Paper Menu >>

Journal Menu >>

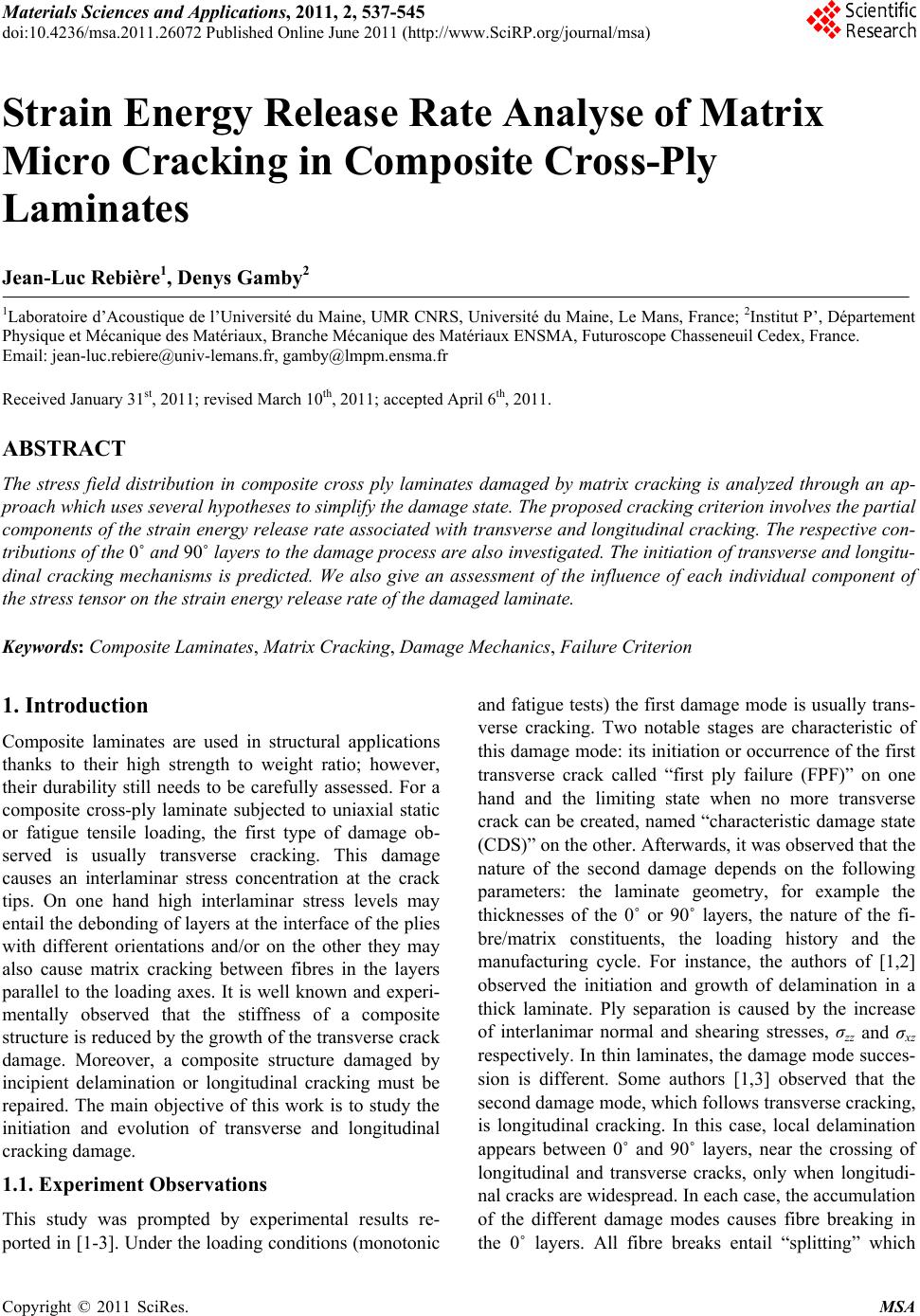

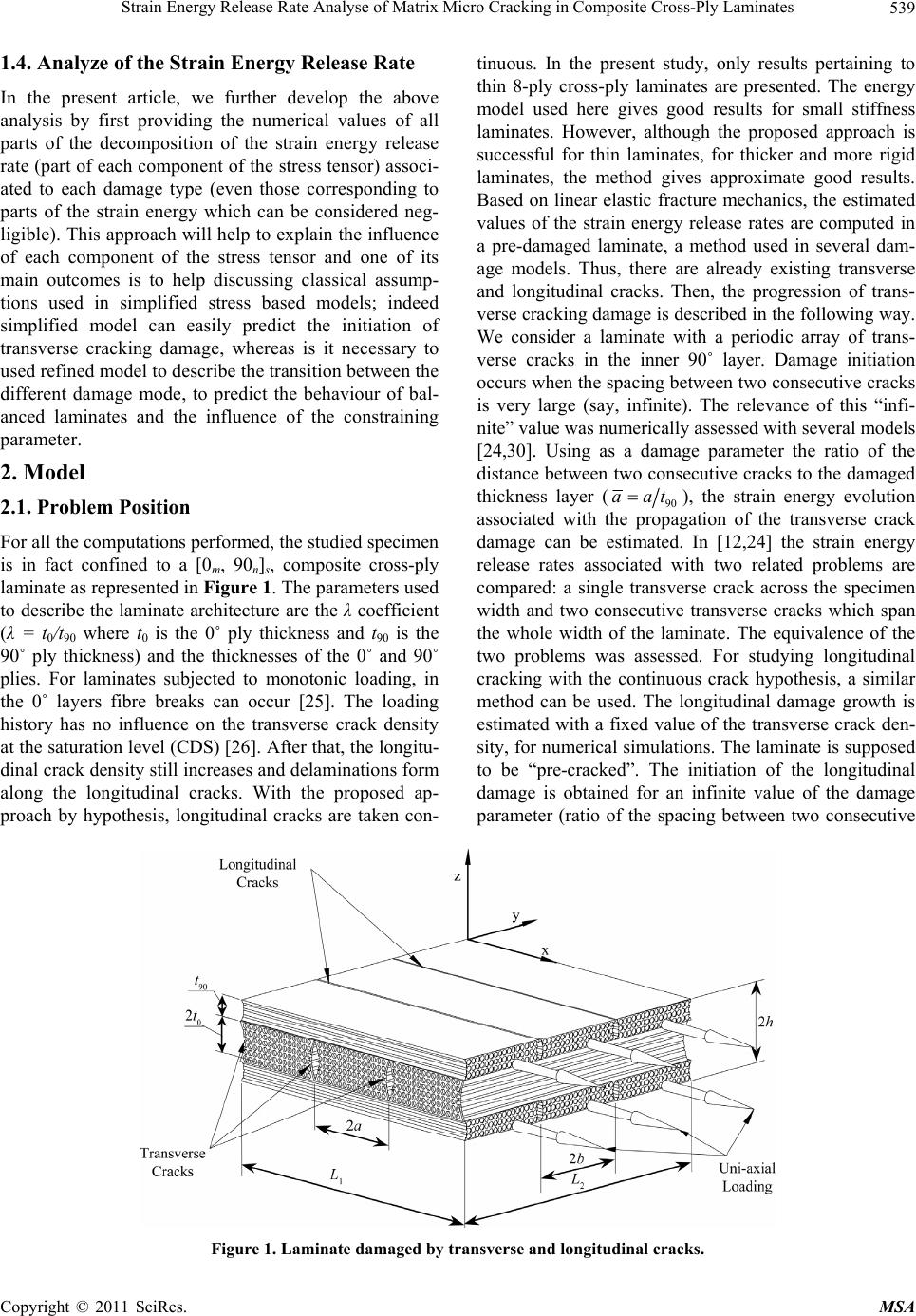

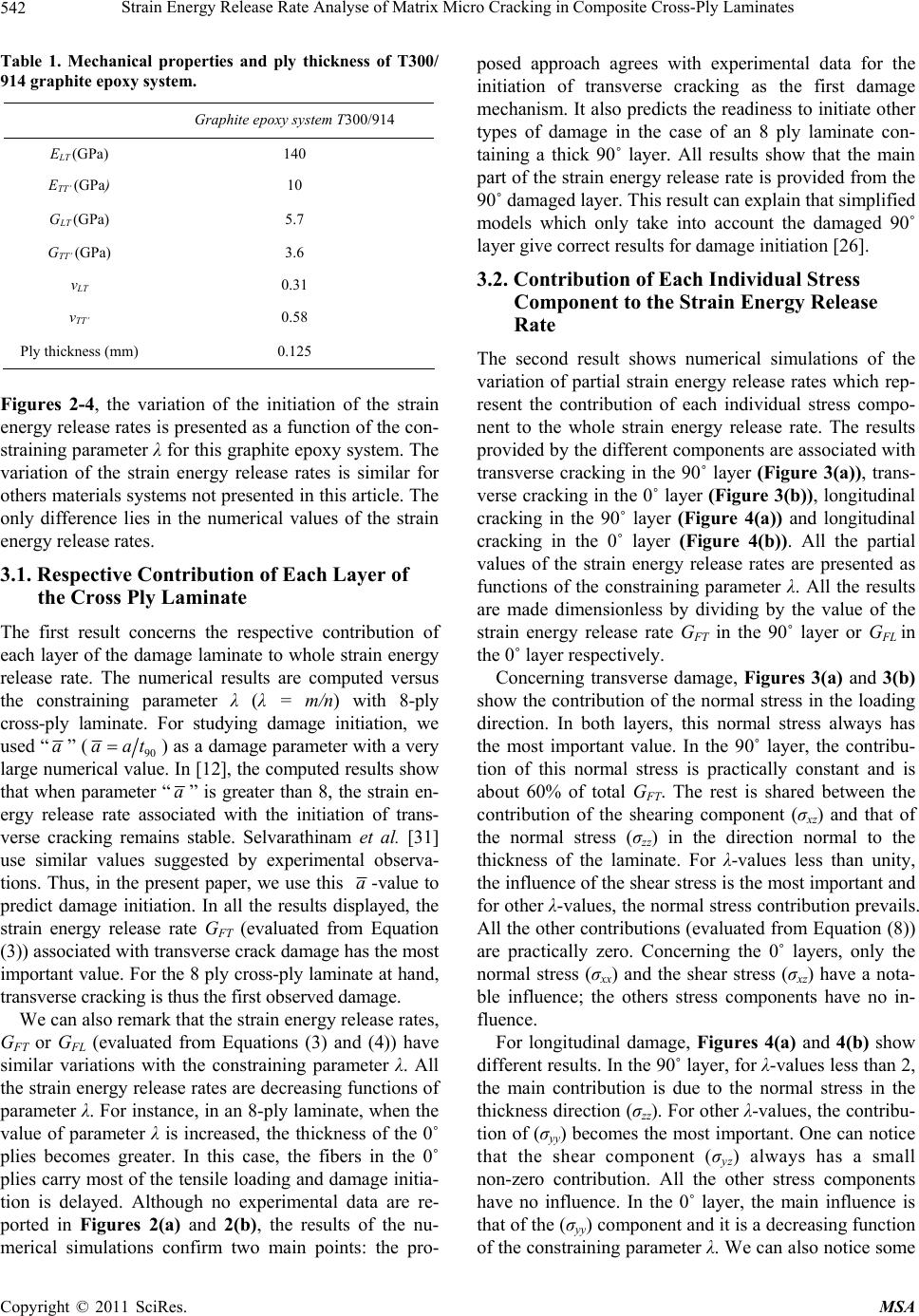

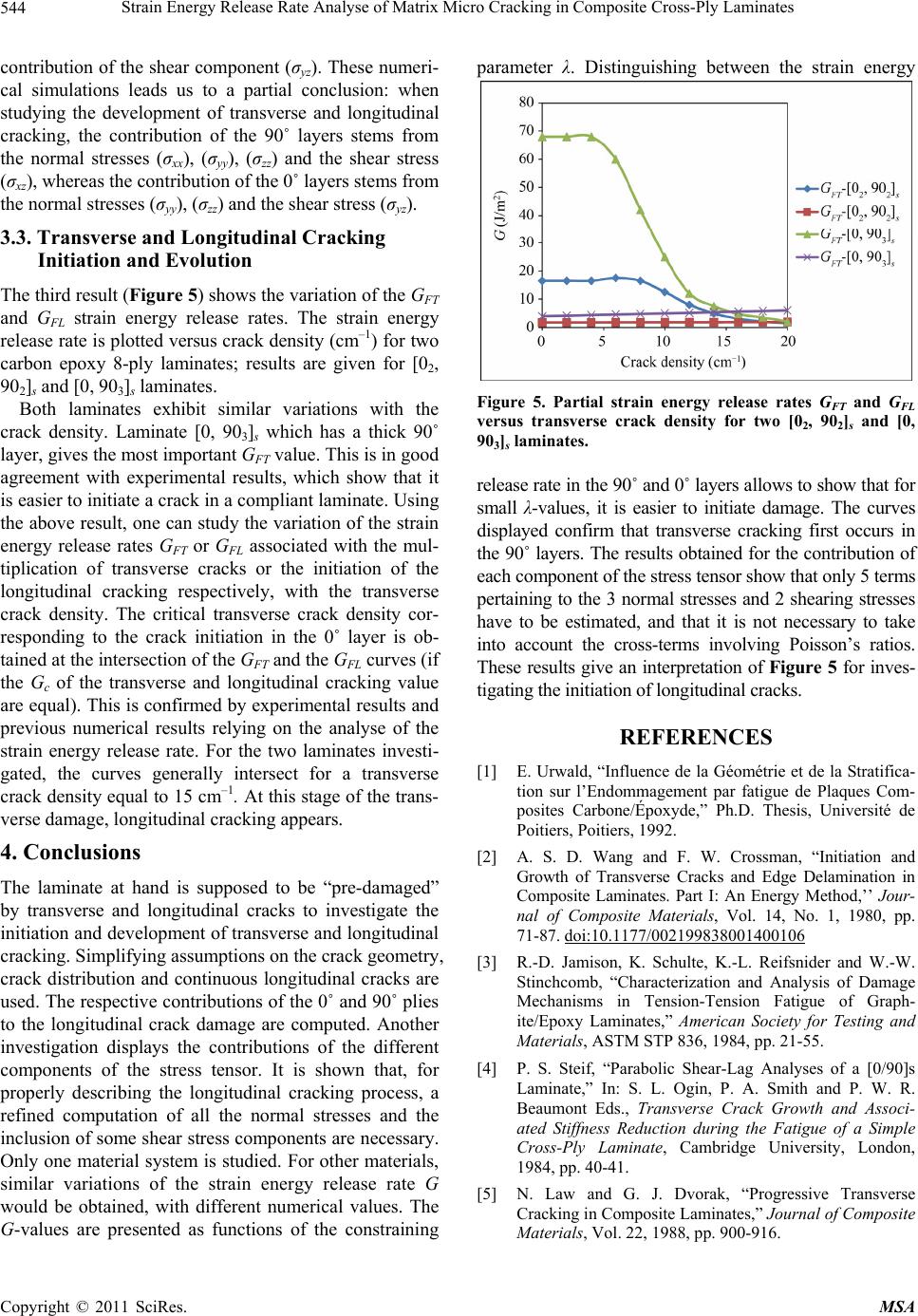

Materials Sciences and Applications, 2011, 2, 537-545 doi:10.4236/msa.2011.26072 Published Online June 2011 (http://www.SciRP.org/journal/msa) Copyright © 2011 SciRes. MSA 537 Strain Energy Release Rate Analyse of Matrix Micro Cracking in Composite Cross-Ply Laminates Jean-Luc Rebière1, Denys Gamby2 1Laboratoire d’Acoustique de l’Université du Maine, UMR CNRS, Université du Maine, Le Mans, France; 2Institut P’, Département Physique et Mécanique des Matériaux, Branche Mécanique des Matériaux ENSMA, Futuroscope Chasseneuil Cedex, France. Email: jean-luc.rebiere@univ-lemans.fr, gamby@lmpm.ensma.fr Received January 31st, 2011; revised March 10th, 2011; accepted April 6th, 2011. ABSTRACT The stress field distribution in composite cross ply laminates damaged by matrix cracking is analyzed through an ap- proach which uses several hypotheses to simplify the damage state. The proposed cracking criterion involves the partial components of the strain energy release rate associated with transverse and longitudinal cracking. The respective con- tributions of the 0˚ and 90˚ layers to the damage process are also investigated. The initiation of transverse and longitu- dinal cracking mechanisms is predicted. We also give an assessment of the influence of each individual component of the stress tensor on the strain energy release rate of the damaged laminate. Keywords: Composite Laminates, Matrix Cracking, Damage Mechanics, Failure Criterion 1. Introduction Composite laminates are used in structural applications thanks to their high strength to weight ratio; however, their durability still needs to be carefully assessed. For a composite cross-ply laminate subjected to uniaxial static or fatigue tensile loading, the first type of damage ob- served is usually transverse cracking. This damage causes an interlaminar stress concentration at the crack tips. On one hand high interlaminar stress levels may entail the debond ing of layers at the interface of the plies with different orientations and/or on the other they may also cause matrix cracking between fibres in the layers parallel to the loading axes. It is well known and experi- mentally observed that the stiffness of a composite structure is reduced by the growth of the transverse crack damage. Moreover, a composite structure damaged by incipient delamination or longitudinal cracking must be repaired. The main objective of this work is to study the initiation and evolution of transverse and longitudinal cracking damage. 1.1. Experiment Observations This study was prompted by experimental results re- ported in [1-3]. Under the loading conditions (monotonic and fatigue tests) the first damage mode is usually trans- verse cracking. Two notable stages are characteristic of this damage mod e: its initiation or occurrence of the first transverse crack called “first ply failure (FPF)” on one hand and the limiting state when no more transverse crack can be created, named “characteristic damage state (CDS)” on the other. Afterwards, it was observed that the nature of the second damage depends on the following parameters: the laminate geometry, for example the thicknesses of the 0˚ or 90˚ layers, the nature of the fi- bre/matrix constituents, the loading history and the manufacturing cycle. For instance, the authors of [1,2] observed the initiation and growth of delamination in a thick laminate. Ply separation is caused by the increase of interlanimar normal and shearing stresses, σzz and σxz respectively. In thin laminates, the damage mode succes- sion is different. Some authors [1,3] observed that the second damage mode, which follows transverse cracking, is longitudinal cracking. In this case, local delamination appears between 0˚ and 90˚ layers, near the crossing of longitudinal and transverse cracks, only when longitudi- nal cracks are widespread. In each case, the accumulation of the different damage modes causes fibre breaking in the 0˚ layers. All fibre breaks entail “splitting” which  Strain Energy Release Rate Analyse of Matrix Micro Cracking in Composite Cross-Ply Laminates 538 appears just before the ultimate failure of the laminate. 1.2. Damage Models For modelling the strain/stress relationship during dam- age growth, analytical and numerical approaches have been proposed. Several models describe the initiation of the first damage mode. They mainly rely on some stress field distribution and a relationship between loading and crack density is usually proposed. The simplest models, called “shear lag analyses” [4-6], usually involve ele- mentary assumptions regarding the displacement and stress distributions. Other models such as variational approaches, whose principles are explained in [7,8], use the principle of minimum complementary energy [9-12]. Other studies rely on the finite element method [13,14]. Alternative models are based on phenomenological ap- proaches [15,16], self-consistent analyses [17,18] or ap- proaches relying on specific aspects of the cracks pat- terns [19]. Hashin [20] analyses longitudinal and trans- verse cracking through a variational model, with a re- strictive hypothesis of constant trough-thickness normal stress distribution in each damaged layer. Binienda et al. [21], who propose a finite element approach, use an en- ergy criterion to analyze the influence of the material on the strain energy release rate. Longitudinal cracking is similar to transv erse cracking , but appears in the layers where fibres are parallel to the main loading direction, and longitudinal cracks are not always continuous [11,22]. For some laminates, longitu- dinal cracking does not occur before the end of life of the structure. In other laminates, longitudinal cracks can ap- pear before the ultimate failure of the laminate. The ob- served behaviour principally depends on the nature of the material constituents, th e layer stacking sequence and the type of loading. For these reasons, the investigation of longitudinal cracking is often ignored by many models. In the present approach, relying on experimental obser- vations, we suppose that the longitudinal cracks are con- tinuous and that they span the whole length of the studied specimen. 1.3. Failure Criterion In the literature, several approaches have been proposed to investigate the development of the different types of damage in cross-ply laminates and several kinds of crite- ria have been proposed [23], among them maximum stress based approaches. Other kinds of criteria [12,24,25] rely on the energy release rates associated with each type of damage. Our interest in damage mechanism evolution and succession lead us to bring out the respective contri- butions of the transverse or longitudinal damage mecha- nism development which can be found in the strain en- ergy release rate [26,27]. In this article, the strain energ y release rate is expressed through an appropriate semi- analytical model and decomposed into individual com- ponents related to damage mechanisms. Only the most significant components need to be retained to obtain a good approximation of the whole strain energy release rate. In contrast to the simplest models encountered in the literature, which only take into account the normal stress in the loading direction, the general model used here allows a thorough investigation of the strain energy release rate to be achieved. In the energetical model pro- posed in [27,28], the strain energy properties is investi- gated for laminates with arbitrary stacking sequence. The present study is restricted to damage growth in cross ply laminates. Here, we again use the decomposition of the strain energy of the whole laminate already proposed in [26]. This analysis relies upon some estimate of the role of each strain energy component in the initiation and propagation of a given damage mechanism, such as transverse cracking or longitudinal cracking. Thus each component of the stress tensor can be associated with one pair of damage mechanism. After numerous numerical simulations, it could be established that the influence of a given component of the stress field on some of the dam- age mechanisms can often be neglected [29]. In this arti- cle we use some further results to v alid ate this hypo th esis. The present study also gives a critical assessment of sev- eral simple cracking models; namely, the proposed ap- proach provides a justification for using the only normal stress in the loading direction in damage criteria. Con- cerning the initiation of transverse cracking, this kind of assumption gives good results. However, when the evo- lutions of transverse cracking or the transition to other types of damage are of interest, the simplest damage models cannot be used. In these cases, a more accurate description of the stress field is necessary. Besides inves- tigating transverse crack growth, the present paper aims at analyzing the influence of longitudinal cracking on strain energy release rate. All numerical simulations are performed for a thin 8-ply cross ply laminate. Balanced laminates correspond to a constraining parameter equal to 1 (λ = 1); rigid laminates are obtained for λ < 1; and soft laminates are in the range λ < 1. The computation of the strain energy release rate associated to the different damage types, transverse cracking, longitudinal cracking and delamination is developed in [26]. In the article [29], the proposed results concern the decomposition of the strain energy release rate of each layer of the laminate. In the article [29] we presented the strain en ergy release rate associated to the different types of damage associated with the three damage modes (mode I (opening mode), mode II (sliding mode) and mode III (tearing mode)). Copyright © 2011 SciRes. MSA  Strain Energy Release Rate Analyse of Matrix Micro Cracking in Composite Cross-Ply La minates Copyright © 2011 SciRes. MSA 539 1.4. Analyze of the Strain Energy Release Rate In the present article, we further develop the above analysis by first providing the numerical values of all parts of the decomposition of the strain energy release rate (part of each component of the stress tensor) associ- ated to each damage type (even those corresponding to parts of the strain energy which can be considered neg- ligible). This approach will help to explain the influence of each component of the stress tensor and one of its main outcomes is to help discussing classical assump- tions used in simplified stress based models; indeed simplified model can easily predict the initiation of transverse cracking damage, whereas is it necessary to used refined model to describe the transition between the different damage mode, to predict the behaviour of bal- anced laminates and the influence of the constraining parameter. 2. Model 2.1. Problem Position For all the computations performed, the studied specimen is in fact confined to a [0m, 90n]s, composite cross-ply laminate as represented in Figure 1. The parameters used to describe the laminate architecture are the λ coefficient (λ = t0/t90 where t 0 is the 0˚ ply thickness and t 90 is the 90˚ ply thickness) and the thicknesses of the 0˚ and 90˚ plies. For laminates subjected to monotonic loading, in the 0˚ layers fibre breaks can occur [25]. The loading history has no influence on the transverse crack density at the saturation level (CDS) [26]. After that, the longitu- dinal crack density still increases and delaminations form along the longitudinal cracks. With the proposed ap- proach by hypothesis, longitudinal cracks are taken con- tinuous. In the present study, only results pertaining to thin 8-ply cross-ply laminates are presented. The energy model used here gives good results for small stiffness laminates. However, although the proposed approach is successful for thin laminates, for thicker and more rigid laminates, the method gives approximate good results. Based on linear elastic fracture mechanics, the estimated values of the strain energy release rates are computed in a pre-damaged laminate, a method used in several dam- age models. Thus, there are already existing transverse and longitudinal cracks. Then, the progression of trans- verse cracking damage is described in the following way. We consider a laminate with a periodic array of trans- verse cracks in the inner 90˚ layer. Damage initiation occurs when the spacing between two consecutive cracks is very large (say, infinite). The relevance of this “infi- nite” value was numerically assessed with several models [24,30]. Using as a damage parameter the ratio of the distance between two consecutive cracks to the damaged thickness layer (90 aat ), the strain energy evolution associated with the propagation of the transverse crack damage can be estimated. In [12,24] the strain energy release rates associated with two related problems are compared: a single transverse crack across the specimen width and two consecutive transverse cracks which span the whole width of the laminate. The equivalence of the two problems was assessed. For studying longitudinal cracking with the continuous crack hypothesis, a similar method can be used. The longitudinal damage growth is estimated with a fixed value of the transverse crack den- sity, for numerical simulations. The laminate is sup posed to be “pre-cracked”. The initiation of the longitudinal damage is obtained for an infinite value of the damage parameter (ratio of the spacing between two consecutive Figure 1. Laminate damaged by transver se and longitudinal cracks.  Strain Energy Release Rate Analyse of Matrix Micro Cracking in Composite Cross-Ply Laminates 540 cracks to the central damaged layer thickness). The problem at hand is thus to compute the strain energy re- lease rate for a laminate which is supposed to be previ- ously damaged by transverse and longitudinal cracks, see Figure 1 for the whole cross-ply laminate. The accepted assumptions for the crack geometries in the two types of layers of the laminate are as follows. The cracks surfaces are supposed to have a rectangular plane geometry. Each crack extends over the whole thickness and the whole width of the 90˚ damaged ply. Similar assumptions are made for the longitud inal cracks in the two 0˚ layers. Moreover, the crack distribution is supposed to be unif orm along both x and y directions, i.e. for transverse cracks and for longitudinal cracks. With these assumptions, it is sufficient to study the only “unit damaged cell”. This “unit damaged cell” thus lies be- tween two consecutive transverse and longitudinal cracks. We give in [22] the summary of the method used to es- timate the stress field distribution in the cracked laminate. The proposed analytical model is based on a variational approach relying on the proper choice of a statically ad- missible stress field [22]. In the damaged laminate, the stress field in the two layers has the following form: 0Tkk Pk ijij ij (1) In the undamaged laminate loaded in the x direction, the layers experience a uniform plane stress state obtained by the laminate plate theory (where k is the ply index, k = 0˚, 90˚). The orthogonal cracks induce stress perturbations in the 0˚ and 90˚ layers which are denoted [22]. In the present approach, for the sake of simplicity, thermal stresses are not taken into account. 0k ij Tk ij 2.2. Strain Energy Release Rate As explained in the previous section, the laminate is supposed to be damaged by “pre-existing” transverse and longitudinal cracks. The size of the unit damaged cell depends on the transverse and longitudinal damage levels in the 90˚ and 0˚ layers. The strain energy release rate G associated with the initiation and development of intra ply cracking for a given stress state is defined by the fol- lowing expression: d, with ddd GUA UNMU A cel (2) where is the strain energy of the whole laminate d U and A is the cracked area. Let L1 denote the laminate length in the x direction and L2 its width in the y direction (Figure 1). The strain energy in the damaged unit cell is denoted by cel UN (190 2atNL ) is the number of transverse cracks and M (290 2 M Lbt) is the number of longitudinal cracks. Dimensionless quantities are defined by, 90 x xt , 90 yyt , 90 zzt, 90 hht, 90 aat , 90 bbt and the constraining parameter is 090 tt . The transverse crack density is defined by dt (dt = 1/2a) and the longitudinal crack density is d(d = 1/2b). The crack area is l l 121 A LL ab . We will now distinguish between the strain energy release rate associated with different damage mechanisms. The strain energy release rates associated with transverse and longitudinal cracking are denoted GFT and GFL respecti vely . The transverse (resp. longitudinal) cracking growth is characterized by the increase of the transv erse (resp . lon- gitudinal) crack surface initiated in the 90˚ (resp. 0˚) lay- ers. All details are given in [25]. Then: dd d ddd dd d dd d dd FT dd FL UU a G A aA UU b G A A b (3) whence 2 90 2 90 d 1 d 2 d 1 d 2 cel FT cel cel FL cel U GUa a bt U GUb b at (4) 2.3. Decomposition of the Strain Energy Release Rate The strain energy (2) is decomposed to display the contribution of each the stress product in the strain energy. The following quantities are related to the products in pairs of the components of the stress tensor, they are given by the expression (8): k ij U 90 090 0 12 90 12 90 22 2 ijij ijij ij ij LL UNMUU UU abt LL U abt (5) where: 22 2 2 2 22 0 90 00 0 0 0 12 00 000 022 2 yy zzyz xx xz LT TT ijxxyyzzyy zz V LT LTTTLT vv LL Uxyz EE EEGG abt ddd (6) Copyright © 2011 SciRes. MSA  Strain Energy Release Rate Analyse of Matrix Micro Cracking in Composite Cross-Ply La minates541 22 2 2 2 22 90 90 90 90 90 90 90 12 90909090 90 90 22 2 xx zz yy yz xz LT TT ij yyxxzzxx zz V LTLTTT LT vv LL Uxyz EE EEGG abt ddd (7) where V0 is the half volume of the 0˚ plies ( x a , y b, and 90 zt) and V90 is the half volume of the 90˚ plies ( x a, y b, and 0 tzh) in the unit cell. It can be remarked that in [26], cross-terms involv- ing Poisson’s ratios were not taken into account. We can deduce the 16 components by: k ij U 2 90 2 0 2 90 2 0 2 90 2 0 90 90 90 1 0 00 1 90 90 90 2 0 00 2 90 90 90 3 0 00 3 90 90 4, 1ddd 2 1ddd 2 1ddd 2 1ddd 2 1ddd 2 1ddd 2 xx xx V T xx xx V L yy yy V L yy yy V T zz zz V T zz zz V T xx yy UU xyz E UU xyz E U Uxyz E UU xyz E UU xyz E UU xyz E UU 90 0 90 0 90 90 90 00 00 4, 90 90 90 90 5, 00 00 5, 90 90 90 90 6, 00 6, ddd ddd ddd ddd ddd LT xx yy V L LT xx yyxxyy V L LT yy zzyyzz V L LT yy zzyyzz V L LT xx zzxxzz V L xx zz v x yz E v UU xyz E v UU xyz E v UU xyz E v U Uxyz E v UU 0 2 90 2 0 2 90 2 0 00 90 90 90 7 0 00 7 90 90 90 8 0 00 8 ddd 1ddd 2 1ddd 2 1ddd 2 1ddd 2 LT xx zz V L xz xz V TT xz xz V LT yz yz V LT yz yz V TT x yz E UU xyz G UU xyz G UU xyz G UU xyz G (8) The contribution of each selected component pair to the strain energy release rate is such that: d d k ij k ij U G x where i = x, y, z and k = 0˚, 90˚ (9) 2.4. Respective Influence of Each Layer of the Cross Ply Laminate The whole strain energy release rate of the damaged cross ply laminate can alternatively be decomposed into two parts. The first part represents the contribution to the strain e nergy of th e 0˚ layers on one h and and th e second one is the contribution of the 90˚ layer to the strain en- ergy release rate. 09 GG G 0 0 (10) Using the present approach, we now estimate the re- spective contribution of each damaged layer to the whole strain energy release rate. This unfamiliar procedure will help us to understand how damage evolves in cross ply laminates and clarify the domain of validity of some simplified approaches. We also applied this type of de- composition () to six other models [12,24] in order to predict the initiation of transverse matrix cracking in the central layer of a cross ply laminate. The present study allows assumptions used in several simplified models to be validated. Analytical models were used and a 3D finite element analysis was per- formed [24]. In some models, when strong hypothses are used to model the stress field distribution, the strain energy is only attributable to the normal stress in the damaged layer. Such models, which use simplified stress field distributions give good results for the initiation of the transverse cracking damage but they cannot describe the characteristic damage state (CDS). 09 GG G 3. Results The parameters involved in the present study are the constraining parameter, the thickness of the two 0˚ and 90˚ layers and the nature of the material constituent sys- tem. The constraining parameter is λ (λ = m/n), where n is the number of plies with 90˚ orientation and m is the number of plies with 0˚ orientation. Let us recall that the hypothesis of continuous longitudinal cracks is used and that the distributions of all transverse and longitudinal cracks are supposed to be uniform. In all the displayed results, the numerical simulations are carried out for a prescribed uni-axial loading of 150 MPa. Only one T300-914 graphite/epoxy material system is studied in the following numerical computations (see Table 1). In Copyright © 2011 SciRes. MSA  Strain Energy Release Rate Analyse of Matrix Micro Cracking in Composite Cross-Ply Laminates 542 Table 1. Mechanical properties and ply thickness of T300/ 914 graphite epoxy system. Graphite epoxy system T300/914 ELT (GPa) 140 ETT’ (GPa) 10 GLT (GPa) 5.7 GTT’ (GPa) 3.6 vLT 0.31 vTT’ 0.58 Ply thickness (mm) 0.125 Figures 2-4, the variation of the initiation of the strain energy release rates is presented as a function of the con- straining parameter λ for this graphite epoxy system. The variation of the strain energy release rates is similar for others materials systems not presented in this article. The only difference lies in the numerical values of the strain energy release rates. 3.1. Respective Contribution of Each Layer of the Cross Ply Laminate The first result concerns the respective contribution of each layer of the damage laminate to whole strain energy release rate. The numerical results are computed versus the constraining parameter λ (λ = m/n) with 8-ply cross-ply laminate. For studying damage initiation, we used “a” (90 aat) as a damage parameter with a very large numerical value. In [12], the computed results show that when parameter “a” is greater than 8, the strain en- ergy release rate associated with the initiation of trans- verse cracking remains stable. Selvarathinam et al. [31] use similar values suggested by experimental observa- tions. Thus, in the present paper, we use this a-value to predict damage initiation. In all the results displayed, the strain energy release rate GFT (evaluated from Equation (3)) associated with transverse crack damage has the most important value. For the 8 ply cross-ply laminate at hand, transverse cracking is thus the first observed dam age. We can also remark that the strain energy release rates, GFT or GFL (evaluated from Equations (3) and (4)) have similar variations with the constraining parameter λ. All the strain energy release rates are decreasing functions of parameter λ. For instance, in an 8-ply laminate, when the value of parameter λ is increased, the thickness of the 0˚ plies becomes greater. In this case, the fibers in the 0˚ plies carry most of the tensile loading and damage initia- tion is delayed. Although no experimental data are re- ported in Figures 2(a) and 2(b), the results of the nu- merical simulations confirm two main points: the pro- posed approach agrees with experimental data for the initiation of transverse cracking as the first damage mechanism. It also predicts the readiness to initiate other types of damage in the case of an 8 ply laminate con- taining a thick 90˚ layer. All results show that the main part of the strain energy release rate is provided from the 90˚ damaged layer. This result can explain that simplified models which only take into account the damaged 90˚ layer give correct results for damage initiation [26]. 3.2. Contribution of Each Individual Stress Component to the Strain Energy Release Rate The second result shows numerical simulations of the variation of partial strain energy release rates which rep- resent the contribution of each individual stress compo- nent to the whole strain energy release rate. The results provided by the different components are associated with transverse cracking in the 90˚ layer (Figure 3(a)), trans- verse cracking in the 0˚ layer (Figure 3(b)), longitudinal cracking in the 90˚ layer (Figure 4(a)) and longitudinal cracking in the 0˚ layer (Figure 4(b)). All the partial values of the strain energy release rates are presented as functions of the constraining parameter λ. All the results are made dimensionless by dividing by the value of the strain energy release rate GFT in the 90˚ layer or GFL in the 0˚ layer respectively. Concerning transverse damage, Figures 3(a) and 3(b) show the contribution of the normal stress in the loading direction. In both layers, this normal stress always has the most important value. In the 90˚ layer, the contribu- tion of this normal stress is practically constant and is about 60% of total GFT. The rest is shared between the contribution of the shearing component (σxz) and that of the normal stress (σzz) in the direction normal to the thickness of the laminate. For λ-values less than unity, the influence of the shear stress is the most important and for other λ-values, the normal stress contribution prevails. All the other contributions (evaluated from Equation (8)) are practically zero. Concerning the 0˚ layers, only the normal stress (σxx) and the shear stress (σxz) have a nota- ble influence; the others stress components have no in- fluence. For longitudinal damage, Figures 4(a) and 4(b) show different results. In the 90˚ layer, for λ-values less than 2, the main contribution is due to the normal stress in the thickness direction (σzz). For other λ-values, the contribu- tion of (σyy) becomes the most important. One can notice that the shear component (σyz) always has a small non-zero contribution. All the other stress components have no influence. In the 0˚ layer, the main influence is that of the (σyy) component and it is a decreasing function of the constraining parameter λ. We can also notice some Copyright © 2011 SciRes. MSA  Strain Energy Release Rate Analyse of Matrix Micro Cracking in Composite Cross-Ply La minates Copyright © 2011 SciRes. MSA 543 (a) (b) Figure 2. Respective contribution of 0˚ and 90˚ layers to the strain energy release rate as functions of constraining parameter λ. (a) Transverse crack ( 090 F TFTF GGG T 0 ); (b) Longitudinal crack ( 09 F LFLF GGG L ). (a) (b) Figure 3. Variation of the portion of the strain energy release rate responsible for transverse cracking in the 90˚ layer (a) and in the 0˚ layer (b) with constraining parameter λ. (a) (b) Figure 4. Variation of the portion of the strain energy release rate responsible for longitudinal cracking in the 90˚ layer (a) and in the 0˚ layer (b) with constraining parameter λ.  Strain Energy Release Rate Analyse of Matrix Micro Cracking in Composite Cross-Ply Laminates 544 contributio n of the shear component (σyz). These numeri- cal simulations leads us to a partial conclusion: when studying the development of transverse and longitudinal cracking, the contribution of the 90˚ layers stems from the normal stresses (σxx), (σyy), (σzz) and the shear stress (σxz), whereas the contribution of the 0˚ layers stems from the normal stresses (σyy), (σzz) and the shear stress (σyz). 3.3. Transverse and Longitudinal Cracking Initiation and Evolution The third result (Figure 5) shows the variation of the GFT and GFL strain energy release rates. The strain energy release rate is plotted versus crack density (cm–1) for two carbon epoxy 8-ply laminates; results are given for [02, 902]s and [0, 903]s laminates. Both laminates exhibit similar variations with the crack density. Laminate [0, 903]s which has a thick 90˚ layer, gives the most important GFT value. This is in good agreement with experimental results, which show that it is easier to initiate a crack in a compliant laminate. Using the above re sult, one can study the variation of the strain energy release rates GFT or GFL associated with the mul- tiplication of transverse cracks or the initiation of the longitudinal cracking respectively, with the transverse crack density. The critical transverse crack density cor- responding to the crack initiation in the 0˚ layer is ob- tained at the intersection of the GFT and the GFL curves (if the Gc of the transverse and longitudinal cracking value are equal). This is confirmed by experimental results and previous numerical results relying on the analyse of the strain energy release rate. For the two laminates investi- gated, the curves generally intersect for a transverse crack density equal to 15 cm–1. At this stage of the trans- verse damage, longitudinal cracking appears. 4. Conclusions The laminate at hand is supposed to be “pre-damaged” by transverse and longitudinal cracks to investigate the initiation and development of transverse and longitudinal cracking. Simplifying assumptions on the crack geometry, crack distribution and continuous longitudinal cracks are used. The respective contributions of the 0˚ and 90˚ plies to the longitudinal crack damage are computed. Another investigation displays the contributions of the different components of the stress tensor. It is shown that, for properly describing the longitudinal cracking process, a refined computation of all the normal stresses and the inclusion of some shear stress components are necessary. Only one material system is studied. For other materials, similar variations of the strain energy release rate G would be obtained, with different numerical values. The G-values are presented as functions of the constraining parameter λ. Distinguishing between the strain energy Figure 5. Partial strain energy release rates GFT and GFL versus transverse crack density for two [02, 902]s and [0, 903]s laminates. release rate in the 90˚ and 0˚ layers allows to show that for small λ-values, it is easier to initiate damage. The curves displayed confirm that transverse cracking first occurs in the 90˚ layers. The results obtained for the contribution of each component of the stress tensor show that only 5 terms pertaining to the 3 normal stresses and 2 shearing stresses have to be estimated, and that it is not necessary to take into account the cross-terms involving Poisson’s ratios. These results give an interpretation of Figure 5 for inves- tigating the initiation of longitudinal cracks. REFERENCES [1] E. Urwald, “Influence de la Géométrie et de la Stratifica- tion sur l’Endommagement par fatigue de Plaques Com- posites Carbone/Époxyde,” Ph.D. Thesis, Université de Poitiers, Poitiers, 1992. [2] A. S. D. Wang and F. W. Crossman, “Initiation and Growth of Transverse Cracks and Edge Delamination in Composite Laminates. Part I: An Energy Method,’’ Jour- nal of Composite Materials, Vol. 14, No. 1, 1980, pp. 71-87. doi:10.1177/002199838001400106 [3] R.-D. Jamison, K. Schulte, K.-L. Reifsnider and W.-W. Stinchcomb, “Characterization and Analysis of Damage Mechanisms in Tension-Tension Fatigue of Graph- ite/Epoxy Laminates,” American Society for Testing and Materials, ASTM STP 836, 1984, pp. 21-55. [4] P. S. Steif, “Parabolic Shear-Lag Analyses of a [0/90]s Laminate,” In: S. L. Ogin, P. A. Smith and P. W. R. Beaumont Eds., Transverse Crack Growth and Associ- ated Stiffness Reduction during the Fatigue of a Simple Cross-Ply Laminate, Cambridge University, London, 1984, pp. 40-41. [5] N. Law and G. J. Dvorak, “Progressive Transverse Cracking in Composite Laminates,” Journal of Composite Materials, Vol. 22, 1988, pp. 900-916. Copyright © 2011 SciRes. MSA  Strain Energy Release Rate Analyse of Matrix Micro Cracking in Composite Cross-Ply La minates545 [6] S. G. Lim and C. S. Hong, “Effect of Transverse Cracks on the Thermomechanical Properties of Cross-Ply Lami- nated Composites,” Composites Science and Technology, Vol. 34, No. 2, 1989, pp. 145-162. doi:10.1016/0266-3538(89)90102-4 [7] E. Reissner, “On a Variational Theorem in Elasticity,” Journal of Mathematical Physics, Vol. 29, No. 2, 1950, pp. 90-95. [8] J. Lemaître and J.-L. Chaboche, “Mechanics of Solid Ma- terials,” Cambridge University Press, Cambridge, 1994. [9] V. V. Vasil’ev and A. A. Duchenco, “Analysis of the Tensile Deformation of Glass-Reinforced Plastics,” Me- chanics of Composite Materials, Vol. 6, No. 1, 1970, pp. 127-130. doi:10.1007/BF00860460 [10] Z. Hashin, “Analysis of Cracked Laminates: A Varia- tional Approach,” Mechanics of Materials, Vol. 4, No. 2, 1985, pp. 121-136. doi:10.1016/0167-6636(85)90011-0 [11] J. A. Nairn, “The Strain Energy Release Rate of Compos- ite Micro Cracking: A Variational Approach,” Journal of Composite Materials, Vol. 23, No. 11, 1989, pp. 1106- 1129. doi:10.1177/002199838902301102 [12] J.-L. Rebière, “Modélisation du Champ des Contraintes Créé par des Fissures de Fatigue dans un Composite Stratifié Carbone/Polymère,” Ph.D. dissertation, Univer- sité de Poitiers, Poitiers, 1992. [13] C. T. Herakovich, J. Aboudi, S. W. Lee and E. A. Strauss, “Damage in Composite Laminates: Effects of Transverse Cracks,” Mechanics of Materials, Vol. 7, No. 2, 1988, pp. 91-107. doi:10.1016/0167-6636(88)90008-7 [14] D. Gamby, C. Henaff-Gardin and J.-L. Rebière, “Model- ling of the Damage Distribution along the Width of a Composite Laminate Subjected to a Tensile Fatigue Test,” 2nd International Conference on Computer Aided Assessment and Control, Localized Damage II, South- ampton, 1-3 July 1992, pp. 315-325. [15] D. H. Allen, S. E. Groves and C. E. Harris, “A Ther- momechanical Constitutive Theory for Elastic Compos- ites with Distributed Damage. Part I: Theoretical Devel- opment,” Mechanics and Materials Center, Texas A & M University, Report MM-5023-85-17, 1985. [16] O. Allix, P. Ladevèze and E. Le Dantec, “Modélisation de l’Endommagement d’un Pli Élémentaire des Composites Stratifiés,” Proceedings of 7th Journées Nationales des Composites, Paris, November 1990, pp.715-724. [17] S. Adali and R. K. Markins, “Effect of Transverse Matrix Cracks on the Frequencies of Unsymmetrical, Cross-Ply Laminates,” Journal of the Franklin Institute, Vol. 329, No. 4, 1992, pp. 655-665. doi:10.1016/0016-0032(92)90078-U [18] J. R. Yeh, “The Mechanics of Multiple Transverse Crack- ing in Composite Laminates,” International Journal of Solids and Structures, Vol. 25, No. 12, 1989, pp. 1445- 1455.doi:10.1016/0020-7683(89)90111-X [19] A. K. Kaw and G. H. Besterfield, “Mechanics of Multiple Periodic Brittle Matrix Cracks in Unidirectional Fi- ber-Reinforced Composites,” International Journal of Solids and Structures, Vol. 29, No. 10, 1992, pp. 1193-1207. doi:10.1016/0020-7683(92)90231-H [20] Z. Hashin, “Analysis of Orthogonally Cracked Laminates under Tension,” Journal of Applied Mechanics, Vol. 54, No. 4, 1987, pp. 872-879. doi:10.1115/1.3173131 [21] W. K. Binienda, A. Hong and G. D. Roberts, “Influence of Material Parameters on Strain Energy Release Rates for Cross-Ply Laminate with Pre-Existing Transverse Crack,” Composites Engineering, Vol. 4, No. 12, 1994, pp. 1167- 1210. doi:10.1016/0961-9526(95)91390-3 [22] J.-L. Rebière, M.-N. Maâtallah and D. Gamby, “Initiation and Growth of Transverse and Longitudinal Cracks in Composite Cross-Ply Laminates,” Composite Structures, Vol. 53, No. 2, 2001, pp. 173-187. doi:10.1016/S0263-8223(01)00002-2 [23] N.-V. Akshantala and R. Talreja, “A Micromechanics Based Model for Predicting Fatigue Life of Composite Laminate,” Materials Science and Engineering A, Vol. 285, No. 1-2, 2000, pp. 303-313. doi:10.1016/S0921-5093(00)00679-1 [24] D. Gamby, J. Martins, S. Maison and J.-L. Rebière, “In- fluence du Confinement sur le Taux de restitution d’Énergie Associé à la Fissuration Transverse d’un Strati- fié. Comparaison de Deux Simulations Numériques,” Proceedings of 7th Journées Nationales des Composites, Lyon, November 1990, pp. 609-617. [25] J.-L. Rebière, M.-N. Maâtallah and D. Gamby, “Analy sis of Damage Mode Transition in a Cross-Ply Laminate un- der Uniaxial Loading,” Composite Structures, Vol. 55, No. 2, 2002, pp. 115-126. [26] J.-L. Rebière and D. Gamby, “A Criterion for Modelling Initiation and Propagation of Matrix Cracking and De- lamination in Cross-Ply Laminates,” Composites Science and Technology, Vol. 64, No. 13-14, 2004, pp. 2239-2250. doi:10.1016/j.compscitech.2004.03.008 [27] L. N. McCartney, “Energy-Based Prediction of Progres- sive Ply Cracking and Strength of General Symmetric Laminates Using an Homogenisation Method,” Compos- ites Part A, Vol. 36, No. 2, 2005, pp. 119-128. [28] E. J. Barbero and D. H. Cortes, “A Mechanistic Model for Transverse Damage Initiation, Evolution, and Stiffness Reduction in Laminated Composites,” Composites Part B, Vol. 41, No. 2, 2010, pp. 124-132. doi:10.1016/j.compositesb.2009.10.001 [29] J.-L. Rebière and D. Gamby, “A Decomposition of the Strain Energy Release Rate Associated with the Initiation of Transverse Cracking, Longitudinal Cracking and de- lamination in Cross-Ply Laminates,” Composite Struc- tures, Vol. 84, No. 2, 2008, pp. 186-197. doi:10.1016/j.compstruct.2007.12.004 [30] K. L. Reifnider and R. D. Jamison, “Fracture of Fa- tigue-Loaded Composite Laminates,” International Jour- nal of Fatigue, Vol. 4, No. 4, 1982, pp. 187-197. doi:10.1016/0142-1123(82)90001-9 [31] A. S. Selvarathinam and Y. J. Weistman, “A Shear Lag Analysis of Transverse Cracking and Delamination in Cross-Ply Carbon-Fibre/Epoxy Composites under Dry, Saturated and Immersed Fatigue Conditions,” Composites Copyright © 2011 SciRes. MSA  Strain Energy Release Rate Analyse of Matrix Micro Cracking in Composite Cross-Ply Laminates Copyright © 2011 SciRes. MSA 546 Science and Technology, Vol. 59, No. 14, 1999, pp. 2115-2123. doi:10.1016/S0266-3538(99)00069-X |