M. M. A. RAFIQUE ET AL.33

ga

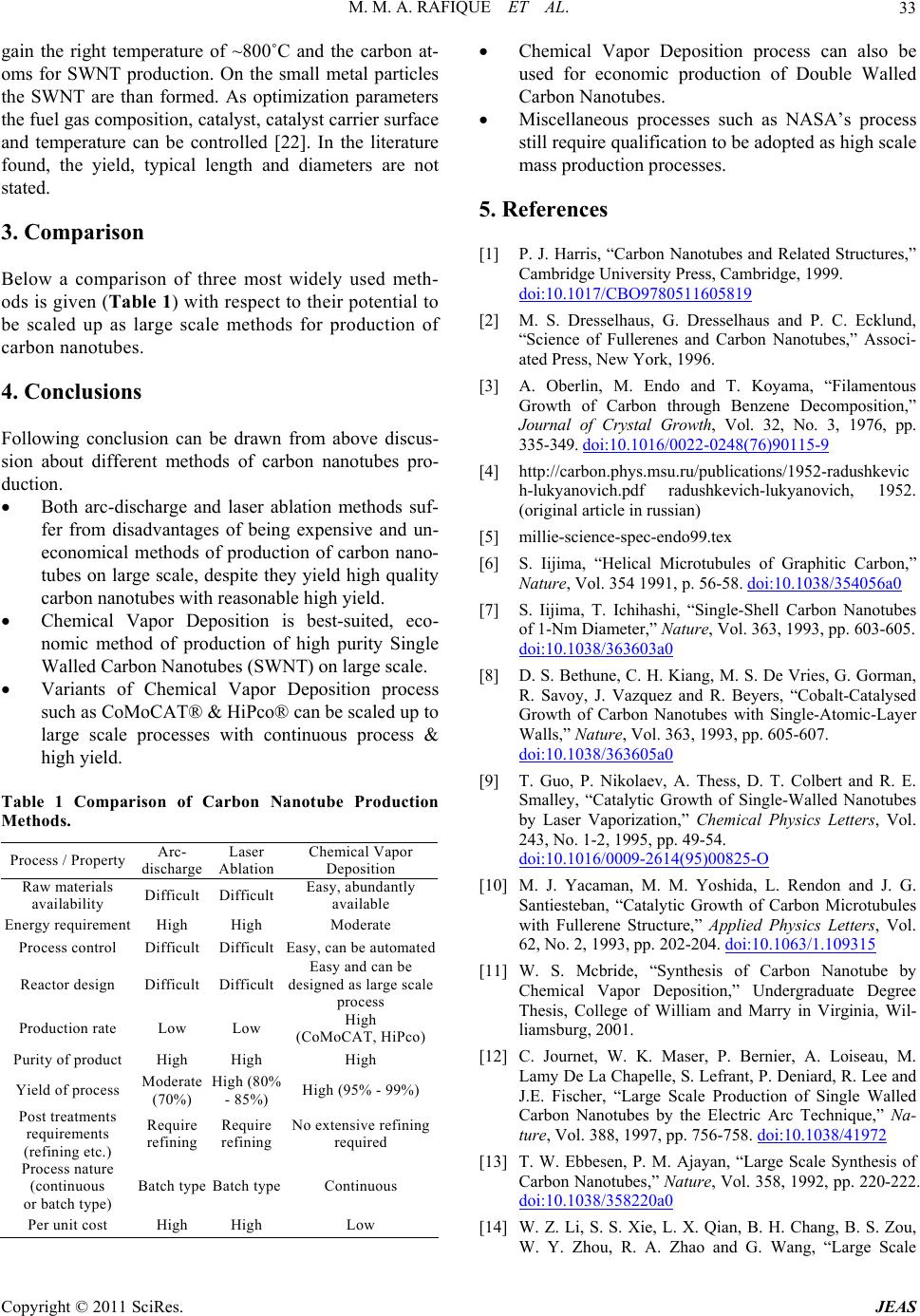

. Comparison

elow a comparison of three most widely used meth-

. Conclusions

ollowing conclusion can be drawn from above discus-

arc-discharge and laser ablation methods suf-

able 1 Comparison of Carbon Nanotube Production

operty Arc-

die Laser

A Chemical Vapor

in the right temperature of ~800˚C and the carbon at-

oms for SWNT production. On the small metal particles

the SWNT are than formed. As optimization parameters

the fuel gas composition, catalyst, catalyst carrier surface

and temperature can be controlled [22]. In the literature

found, the yield, typical length and diameters are not

stated.

3

B

ods is given (Table 1) with respect to their poten tial to

be scaled up as large scale methods for production of

carbon nanotubes.

4

F

sion about different methods of carbon nanotubes pro-

duction.

Both

fer from disadvantages of being expensive and un-

economical methods of production of carbon nano-

tubes on large scale, despite they yield high quality

carbon nanotubes with reasonable high yield.

Chemical Vapor Deposition is best-suited,eco-

nomic method of production of high purity Single

Walled Carbon Nanotubes (SWNT) on large scale.

Variants of Chemical Vapor Deposition process

such as CoMoCAT® & HiPco® can be scaled up to

large scale processes with continuous process &

high yield.

T

Methods.

Process / Prscharg blation Deposition

Raw materials

availab ili ty Difficult Difficult Easy, abundantly

available

Ennt

D D Easy, ated

Production rate Low Low (CoMo iPco)

MHi High 99%)

No exte

Batch type Batch type Continuous

High High Low

eergy requiremHigh High Moderate

Process control ifficultifficultcan be autom

Reactor design Difficult Difficult Easy and can be

des igned as l arg e s cal e

process

High

CAT, H

Purity of product High High High

Yield of process oderate

(70%) gh (80%

- 85%)

Require

(95% -

Post treatments

requirements

(refining etc.)

Require

refining refining nsive refining

required

Process nature

(continuous

or batch type)

Per unit cost

Chemical Vapor Deposition process can also be

used for economic production of Double Walled

Carbon Nanotubes.

Miscellaneous processes such as NASA’s process

still require qualification to be adop ted as high scale

mass production processes.

5. References

[1] P. J. Harris, “Carbon Nanotubes and Related Structures,”

Cambridge University Press, Cambridge, 1999.

doi:10.1017/CBO9780511605819

[2] M. S. Dresselhaus, G. Dresselhaus and P. C. Ecklund,

“Science of Fullerenes and Carbon Nanotubes,” Associ-

ated Press, New York, 1996.

[3] A. Oberlin, M. Endo and T. Koyama, “Filamentous

Growth of Carbon through Benzene Decomposition,”

Journal of Crystal Growth, Vol. 32, No. 3, 1976, pp.

335-349. doi:10.1016/0022-0248(76)90115-9

[4] http://carbon.phys.msu.ru/publications/1952-radushkevic

h-lukyanovich.pdf radushkevich-lukyanovich, 1952.

(original article in russian)

[5] millie-science-spec-endo99.tex

[6] S. Iijima, “Helical Microtubules of Graphitic Carbon,”

Nature, Vol. 354 1991, p. 56-58. doi:10.1038/354056a0

[7] S. Iijima, T. Ichihashi, “Single-Shell Carbon Nanotubes

of 1-Nm Diameter,” Nature, Vol. 363, 1993, pp. 603-605.

doi:10.1038/363603a0

[8] D. S. Bethune, C. H. Kiang, M. S. De Vries, G. Gorman,

R. Savoy, J. Vazquez and R. Beyers, “Cobalt-Catalysed

Growth of Carbon Nanotubes with Single-Atomic-Layer

Walls,” Nature, Vol. 363, 1993, pp. 605-607.

doi:10.1038/363605a0

[9] T. Guo, P. Nikolaev, A. Thess, D. T. Colbert and R. E.

Smalley, “Catalytic Growth of Single-Walled Nanotubes

by Laser Vaporization,” Chemical Physics Letters, Vol.

243, No. 1-2, 1995, pp. 49-54.

doi:10.1016/0009-2614(95)00825-O

[10] M. J. Yacaman, M. M. Yoshida, L. Rendon and J. G.

Santiesteban, “Catalytic Growth of Carbon Microtubules

with Fullerene Structure,” Applied Physics Letters, Vol.

62, No. 2, 1993, pp. 202-204. doi:10.1063/1.109315

[11] W. S. Mcbride, “Synthesis of Carbon Nanotube by

Chemical Vapor Deposition,” Undergraduate Degree

Thesis, College of William and Marry in Virginia, Wil-

liamsburg, 2001.

[12] C. Journet, W. K. Maser, P. Bernier, A. Loiseau, M.

Lamy De La Chapelle, S. Lefrant, P. Deniard, R. Lee and

J.E. Fischer, “Large Scale Production of Single Walled

Carbon Nanotubes by the Electric Arc Technique,” Na-

ture, Vol. 388, 1997, pp. 756-758. doi:10.1038/41972

[13] T. W. Ebbesen, P. M. Ajayan, “Large Scale Synthesis of

Carbon Nanotubes,” Nature, Vol. 358, 1992, pp. 220-222.

doi:10.1038/358220a0

[14] W. Z. Li, S. S. Xie, L. X. Qian, B. H. Chang, B. S. Zou,

W. Y. Zhou, R. A. Zhao and G. Wang, “Large Scale

Copyright © 2011 SciRes. JEAS