Journal of Power and Energy Engineering, 2015, 3, 417-422 Published Online April 2015 in SciRes. http://www.scirp.org /journal/j pee http://dx.doi.org/10.4236/jpee.2015.34056 How to cite this paper: Zhao, Q.S., et al. (2015) The Research of Heat Transfer Area for 55/19 Steam Generator. Journal of Power and Energy Engineering, 3, 417-422. http://dx.doi.org/10.4236/jpee.2015.34056 The Research of Heat Transfer Area for 55/19 Steam Generator Qingsen Zhao, Debing Deng, Shenbin Nie, Wei Chen, Jiayong Wang, Ding Zhang Suzhou Nuclear Power Research Institute, Suzhou, China Email: zhaoqingsen@cgnpc.com.cn Received December 2014 Abstract A calculation method of heat transfer area for vertical natural circulated steam generator was in- troduc ed. According to the design requirements of steam generator 55/ 19 of CPR1000, its heat transfer area was calculated based on this method. The results show that the accuracy of p arti- tional and overall calculation method is almost the same, but the result is different when using different calculation models. And the results are compared with the foreign c ompan ies for 55/19 steam generator. Keywords Steam Generator, Heat Transfer Area, 55/19 1. Introduction Vertical, U-tubed and natural circulation steam generator, which is a key equipment of nuclear steam supply system (NSSS), is widely used in pressurized water reactor (PWR) system of nuclear plant. As the hub of pri- mary loop and secondary Loop, its function is to transfer the primary loop heat to the coolant of secondary loop and produce steam to drive a turbine to generate electricity. Computation of heat transfer area in the steam generator is the basis of thermal-hydraulic design and one of the important contents for a steam generator. The main purpose is to calculate the heat exchange area, which sa- tisfies the heat exchange load between the coolants of primary and secondary loop. A proper heat exchange area of the steam generator has an important influence on its performance and economic benefit of the whole plant. Therefore, a right calculation method, suitable calculation models, and consideration of a certain amount of plugging and appropriate fouling resistance have great significance of ensuring the performance requirements of the steam generator during the entire design life. This paper introduces a calculation method of the vertical, U-tubed and natural circulation steam generator, calculates the heat transfer area of steam generator 55/19 based on this model, and compares with the results of foreign companies. 2. The Input Parameters The input parameters (known conditions) of the steam generator 55/19 heat transfer area calculation are lists in  Q. S. Zhao et al. Table 1 [1]. Considering the U tube fouling on the outside wall and the uncertainty of U tube damage during late stage of the steam generator, the design tube plugging was 10%, the U tube fouling coefficient is 88 × 10−7 m2∙K/W. 3. Calculation of Heat Transfer Area The heat transfer equation is as follows: (1) where Pt is the total thermal power, kW; qm,p is the coolant flow rate, kg/s; hin and hout are the coolant enthalpies of inlet and outlet, kJ/kg. Excluding blowdown energy loss, steam production calculated from the heat balance equation is showed that: (2) where ηsg is thermal efficiency of the steam generator, 0.97 - 0.99; hg and hfw are the steam enthalpy and the feed water enthalpy, kJ/kg. The calculation equation of heat transfer area is shown that: (3) where K is the Heat transfer coefficient, W/m2∙K; Δtm is the logarithmic temperature difference of heat transfer, ˚C. According to the cylinder wall heat transfer theory [2]: ee 1i 2o 1 Kdd 11 RR αdαd 1 RR R R wf im f o = ⋅+⋅+ + =+++ (4) Table 1. Input parameters of design. Parameter Sym b ol Unit Value Total thermal power P MW 968.3 Coolant pressure Pp Mpa 15.5 Coolant inlet temperature Tp,in ˚C 327.0 Coolant outlet temperature Tp,out ℃ 293.0 Average coolant temperature Tagv ˚C 310.0 Coolant flow rate Q m3/h 23790.0 Number of tubes N n 4474 Feed water temperature Ts,in ˚C 226.0 Steam outlet pressure Psteam Mpa 6.89 Steam outlet temperature Tstea m ˚C 282.9 Steam outlet flow rate wsteam kg/s 538.40 Steam outlet wetness X % 0.0025 Fouling factor Rfouling m2∙K/W 8.80E−06 Tube outside diameter do m 0.01905 Tube wall thickness δ m 0 Tube inside diameter di m 0.01687 Full load circulation ratio 3.10 Heat transfer area A m2 5429.00  Q. S. Zhao et al. where α1 is the heat transfer coefficient inside the tube, W/m2∙K; Ri is the thermal resistance in the tube, m2∙K/W; α2 is the heat transfer coefficient outside the tube, W/m2∙K; Ro is the thermal resistance outside the tube, m2∙K/W; Rw is the Tube wall heat conduction thermal resistance, m2∙K/W; RF is the fouling resistance outside the tube, m2∙K/W; di, do and de are the inner diameter, outer diameter and equivalent diameter of tube, respectively, m. In this paper, equivalent diameter is equaled to the outer diameter. The equation of logarithmic temperature difference (LMTD) of heat transfer logarithmic mean temperature difference is showed that: max min mmax min ΔtΔt ΔtΔt ln( ) Δt − = (5) where Δtmax and Δtmin are the maximum temperature difference and minimum temperature difference, respec- tively, ˚C. The main ta sk of design calculation is to calculate heat transfer temperature difference, determine the thermal resistance, obtain the overall coefficient of heat transfer, and the heat transfer area. Along the flow direction of the primary side coolant in the U-shaped tube, according to the difference be- tween the two coolant physical conditions, the heat exchange area can be divided into three sub regions (Figure 1). The secondary side coolants in the Region 1 and Region 3 belong to subcooled boiling, in the Region 2 be- longs to saturated nucleate boiling [3]. The area can be calculated according to the regions in the fluid, or by as- suming that the cold section is ignored. That’s to say, partitional and overall calculation method can be em- ployed. The two methods are compared in this paper. 3.1. The Heat Transfer in Different Regions The critical point of the Region 2 and Regio n 1, 3 is the temperature when the coolant gets to saturation temper- ature. According to the energy conservation law, heat transfer energy Q1 or Q3 is equaled to the energy of heat- ing the feed water from sub cooled temperature to the saturation temperature. (6) where Mfs is the feed water flow rate, kg/s; Hsat is the feed water enthalpy at saturation temperature, kJ/kg; Hfw is the feedwater enthalpy, kJ/kg. The heat transfer energy of Region 2 is as follows: (7) 3.2. The Calculation of Heat Transfer in the Primary Loop The equation of heat transfer in the primary loop is based on the McAdams formula [4]: Figure 1. The division of heat transfer regions. Tp,in 1 2Tp,out 3 Tsat Ts,in Ts,in  Q. S. Zhao et al. (8) 3.3. The Calculation of Heat Transfer in the Secondary Loop The Jens-Lottes formula, Thom formula and Rohsenow formula are usually used to calculate the heat transfer of the secondary side loop. The Jens-Lottes formula [4] is as follows: 0.25 6.2 sat 0.792037 p T qe − ∆= (9) 0.75 6.2 2 R 0.792037 p qe − − = (10) where the unit of ΔT is ˚C; P, MPa; q, MW/m2; R2 is thermal resistance outside the tube, m2∙K/W. The Thom formula: (11) The Rohsenow formula [4]: ,f 0.33 0.67 1 () α( )(μ) Pr p fg f fg m fg w Cg hq hC ρρ σ − = (12) where the value of m is equal to 1; Cw1 is 0.013; σ is the surface tension, Nm; Cp,f is the specific heat capacity at constant pressure of saturated liquid, J/( kg∙K); hfg is the latent heat of vaporization, J/kg; μf is the dynamic vis- cosit y of saturated liquid, Pa∙s; ρf and ρg are densit ies of the saturated liquid and vapor, respectively, kg/m3; Pr is Pr and tl c onst ant of the saturated liquid. Different companies employed different formulas to calculate the heat transfer in the secondary side loop. Western countries usua ll y use Rohsenow formula [3]. But the Westinghouse used the revised Lottes Jens for- mula , Framatome used Thom formula. 3.4. Thermal Resistance of the Tube Wall The equation of tube wall thermal conductivity is: (13) where λW is the thermal conductivity of the tube materials, W/m2∙K. For Inconel-690, the coefficient of thermal conductivity varies with temperature (Table 2). 3.5. Fouling Factor The fouling resistance is usually neglected as calculating the heat transfer coefficient. But a safety coefficient is considered when decides the heat transfer area. The primary loop water usually keeps hi ghly clean, so the foul- ing resistance of the primary loop can be neglected. Due to the economy, the quality requirement of the second- ary loop is not as strict as the primary loop. Therefore, a certain degree of deposit exists in the pipe of the sec- ondary loop. The steam generator fouling resistance was 528.8 × 10−7 m2∙K/W recommended by George [5], and the foul- ing resistance of Bristol used for steam generator of nuclear power plant A is 257.94 × 10−7 m2∙K/W. 55/19 steam generator’s fouling resistance in Daya Bay nuclear power plant is 88 × 10−7 m2∙K/W [4]. The design value of steam generator 60F is 134 × 10−7 m2∙K/W in the second phase of Qinshan nuclear power plant [6]. The de- Table 2. Thermal conductivity of Inconel-690 at different temperature. Temperature ˚C 100 200 300 400 500 Thermal con ducti vity W/(m ∙K ) 13.5 15.1 17.3 19.1 21  Q. S. Zhao et al. sign fouling factor of steam generator AP1000 is 193. 89 × 10 −7 m2∙K/W [7]. 4. Calculation Results The parameters of steam generator 55/19, including thermal power, heat transfer coefficient and LMTD are cal- culated based on the models in this paper. And the results are showed in Table 3. The calculated heat transfer coefficients are different when using different models. The heat transfer coeffi- cient from the Jens model is larger than the Rohsenow model, whereas the Thom model is the smallest. For the calculated heat transfer area, the results are in an opposite order. That is to say, the calculated area based on the Thom model is the largest, whereas the Jens model is the smallest. The area deviation between the Jens model and the design value was 10%, which meets the requirement of the tube plugging margin (10%) in normal design of steam generator. The calculation errors are 1.33% and 0.64% compared with the design value when using the Jens model. It can be seen that the area deviation between the partitional coverall calculation methods was small. So the simple overall calculation method is usually used in the engineering design, and the preheating section can be neglected. The distribution of four resistances between the partitional and overall calculation methods displa yed in Fig- ure 2 and Figure 3 based on the Jens modes. It concludes that thermal resistance of the tube wall is the largest among the four resistances, and the percentage is 57%. The percentages of the thermal resistance inside and out- side the tub e are 24% and 11%, respectively. The fouling factor is the smallest, 8%. Table 3. The results of partitional and overall calculation methods. Parameters Sym b ol Unit Partitional calculation method calculation Region 1 Region 2 Region 3 Thermal power P MW 75.23 817.86 75.23 968.33 Tube ID resistance Ri m2∙K/W 2.68E−05 2.66E−05 2.63E−05 2.74E−05 Tube wall resistance Rm m2∙K/W 6.51E−05 6.52E−05 6.73E−05 6.51E−05 Fouling factor Rf m2∙K/W 8.80E−06 8.80E−06 8.80E−06 8.80E−06 Tube OD resistance Ro-R m2∙K/W 1.30E−05 1.99E−05 3.79E−05 2.12E−05 Ro-T m2∙K/W 1.71E−05 2.35E−05 3.74E−05 2.45E−05 Ro-J m2∙K/W 7.72E−06 1.23E−05 2.47E−05 1.31E−05 Heat transfer Coefficient K-R W/m 2∙K 8794.25 8293.74 7123.17 8166.20 K-T W/ m 2∙K 8488.42 8056.59 7148.53 7947.01 K-J W/m 2∙K 9224.86 8855.24 7863.01 8739.86 Inlet temperature of primary loop Tp,in ˚C 327.60 325.16 295.30 327.60 Outlet temperature of primary loop Tp,out ˚C 325.16 295.30 292.30 292.30 Inlet temperature of secondary loop Ts,in ˚C 265.50 282.94 282.94 265.50 Outlet temperature of secondary loop Ts,ou t ˚C 282.94 282.94 265.50 282.94 LM T D ΔTm ˚C 43.42 2 4.30 10.79 2 2.59 Heat transfer area A-R m2 197.00 4057.71 979.05 5249.63 A-T m2 204.10 4177.15 975.58 5394.42 A-J m2 187.81 3800.41 886.93 4905.06 Total area of heat transfer A-R m2 5233.77 5249.63 A-T m2 5356.83 5394.42 A-J m2 4875.15 4905.06 The area deviation between the calculation and design δ-R 3.60 3.30 δ-T 1.33 0.64 δ-J 10.20 9.65  Q. S. Zhao et al. Figure 2. The distribution of four resistances between the partitional and overall calculation methods. Figure 3. The distribution of four resistances from the overal l calculation method. 5. Conclusions The re are small area deviations between the partitional and overall calculation method. The overall calculation method which usually can be used in the engineering design neglected the preheating section. The thermal resist anc e of tube wall is the largest among the four resistances, then the inside and outside of the tube. The fouling resistance is the smalle st. The computation of heat transfer area is one of most important content in steam generator design. Once the heat transfer area of the steam generator is accurately calculated, the structure of the steam generator, including the tube sheet size, the U-tube height and the tube support plate shape, can be well designed. In this paper, the heat transfer area was calculated for the steam gener at or 55/19. The deviation between the calculated area and the design value can be neglected. It indicates that the model used in calculation process is proper and correct. The research work is very pro mising for the design of steam generator with independent in- tellectual property rights. References [1] Guangdong Nuclear Power Joint Venture (1986) 55/19 Steam Generator Thermal Hydraulic Design Studies. [2] Steam Generator Compiling Group (1982) The Steam Generator. Atomic Energy Press. [3] Wan g, W. (2013) Calculation of Heat Transfer Area for CPR1000 Steam Generator. Dong Fang Electric R eview, 27, 53-55. [4] Suzhou Nuclear Power Institute (2014) The Research of CPR1000 Unit Steam Generator. Suzhou. [5] Ding, X.S. (2000) Chemical Cleaning and Heat Transfer Performance of Steam Generator of Nuclear Power Plant. The Cleaning World, 7, 17-22. [6] Westinghouse Electric Company, WNEP-9722 (1997) Mode 60F Steam Generator Thermal and Hydraulic Design Data Report. Qinshan II Nuclear Power Project Units 1 and 2. [7] Li n, C.G., Yu, Z.S. and Yu, O.Y. (2012) AP1000 for Passive Advanced Nuclear Power Plant. Atomic Energy Press. 0.00E+00 2.00E-05 4.00E-05 6.00E-05 8.00E-05 1.00E-04 1.20E-04 1.40E-04

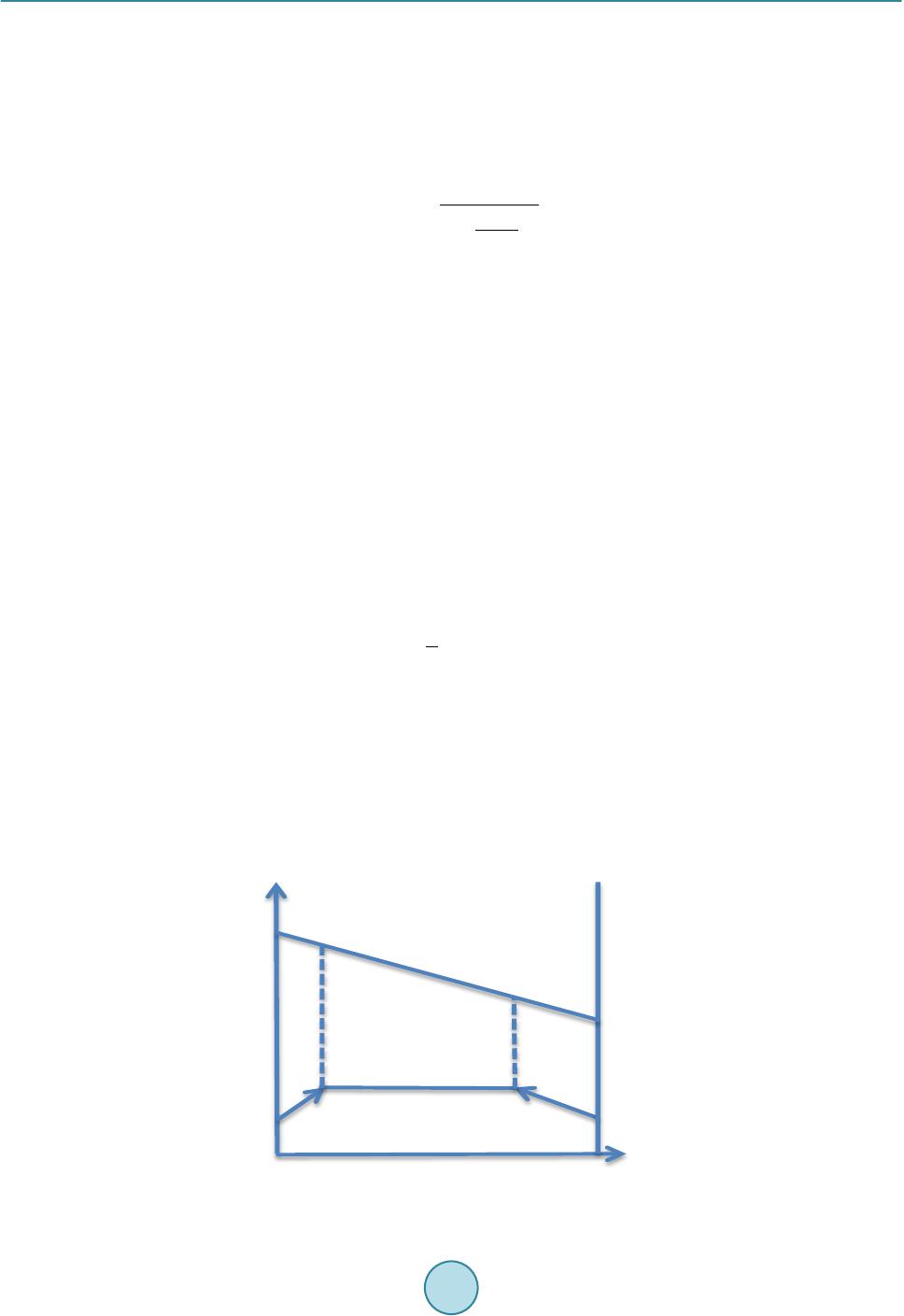

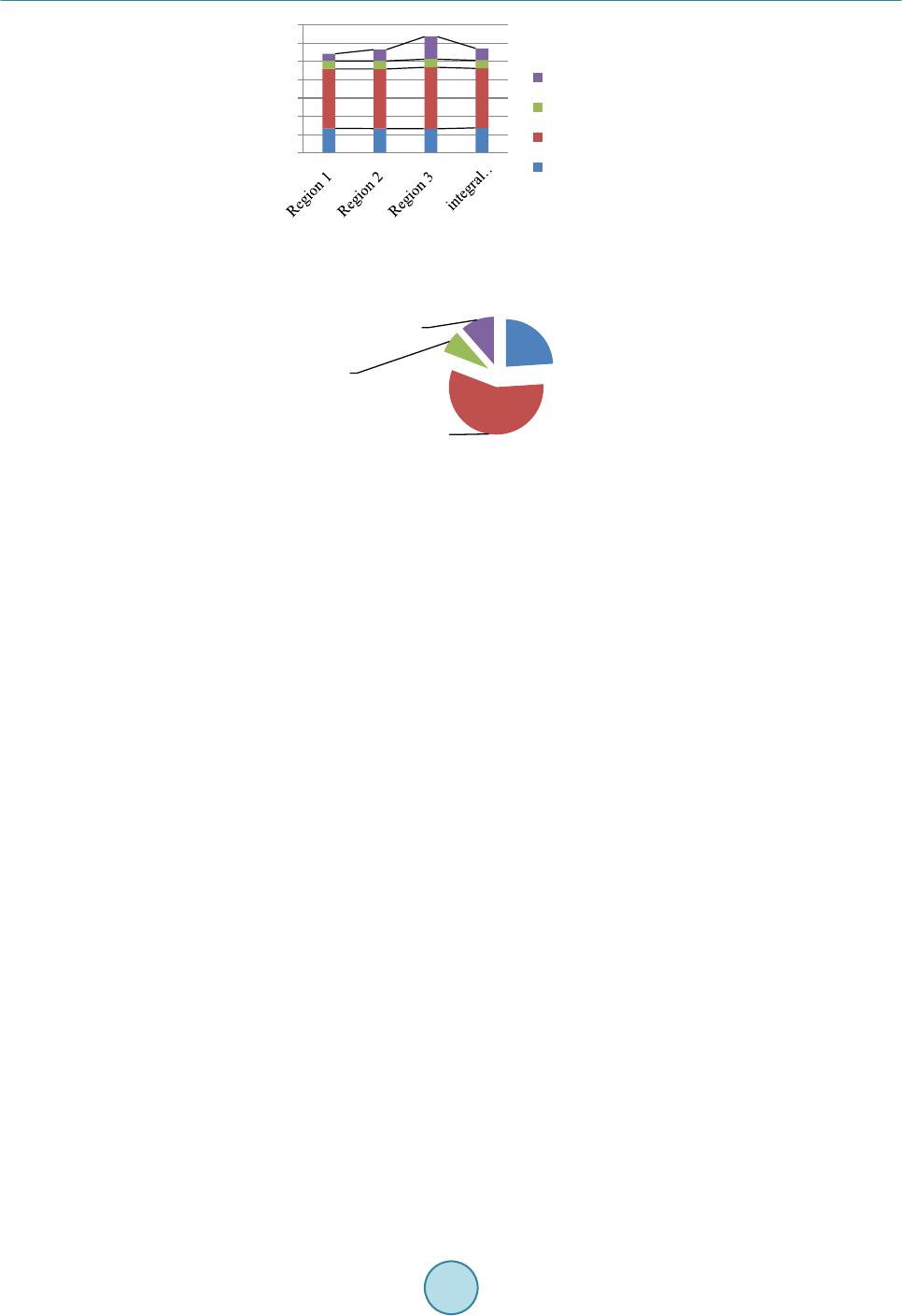

|