W. M. Haggag et al. / Agricultural Sciences 2 (2011) 146-157

Copyright © 2011 SciRes. http://www.scirp.org/journal/AS/

156

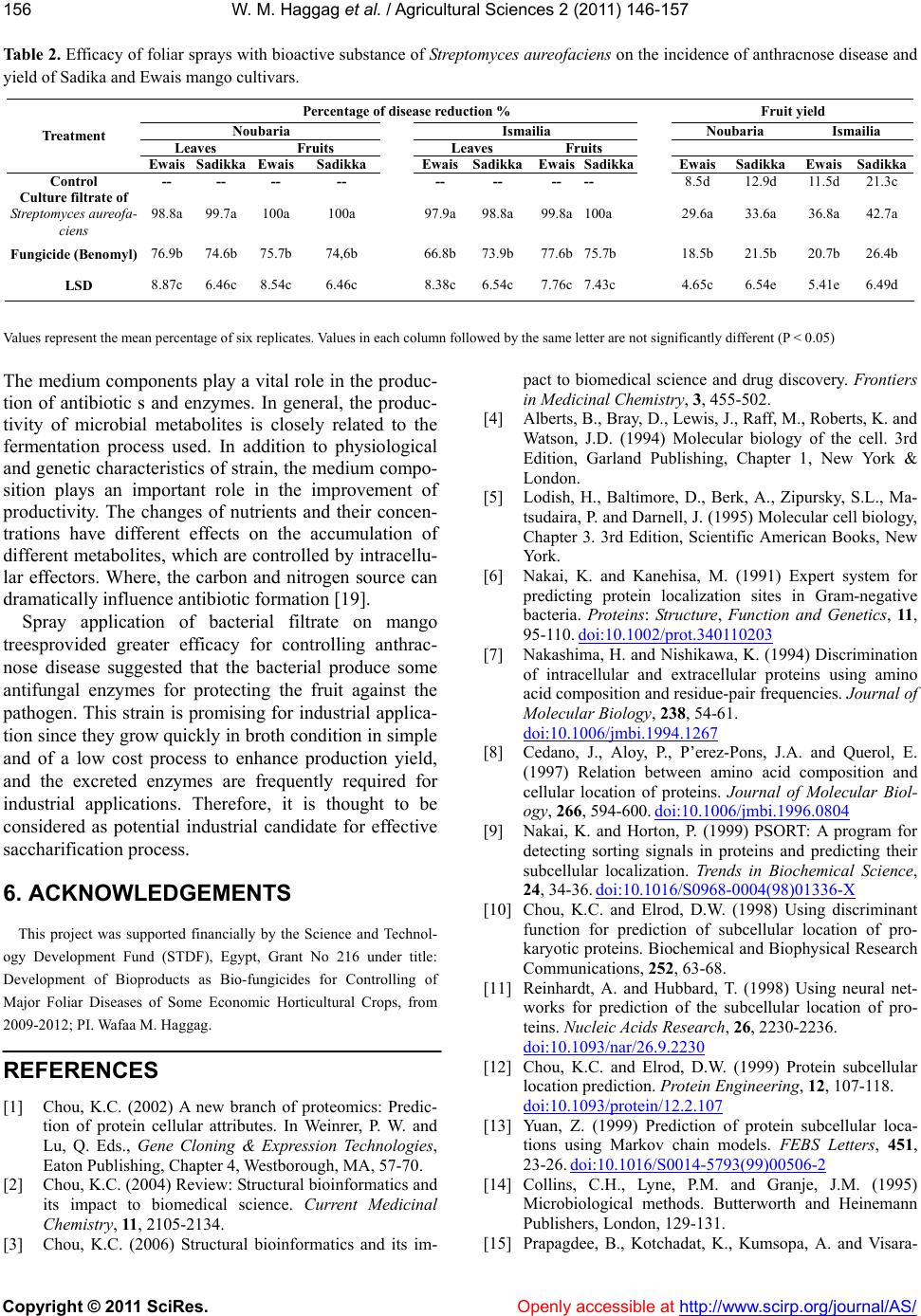

Table 2. Efficacy of foliar sprays with bioactive substance of Streptomyces aureofaciens on the incidence of anthracnose disease and

yield of Sadika and Ewais mango cultivars.

Percentage of disease reduction % Fruit yield

Noubaria Ismailia Noubaria Ismailia

Leaves Fruits Leaves Fruits

Treatment

Ewais Sadikka Ewais Sadikka EwaisSadikkaEwaisSadikka Ewais Sadikka EwaisSadikka

Control -- -- -- -- -- -- -- --

8.5d 12.9d 11.5d21.3c

Culture filtrate of

Streptomyces aureofa-

ciens 98.8a 99.7a100a 100a 97.9a98.8a 99.8a100a 29.6a 33.6a 36.8a42.7a

Fungicide (Benomyl) 76.9b 74.6b 75.7b 74,6b 66.8b73.9b 77.6b75.7b 18.5b 21.5b 20.7b26.4b

LSD 8.87c 6.46c 8.54c 6.46c 8.38c6.54c 7.76c7.43c 4.65c 6.54e 5.41e6.49d

Values represent the mean percentage of six replicates. Values in each column followed by the same letter are not significantly different (P < 0.05)

The medium components play a vital role in the produc-

tion of antibiotic s and enzymes. In general, the produc-

tivity of microbial metabolites is closely related to the

fermentation process used. In addition to physiological

and genetic characteristics of strain, the medium compo-

sition plays an important role in the improvement of

productivity. The changes of nutrients and their concen-

trations have different effects on the accumulation of

different metabolites, which are controlled by intracellu-

lar effectors. Where, the carbon and nitrogen source can

dramatically influence antibiotic formation [19].

Openly accessible at

Spray application of bacterial filtrate on mango

treesprovided greater efficacy for controlling anthrac-

nose disease suggested that the bacterial produce some

antifungal enzymes for protecting the fruit against the

pathogen. This strain is promising for industrial applica-

tion since they grow quickly in broth condition in simple

and of a low cost process to enhance production yield,

and the excreted enzymes are frequently required for

industrial applications. Therefore, it is thought to be

considered as potential industrial candidate for effective

saccharification process.

6. ACKNOWLEDGEMENTS

This project was supported financially by the Science and Technol-

ogy Development Fund (STDF), Egypt, Grant No 216 under title:

Development of Bioproducts as Bio-fungicides for Controlling of

Major Foliar Diseases of Some Economic Horticultural Crops, from

2009-2012; PI. Wafaa M. Haggag.

REFERENCES

[1] Chou, K.C. (2002) A new branch of proteomics: Predic-

tion of protein cellular attributes. In Weinrer, P. W. and

Lu, Q. Eds., Gene Cloning & Expression Technologies,

Eaton Publishing, Chapter 4, Westborough, MA, 57-70.

[2] Chou, K.C. (2004) Review: Structural bioinformatics and

its impact to biomedical science. Current Medicinal

Chemistry, 11 , 2105-2134.

[3] Chou, K.C. (2006) Structural bioinformatics and its im-

pact to biomedical science and drug discovery. Frontiers

in Medicinal Chemistry, 3, 455-502.

[4] Alberts, B., Bray, D., Lewis, J., Raff, M., Roberts, K. and

Watson, J.D. (1994) Molecular biology of the cell. 3rd

Edition, Garland Publishing, Chapter 1, New York &

London.

[5] Lodish, H., Baltimore, D., Berk, A., Zipursky, S.L., Ma-

tsudaira, P. and Darnell, J. (1995) Molecular cell biology,

Chapter 3. 3rd Edition, Scientific American Books, New

York.

[6] Nakai, K. and Kanehisa, M. (1991) Expert system for

predicting protein localization sites in Gram-negative

bacteria. Proteins: Structure, Function and Genetics, 11,

95-110. doi:10.1002/prot.340110203

[7] Nakashima, H. and Nishikawa, K. (1994) Discrimination

of intracellular and extracellular proteins using amino

acid composition and residue-pair frequencies. Journal of

Molecular Biology, 238, 54-61.

doi:10.1006/jmbi.1994.1267

[8] Cedano, J., Aloy, P., P’erez-Pons, J.A. and Querol, E.

(1997) Relation between amino acid composition and

cellular location of proteins. Journal of Molecular Biol-

ogy, 266, 594-600. doi:10.1006/jmbi.1996.0804

[9] Nakai, K. and Horton, P. (1999) PSORT: A program for

detecting sorting signals in proteins and predicting their

subcellular localization. Trends in Biochemical Science,

24, 34-36. doi:10.1016/S0968-0004(98)01336-X

[10] Chou, K.C. and Elrod, D.W. (1998) Using discriminant

function for prediction of subcellular location of pro-

karyotic proteins. Biochemical and Biophysical Research

Communications, 252, 63-68.

[11] Reinhardt, A. and Hubbard, T. (1998) Using neural net-

works for prediction of the subcellular location of pro-

teins. Nucleic Acids Research, 26, 2230-2236.

doi:10.1093/nar/26.9.2230

[12] Chou, K.C. and Elrod, D.W. (1999) Protein subcellular

location prediction. Protein Engineering, 12, 107-118.

doi:10.1093/protein/12.2.107

[13] Yuan, Z. (1999) Prediction of protein subcellular loca-

tions using Markov chain models. FEBS Letters, 451,

23-26. doi:10.1016/S0014-5793(99)00506-2

[14] Collins, C.H., Lyne, P.M. and Granje, J.M. (1995)

Microbiological methods. Butterworth and Heinemann

Publishers, London, 129-131.

[15] Prapagdee, B., Kotchadat, K., Kumsopa, A. and Visara-