Treatment and Recycling of Wastewater by Submerged Hollow Fiber Membrane

Copyright © 2011 SciRes. NR

74

[5] X. C. Wang and J. Wang, “Kinetic Study of Membrane

Fouling under Cross-Flow Ultrafiltration Opteration,”

Environmental Chemistry, Vol. 21, No. 6, 2002, pp.

552-558.

[6] G. E. Wetterau, M. M. Clark and C. Anselme, “A dynamic

model for predicting fouling effects during the ultrafiltra-

tion of a groundwater,” Journal of Membrane Science,

Vol. 109, No. 2, 1996, pp. 185-204.

doi:10.1016/0376-7388(95)00200-6

[7] M. Cheryan, “Ultrafiltration Handbook,” Technomic,

Lancaster, 1986.

[8] S. Kunikane, Y. Magara, M. Itoh and O. Tanaka, “A

Comparative Study on the Application of Membrane

Technology to the Public Water Supply,” Journal of

membrane science, Vol. 102, 1995, pp. 149-154.

doi:10.1016/0376-7388(94)00292-7

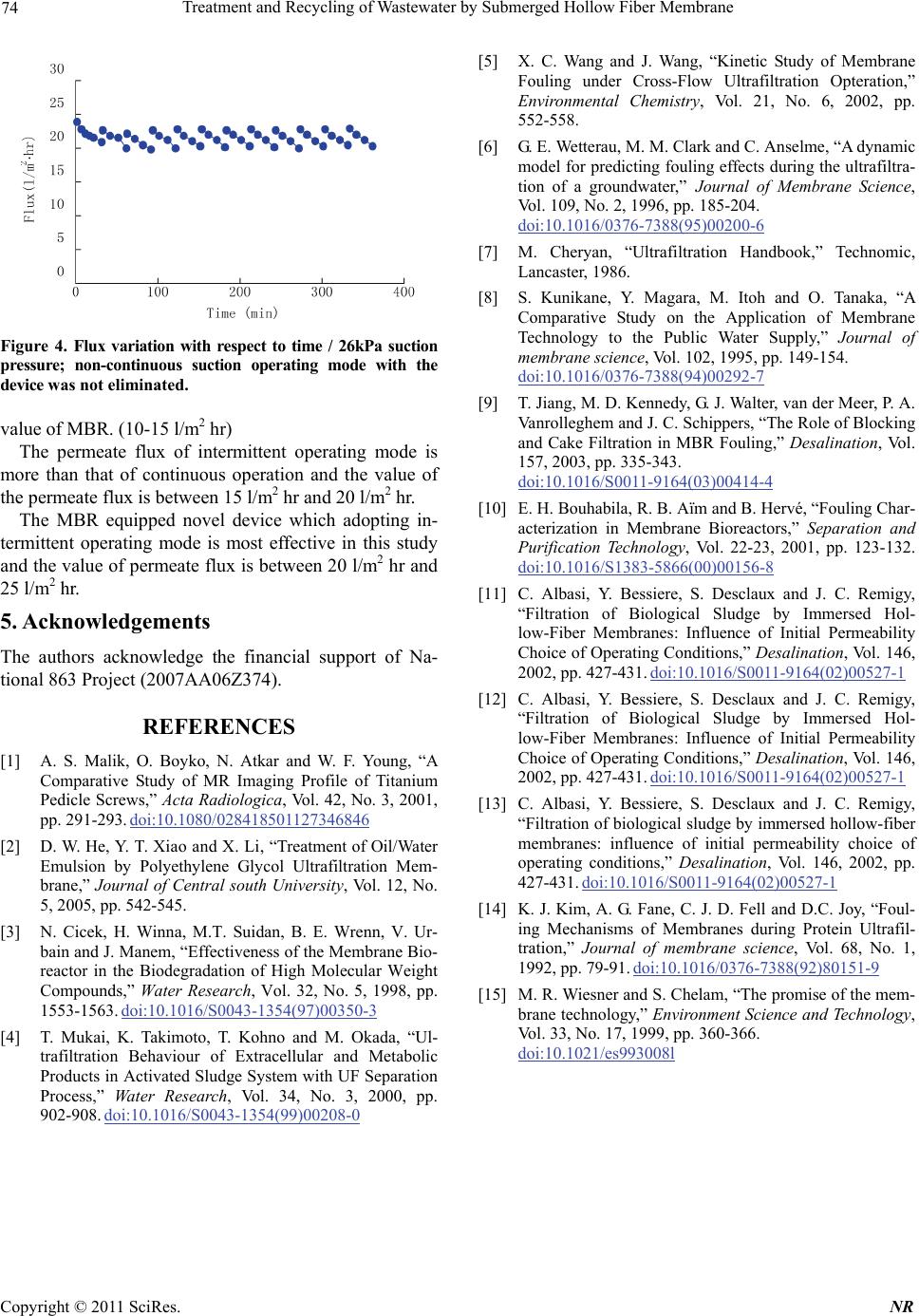

Figure 4. Flux variation with respect to time / 26kPa suction

pressure; non-continuous suction operating mode with the

device was not eliminated.

[9] T. Jiang, M. D. Kennedy, G. J. Walter, van der Meer, P. A.

Vanrolleghem and J. C. Schippers, “The Role of Blocking

and Cake Filtration in MBR Fouling,” Desalination, Vol.

157, 2003, pp. 335-343.

doi:10.1016/S0011-9164(03)00414-4

value of MBR. (10-15 l/m2 hr)

The permeate flux of intermittent operating mode is

more than that of continuous operation and the value of

the permeate flux is between 15 l/m2 hr and 20 l/m2 hr. [10] E. H. Bouhabila, R. B. Aïm and B. Hervé, “Fouling Char-

acterization in Membrane Bioreactors,” Separation and

Purification Technology, Vol. 22-23, 2001, pp. 123-132.

doi:10.1016/S1383-5866(00)00156-8

The MBR equipped novel device which adopting in-

termittent operating mode is most effective in this study

and the value of permeate flux is between 20 l/m2 hr and

25 l/m2 hr. [11] C. Albasi, Y. Bessiere, S. Desclaux and J. C. Remigy,

“Filtration of Biological Sludge by Immersed Hol-

low-Fiber Membranes: Influence of Initial Permeability

Choice of Operating Conditions,” Desalination, Vol. 146,

2002, pp. 427-431. doi:10.1016/S0011-9164(02)00527-1

5. Acknowledgements

The authors acknowledge the financial support of Na-

tional 863 Project (2007AA06Z374).

[12] C. Albasi, Y. Bessiere, S. Desclaux and J. C. Remigy,

“Filtration of Biological Sludge by Immersed Hol-

low-Fiber Membranes: Influence of Initial Permeability

Choice of Operating Conditions,” Desalination, Vol. 146,

2002, pp. 427-431. doi:10.1016/S0011-9164(02)00527-1

REFERENCES

[1] A. S. Malik, O. Boyko, N. Atkar and W. F. Young, “A

Comparative Study of MR Imaging Profile of Titanium

Pedicle Screws,” Acta Radiologica, Vol. 42, No. 3, 2001,

pp. 291-293. doi:10.1080/028418501127346846

[13] C. Albasi, Y. Bessiere, S. Desclaux and J. C. Remigy,

“Filtration of biological sludge by immersed hollow-fiber

membranes: influence of initial permeability choice of

operating conditions,” Desalination, Vol. 146, 2002, pp.

427-431. doi:10.1016/S0011-9164(02)00527-1

[2] D. W. He, Y. T. Xiao and X. Li, “Treatment of Oil/Water

Emulsion by Polyethylene Glycol Ultrafiltration Mem-

brane,” Journal of Central south University, Vol. 12, No.

5, 2005, pp. 542-545. [14] K. J. Kim, A. G. Fane, C. J. D. Fell and D.C. Joy, “Foul-

ing Mechanisms of Membranes during Protein Ultrafil-

tration,” Journal of membrane science, Vol. 68, No. 1,

1992, pp. 79-91. doi:10.1016/0376-7388(92)80151-9

[3] N

. Cicek, H. Winna, M.T. Suidan, B. E. Wrenn, V. Ur-

bain and J. Manem, “Effectiveness of the Membrane Bio-

reactor in the Biodegradation of High Molecular Weight

Compounds,” Water Research, Vol. 32, No. 5, 1998, pp.

1553-1563. doi:10.1016/S0043-1354(97)00350-3

[15] M. R. Wiesner and S. Chelam, “The promise of the mem-

brane technology,” Environment Science and Technology,

Vol. 33, No. 17, 1999, pp. 360-366.

doi:10.1021/es993008l

[4] T. Mukai, K. Takimoto, T. Kohno and M. Okada, “Ul-

trafiltration Behaviour of Extracellular and Metabolic

Products in Activated Sludge System with UF Separation

Process,” Water Research, Vol. 34, No. 3, 2000, pp.

902-908. doi:10.1016/S0043-1354(99)00208-0