Intelligent Control and Automation, 2011, 2, 100-111 doi:10.4236/ica.2011.22012 Published Online May 2011 (http://www.SciRP.org/journal/ica) Copyright © 2011 SciRes. ICA A Robust Fuzzy Tracking Control Scheme for Robotic Manipulators with Experimental Verification Abdel Badie Sharkawy*, Mahmoud M. Othman, Abouel Makarem A. Khalil Mechanical Engineering Department, Faculty of Engineering, Assiut University, Assiut, Egypt E-mail: ab.shark@aun.edu.eg Received March 19, 2011; revised April 2, 2011; accepted April 7, 2011 Abstract The performance of any fuzzy logic controller (FLC) is greatly dependent on its inference rules. In most cases, the closed-loop control performance and stability are enhanced if more rules are added to the rule base of the FLC. However, a large set of rules requires more on-line computational time and more parameters need to be adjusted. In this paper, a robust PD-type FLC is driven for a class of MIMO second order nonlin- ear systems with application to robotic manipulators. The rule base consists of only four rules per each de- gree of freedom (DOF). The approach implements fuzzy partition to the state variables based on Lyapunov synthesis. The resulting control law is stable and able to exploit the dynamic variables of the system in a lin- guistic manner. The presented methodology enables the designer to systematically derive the rule base of the control. Furthermore, the controller is decoupled and the procedure is simplified leading to a computationally efficient FLC. The methodology is model free approach and does not require any information about the sys- tem nonlinearities, uncertainties, time varying parameters, etc. Here, we present experimental results for the following controllers: the conventional PD controller, computed torque controller (CTC), sliding mode con- troller (SMC) and the proposed FLC. The four controllers are tested and compared with respect to ease of design, implementation, and performance of the closed-loop system. Results show that the proposed FLC has outperformed the other controllers. Keywords: Fuzzy Logic Control (FLC), PD Control, Computed-Torque Control (CTC), Sliding Mode Control (SMC), Lyapunov Synthesis, Test Rig 1. Introduction Robots are familiar examples of trajectory-following mechanical systems. Their nonlinearities and strong cou- pling of the robot dynamics present a challenging control problem, [1-3]. Conventional methods of controlling a nonlinear system are based on models, especially in the field of robot control. Many robotic control schemes can be considered as special cases of model-based control called computed torque approach, [4]. The basic concept of computed torque is to linearize a nonlinear system, and then to apply linear control theory. Practical imple- mentation of the computed torque and other model based approaches can be found in [5], where the experimental results revealed that the simple PD controller has out- performed the other model based controllers. This is mainly due to the fact that in many dynamic systems the parameters may slowly change or cannot be exactly pre- dicted in advance due to different operating conditions. Sliding mode controllers (SMCs) were first proposed in early 1950s. Due to their good robustness to uncer- tainties, SMC has been accepted as an efficient method for robust control of uncertain systems. Being limited only by practical constraints on the magnitude of control signals, the sliding mode controller, in principle, can treat a variety of uncertainties as well as bounded exter- nal disturbances, [6]. A key step in the design of control- lers is to introduce a proper transformation of tracking errors to generalized errors so that an n-order tracking problem can be transformed into an equivalent first-order stabilization problem. Since the equivalent first-order problem is likely to be simpler to handle, a control law may thus be easily developed to achieve the so-called reaching condition. Unfortunately, an ideal sliding mode controller inevitably has a discontinuous switching func- tion. Due to imperfect switching in practice it will raise  A. B. SHARKAWY ET AL.101 the issue of chattering, which is highly undesirable. To suppress chattering, a continuous approximation of the discontinuous sliding control is usually employed in the literature. Although chattering can be made negligible if the width of the boundary layer is chosen large enough, the guaranteed tracking precision will deteriorate if the available control bandwidth is limited, [7]. A number of works related to sliding mode control of robotic manipu- lators have been published in [8-12]. Generally speaking, multiple-input multiple-output (MIMO) systems usually have characteristics of nonlin- ear dynamics coupling. Therefore, the difficulty in con- trolling MIMO systems is how to overcome the coupling effects between the degrees of freedom. The computa- tional burden and dynamic uncertainty associated with MIMO systems make model-based decoupling impracti- cal for real-time control. Adaptive control has been stud- ied for many decades to deal with constant or slowly changing unknown parameters. Applications include manipulators, ship steering, aircraft control and process control. Although the perfect knowledge of the inertia parameters can be relaxed via adaptive technique, its real practical usefulness is not really clear and the obtained controllers may be too complicated to be easily imple- mented, [13]. Because many design parameters (like learning rates and initialization of the parameters to be adapted) have to be considered in controller construction, most existing methodologies have limitations. Moreover, owing to the different characteristics among design pa- rameters, attaining a complete learning, while consider- ing an overall perfomance goal, is an extremely difficult task. Nevertheless, some experiments have been pre- sented in [14,15]. Fuzzy controllers have demonstrated excellent ro- bustness in both simulations and real-life applications, [16]. They are able to function well even when the con- trolled system differs from the system model used by the designer. A customary for this phenomenon is that fuzzy sets, with their gradual membership property, are less sensitive to errors than crisp sets. Another explanation is that a design based on the “computing with words” para- digm is inherently robust; the designer forsakes some mathematical rigor but gains a very general model which remains valid even when the system’s parameters and structure vary. Otherwise, FLCs consist of a number of parameters that are needed to be selected and configured in prior, i.e. input membership functions, fuzzificztion method, out- put membership functions, rule base, premises connec- tive, inference method and defuzzification. Optimal tun- ing of FLCs using genetic algorithms has attracted many authors, [17-19]. In these papers, however, there are too many parameters involved in the development of FLCs. Furthermore, genetic algorithms cannot be used in real time control applications. In another study similar to the presnt work, i.e. real-time trajectory tracking control of two link robot using fuzzy systems [20], the controller needs 26 parameters to be experimentally selected. Also, the FLC in [21] needs 45 parameters to be tuned. This is beside the huge number of calculations involved in the online computation of the control signals. In this research paper, we introduce a simple and computationally efficient FLC for MIMO second order systems with application to robotic manipulators. Earlier theoritical investigation of this controller, by the first author, can be found in [22]. The controller is stable in the sense of Lyapunov theory of stability and few pa- rameters are needed to be tuned. The approach can be implemented to both tracking and stabilizing control problems. However, in this paper, the emphasis is on the tracking control problem of robotic systems. The per- formance of the proposed controller is experimentally verified and compared with the conventional PD con- troller, computed-torque controller (CTC), and sliding mode controller (SMC). The rest of this paper is organized as follows. Section 2 presents the model based controllers (CTC and SMC) that are used for comparison purposes. The proposed control scheme is introduced in Section 3 and Section 4 describes the experimental setup, the examined trajecto- ries and the performance measures used in the control performance evaluation. The experimental results are demonstrated and discussed in Section 5. Section 6 offers our concluding remarks. 2. Model-Based Control Schemes 2.1. Preliminaries The dynamic model of an n-joint manipulator can be written as follows: , qqCqqqgqf qut (1) where q is the 1n joint angle vector, ut is the 1n input torque vector, q is the nn posi- tive definite inertia matrix, is the ,Cqq nn ma- trix representing the centrifugal and Coriolis terms, q is the 1n vector of the frictional terms and q is the 1n vector of the gravity terms. Decoupled or decentralized (also independent) control means that the torque i to be generated by the ith ac- tuator is based only on the value of the position of the ith joint and its time derivative u ,, , iii i di di uuqqqq , , (2) 1, 2,,in where is the actual value of the ith joint coordinate, i q Copyright © 2011 SciRes. ICA  A. B. SHARKAWY ET AL. Copyright © 2011 SciRes. ICA 102 i and di is its desired value. The later (di ) is usually available signal from the robot operating system and is planned in advance. Generally, defining the position er- ror as , (2) can be written as q q n idi eq q ii uu where, again, d eq q is the difference between the desired joint position vector and the actual one. Obviously, the assumption of exact knowledge of the robot dynamic model cannot be satisfied in practical cases. Hence, the achievement of the desired tracking performance cannot be guaranteed. For this purpose, it would be desirable to add a term in the controller that compensates for the modeling errors. Several related works can be found in literature which suggests the use of neural networks [23] and neuro-fuzzy systems [24] in-order to compensate for the modeling errors. However, a complete review in this area is out of the scope of this work. In the experimental verification (Section 5), the CTC algorithm has been implemented as it is shown in Figure 1. , ii ee , 1,2,,i (3) This approach is widely adopted in industrial settings because of its simplicity (no dynamic model is required, in general) and because of its fault-tolerant feature, since, in case a single joint is affected by a failure, the robot can be retrieved in a safe position by means of the other joints. The motion control problem of manipulators in joint space can be stated in the following terms. Assume that the joint position q and the joint velocity q are available for measurement. Let the desired joint position d be a differential vector function. We define a motion control- ler as a controller which determines the actuator torques u in such a way that the following control aim be achieved: q 2.3. Sliding Mode Control In this subsection, the well-developed literature is used to demonstrate the main features and assumptions needed to synthesis a SMC for robotic systems. SMC employs a discontinuous control effort to derive the system trajec- tories toward a sliding surface, and then switching on that surface. Accordingly, it will gradually approach the control objectives, i.e. keep these trajectories at the ori- gin of the phase plane. The following assumptions are needed to synthesis a SMC. lim d tqtq t (4) 2.2. Computed Torque Control The computed torque (also called inverse dynamics) technique is a special application of feedback lineariza- tion of nonlinear systems. The computed torque control- ler is utilized to linearize the nonlinear equation of robot motion by cancellation of some, or all, nonlinear terms. For this purpose, the dynamic model of the manipulator is exploited. Taking into account (1) and defining Assumption 1: The matrix q is positive definite and is bounded by a known positive definite matrix ˆ q. Assumption 2: There exists a known estimate ˆ,hqq for the vector function ,hqq in (5). Now, let us define the linear time-varying surface t, [9]: hqq ,,Cqqq gqf q (5) T 12 , ,,, n st ett tststst (7) we can derive the control scheme shown in Figure 1, where and v are user-chosen diagonal matrices. So that the system is decoupled, linearized and the error dynamics is governed by the following expression [23]: where t is a time-varying linear function. From (1), (5) and (7), we can get the equivalent con- troller (also called ideal controller) 0 vp eKeKe (6) Robot )(qM ),( qqh v K p K q q d q d q d q _ _ + + u Figure 1. Computed torque control scheme.  A. B. SHARKAWY ET AL. Copyright © 2011 SciRes. ICA 103 ,) eq d ut hqqMqq (8) where eq ut is equivalently the average value of ut which maintains the system’s trajectories (i.e. tracking errors) on the sliding surface . To ensure that they attain the sliding surface in a finite time and there- after maintain there, the control torque 0st ut consists of a low frequency (average) component eq ut and a hitting (high frequency) component ht ut so that: eq ht ututu t (9) The role of ht ut acts to overcome the effects of the uncertainties and bends the entire system trajectories towards the sliding surface until sliding mode occurs. The hitting controller ht ut is taken as: sgn ht ut MqKs (10) where 12 diag,,n kk k 12 sgn ,sgn,sss , , and . 0 i k ,sgn n 1, 2,in T s sgn To verify the control stability, let us first get an ex- pression for t . Using (1), (5), (9) and (10), the first derivative of (7) is: 1 1 , , sgn d d ht sqtett qt qtt q tMquthqqt Mqu Ks (11) Choosing a Lyapunov function 2 1 1 2 n si i Vs t (12) and differentiating (12) using (11) 11 1 sgn 0. nn siiii i ii n ii i Vstst kstst kst (13) which provides an asymptotically stable system. Since the parameters of (1) and (5) depend on the ma- nipulator structure, it is difficult to obtain completely accurate values for q and . In SMC theory, estimated values are usually used in the control context instead of the exact parameters. So that, (8)-(10) can be written as: ,hqq , ˆˆ , ˆsgn , eq d ht eq ht ut hqqMqq ut MqKs ututu t (14) where ˆ q and are bounded estimates for ˆ,hqq q and ,qq tively. As mentioned earlier mption2, they are assumed to be known in advance. In sliding h 1 and mode, th respec e system trajectories are governed in assu by: i st 0 and 0 i st , 1,2,,in (15) at, thynamicsre determinSo th funct e error d aed by the ion t . If the coefficients of t were cho- sen to corresnd to the coefficients of itz polyno- mial, it is thus implying that lim 0 tet . This sug- gests po Hurw t taking the following form: 12 dcetcett with t 12 ,0cc (16) at ing mode, the error dynamics is: So th the slidin 12 0et cetcet , (17) e desirmance is gover iding mode controller in (14) can PrFLC Scheme apued Fuzzy Logic Controllers sectipply the fuzzy synthesis [25], to the and th gu . The .1. Ly this red perfo th oposed nov Bas on, we a ned by the coeffi- cients 1 c and 2 c. In sumary, e slm arantee the stability in the Lyapunov sense even under parameter variations. As a result, the system trajectories are confining to the sliding surfaces (7). The control law (14) however, shows that the coupling effects have not been eliminated since the control signal for each degree of freedom is dependent on the dynamics of the other degrees of freedom. Independency is usually preferred in practice. Furthermore, to satisfy the existence condition of the sliding modes, a large uncertainty bound should be used. In this case, the controller results in large imple- mentation cost and may lead to chattering efforts which should be avoided in practical implementation. 3 3 In design of stable controllers. To this end, consider a class of MIMO nonlinear second order systems whose dy- namic equation can be expressed as: ,, tfxxu , (18) where ,, xxu is an inpu continuous function, u unknown is the cot and ntrol 12 T 11 1 ,,, n txx x is the state vector and T 12 22 2 ,,, n xx xx dx dt , wher e 12 ii x , 1, 2,,in . apunov We now seek a smooth Lyfunction n :VR that is po n R sitiv for the continuous feedback model (18) e definite, i.e. 0Vx when 0x and 0Vx when x = 0, and gfinity: rows to in x general V as T xx. Obviously, tfor a his holds ized  A. B. SHARKAWY ET AL. 104 Lyapunovg quadrati : candidate function of the followin form c TT 11 ,22 Vxtxx xx (19) Differentiating (19) with respect to time gives 1122 11111 1 ,nn Vxtxx xxxx 11 22 22 2222 nn xxxxx So that 112 2 121 212 11 22 22 2222 , nn nn Vxtxx xxxx xxxxx From which This is equal to (20) where Then the standard results in unov stability theory imply that the dynamic system (18) has a stabuilib- riu ,Vxt 111122 22 12221 222 12 22 nn nn xx xxxxxx xx xx 12 ,n VxtV VV 12 22 ,iiii i Vxtxx xx , 1, 2,,in Lyap le eq m e x if each i V in (20) is 0 along the sys- tem trajectories. To achieve this, we have chosen the contro ix to be pportional to 2 l uro i . Next, our controller design is achieved if we determine a fuzzy co ux so that: ntrol where 2 ,0 iii iii Vxt xux , 1,2,,in (21) 12 xx i ists is a positive constant. The results o [26] state that, a fuzzy system that would approximate f Wang (21) ex. To this end, one would consider the state vector t and t to be the inputs to the fuzzy system. The output of the fuzzy system is the control u. A possiorm of ontrol rules is: IF 1 i ble fthe c is (lv) and/or 2 i is (lv) THEN u is (lv) i whe sti os a- tive hetut- are: surements. re the (lv) are linguic values (e.g. p itive, neg ). Tse rules constie the rule base for a Mam dani-type FLC. In the above formulation, two basic assumptions have been made. They The knowledge of the state vector. It is assumed to be available from mea The control input, u is proportional to 2 . This as- sumption can be justified for a largf second rules. O ro zy Tracking Control ry-following echanical systems. Their nonlinearities and strong cou- rder to find a fuzzy controller that would ac e class o order nonlinear mechanical systems, [27,28]. For in- stance, here in robotics, it means that the acceleration of links is proportional to the input torque. These two assumptions represent the basic knowledge about the system which is needed to derive the FLC f course, the exact mathematical model is not needed. In the coming sub-section, we use this approach to de- sign a PD-type FLC for the tracking control problem of botic systems. 3.2. Robotic Fuz Robots are familiar examples of trajecto m pling of the robot dynamics present a challenging control problem. In practice, the load may vary while performing different tasks, the friction coefficients may change in different configurations and some neglected nonlineari- ties as backlash may appear. Therefore, the control ob- jective is to design a stable fuzzy controller so that the link movement follows the desired trajectory in spite of such effects. We now apply the approach presented in the previous subsection in o hieve tracking to the robotic system under considera- tion. To this end, let us choose the following Lyapunov function candidate TT 1 Ve 2eee (22) where again, d etq tqt , d etq tqt d qt and and d qt are vectors locity respectiv of the desired joint ely. Differentiating withposition and ve respeime andg (20) gives iiiii Veeee ct to t usin To enforce asymptotic stability, it is required to find u so that 0Veeee iiiii (23) in some neighborhood of the equilibr the control u to be proportional to ium of (22). Taking , (23) can be re- e written as: 0 iiiiii Vee eu (24) where i is positive constant, (24) to hold can fo 1,i be stated as ,n. Sufficient follows. conditions for 1) if, r each 1, ,in, i e aave opposite signs and i u is zero, inequality (24) holds; nd h i e 2) if i e and i epositive, then (24) will hold if i u is negative; and are both 3) if i and i e are both negative, then (24) will hold if is positive. e i u 1 , ,indenotes the joint number. ow in Tab Using these observations, one can easily obtain the four rules listed belle 1. Copyright © 2011 SciRes. ICA  A. B. SHARKAWY ET AL.105 Table 1. Fuzzy rules for the tracking controller. i e P N P uNu Z i e N uZ u P 1, ,in In this table, , denoespectiv positive, nega- ve errors; P, Nte rely ti u, u and u a are respectively positive, ne lassical Lyapunov synthesis from the world ex rule ba gative and zero control inputs. These rules are simply the fuzzy paronf e, e nd u which follow directly from the stabilizing conditions of the Lyapunov function, (22). In concluding words, the presented approach trans- forms c titis o of act mathematical quantities to the world of words [16]. This combination provides us with a solid analytical ba- sis from which the rules are obtained and justified. To complete the design, we must specify the mem- bership functions defining the linguistic terms in the se. Here, we use the Gaussian membership functions 2 ,exp positive zz xGxa xa , negative z Gx a ,0 zero Gx where and z stands for control variable, the product nd” and center of gravity inferencing. some p in eq 0 z a for “a g For ositive constants u a, ep a and ev a, the above four rules can be represented by the follow uation: ,, ii iepiuiepi u i GeaaGe aa u ,, ,, ,, ii iepii epi i eviuieviu i eviievi GeaGe a GeaaGeaa GeaGe a in more details 2 2 22 2 2 2 2 p exp exp exp exp exp exp exp i epii epi iui i epii epi i evii evi ui i eviievi ea ea ea ea ea ea aea ea from which ex ua exp 2exp2 exp 2exp2 exp 2exp2 exp 2exp2 epi iepi i i uu i epiiepii evi ievi i ui evi ievi i ae ae aae ae ae ae aae ae This yields the FLC tanh 2tanh 2 ii iuiepievi ua aeae ,1,, in (25) In (25), the inputs are the error in position and the error in velocity and the output is the contrl input of joint i; i.e. it is a PD-type FLC. The followinremarks ar The FLC in (25) is a special case of fuzzy sy where Gaussian membership functions are used t t , natives. For e amng different . i e o g i e e in order: stems, o in- troduce the input variables (i e and i e ) tohe fuzzy network. Alsothe fuzzification and defuzzification methods used in this study are not unique; see [28] for other alterxple, usi membership functions (e.g. triangular, trapezoidal etc.) will result in a different FLC. However, the FLC in (25) is a simple one and the closed form rela- tion between the inputs and the output makes it com- putationally inexpensive. Only three parameters per each DOF need to be tuned, namely, they are i u a, i ep a and i ev a. This greatly simplifies the tuning procedure, since the search space is quite small relative to other works. For in- stance, the FLC in [21] needs 45 parameters to be tuned for a one DOF system This controller is inherently bounded since tanh 1x . Each joint has independent control input i u 1, 2,,in . In the case of robotic control, this controller can be regarded as output feedback controller since the joint’s joi easured, it can be easily ob- igure, and are the links lengths; and tio position and velocity are usually the outputs. If the nt velocity is not m tained using a differentiator as shown in Figure 2. 4. Experimental Setup: Test Rig, Reference Trajectory and Per formance Measures In this study, we have considered a two link planar robot whose diagrammatic sketch is shown in Figure 3. In this F1 212 are the masses of the links; 1c and 2c are the loca n of the center of masses; 1 mm - and 2 are the moment of inertioutnter ofks. ments of the ints; Figure 4. The robot has been built at the a ab the ce masses of the two lin The parameter values of the links are given in Table 2. These inertia parameters have been calculated by simply measuring and weighting the mechanical ele arms. 4.1. The Test Rig The test rig consists of a geared-drive horizontal robot arm with 2 DOF whose rigid links are joined with revo- lute jo Copyright © 2011 SciRes. ICA  A. B. SHARKAWY ET AL. Copyright © 2011 SciRes. ICA 106 Fuzzy controller (25) for joint 1 Fuzzy controller (25) for joint 2 2d q 2 q 1d q 2 u Robot arms 1 q 1 u dtde / 1 dtde / 2 1 e 2 e Differentiator Differentiator de 1 /dt de 2 /dt e 1 q d1 q d2 q 1 u 1 e 2 q 2 u 2 Figure 2. Configuration of the robotic fuzzy control structure (the case of two-link robot). Figure 3. Schematic diagram of the two-link r obot. Table 2. Parameters of the robot arm. Parameter Link 1 Link 2 m mass (0.096 kg) 0.471 length .g. (m) (m) 0.154 0.205 c position of c0.154 0.1025 212m ineIrtia (kg·m2) 0 0 .00093.00033 Figure 4. Experimental two-link planar arm. Mechatronics lab, Faculty of Engineering, Assiut Uni versity motor rivers, AD/DA interface card, and a host computer. H-bridge drive circuit. The motors operate at rated 24 n is obtained from analogue angular potentiometers for both angles. d ex blends and the ubic polynomial trajectory. In this paper, we present lts of other two tra- ctories; sinusoidal trajectory and linear trajectory with - volt, 2 rpm, and 1.5 Nm. Position informatio . It is equipped with joint position sensors, d Both links, made of aluminum, are actuated by brushed dc motors with gear reduction controlled via simple The potentiometers are one turn (300 degrees) and 1 kΩ. Each potentiometer is coupled to the joint motor. Both potentiometers are supplied by ±5 V, so that each one has a resolution of 0.033 volt/degree. The velocity of each link is obtained by using the position signal and utilizing first order backward differencing technique. The feedback signals from the potentiometers and the control signals to the motor drives are sent to/from the computer via PCI-DAS6014 AD/DA interface card. The card has a minimum 200 kS/s conversion rate and has an absolute accuracy of 8.984 mV when operates at the range ±10 V. The control program is written in C++ an ecuted at 1 ms sampling rate. Figure 5 shows the closed loop control system. 4.2. The Reference Trajectory During the preliminary evaluation of the proposed FLC, we have examined three trajectories. They are sinusoidal trajectory, linear trajectory with parabolic c results of the latest trajectory. Resu je parabolic blends, can be found in the master thesis of the second author, [29]. A cubic polynomial trajectory in the joint space is defined by: 23 01 23 d qtaatatat (26) where 012 ,,aaa and 3 a are constants determined upon the trajectory constraints. The desired motion of the two joints is identical and starts from zero to 45˚ in 10 seconds. The motion constraints (boundary conditions) are: (0)qt 0 di , ( 10) di qt 45˚, (0)0 and di qt (10)0 di qt , w here 21,i is the joint number. The desiredto (26) will be: trajectory according 23 1.350.09, 010 di qttt t , (27) where d qt is in degrees.  A. B. SHARKAWY ET AL.107 Figure 5. Block diagram of the test rig. 4.3. The Performance Measures While comparing the efficiencies of the ere experimentally tested on the robot arm, we will use king error to quan- tatively compare the performance results. One measure controllers that w some meaningful measures of the trac ti that will be used is the scalar valued Root Mean Square (RMS) error defined as 1/2 T 2 0 1d f f RMSTe tt (28) where is the tracking error. Since data are only discrete time intervals, et sent back at 1 tt with con- stant samling period p1 j Ttt for all j; we discre- tize (28) as 2 1 2 1 1N d j T qjqj N where 1N d j f RMSqjqj T (29) qj denotes j qtq jT and fNTT . To get mnsight oform use the maximum absolute value of the tracking error after two second from the starting time. We name it as as ore in the tracking perance, we also max e which is defined max 1 max d jN eqjqj (30) The above two measures have been also adopted in [15]. 5. Results a n, the experiments conducted using four are the con- osed FLC, the CTC and e SMC. For the sake of comparison, we ran each strength and weakness of each design. To show robustness, the four controllers have been initiated with initial ual to 10˚, i.e. T (0)[1010 ]q and the robot is at rest, i.e. . This condition nd Discussion n this sectioI controllers are presented. These controller ventional PD controller, the prop th controller with the same initial conditions to analyze the yields an initial position error [0.175 0.175]T e radian. The control torque for the proportional-plus-derivative (PD) controller is defined by: position error eq T (0)[00]q PD utKet Ket (31) where KP and KD are 2 2 pogonal matrices called the propore derivative gain matrices, respectively. A traditional with PD c sitive definite dia tional and th problem associated ontrol is that we cannot increase the controller ga of the gains exceed their critical values, the system becomes u performance of the PD controller is restri ins, as much as we want, to improve the controller’s performance. When the values nstable. Thus the cted with the values of these gains. In the experiments, the proportional feedback gains of the PD controller were set to 140 P K, 230 P K and the derivative gains were chosen to be 10.01 D K , 20.005 D K for the base and elbow links, respectively. They have been selected as high as possible without violating the stability of the overall system. With respect to the proposed FLC, the control gains were set to 12uu aa5 thus ensuring that the control sig ardware uirement nals which are computed according to (25) remain in the range of ±10 V which is a hreq. The other control parameters were picked as110 ep a , 29 ep a and 10.05 ev a , 20.045 ev a. We chose these parameters experimentally after few trials. The criteria upon which these values have been chosen is simply the fa C, the cont stest possible convergence of the initial errors. For the CTrol gains according to (6) were selected after trials as 6 18 10 P K , 6 27 10 P K and the derivative gains were chosen to be 13 D K , 22.5 D K for the base and elbow links, respectively. ontrolve e best possible tracking performance. The matrix These c gains haachieved th q and the vector Copyright © 2011 SciRes. ICA  A. B. SHARKAWY ET AL. 108 otion stimated values for ,hqq were computed on-line using the parameter values presented in Table 2 and the equation of m of two link planar robot which can be found in [4]. For the SMC, the e ˆ q ere se , ˆ, hqq and the hitting control gain K in (14) wt 0.5 0 ˆ 00.3 M , 0.01 ˆ 0.003 h a40 0 030 . The coefficients of the function as: nd K t in (16) were selected as 1(0.3,0.2)cdiag and 2(50, 4cdiag0) picked . otion and achieve the best possible tracking nce, i.e. the fastest possible rate of converg rors. In thcoming expts, the sign fu (10) has been replaced by saturation function t mance criteria defined in (29) Ag after a t robot m performa of the er tion in av ain, these control parameter values have been rial and error procedure so as to keep stability of the ence - o When applying initial position and velocity errors, it can be noticed that the FLC performs better than the PD controller in terms of the two performance criteria; i.e. RMS of errors and the maximum error. e erimennc oid chattering. The perforMS as and the maximum error (30) for all experiments are visualized in order. These two criteria are accounted for after 2 seconds in order to avoid the transient period and to give more insight on the performance at the steady state. The tracking performance of the four controllers is R demonstrated in Figures 6-10. They show that, after suitable selection of the tuning parameters, the tracking errors of the four controllers have converged to a close zone around zero in the steady state phase. Figure 6 shows that the transient period of the PD controller is slightly higher than that of the FLC, Figure 7. The transient phase of the CTC was the longest one as it can be noticed from Figure 8. Figure 10 shows that the SMC was successful in bending the system trajectories toward sliding surfaces and consequently the errors have converged as depicted in Figure 9. The performance measures are given in Figure 11 and Figure 12. Referring to these two Figures the following remarks are in order. The CTC requires the accurate knowledge of the system dynamic model and the complete equations of motion are computed in real time. These conditions are difficult to verify in practice. As a result the CTC has the worst tracking performance. There are too many parameters which are needed to be tuned (experimentally selected) in the case of the Time (sec) J t a a ) Joint 1 desired and actual trajectories 02468 10 -0.2 0 0. 2 0. 4 0. 6 0. 8 PD Time (sec) J d actual trajectories - oint 2(radian) Joint 2 desired an 02 46 810 -0.2 0 0.2 0.4 0.6 0.8 Time (sec) o ( a an) Errors of joint 1 & 2 02468 10 -0.2 -0.1 0 0.1 0.2 Joint 1 Joint 2 PD - - PD - (a) (b) (c) Figure 6. The desired and actual trajectories of (a) joint one, (b) joint two (b) and (c) the tracking errors of the PD controller. Time (sec) t 1 (radian) Joint 1 desired and actual trajectories Join 02468 10 -0.2 0 0.2 0.4 0.6 0.8 FLC Time sec - Joint 2 (radian) Joint 2 desired and actual trajectories 02 46 810 -0.2 0 0.2 0.4 0.6 0.8 FLC Time (sec) - o a an) Errors of joint 1 & 2 02 46 810 -0.2 0.2 -0.1 0 Joint 1 Joint 2 0.1 FLC - - (a) (b) (c) Figure 7. The desired and actual trajectories of (a) joint one, (b) joint two (b) and (c) the tracking errors of the proposed FLC. Copyright © 2011 SciRes. ICA  A. B. SHARKAWY ET AL.109 Joint 2 desired and actual trajectories Time (sec) 02 4 6 810 0 0.2 0.4 0.6 0.8 2 a a ) 0 2 4 6 810 -0.2 0 0.2 0.4 0.6 0.8 CTC - Errors of joint 1 & 2 Time (sec) Error (radian) 02 4 6 81 -0.2 -0.1 0 0.1 0.2 Joint 1 Joint 2 CTC - - (a)c) Joint 1 desired and actual trajectorie (b) ( Figure 8. The desired and actual trajectories of (a) joint one, (b) joint two (b) and (c) the tracking errors of the CTC. Time (sec) J nt ( a an) 0 2 46 810 -0.2 0 0. 2 0. 4 0. 6 0. 8 SMC - Joint 2 desired and actual trajectories Time (sec) Joint 2 (radian) 0246810 -0. 2 0 0.2 0.4 0.6 0.8 SMC - 0 24 6810 -0.2 -0.1 0 0.1 0.2 Errors of joint 1 & 2 Time (sec) a a ) Joint 1 Joint 2 SMC - - (a) (b) (c) Figure 9. The desired and actual trajectories of (a) joint one, (b) joint two (b) and (c) the tracking errors of the SMC. Sliding surface of joint Time (sec) 0 2.5 57.5 10 -0. 2 -0.15 -0. 1 -0.05 0 0. 05 SMC - - - - 1 Sliding surface of joint 2 Time (sec) 0 2.557.5 10 -0.01 0 0.01 0.02 0.03 SMC 2 - (a) (b ) SM gence of the initial errors. This fact has affected the tracking performance of the controller. Finally, it can be concluded that the proposed FLC has achieved the ease of implementation and the best tracking performance. 6. Conclusions Since extracting knowledge from experts in many ca is a tedious task, one would assume formation about the system. We have im apunov second method to get such b nd designed a fuzzy control law so that the system is simplifies the extraction of the fuzzy rules. An important feature of this study is that it has trans- ferred the proposed fuzzy PD controller to a closed-form relation between the inputs and the output, leading to a computationally efficient FLC. Relative to other works in this area, the number of parameters needs to be tuned is quite small which has greatly facilitated the imple- mentation. Unlike the PD controller, CTC and SMC, the posed FLC is inherently boundhe upper and trary selected by suitably adjust approach provides a systematic step by step procedure for the design of fuzzy-based decoupled Figure 10. The sliding surfaces (SMC). C in order to achieve the fastest possible conver- stable in the sense of Lyapunov. This procedure greatly ses proed; t basic physical in- lower bounds can be arbi plemented the asic information its parameters. The presented Ly a Copyright © 2011 SciRes. ICA  A. B. SHARKAWY ET AL. 110 t 2 for the four controllers in ian. Figure 11. The RMS error of joint 1 and joinrad Figure 12. The maximum error of the four controllers in radian. edback controllers rder nonlinear systems. This control scheme has been applied to the control of a two-link robot. It can also be extended to n number of link robots. Experimental re- sults show that the design procedure has been successful in representing the nonlinear dynamics in the control context and resulted in a stable closed-loop control. Ro- bustness of the FLC has been examined via initial posi- tion errors. Relative to the conventional PD controller, CTC and SMC, the proposed FLC exhibits the best per- formance. 7. References [1] Z. Bingul and O. Karahan, “A Fuzzy Logic Controller Tuned with PSO for 2 D Expert Systems with Applications, Vol. 38, No. 1, 2011, fe o for a wide class of MIMO second OF Robot Trajectory Control,” pp. 1017-1031. doi:10.1016/j.eswa.2010.07.131 [2] T.-H. S. Li and Y.-C. Huang, “MIMO Adaptive Fuzzy Terminal Sliding-Mode Controller for Robotic Manipu- lators,” Information Sciences, Vol. 180, No. 23, 2010, pp. 4641-4660. doi:10.1016/j.ins.2010.08.009 [3] L. Tian and C. Collins, “Optimal Placement of a Two-Link Planar Manipulator Using a Genetic Algo- rithm,” Robotica, Cambridge University Press, Cam- bridge, Vol. 23, No. 2, 2005, pp. 169-176. [4] M. W. Spong, S. Hutchinson and M. Vidyasagar, “Robot Modeling and Control,” John Wiley & Sons Inc., New York, 2006. [5] F. Reyes and R. Kelly, “Experimental Evaluation of Model-Based Controllers on a Direct-Drive Robot Arm,” Mechatronics, Vol. 11, No. 3, 2001, pp. 267-282. doi:10.1016/S0957-4158(00)00008-8 [6] J. Slotine and W. Li, “Applied Nonlinear Control,” Pren- tice-Hall Inc., New Jersey, 1991. [7] H. B. Guo, Y. G. Liu, G. R. Liu and H. R. Li, “Cascade Control of a Hydraulically Driven 6-DOF Parallel Robot Manipulator Based on a Slidg Mode,” Control Engi- , No. 9, 2008, pp. 1055-1068. doi:10.1016/j.conengprac.2007.11.005 in neering Practice, Vol. 16 [8] W. Gueaieb, S. Al-Sharhan and M. Bolic, “Robust Com- Putationally Efficient Control of Cooperative Closed- Chain Manipulators with Uncertain Dynamics,” Auto- matica, Vol. 43, 2007, pp. 842-851. doi:10.1016/j.automatica.2006.10.025 Copyright © 2011 SciRes. ICA  A. B. SHARKAWY ET AL.111 , pp. 353-363. franklin.2004.12.001 [9] P. Herman, “Sliding Mode Control of Manipulators Us- ing First-Order Equations of Motion with Diagonal Mass Matrix,” Journal of the Franklin Institute, Vol. 342, No. 4, 2005 doi:10.1016/j.j trict Lyapunov Function for Sliding Mode [10] P. Herman, “S Control of Manipulator Using Quasi-Velocities,” chanics Research Communications, Vol. 36, No. 2, 2009, pp. 169-174. Me- doi:10.1016/j.mechrescom.2008.09.010 D. Brambilla, L. M. Capisani, A. Ferrara and [11] P. Pisu, “Fault Detection for Robot Manipulators via Sec- ond-Order Sliding Modes,” IEEE Transactions on Indus- trial Electronics, Vol. 55, No. 11, 2008, pp. 3954-3963. doi:10.1109/TIE.2008.2005932 [12] M. Jin, J. Lee, P. H. Chang and C. Choi, “Practical Non- Singular Terminal Sliding-Mode Control of Robot Ma- nipulators for High-Accuracy Tracking Control,” IEEE Transactions on Industrial Electronics, Vol. 56, No. 9, 2009, pp. 3593-3601. doi:10.1109/TIE.2009.2024097 [13] B. Brogliato, D. Rey, A. Pastore and J. Barnier, “Experi- mental Comparison of Nonlinear Controllers for Flexible Joint Manipulators,” The International Journal of Robot- ics Research, Vol. 17, No. 3, 1998, pp. 260-281. doi:10.1177/027836499801700304 [14] F. Alonge, F. D’Ippolito and F. M. Raimondo, “Globally Convergent Adaptive and Robust Control of Robotic Ma- nipulators for Trajectory Tracking,” Control Engineering Practice, Vol. 12, No. 9, 2004, pp. 1091-1100. doi:10.1016/j.conengprac.2003.11.007 [15] M. K. Ciliz and M. O. Tuncay, “Comparative Experi- ments with a Multiple Model Based Adaptive Controller for a SCARA Type Direct Drive Manipulator,” Robotica, Vol. 23, No. 6, 2005, pp. 721-729. doi:10.1017/S026357470500158X [16] M. Margaloit and G. Langholz, “Fuzzy Control of a Benchmark Problem: Computing with Words Approach,” IEEE Transactions on Fuzzy Systems 2004, pp. 230-235. doi:10.1109/TFUZZ , Vol. 12, No. 2, .2004.825083 Part B: Cyberne t ic s, [17] V. Giordano, D. Naso. and B. Turchiano, “Combining Genetic Algorithms and Lyapunov-Based Adaptation for Online Design of Fuzzy Controllers,” IEEE Transactions on Systems, Man, and Cybernetics- Vol. 36, No. 5, 2006, pp. 1118-1127. doi:10.1109/TSMCB.2006.873187 [18] O. Cordon, F. Herrera, F. Hoffmann and L. Magdalena, “Genetic Fuzzy Systems: Evolutionary Tuning and Learning of Fuzzy Knowledge Bases,” W Singapore, July 2001. [19] A. B. Sharkawy, “Genetic Fuzzy Self-Tuning PID Con- trollers for Antilock Braking Systems,” Engineering Ap- plications of Artificial Intelligence, Vol. 23, No. 7, 2010, pp. 1041-1052. doi:10.1016/j.engappai.2010.06.011 [20] M. A. Llama, R. Kelly and V. Santibanez, “A Stable Motion Control System for Manipulators via Fuzzy Self-Tuning,” Fuzzy Sets and Systems, Vol. 124, No. 2, 2001, pp. 133-154. doi:10.1016/S0165-0114(00)00061-0 f, “Tuning of a [21] T. L. Seng, M. Khalid and R. Yuso Neuro-Fuzzy Controller by Genetic Algorithm,” IEEE Transactions on Systems, Man, and Cybernetics, Part B: Cybernetics, Vol. 29, No. 2, 1999, pp. 226-239. doi:10.1109/3477.752795 [22] A. B. Sharkawy, “A Computationally Efficient Fuzzy Logic Controller for Robotic Systems,” Proceedings of the 9th International Conference on Production Engi- neering, Design and Control (PEDAC’9), Alexandria, 10-12 February 2009. [23] A. Visioli and G. Legnani, “On the Trajectory Tracking Control of Industrial SCARA Robot Manipulators,” IEEE Transactions on Industrial Electronics, Vol. 49, No. 1, February 2002, pp. 224-232. doi:10.1109/41.982266 [24] F.-J. Lin and R.-J. Wai, “A Hybrid C Controller Using Fuzzy Neural omputed Torque Network for Motor- Quick-Return Servo Mechanism,” IEEE/ASME Trans- actions on Mechatronics, Vol. 6, No. 1, March 2001, pp. 75-89. doi:10.1109/3516.914394 [25] L. A Zadeh, “Fuzzy Logic = Computing with Words,” IEEE Transactions on Fuzzy Systems, Vol. 4, No. 2, 1996, pp. 103-111. doi:10.1109/91.493904 [26] L. X. Wang, “Fuzzy Systems Are Universal Approxima- tions,” Proceedings of IEEE International Confer Fuzzy Systems, San Diago, 8 March 1 ence on 992. doi:10.1109/FUZZY.1992.258721 [27] M. Margaloit and G. Langholz, “Fuzzy Lyapunov-Based Approach to the Design of Fuzzy Controllers”, Fuzzy Sets and Systems, Vol. 106, No. 1, 1999, pp. 49-59. doi:10.1016/S0165-0114(98)00356-X [28] L. X. Wang, “A Course in Fuzzy Systems and Control,” Prentice-Hall, Upper Saddle River, 1997. [29] M. M. Othman, “Fuzzy Control of Two Degrees of Free- dom Robotic Arm,” M.Sc Dissertation, Mechanical Engi- neering Department, Assiut University, Assiut, 2010. orld Scientific, Copyright © 2011 SciRes. ICA

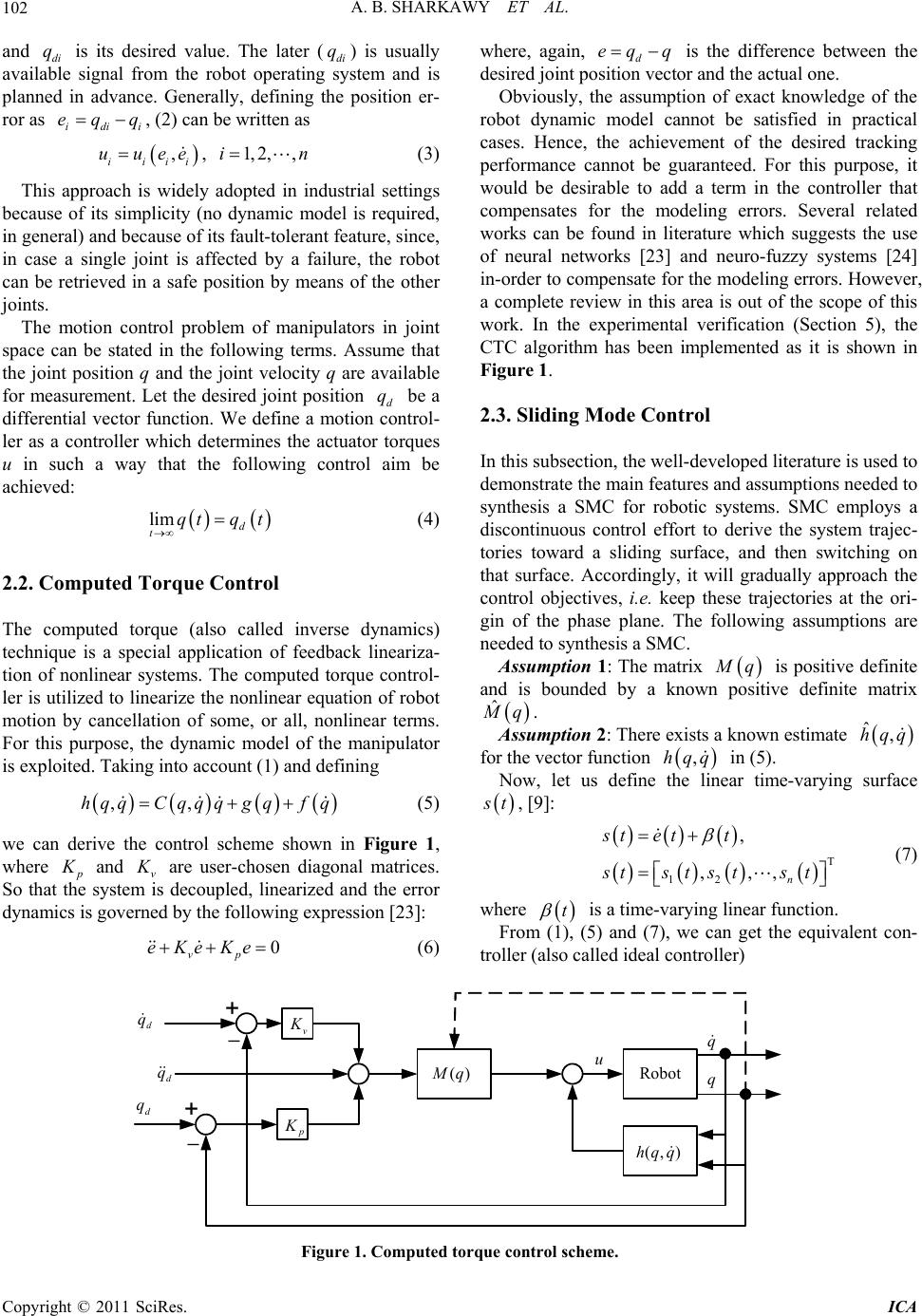

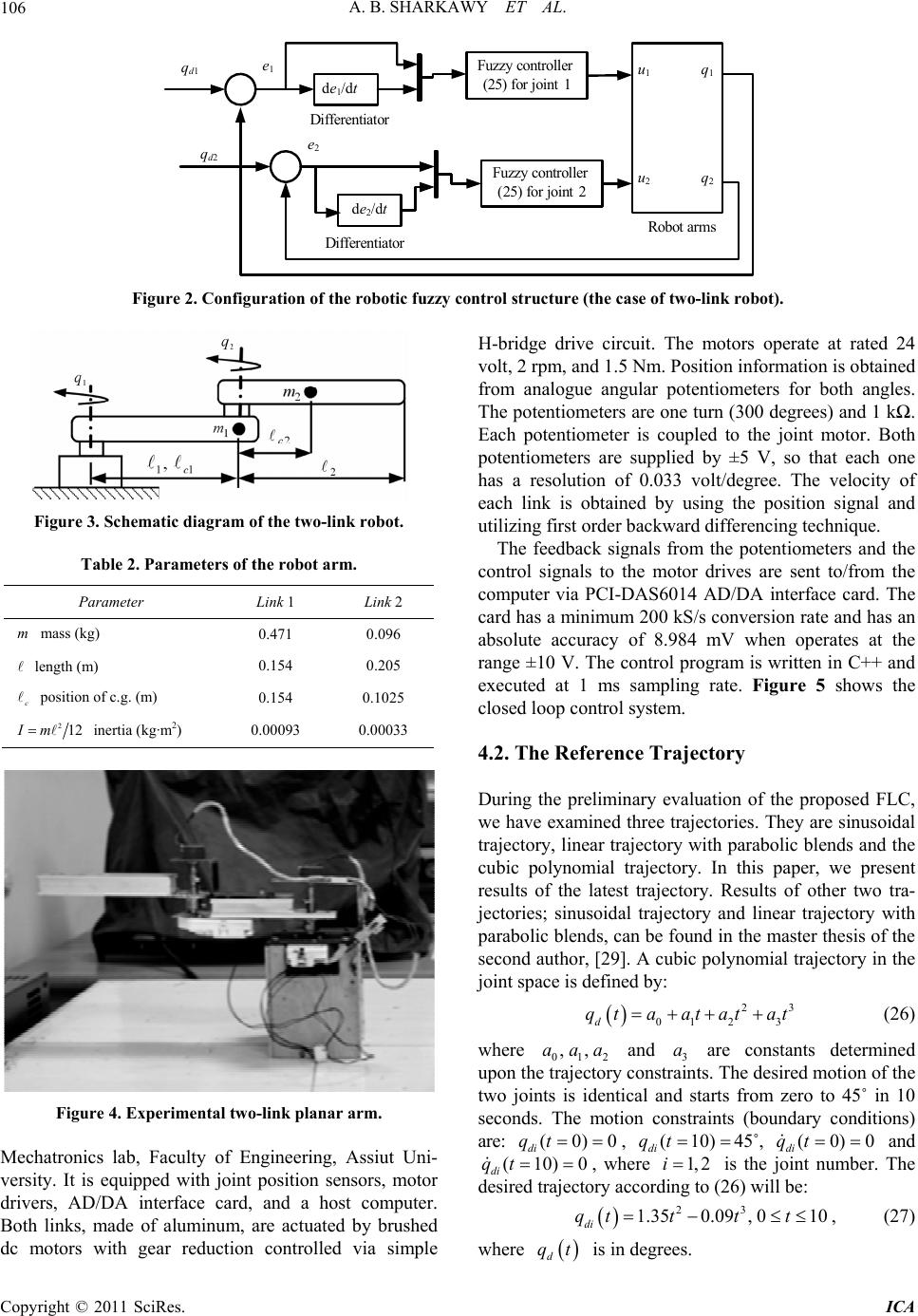

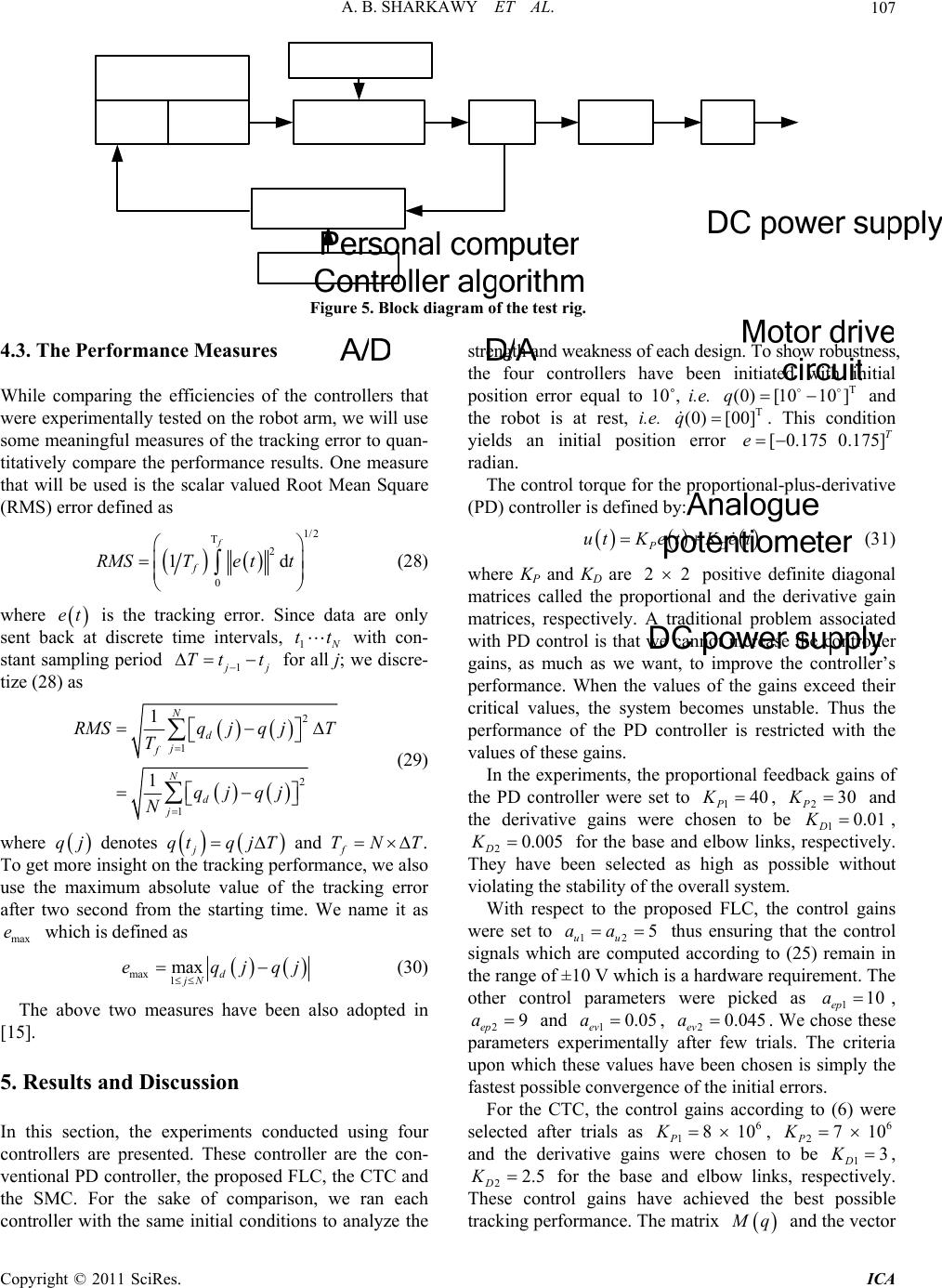

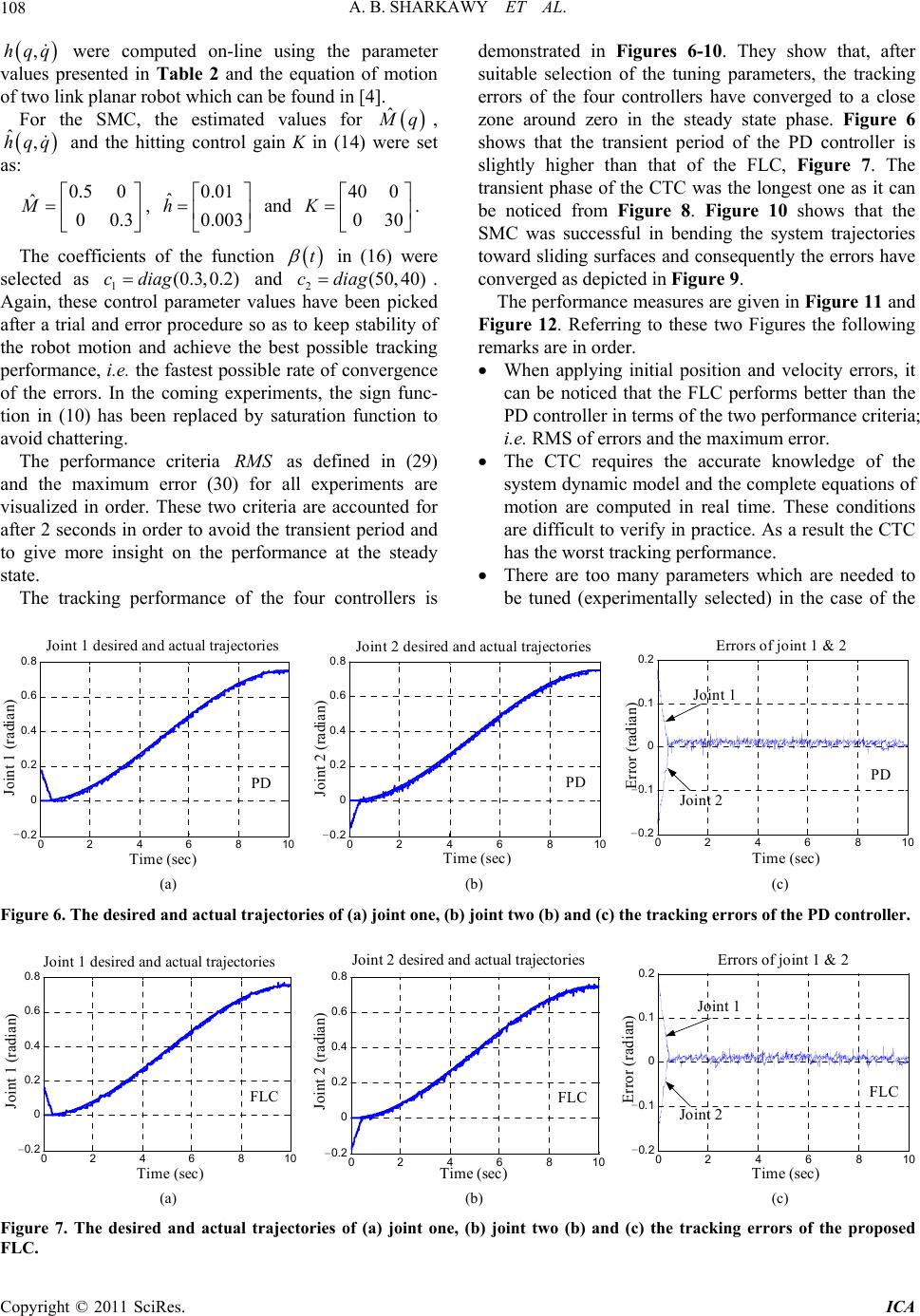

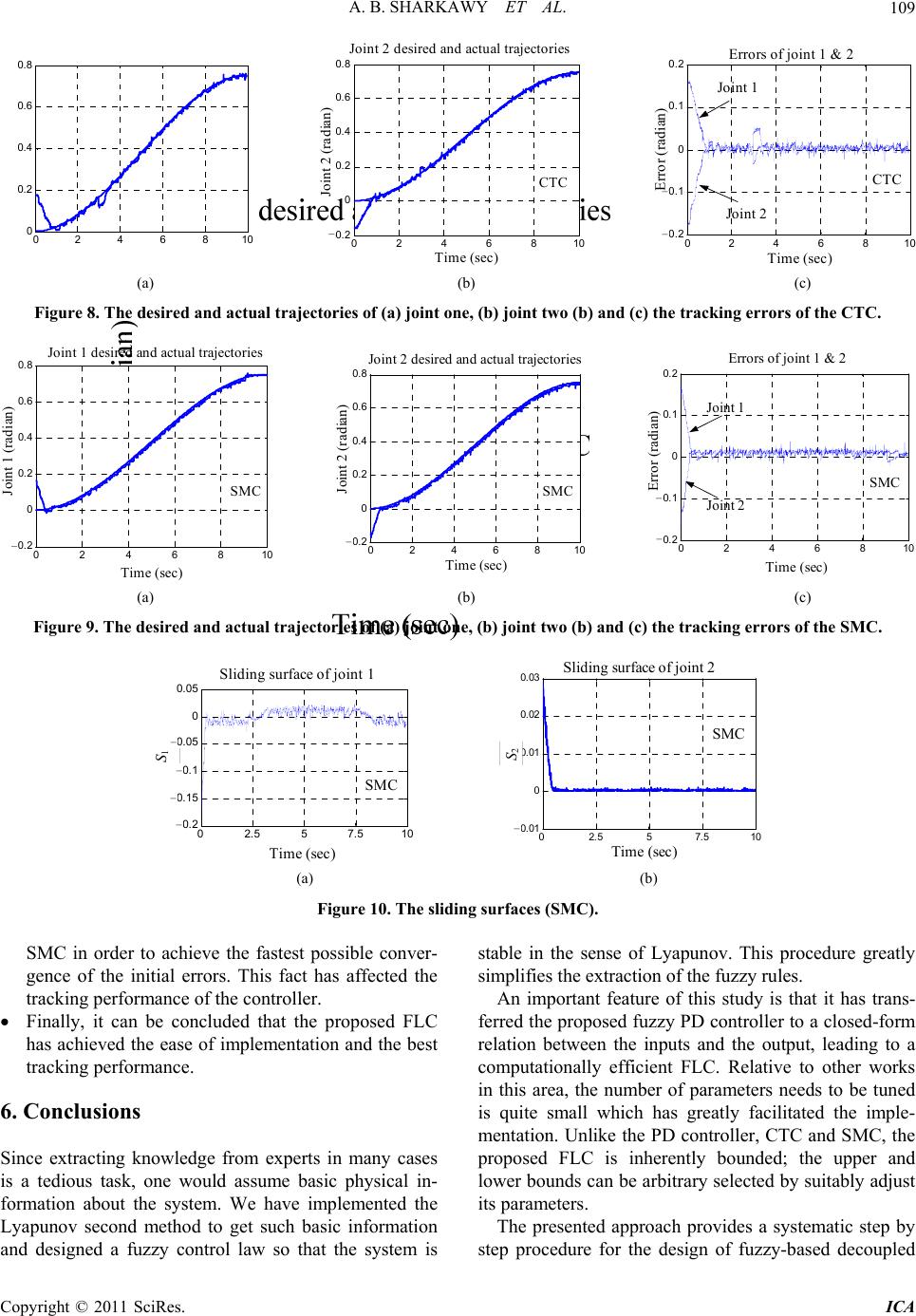

|