Using Kaolinitic Clay for Preparation of a Hydrotalcite-Like Compound

690

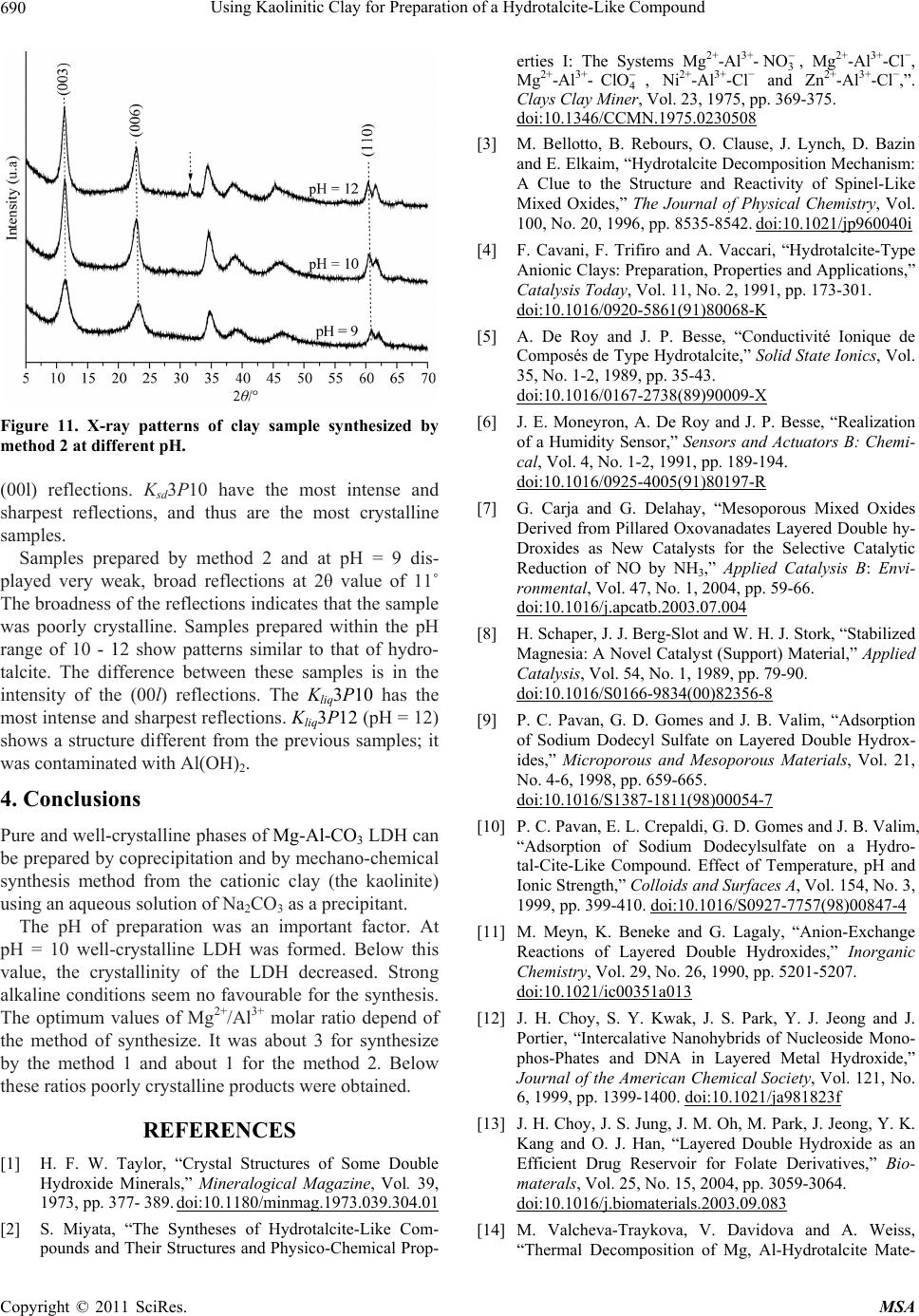

Figure 11. X-ray patterns of clay sample synthesized by

method 2 at different pH.

(00l) reflections. Ksd3P10 have the most intense and

sharpest reflections, and thus are the most crystalline

samples.

Samples prepared by method 2 and at pH = 9 dis-

played very weak, broad reflections at 2θ value of 11˚

The broadness of the reflections indicates that the sample

was poorly crystalline. Samples prepared within the pH

range of 10 - 12 show patterns similar to that of hydro-

talcite. The difference between these samples is in the

intensity of the (00l) reflections. The Kliq3P10 has the

most intense and sharpest reflections. Kliq3P12 (pH = 12)

shows a structure different from the previous samples; it

was contaminated with Al(OH)2.

4. Conclusions

Pure and well-crystalline phases of Mg-Al-CO3 LDH can

be prepared by coprecipitation and by mechano-chemical

synthesis method from the cationic clay (the kaolinite)

using an aqueous solution of Na2CO3 as a precipitant.

The pH of preparation was an important factor. At

pH = 10 well-crystalline LDH was formed. Below this

value, the crystallinity of the LDH decreased. Strong

alkaline conditions seem no favourable for the synthesis.

The optimum values of Mg2+/Al3+ molar ratio depend of

the method of synthesize. It was about 3 for synthesize

by the method 1 and about 1 for the method 2. Below

these ratios poorly crystalline products were obtained.

REFERENCES

[1] H. F. W. Taylor, “Crystal Structures of Some Double

Hydroxide Minerals,” Mineralogical Magazine, Vol. 39,

1973, pp. 377- 389. doi:10.1180/minmag.1973.039.304.01

[2] S. Miyata, “The Syntheses of Hydrotalcite-Like Com-

pounds and Their Structures and Physico-Chemical Prop-

erties I: The Systems Mg2+-Al3+-3

NO , Mg2+-Al3+-Cl−,

Mg2+-Al3+-4

ClO

, Ni2+-Al3+-Cl− and Zn2+-Al3+-Cl−,”.

Clays Clay Miner, Vol. 23, 1975, pp. 369-375.

doi:10.1346/CCMN.1975.0230508

[3] M. Bellotto, B. Rebours, O. Clause, J. Lynch, D. Bazin

and E. Elkaim, “Hydrotalcite Decomposition Mechanism:

A Clue to the Structure and Reactivity of Spinel-Like

Mixed Oxides,” The Journal of Physical Chemistry, Vol.

100, No. 20, 1996, pp. 8535-8542. doi:10.1021/jp960040i

[4] F. Cavani, F. Trifiro and A. Vaccari, “Hydrotalcite-Type

Anionic Clays: Preparation, Properties and Applications,”

Catalysis Today, Vol. 11, No. 2, 1991, pp. 173-301.

doi:10.1016/0920-5861(91)80068-K

[5] A. De Roy and J. P. Besse, “Conductivité Ionique de

Composés de Type Hydrotalcite,” Solid State Ionics, Vol.

35, No. 1-2, 1989, pp. 35-43.

doi:10.1016/0167-2738(89)90009-X

[6] J. E. Moneyron, A. De Roy and J. P. Besse, “Realization

of a Humidity Sensor,” Sensors and Actuators B: Chemi-

cal, Vol. 4, No. 1-2, 1991, pp. 189-194.

doi:10.1016/0925-4005(91)80197-R

[7] G. Carja and G. Delahay, “Mesoporous Mixed Oxides

Derived from Pillared Oxovanadates Layered Double hy-

Droxides as New Catalysts for the Selective Catalytic

Reduction of NO by NH3,” Applied Catalysis B: Envi-

ronmental, Vol. 47, No. 1, 2004, pp. 59-66.

doi:10.1016/j.apcatb.2003.07.004

[8] H. Schaper, J. J. Berg-Slot and W. H. J. Stork, “Stabilized

Magnesia: A Novel Catalyst (Support) Material,” Applied

Catalysis, Vol. 54, No. 1, 1989, pp. 79-90.

doi:10.1016/S0166-9834(00)82356-8

[9] P. C. Pavan, G. D. Gomes and J. B. Valim, “Adsorption

of Sodium Dodecyl Sulfate on Layered Double Hydrox-

ides,” Microporous and Mesoporous Materials, Vol. 21,

No. 4-6, 1998, pp. 659-665.

doi:10.1016/S1387-1811(98)00054-7

[10] P. C. Pavan, E. L. Crepaldi, G. D. Gomes and J. B. Valim,

“Adsorption of Sodium Dodecylsulfate on a Hydro-

tal-Cite-Like Compound. Effect of Temperature, pH and

Ionic Strength,” Colloids and Surfaces A, Vol. 154, No. 3,

1999, pp. 399-410. doi:10.1016/S0927-7757(98)00847-4

[11] M. Meyn, K. Beneke and G. Lagaly, “Anion-Exchange

Reactions of Layered Double Hydroxides,” Inorganic

Chemistry, Vol. 29, No. 26, 1990, pp. 5201-5207.

doi:10.1021/ic00351a013

[12] J. H. Choy, S. Y. Kwak, J. S. Park, Y. J. Jeong and J.

Portier, “Intercalative Nanohybrids of Nucleoside Mono-

phos-Phates and DNA in Layered Metal Hydroxide,”

Journal of the American Chemical Society, Vol. 121, No.

6, 1999, pp. 1399-1400. doi:10.1021/ja981823f

[13] J. H. Choy, J. S. Jung, J. M. Oh, M. Park, J. Jeong, Y. K.

Kang and O. J. Han, “Layered Double Hydroxide as an

Efficient Drug Reservoir for Folate Derivatives,” Bio-

materals, Vol. 25, No. 15, 2004, pp. 3059-3064.

doi:10.1016/j.biomaterials.2003.09.083

[14] M. Valcheva-Traykova, V. Davidova and A. Weiss,

“Thermal Decomposition of Mg, Al-Hydrotalcite Mate-

Copyright © 2011 SciRes. MSA