Paper Menu >>

Journal Menu >>

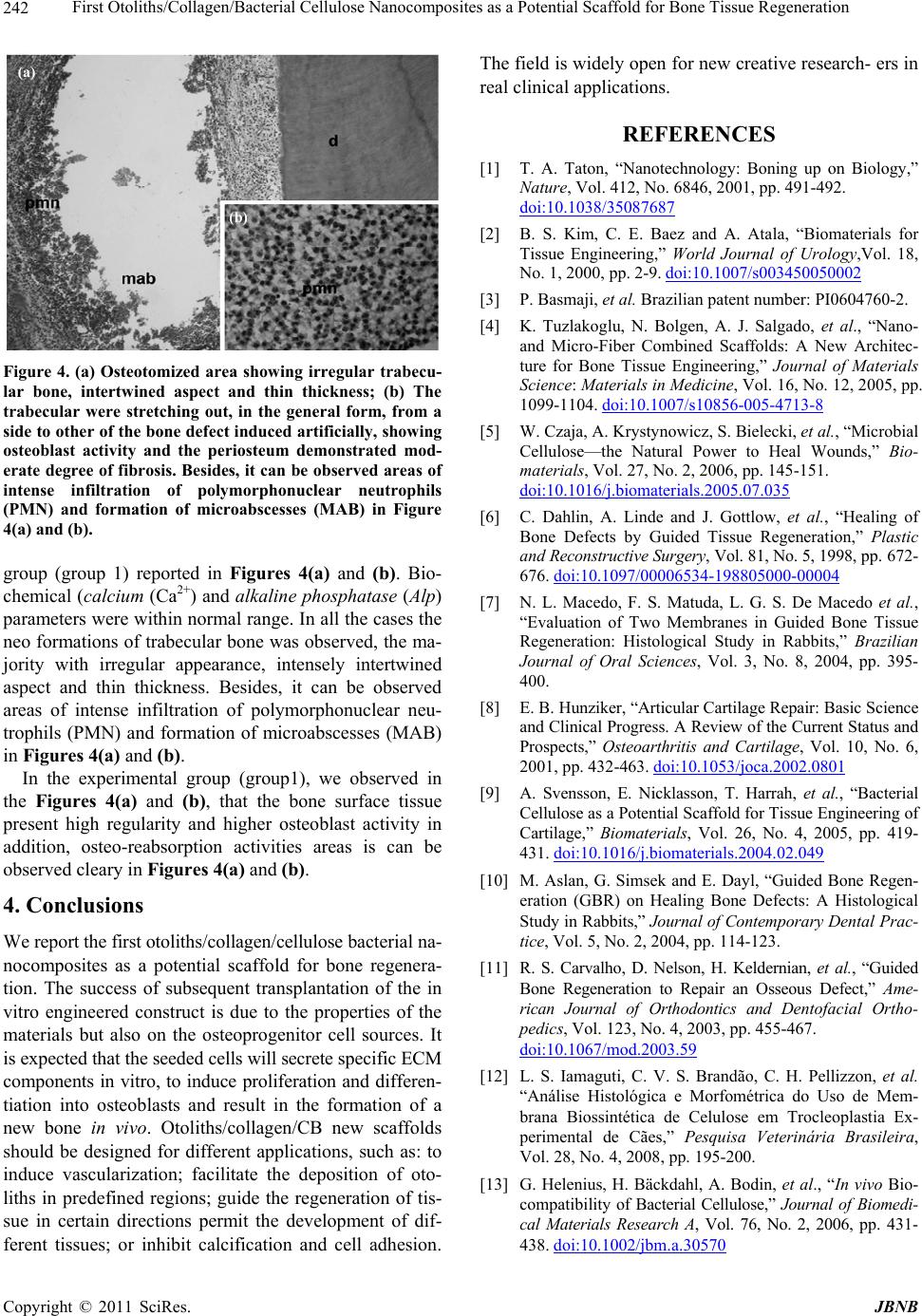

Journal of Biomaterials and Nanobiotechnology, 2011, 2, 239-243 doi:10.4236/jbnb.2011.23030 Published Online July 2011 (http://www.SciRP.org/journal/jbnb) Copyright © 2011 SciRes. JBNB 239 First Otoliths/Collagen/Bacterial Cellulose Nanocomposites as a Potential Scaffold for Bone Tissue Regeneration Gabriel Molina de Olyveira1, Daisy Pereira Valido3, Ligia Maria Manzine Costa1, Plácia Barreto Prata Gois3, Lauro Xavier Filho3, Pierre Basmaji2 1Department of Nanoscience and Advanced Materials, Federal University of ABC, Santo André, Brazil; 2Innovatec’s-Biotechnology Research and Development, São Carlos, Brazil; 3Natural Products Laboratory and Biotechnology, UNIT, Aracaju, Brazil. Email: gmolyveira@yahoo.com.br Received March 11th, 2011; revised May 4th 2011; accepted May 15th, 2011. ABSTRACT In the present work, we report the first bionanocomposite ma terial formed b y otolith s/ collag en/ bacterial cellu lose (BC) networks (OCBC). This biomaterial is an osteoinductor or be, stimulates the bone regeneration, enabling b igg er mi gra- tion of the cells for fo rm ation o f the bon e tissu e regen eration main ly b ecaus e nanoto lith are rich in m inerals considered essential to the bone mineralization process on a protein matrix (otolin). The objective in this study was to analyze the regeneration capacity of bone defects treated with this bionanocomposite. Histological experiments shows bone tissue formation with high regularity, higher osteoblast activity and osteo-reabsorption activities areas. The results suggest the potential for this new biomaterial as a scaffold for bone tissue regeneration. Keywords: Bacterial Cellulose, Natural Composites, Bionanocomposit es , Tissue Engineering, Bone T i ss u e Regenerat i on 1. Introduction Despite many advances in tissue engineering (TE), scien- tists still face significant challenges in repairing or re- placing soft tissues such as tendons, ligaments, skin, liver, nerve and cartilage to improve the quality of people life. Conventional therapeutic treatments targeted to recon- struct the injured tissues or organs have some limitations such as donor limitations and graft rejections [1]. To meet all the necessary requirements for the success of these approaches, the choice of polymer, design of the matrices and knowledge of the factors affecting cell/tissue-material interactions should be investigated. The ideal scaffold also requires a desirable mechanical rigidity and a porous 3D structure which can provide ma- ximum integration with cells and body fluids, plus have a nanostructure surface which facilitates the adhesion of cells [1]. In tissue engineering, matrices are developed to support cells, promoting their differentiation and prolif- eration towards the formation of a new tissue. Such strategies allow for producing hybrid constructs that can be implanted in patients to induce the regeneration of ti- ssues or replace failing or malfunctioning organs. Natural based polymers offer the advantage of being similar to biological macromolecules, which the biologi- cal environment is prepared to recognize and deal with metabolically. Owing to their similarity with the extracel- lular matrix (ECM), natural polymers may also avoid the stimulation of chronic inflammation or immunological reactions and toxicity, often detected with synthetic po- lymers [2]. Bacterial cellulose (BC) has established to be a remarkably versatile biomaterial and can be used in wide variety of applied scientific endeavours. Due to its unique nanostructure and properties, microbial cellulose is a natural candidate for numerous medical and tissue- engineered applications. Moreover, the nanostructure and morphological similarities with collagen make BC attrac- tive for cell immobilization and cell support [3-5]. The application of physical barriers in order to regen- erate bone defects was first described by Dahlin et al. [6] The involvement of repair by fibrous union occurs in the bone defect, invasion of fibroblasts in the blood clot. For this to be avoided, one can resort to surgical techniques that prevent the blood clot and/or bone lesion are popu- lated by undesirable cells by application of physical bar- riers or membranes, thereby facilitating the migration of cells with osteogenic potential. Thus, it is prevented that  First Otoliths/Collagen/Bacterial Cellulose Nanocomposites as a Potential Scaffold for Bone Tissue Regeneration Copyright © 2011 SciRes. JBNB 240 the fibroblasts to colonize the clo t before the osteoblasts, which, being more specialized, are slower in its function. [7] Some in vitro studies have been conducted to verify the performance of membranes in the cartilage tissue as flattering to the migration of chondrogenic cells, as oc- curs in bone tissue [8,9]. Biosynthetic membranes show good acceptance by the body, protecting and aiding the repair of damaged areas by selective permeability, and prevent contamination by microorganisms [10,11]. The biosynthetic membrane based on cellulose was used in experiments in dogs trochleoplasty, not interfering in biomechanics and even in the intra-articular [12]. More- over, it accelerated the initial repair of the trochleoplasty area, showing good integration of newly formed tissue with the adjacent cartilage. However, as a single part, is not effective to promote complete regeneration of articu- lar cartilage [12]. According to Helenius et al. [13], the cellulose membrane obtained from bacteria has good compatibility and has promising potential for use in tis- sue engineering. The mimicking of ECM by using natural origin mate- rials has been further attempted using complementary approaches too, in order to improve the performance of these materials. A nano- and microfiber combined starch-based scaffold [14] showed that its unique archi- tecture, being able to support and guide cells, can also provide an ideal structure for cell deposition and organi- zation to be used to bone tissue engineering. Grande et al. [15] fabricated BC-Hap nanocomposites to bone tissue regeneration by the formation of cellulose nanofibrils in the presence of a mineral phase in a static culture. In or- der to suspend Hap nanoparticles, bacteria culture me- dium were modified with carboxymethylcellulose (CMC). In vitro biocompatibility and v iability was assessed using HEK cells. The pore size and fibre diameter of BC net- works are influenced by the water extraction method. Studies reported by Bhattarai et al. [16] and Yang et al. [17] indicate that the pore size and fibre diameter of scaffolds influence the cell growth. In this work, we report a new bionanocomposite mate- rial formed by otoliths/collagen/bacterial cellulose (BC) networks (OCBC). The biomaterial (OCBC) is consti- tuted of some elements constituents of the bones, as col- lagen (protein) and nano-otoliths, beyond the membrane of bacterial cellulose. Collagen is regarded by many as an ideal scaffold or matrix for tissue engineering as it is the major protein component of the extracellular matrix, providing support to connective tissues such as skin, tendons, bones, cartilage, blood vessels, and ligaments [18,19]. In its native environment, co llagen interacts with cells in connective tissues and transduces essential sig- nals for the regulation of cell anchorage, migration, pro- liferation, differentiation, and survival [19,20]. Collagen scaffolds, due to their fast degradation , do not allow iso- morphous replacement with a newly formed bone. Pre- sumably, due to the stable macro porous structure and slow degradation, the progression and extent of osteo- genesis were markedly and significantly higher for silk and RGD–silk scaffolds when compared with collagen scaffolds [20]. Then, BC is our option to be a substrate with collagen and nano-otholits. Nano-otholits is an osteoinductor or be, stimulates the bone regeneration, enabling bigger migration of the cells for formation of the bone tissue. Otoliths of Cynoscion acoupa are small particles, composed of a combination of a gelatinous matrix and calcium carbonate, present in the ear internal bony fishes and are part of a system which acts as a sensor of depth and balance, so as a detector of sound vibrations. The Cynoscion acoupa is commercial- ized in all the coast of Brazil. The Cynoscion acoupa of the fish demonstrated to be an important source of colla- gen too; the membranes of collagens can be gotten from the acid extraction and posterior saline precipitation. New advances in bone tissue engineering have moti- vated the search for new materials that are biocompatib le with the different bioactive functions which actually oc- cur in live, growing tissues. [21] This b iomaterial has po- tential also as help in others kinds of bone regeneration, of threesomes or small fractures or same cases associated to the osteoporosis. The goal of this study is to produce highly efficacious scaffolds to engineer functional bone tissue with natural bone histological structure and prop- erties for the cure of bone loss in clinical settings. 2. Experimental Details 2.1. Materials Bacterial cellulose membranes, ~500 mm thick, were supplied from Innovatecs-Produtos Biotecnológicos Ltda, Brazil; Otoliths were supplied by VIAFARMA LTDA, Brazil and Collagen were supplied by Sigma Aldrich. 2.2. Synthesis of Bacterial Cellulose Bacterial Cellulose (BC) produced by Gram-negative acetic acid bacteria Gluconacetobacter xylinus can be obtained from the culture medium in the pure 3-D struc- ture consisting of an ultra fine network of cellulose nano- fibres (3 - 8 nm), highly hydrated (99% in weight), and displaying higher molecular weight, higher cellulose crystallinity (60% - 90%), enormous mechanical strength and full biocompatibility [2 2]. 2.3. Nano-Otholits Gels The material in this study was prepared with 1 g powder of otolith of Cynoscion acoupa with particle size 60 mesh and addiction 0.25 g of hydrolyzed collagen, di- luted in distilled water. The final product was packaged  First Otoliths/Collagen/Bacterial Cellulose Nanocomposites as a Potential Scaffold for Bone Tissue Regeneration Copyright © 2011 SciRes. JBNB 241 in dishes Petri and sterilized in UV rays (25 min). Sub- sequently, 1.0 g of the otoliths was diluted in 100 mL of distillated water, and the pH of the compound was as- sessed by using phmetro Digimed® (São Paulo, SP, Bra- zil) according to the manufacturer instructions. Stable gel is formulated with a otoliths calcium salt concentration solution. The use of poorly water-soluble salts (CaCO3) influences gelatin rate and, consequently, mechanical properties. 2.4. Bionanocomposite Preparation In the present study, we have explored a novel biomate- rial, and prepared different bacterial cellulose nanocom- posites(BC); 1) Pure BC, 2) BC with collagen and 3) BC/otoliths/collagen. Bacterial cellulose nanocomposite was obtained by immersion of dried bacterial cellulose into collagen and otolith/collagen gels and posterior soft drying at 50˚C by 12 hours. Bionanocomposites Characterization Scanning Electron Microscopy (SEM)-Scanning elec- tronic microscopy images were performed on a PHILIPS XL30 FEG. The samples were covered with gold and silver paint for electrical contact and to perform the nec- essary images. Histological Experiment—The experiment was per- formed with 20 Wistar rats randomized into two groups, in which a bone defect was inflicted in th e tibia. In group 1 (experimental), bone cavities were filled with otoliths nanocomposites [23]. 3. Results and Discussion 3.1. Scanning Electronic Microscopy (SEM) Bacterial cellulose mats were characterized by SEM. Figure 1 shows, as an example, SEM image of Bacterial cellulose mats. In order to obtain a bionanocomposite with mechanical properties and an osteoconductive environment that can facilitate cell attachment [24] and to increase in vitro pro- liferation and differentiation of osteoblastic cells [25] as well as the rapid vascularization and deposition of con- nective tissue and calcified matrix in vivo, BC/col- la- gen/nano-otholits were obtained. In Figures 2 and 3, scanning electron microscopy (SEM) image of the bacterial cellulose/collagen surface morphology and bacterial cellulose/collagen/otholits na- nocomposites is ilustred. 3.2. Cellulose Bacterial/Otoliths/Collagen Membrane in Vivo Biological Performance The Histological sections revealed that the newly formed trabecular bone was denser and the periosteal reabsorp- tive activity was less conspicuous in the experimental Figure 1. Scanning elec tron microscopy (SEM) of pure bac- terial cellulose. Figure 2. Cellulose bacterial/collagen surface morphology. Figure 3. Cellulose bacterial with otoliths/collagen mem- brane.  First Otoliths/Collagen/Bacterial Cellulose Nanocomposites as a Potential Scaffold for Bone Tissue Regeneration Copyright © 2011 SciRes. JBNB 242 (a) (b) Figure 4. (a) Osteotomized area showing irregular trabecu- lar bone, intertwined aspect and thin thickness; (b) The trabecular were stretching out, in the general form, from a side to other of the bone defect induced artificially, showing osteoblast activity and the periosteum demonstrated mod- erate degree of fibrosis. Besides, it can be observed areas of intense infiltration of polymorphonuclear neutrophils (PMN) and formation of microabscesses (MAB) in Figure 4(a) and (b). group (group 1) reported in Figures 4(a) and (b). Bio- chemical (calcium (Ca2+) and alkaline phosphatase (Alp) parameters were within normal range. In all the cases the neo formations of trabecular bone was observed, the ma- jority with irregular appearance, intensely intertwined aspect and thin thickness. Besides, it can be observed areas of intense infiltration of polymorphonuclear neu- trophils (PMN) and formation of microabscesses (MAB) in Figures 4(a) and (b). In the experimental group (group1), we observed in the Figures 4(a) and (b), that the bone surface tissue present high regularity and higher osteoblast activity in addition, osteo-reabsorption activities areas is can be observed cleary in Figures 4( a) and (b). 4. Conclusions We report the first otoliths/collagen/cellulose bacterial na- nocomposites as a potential scaffold for bone regenera- tion. The success of subsequent transplantation of the in vitro engineered construct is due to the properties of the materials but also on the osteoprogenitor cell sources. It is expected that th e seeded cells will secrete specific ECM components in vitro, to induce proliferation and differen- tiation into osteoblasts and result in the formation of a new bone in vivo. Otoliths/collagen/CB new scaffolds should be designed for different applications, such as: to induce vascularization; facilitate the deposition of oto- liths in predefined regions; guide the regeneration of tis- sue in certain directions permit the development of dif- ferent tissues; or inhibit calcification and cell adhesion. The field is widely open for new creative research- ers in real clinical applications. REFERENCES [1] T. A. Taton, “Nanotechnology: Boning up on Biology,” Nature, Vol. 412, No. 6846, 2001, pp. 491-492. doi:10.1038/35087687 [2] B. S. Kim, C. E. Baez and A. Atala, “Biomaterials for Tissue Engineering,” World Journal of Urology,Vol. 18, No. 1, 2000, pp. 2-9.doi:10.1007/s003450050002 [3] P. Basmaji, et al. Brazilian patent number: PI0604760-2. [4] K. Tuzlakoglu, N. Bolgen, A. J. Salgado, et al., “Nano- and Micro-Fiber Combined Scaffolds: A New Architec- ture for Bone Tissue Engineering,” Journal of Materials Science: Materials i n Me dic ine , Vol. 16, No. 12, 2005, pp. 1099-1104.doi:10.1007/s10856-005-4713-8 [5] W. Czaja, A. Krystynowicz, S. Bielecki, et al., “Microbial Cellulose—the Natural Power to Heal Wounds,” Bio- materials, Vol. 27, No. 2, 2006, pp. 145-151. doi:10.1016/j.biomaterials.2005.07.035 [6] C. Dahlin, A. Linde and J. Gottlow, et al., “Healing of Bone Defects by Guided Tissue Regeneration,” Plastic and Reconstructi ve Surgery, Vol. 81, No. 5, 1 998, pp. 672- 676.doi:10.1097/00006534-198805000-00004 [7] N. L. Macedo, F. S. Matuda, L. G. S. De Macedo et al., “Evaluation of Two Membranes in Guided Bone Tissue Regeneration: Histological Study in Rabbits,” Brazilian Journal of Oral Sciences, Vol. 3, No. 8, 2004, pp. 395- 400. [8] E. B. Hunziker, “Articular Cartilage Repair: Basic Science and Clinical Progress. A Review of the Current Status and Prospects,” Osteoarthritis and Cartilage, Vol. 10, No. 6, 2001, pp. 432-463.doi:10.1053/joca.2002.0801 [9] A. Svensson, E. Nicklasson, T. Harrah, et al., “Bacterial Cellulose as a Potential Scaffold for Tissue Engineering of Cartilage,” Biomaterials, Vol. 26, No. 4, 2005, pp. 419- 431.doi:10.1016/j.biomaterials.2004.02.049 [10] M. Aslan, G. Simsek and E. Dayl, “Guided Bone Regen- eration (GBR) on Healing Bone Defects: A Histological Study in Rabbits,” Journal of Contemporary Dent al Pr ac- tice, Vol. 5, No. 2, 2004, pp. 114-123. [11] R. S. Carvalho, D. Nelson, H. Keldernian, et al., “Guided Bone Regeneration to Repair an Osseous Defect,” Ame- rican Journal of Orthodontics and Dentofacial Ortho- pedics, Vol. 123, No. 4, 2003, pp. 455-467. doi:10.1067/mod.2003.59 [12] L. S. Iamaguti, C. V. S. Brandão, C. H. Pellizzon, et al. “Análise Histológica e Morfométrica do Uso de Mem- brana Biossintética de Celulose em Trocleoplastia Ex- perimental de Cães,” Pesquisa Veterinária Brasileira, Vol. 28, No. 4, 2008, pp. 195-200. [13] G. Helenius, H. Bäckdahl, A. Bodin, et al., “In vivo Bio- compatibility of Bacterial Cellulose,” Journal of Biomedi- cal Materials Research A, Vol. 76, No. 2, 2006, pp. 431- 438.doi:10.1002/jbm.a.30570  First Otoliths/Collagen/Bacterial Cellulose Nanocomposites as a Potential Scaffold for Bone Tissue Regeneration Copyright © 2011 SciRes. JBNB 243 [14] C. J. Gran de. F. G. Torres, C. M. Gomez, et al., “Develop- ment of Self-Assembled Bacterial Cellulose-Starch Nano- composites,” Materials Science and Engineering C, Vol. 29, No. 4, 2009, pp. 1098-1104. doi:10.1016/j.msec.2008.09.024 [15] C. J. Grande, F. G. Torres, C. M. Gomez, et al., “Nano- composites of Bacterial Cellulose/Hydroxyapatite for Bio- medical Applications,” Acta Biomaterialia, Vol. 5, No. 5, 2009, pp. 1605-1615. doi:10.1016/j.actbio.2009.01.022 [16] S. J. Bhattarai, N. Bhattarai, H. K. Yi, et al., “Novel Bio- degradable Electrospun Membrane: Scaffold for Tissue Engineering,” Biomaterials, Vol. 25, No. 13, 2004, pp. 2595-2602.doi:10.1016/j.biomaterials.2003.09.043 [17] S. Yang, K. F. Leong, Z. Du, et al., “The Design of Sca- ffolds for Use in Tissue Engineering Part I Traditional Factors,” Tissue Engineering, Vol. 7, No. 6, 2001, pp. 679-689.doi:10.1089/107632701753337645 [18] G. P. Chen, T. Ushida and T. Tateishi, “Hybrid Biomate- rials for Tissue Engineering: A Preparative Method for PLA or PLGA-Collagen Hybrid Sponges,” Advanced Ma- terials, Vol. 12, No. 6, 2000, pp. 455-467. doi:10.1002/(SICI)1521-4095(200003)12:6<455::AID-A DMA455>3.0.CO;2-C [19] M. Geiger, R. H. Li and W. Friess, “Collagen Sponges for Bone Regeneration with rhBMP-2,” Advanced Drug De- livery Reviews, Vol. 55, No. 12, 2003, pp. 1613-1629. doi:10.1016/j.addr.2003.08.010 [20] L. Meinel, R. Langer, G. Vunjak-Novakovic, et al., “Bone Tissue Engineering Using Human Mesenchymal Stem Cells: Effects of Scaffold Material and Medium Flow,” Annals of Biomedical Engineering, Vol. 32, No. 1, 2004, pp. 112-122. doi:10.1023/B:ABME.0000007796.48329.b4 [21] F. Korkusuz, P. Korkusuz and V. Hasirci, “In Vivo Tissue Engineering of Bone Using Poly(3-Hydroxybutyric Acid- co-3-Hydroxyvaleric Acid) and Collagen Scaffolds,” Tissue Engineering, Vol. 10, No. 7-8, 2004, pp. 1234-1250. doi:10.1089/ten.2004.10.1234 [22] D. Klemm, B. Heublein, H. P. Fink, et al., “Cellulose: Fa- scinating Biopolymer and Sustainable Raw Material A,” Angewandte Chemie International Edition, Vol. 44, No. 22, 2005, pp. 3358-3393. doi:10.1002/anie.200460587 [23] D. P. Valido and T. S. Bastos, R. L. C. Albuquerque- Jú- nior, et al., “Estudo Preliminar da Utilização de Ot ólitos de Cynoscion Acoupa Sobre o Processo de Neoformação Óssea em Ratos,” Jornal Brasileiro de Patologia e Me- dicina Laboratorial, Vol. 46, No. 4, 2010, pp. 315-322. doi:10.1590/S1676-24442010000400009 [24] V. Luginbuehl, E. Wenk, A. Koch, et al., “Insulin-Like Growth Factori-Releasing Alginate-Tricalciumphosphate Composites for Bone Regeneration,” Pharmaceutical Re- search, Vol. 22, No. 6, 2005, pp. 940-950. doi:10.1007/s11095-005-4589-9 [25] Y. J. Seol, J. Y. Lee, Y. J. Park, et al., “Chitosan Sponges as Tissue Engineering Scaffolds for Bone Formation,” Biotechnology Letters, Vol. 26, No. 13, 2004, pp. 1037- 1041. doi:10.1023/B:BILE.0000032962.79531.fd |