128 Effect of Ultrasound and Xylanase Treatment on the Physical-Mechanical Properties of Bleached Eucalyptus Kraft Pulp

ity of the paper.

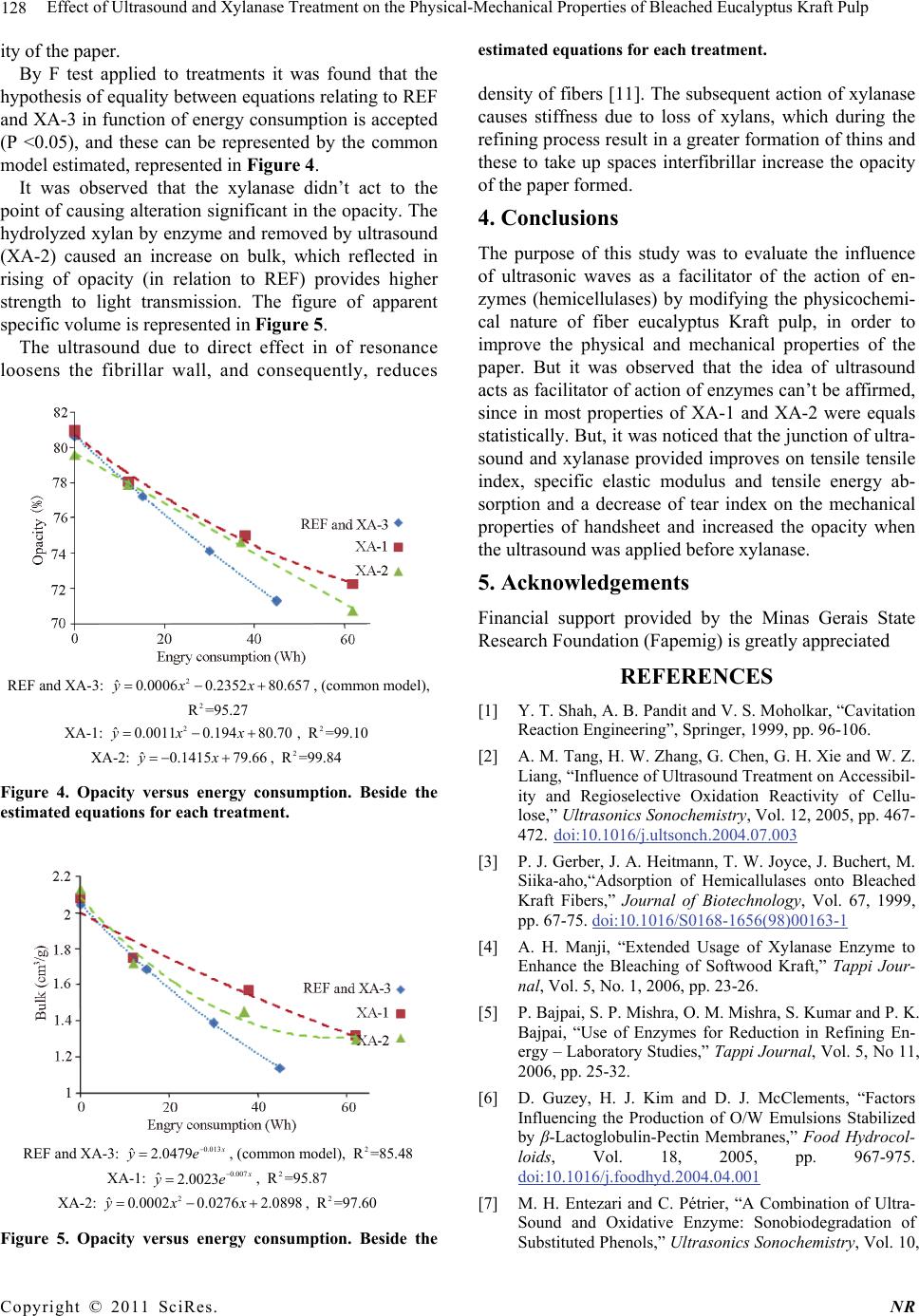

By F test applied to treatments it was found that the

hypothesis of equality between equations relating to REF

and XA-3 in function of energy consumption is accepted

(P <0.05), and these can be represented by the common

model estimated, represented in Figure 4.

It was observed that the xylanase didn’t act to the

point of causing alteration significant in the opacity. The

hydrolyzed xylan by enzyme and removed by ultrasound

(XA-2) caused an increase on bulk, which reflected in

rising of opacity (in relation to REF) provides higher

strength to light transmission. The figure of apparent

specific volume is represented in Figure 5.

The ultrasound due to direct effect in of resonance

loosens the fibrillar wall, and consequently, reduces

Figure 4. Opacity versus energy consumption. Beside the

estimated equations for each treatment.

Figure 5. Opacity versus energy consumption. Beside the

estimated equations for each treatment.

density of fibers [11]. The subsequent action of xylanase

causes stiffness due to loss of xylans, which during the

refining process result in a greater formation of thins and

these to take up spaces interfibrillar increase the opacity

of the paper formed.

4. Conclusions

The purpose of this study was to evaluate the influence

of ultrasonic waves as a facilitator of the action of en-

zymes (hemicellulases) by modifying the physicochemi-

cal nature of fiber eucalyptus Kraft pulp, in order to

improve the physical and mechanical properties of the

paper. But it was observed that the idea of ultrasound

acts as facilitator of action of enzymes can’t be affirmed,

since in most properties of XA-1 and XA-2 were equals

statistically. But, it was noticed that the junction of ultra-

sound and xylanase provided improves on tensile tensile

index, specific elastic modulus and tensile energy ab-

sorption and a decrease of tear index on the mechanical

properties of handsheet and increased the opacity when

the ultrasound was applied before xylanase.

REF and XA-3: , (common model),

2

ˆ0.00060.2352 80.657yx x

2

R =95.27

XA-1: ,

2

ˆ0.00110.19480.70yxx 2

R =99.10

XA-2: ,

ˆ0.141579.66yx 2

R =99.84

5. Acknowledgements

Financial support provided by the Minas Gerais State

Research Foundation (Fapemig) is greatly appreciated

REFERENCES

[1] Y. T. Shah, A. B. Pandit and V. S. Moholkar, “Cavitation

Reaction Engineering”, Springer, 1999, pp. 96-106.

[2] A. M. Tang, H. W. Zhang, G. Chen, G. H. Xie and W. Z.

Liang, “Influence of Ultrasound Treatment on Accessibil-

ity and Regioselective Oxidation Reactivity of Cellu-

lose,” Ultrasonics Sonochemistry, Vol. 12, 2005, pp. 467-

472. doi:10.1016/j.ultsonch.2004.07.003

[3] P. J. Gerber, J. A. Heitmann, T. W. Joyce, J. Buchert, M.

Siika-aho,“Adsorption of Hemicallulases onto Bleached

Kraft Fibers,” Journal of Biotechnology, Vol. 67, 1999,

pp. 67-75. doi:10.1016/S0168-1656(98)00163-1

REF and XA-3: 0.013

ˆ2.0479

ye

, (common model),

2

R=85.48

XA-1: 0.007

ˆ2.0023

ye

2

,

2

R =95.87

2

XA-2: ,

ˆ0.00020.0276 2.0898yxx

R =97.60

[4] A. H. Manji, “Extended Usage of Xylanase Enzyme to

Enhance the Bleaching of Softwood Kraft,” Tappi Jour-

nal, Vol. 5, No. 1, 2006, pp. 23-26.

[5] P. Bajpai, S. P. Mishra, O. M. Mishra, S. Kumar and P. K.

Bajpai, “Use of Enzymes for Reduction in Refining En-

ergy – Laboratory Studies,” Tappi Journal, Vol. 5, No 11,

2006, pp. 25-32.

[6] D. Guzey, H. J. Kim and D. J. McClements, “Factors

Influencing the Production of O/W Emulsions Stabilized

by β-Lactoglobulin-Pectin Membranes,” Food Hydrocol-

loids, Vol. 18, 2005, pp. 967-975.

doi:10.1016/j.foodhyd.2004.04.001

[7] M. H. Entezari and C. Pétrier, “A Combination of Ultra-

Sound and Oxidative Enzyme: Sonobiodegradation of

Substituted Phenols,” Ultrasonics Sonochemistry, Vol. 10,

Copyright © 2011 SciRes. NR