± 0.00 240 24 4873 1.32 ± 0.11 0.00 ± 0.00 0.00 ± 0.00 0.00 ± 0.00 0.33 ± 0.01 240 48 9529 0.00 ± 0.00 0.00 ± 0.00 0.00 ± 0.00 0.00 ± 0.00 0.00 ± 0.00 240 72 13,532 0.00 ± 0.00 0.00 ± 0.00 0.00 ± 0.00 0.00 ± 0.00 0.00 ± 0.00 Mean 0.82 ± 0.14 0.66 ± 0.18 1.48 ± 0.24 0.77 ± 0.23 0.00 ± 0.00 xPercentage of samples removed from fumigated wood that showed C. fagacearum growth after transfer onto amended malt yeast agar and oak wilt medium. yThe average concentration was multiplied by the period of exposure in hours to obtain the concentration time product (C × T) used to express dosage. zMean of duplicate experiments (200 isolations total). Table 4. Percent Ceratocystis fagacearum recovered from cultured wood samples non-fumigated with sulfuryl fluoride and methyl iodide. Percent pathogen recoveryy Exposure time (h) Birch Red pine Maple Poplar Mean 24 84.26 ± 3.57z 98.84 ± 2.13 94.66 ± 3.07 96.73 ± 1.51 93.62 ± 2.22 48 98.24 ± 1.86 98.38 ± 2.52 96.01 ± 1.386 97.18 ± 2.12 97.45 ± 1.73 72 97.79 ± 2.11 99.03 ± 2.68 97.48 ± 1.83 98.86 ± 3.67 98.29 ± 1.98 Mean 93.43 ± 2.36 98.75 ± 2.12 96.05 ± 2.15 97.57 ± 2.04 yPercentage of samples removed from nonfumigated wood that showed fungal growth after transfer onto oak wilt medium. zMean of duplicate experiments (100 isolations total). The results from this study suggest that longer treat- ment time might achieve the goal of complete eradication of C. fagacearum and imply that MeI performed as well as MeBr in killing the fungus in some wood species by Copyright © 2011 SciRes. AJPS  Fungitoxicity of Methyl Iodide, Sulfuryl Fluoride, and Methyl Bromide to Ceratocystis fagacearum 272 in Red Oak, Maple, Poplar, Birch and Pine Wood Exposure time (h) 24 48 72 Perce nt path og en recovery 0 10 20 30 40 160 g/ m 3 240 g/ m 3 A (a) Exposure time (h) 24 48 72 Percent pathogen recovery 0 10 20 30 40 160 g/ m 3 240 g/ m 3 B (b) Exposur e time ( h) 24 48 72 Percent pathogen recovery 0 10 20 30 40 160 g/m 3 240 g/m 3 C (c) Figure 1. Percent pathogen recovery from cultured birch, red pine, maple, and poplar samples fumigated with 160 g/m3 and 240 g/m3 of methyl iodide (a), sulfuryl fluoride (b), and methyl bromide (c). Data are averaged across wood species. exposure time combination. Overall, MeI was most ef- fective in killing the fungus than SF under the conditions of this study. 4. Discussion The isolation of fungus from wood samples previously inoculated and colonized by C. fugacearum and the ab- sence in uninoculated controls as well as wood samples fumigated at concentrations as high as 80 and 96 g/m3 indicates that these fumigants may be effective against quarantined pest of SWPM. This finding indicates that the efficacy of the MeI, MeBr and SF fumigation may depend on the level of wood colonization of the tested fungi and the technique used to detect the pathogen in wood. Methyl bromide and sulfuryl fluoride did not have an effect on C. fimbriata and C. polonica in red oak and poplar samples at C × T products as high as 2000 g·h/m3 under the conditions of this study (Data not shown). The C × T products used to effectively kill C. fagacearum in this study are, however, less than previously reported for C. fagacearum [22,24-27] but higher than those recom- mended by the USDA [28]. Jones [24] reported a-100% mortality of C. fagacearum with a C × T of 45,000 mgh/L MB. Patridge [26] and Schmidt [26]; Schmidt et al. [27] also reported a-100% mortality of C. fagacearum at a C × T of 45,000 mgh/L. Rhatigan et al. [29] reported survival of 8 and 12% of H. annosum and L. wageneri at C × T values high as 3010 and 4750 mgh/L of MeBr, respectively, in Larch heartwood. They estimated a com- plete eradication of H. annosum and L. wageneri at C × T values less than 4000 and 6000 mgh/L of MeBr, respec- tively. MacDonald et al. (1985) reported that fumigation with MB at 240 g/m3 for 72 h eradicated C. fagacearum from red oak logs. Overall, C. faga cearum was resistant to MeBr or SF in the conditions of this study. It is not known however, if fumigation of natural wood products naturally infected with the plant pathogens would result in fungal mortality or inhibition. In a study on fungitoxicity of sulfuryl fluo- ride to C. fagacearum in vitro and in wilted red oak log sections, Woodward and Schmidt reported 15 and 7% reduction in C. fagacearum isolation at concentrations as high as 160 or 220 g/m3 of SF for 72 h, in red oak log sections, respectively. No C. fagacearum growth was noted from log sections fumigated with 280 g/m3 for 72 h (C × T of 18,530). Woodward and Schmidt [19] labora- tory’s finding on eradication of C. fagacearum with SF were in contrast with field data obtained by Schmidt et al. [30] showing the presence of the fungus after MeBr fu- migation. They suggested longer treatment time to in rease the chance of obtaining complete eradication of c Copyright © 2011 SciRes. AJPS  Fungitoxicity of Methyl Iodide, Sulfuryl Fluoride, and Methyl Bromide to Ceratocystis fagacearum in Red Oak, Maple, Poplar, Birch and Pine Wood Copyright © 2011 SciRes. AJPS 273 Exposure time (h) 24 h48 h72 h Percent pathogen recovery 0 20 40 60 80 100 MeI SF MeBr Control Figure 2. Percent pathogen recovery from cultured birch, red pine, maple, and poplar nonfumigated and fumigated samples with methyl iodide, sulfuryl fluoride, and methyl bromide. Data are averaged across wood species. Fumigan t MeISFMeBr Control Percent pathogen recovery 0 20 40 60 80 100 Figure 3. Percent Ceratocystis fagacearum recovery from cultured birch, red pine, maple and poplar samples follow- ing fumigation with methyl iodide, sulfuryl fluori de, methyl bromide, and nonfumigated controls. Data are averaged across wood species, exposure time and fumigant concen- trations. the fungus in the logs. This suggests that the differences in SF treatment effects may have been accounted for by moisture or other treatment conditions of the two ex- periments. The ineffectiveness of MeBr or SF to kill C. fagacea- rum in red oak and poplar samples may possibly due to their deep penetration into wood, to exposure time used in this study, wood characteristics, sorption, or to other unknown factors. It is probable that SF at concentrations less than 240 g/m3 is not sufficient to deplete energy lev- els of fungal cells to delay hyphal elongation and/ or to disrupt cell metabolism as observed in SF-insect systems reported elsewhere [31,32]. Kawakami et al. [13] sug- gested that when bulk wood of lower moisture content (which is more sorbent of MeBr) is fumigated, such fu- migation will require higher doses than indicated here to achieve the requisite C × T product. This study documents on the effect of MeI, SF and MeBr fumigation on a number of wood-inhibiting fungi. We have demonstrated that a concentration of 240 g/m3 MeBr or SF (highest concentration used in this study) is not effective or adequate to control all wood fungi tested. This study together with previous studies by Rhatigan et al. [29,32-34] showed clearly that the MeBr fumigation is not effective in killing C. fagacearum as tested in this study. Additional studies are aimed at determining the penetration of MeI and SF fumigants throughout logs at different concentrations and temperatures in different wood species and fungi combinations. 5. Acknowledgements We are indebted to Jami L. Nydam (USDA CPHST Otis Pest survey, Detection and Exclusion laboratory, MA) for laboratory assistance, to Drs Tom Harrington of Iowa State University and Jodi Jellison of University of Maine for the culture used in this study, and two anonymous reviewers for helpful comments. REFERENCES [1] R. L. Schmidt, D. L. Cassens and B. A. Jordan, “Control  Fungitoxicity of Methyl Iodide, Sulfuryl Fluoride, and Methyl Bromide to Ceratocystis fagacearum 274 in Red Oak, Maple, Poplar, Birch and Pine Wood of Graystain in Yellow-Poplar Lumber by Log Fumiga- tion with Sulfuryl Fluoride,” Forest Products Journal, Vol. 51, No. 9, 2001, pp. 50-52. [2] J. W. Dubois and J. N. Ruddick, “The Fungal Degrada- tion of Quaternary Ammonium Compounds in Wood,” International Research Group on Wood Preservation, Doc. No. IRG/WP98-10263, IRG Secretariat, Stockholm, 1998. [3] J. J. Morrell, M. E. Corden, B. R. Kropp, P. Przybylowicz, S. M. Smith and C. M. Sexton, “Basidiomycete Coloniza- tion of Air Seasoned Douglas-Fir Poles,” In: Proceedings of American Wood Preserve Association, Vol. 83, 1987, pp. 284-296. [4] E. Allen, “Solid Wood Packing Material as a Pathway for Non-Indigenous Species,” Online Workshop on Exotic Pests, 2011. http://exoticpests.apsnet.org [5] R. W. Haack, J. F. Cavey, E. R. Hocbeke and K. Law, “Anoplophora glabripennis: A New Tree-Infesting Exotic Cerambycid Invades New York,” Newsletter of the Michigan Entomological Societ, Vol. 41, 1996, pp. 1-3. [6] J. E. Cavey, E. R. Hoebeke, S. Passon and S. W. Lin- gafelter, “A New Exotic Threat to North America Har- wood Forests: An Asian Longhorned Beetle, Anoplo- phora Glabripennis (Motschhulsky) (Coleoptera: Ceram- bycidae), I. Larval Description and Diagnosis,” Proceed- ings of the Entomological Society of Washington, Vol. 100, 1998, pp. 373-381. [7] I. D. Dwinell, “Heat Treatment and Drying Southern Yellow Pine Lumber Infested with Pinewood Nema- todes,” Forest Products Journal, Vol. 40, No. 11-12, 1990, pp. 53-56. [8] I. D. Dwinell, “Heat Treatment Southern Yellow Pine Lumber to Eradicate Bursaphalenchus xylophilus,” Nema- tologica, Vol. 36, 1990, pp. 346-347. [9] MBTOC, “Assessment Report of the Methyl Bromide Techinical Options Committee,” UNEP, Nairobi, 2007, p. 486. [10] IPPC, “International Plant Protection Convention, No 15 Guidelines for Regulating Wood Packing Material in In- ternational Trade (2002) With Modification to Annex (2006),” IPPC, Rome, 2006, p. 11. [11] IPPC, “IPPC, Recommendation, Replacement or Reduc- tion of the Use of Methyl Bromide as a Phtosantiary Measure,” Appendix 6, Report of the third session of the Commission on Phytosanitary Measures, IPPC, Rome, 2008, p. 10. [12] IPPC, “International Standards for Phtosantiray Measures, Revision of ISPM No. 15,” Regulation of Wood Packing Material in Intenational Trade, 2006. https://www.ippc.int/servlet/. [13] F. Kawakami, Y. Soma, H. Komatsu and Y. Matsumoto, “Effects of Some Fumigants on the Pine Wood Nematode, Bursaphelenchus xylophilus Infesting Wooden Packages. 4. Mortalility and CT Product in Methyl Bromide Fumi- gation with High Loading of Wood Packing Materials,” Res. Bull. Pl. Prot. Japan, Vol. 40, 2004, pp. 7-12. [14] A. V. Barack, Y. Wang, L. Xu, Z. Rong, X. Hang and G. Zhan, “Methyl Bromide as a Quarantine Treatment for Anoplophora glabripennis (Coleoptera: Cerambycidae) in Regulated Wood Packing Material,” Journal of Economic Entomology, Vol. 98, No. 6, 2005, pp. 1911-1916. doi:10.1603/0022-0493-98.6.1911 [15] K. M. Tubajika and A. V. Barak, “Methyl Iodide and Sulfuryl Fluoride as Quarantine Treatments for Solid Wood Packing Material,” MBAO Conference, Orlando, 5 November 2007, pp. 131-1-7. [16] K. M. Tubajika and A. V. Barak, “Efficacy of Sulfuryl Fluoride and Methyl Bromide against Wood-Inhabiting Fungi,” In: Proceedings Annual Research Conference on Methyl Bromide Alternatives and Emission, Orlando, 6-9 November 2006, pp. 147-1-8. [17] USEPA, “Protection of Stratospheric Ozone: Process for Exemption Quarantine and Pre-Shipment Applications of Methyl Bromide,” Rules and Regulations, Federal Regis- ter, United States Environmental Protection Agency, Vol. 66, No. 139, 2001, pp. 37752-37769. [18] EPA, 2006. http://www.epa.gov/ozone/mbr. [19] R. P. Woodward and R. L. Schmidt, “Fungitoxicity of Sulfuryl Fluoride to Ceratocystis fagacearum in Vitro and in Wilted Red Oak Log Sections,” Plant Disease, Vol. 79, No. 12, 1995, pp. 1237-1239. doi:10.1094/PD-79-1237 [20] E. E. Kanega, “Some Biological, Chemical, and Physical Properties of Sulfuryl Fluoride as Insecticidal Fumigant,” Journal of Economic Entomology, Vol. 50, No. 1, 1957, pp. 1-6. [21] R. L. Schmidt, T. L. Ambergey, M. L. Sanders and C. D. Bell, “Sulfuryl Fluoride and Methyl Bromide Fumigation of Hardwood Logs of Various Ages for Control of Lum- ber Graystain,” Forest Products Journal, Vol. 48, No. 11/12, 1998, pp. 77-80. [22] W. L. MacDonald, R. L. Schmidt and E. J. Harmer, “Methyl Bromide Eradication of the Oak Wilt Fungus from Red and White Oak Logs,” Forest Products Journal, Vol. 35, No. 7-8, 1985, pp. 11-16. [23] H. L. Barnett, “Isolation and Identification of the Oak Wilt Fungus,” West Virginia Experiment Station Bulletin, Vol. 359, 1953, pp. 1-15. [24] T. W. Jones, “Fumigation May End Oak Embargoes,” Forest Products Journal, Vol. 13, No. 12, 1963, p. 564. [25] A. D Partridge, “Fumigants Kill the Oak Wilt Fungus in Wood,” Forest Products Journal, Vol. 11, No. 1, 1961, pp. 12-14. [26] R. L. Schmidt, “Methyl Bromide Eradication of Oak Wilt Fungus from Lumber,” The International Journal of Wood Preservation, Vol. 2, No. 3, 1983, pp. 123-126. [27] E. L. Schmidt, M. Ruetze and D. W. French, “Methyl Bromide Treatment of Oak Wilt Infected Logs: Labora- tory and Preliminary Field Fumigations,” Forest Products Journal, Vol. 32, No. 3, 1982, pp. 46-49. [28] APHIS, “Treatment Manual. Schedule T-312, Oak Logs Copyright © 2011 SciRes. AJPS  Fungitoxicity of Methyl Iodide, Sulfuryl Fluoride, and Methyl Bromide to Ceratocystis fagacearum in Red Oak, Maple, Poplar, Birch and Pine Wood Copyright © 2011 SciRes. AJPS 275 and Lumber,” United States Department of Agriculture (USDA), Animal and Plant Health Inspection Service (APHIS), Frederic, 2011, pp. 5-4-26. http://www.aphis.usda.gov/import_export/plants/manuals/ online_manuals.shtml [29] R. G. Rhatigan, J. J. Morrell and G. M. Filip, “Toxicity of Methyl Bromide to Four Pathogenic Fungi in Larch Heartwood,” Forest Products Journal, Vol. 48, No. 3, 1998, pp. 63-67. [30] R. L. Schmidt, D. L. Cassens and J. J. Steen, “Log Fumi- gation Prevents Sticker Stain and Enzyme-Mediated Sapwood Discolorations in Maple and Hickory Lumber,” Forest Products Journal, Vol. 47, No. 9, 1997, pp. 47-50. [31] W. R. Mikle, D. Stewart and O. A. Globus, “Drywood Termite Metabolism of Vikane Fumigant as Shown by Labeled Pool Technique,” Journal of Agriculture and Food Chemistry, Vol. 11, 1963, pp. 226-230. doi:10.1021/jf60127a022 [32] R. H. Scheffrahn, N. Y. Su and R. C. Hsu, “Diffusion of Methyl Bromide and Sulfuryl Fluoride through Selected Structural Wood Matrices during Fumigation,” Material and Organismen, Vol. 27, 1992, pp. 147-155. [33] D. J. Cross, “Penetration of Methyl Bromide into Pinus Radiate Wood and Its Significance for Export Quaran- tine,” New Zealand Journal of Forestry Science, Vol. 21, No. 2-3, 1991, pp. 235-245. [34] V. Liese, K. Knigge and M. Ruetze, “Fumigation Ex- periments with Methyl Bromide on Oak Wood,” Material and Organismen, Vol. 16, 1981, pp. 265-280.

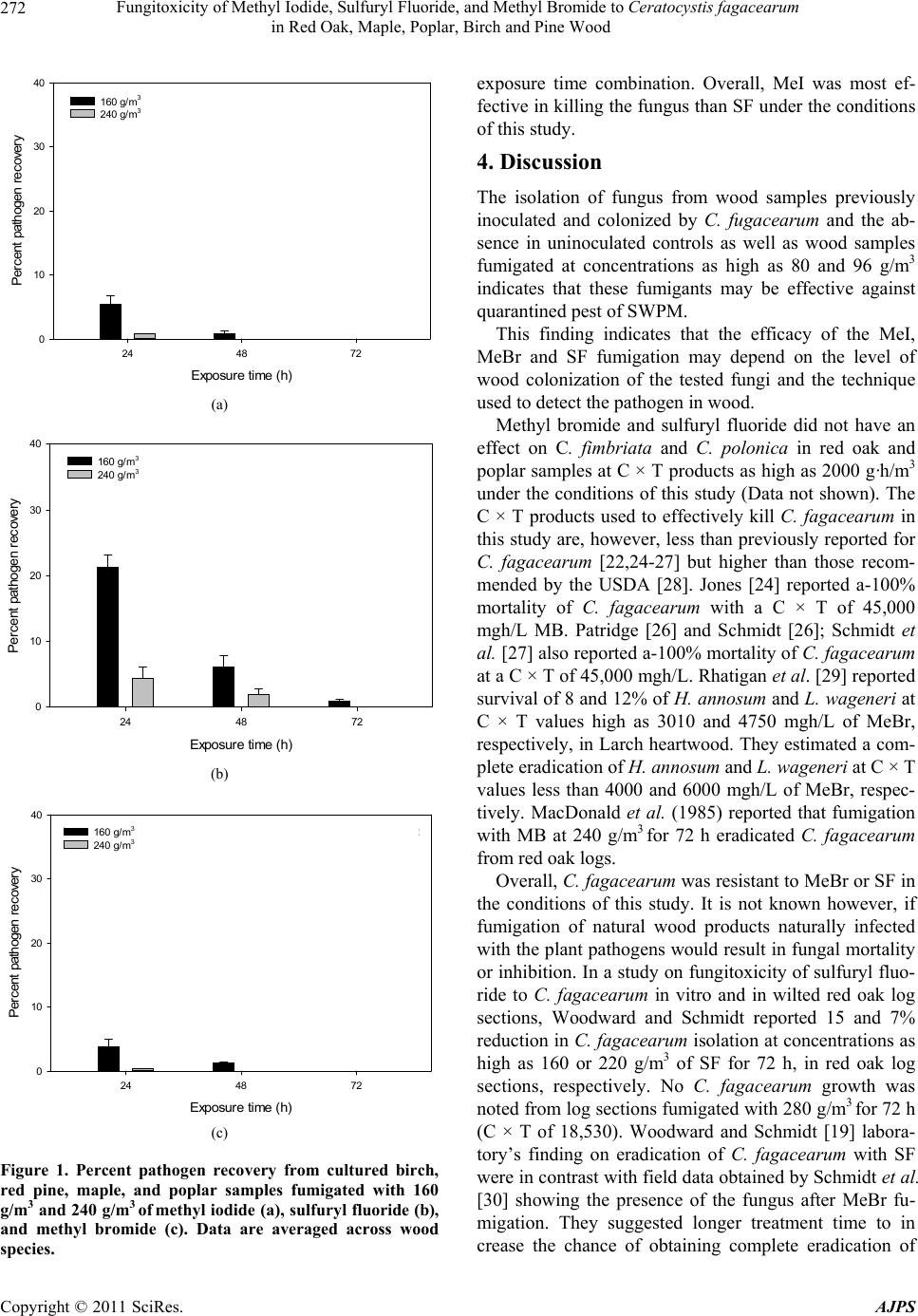

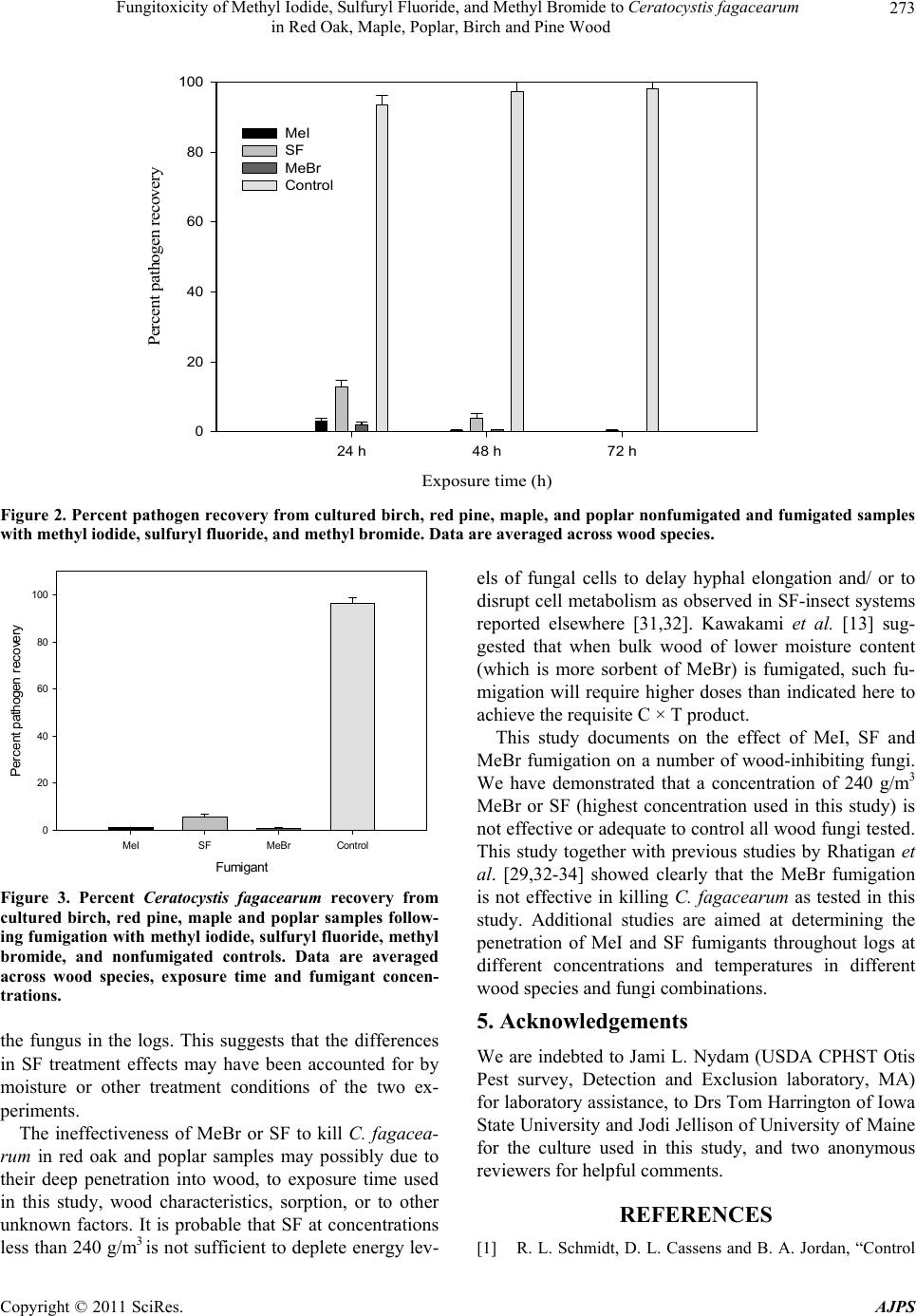

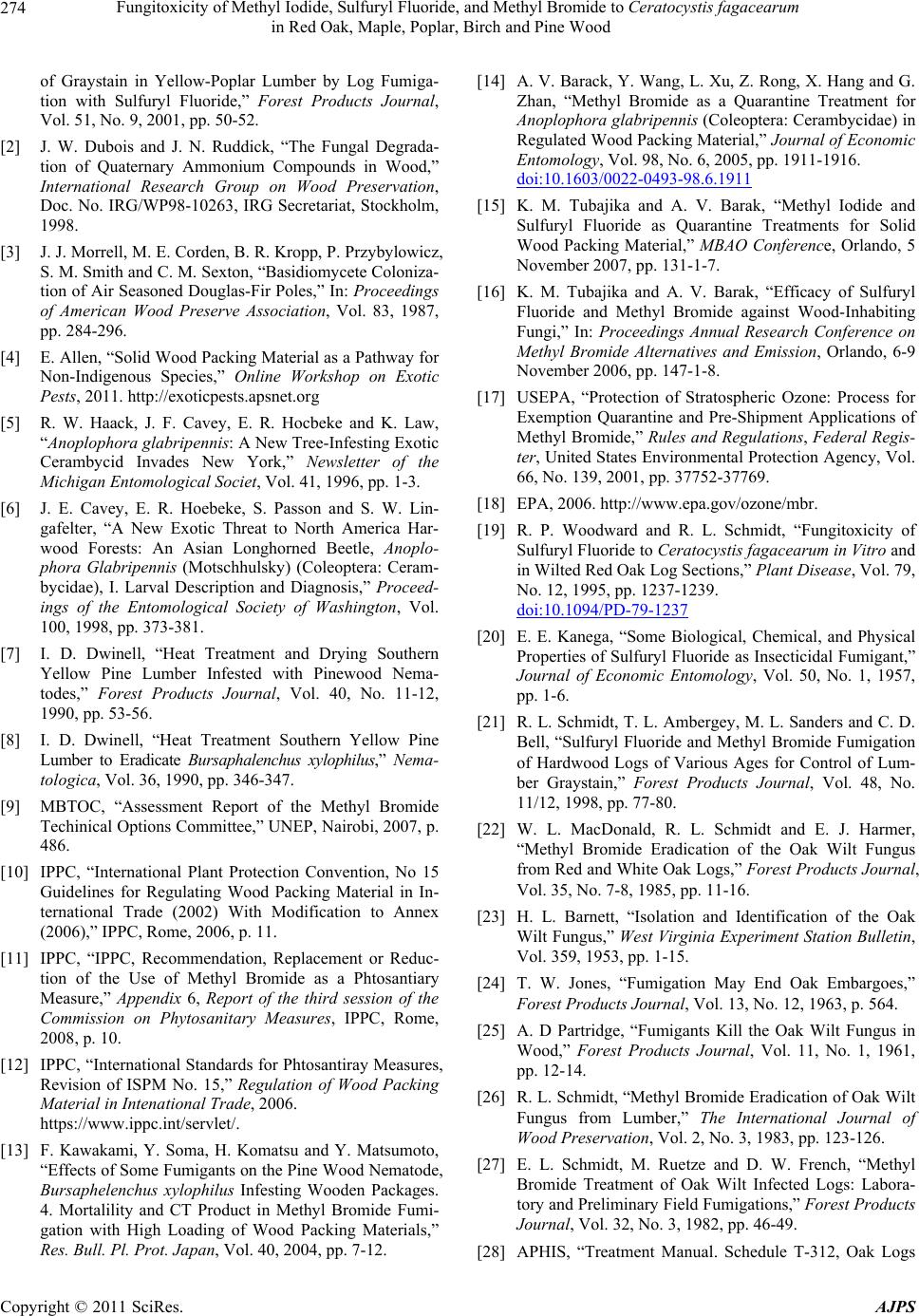

|