Journal of Agricultural Chemistry and Environment, 2014, 3, 1-6 Published Online October 2014 in SciRes. http://www.scirp.org/journal/jacen http://dx.doi.org/10.4236/jacen.2014.34B001 How to cite this paper: Liu, M., Xie, F.C., Cao, R.R., Qi, X.H. and Chen, X.H. (2014) Effect of Different Cover Cultivations in Later Summer on Aroma Constituents of Autumn Tea (Camellia sinensis L.). Journal of Agricultural Chemistry and Environment, 3, 1-6. http://dx.doi.org/10.4236/jacen.2014.34B001 Effect of Different Cover Cultivations in Later Summer on Aroma Constituents of Autumn Tea (Camellia sinensis L.) Min Liu1*, Fucan Xie1*, Renrong Cao2, Xiaohua Qi1, Xuehao Chen1# 1School of Horticulture and Plant Protection, Yangzhou University, Yangzhou, China 2Tea Research Institute of Jiangsu Province, Jurong, China Email: #xhchen@yzu.edu.cn Received 12 August 2014 Abstract Tea plants grown under sunshade net and greenhouse are new methods for coping with high- temperature stress in later summer in middle and south China. Aroma is one of the most impor- tant flavors and qualities of tea. In this research the cultivar “Longjing-changye” (LJCY) was grown under sunshade net, greenhouse and open field as treatments to study the changes of aromatic substances by using Head Space Solid Phase-microextraction and Gas Chromatography-Mass Spectrometry (HS-SPME/GC-MS). The results showed that tea plants grown under sunshade net and greenhouse had higher content of aroma substances in autumn tea. Those growing conditions are good for improving the contents of the ester and geraniol with floral and fruity fragrance in autumn tea. Moreover, overshadowing in summer is helpful to improve fragrance of fresh tea leaves quality in autumn tea, particularly the 50% sunshade net. Keywords Cultivation Conditions, HS-SPME, GC-MS, Aroma, Tea 1. Introduction The characteristic fragrance of tea, the “aroma” of either infused leaf or the tea liquor, is one of the most impor- tant factors for evaluation of its quality [1] [2]. The source of the tea aroma is attributed to various volatile or- ganic compounds (VOCs) present in tea. These VOCs are formed as a result of significant lipid degradations during the tea processing periods. For example, the majority of the aroma compounds are formed from amino acids, fatty acids, carotenoids and glycosides [3]. At present, the production of traditional and better green tea only harv ested in spring. Spring is very shor t for the growth of tea plants, which results in a lack of fresh raw tea leaves, so it is difficult to meet the market need of tea. It is not difficult to see that it needs to break the limitations of raw materials of spring green tea and in- *These authors contributed equally to this work. #Correspondi ng author.  M. Liu et al. crease the output of fresh tea in other seasons by changing cultivation conditions for tea plants. In recent years, some new cultivation techniques in tea have developed to improve the quality of tea. In order to improve the quality of autumn tea, we may let tea plants grow under sunshade net or greenhouse in summer which will improve the micro-climate for te a plants in later summer. Such a condition can yield a har- monious ecological environment and regulate the relationship between “metabolic source” and “metabolic pool”. Although the previous studies showed that it is good for improving the quality and production of tea with prop- erly covering the sunshade net during summer, the impact on the aroma of tea fresh leaves has not been reported yet [4]. In this research, we will compare the changes in aroma contents of LJCY tea grown in greenhouse, sun- shade net and open field conditions, respectively. The results will be helpful to explore the influence on the quality of aroma in fresh tea leaves harvested in autumn with a variety of cultivation. It also can provide tech- nical base to optimize tea cultivation conditions. 2. Materials and Methods 2.1. Materi als Tea plants (“Longjingc hangye” LJCY; Camellia sinensis) were grown under 50% and 75% shading net and greenhouse (from June 1, 2011 to September 10, 2011). Fresh young tea buds were harvested from the same cultivar of tea plants grown under greenhouse, sunshade net and open field of Tea Research Institute of Jiangsu province in China in October 2011 and kept at −80˚C till determination of aroma extraction. 2.2. Measurement of Micro-Climate in Different Conditions We set up 5 sampling points in each condition from the tea cultivar “LJC Y ”. By making use of the temperature and humidity measuring instruments and light intensity meter, the data related to the environmental factors were measured and recorded during the sunshade net treatment (from June 1, 2011 to September 10, 2011) on 8:00, 13:00 and 17:00 of each day. Averages of 5 duplication are calculated and used for statistical analysis. 2.3. Extraction and Concentration of Volatile Components For each sample 2.00 g of tea, previously homogenised, were weighed into a 10 ml vial, and infused with 3 ml boiling water, the vial was s ealed with tetrafluoroeth ylene and immediately kept at 80˚C to equilibr ate for 5 min in a water bath; then, the extraction was performed with a 75 μm Carboxen/PDMS extraction head. After sam- pling during 30 min, the SPME fibre was introduced into the GC injector, and left for 3.5 min to allow the ana- lytes thermal desorption [5] [6]. 2.4. Gas Ch romatog rap hy-Mass Spectrometry (GC-MS) Analysis The analysis of volatile compounds obtained by SPME and SDE was performed by means of a GC-MS using an Agilent 5975C mass selective detector coupled to an Agilent 7890AGC (Agilent, Santa Clara, CA), equipped with HP-5MS capillary column (30 × 0.25 mm inner diameter, 0.25 μm film thickness). Helium was used as carrier gas, and the flow rate was 1 mL∙min −1. For the SDE, 0.1 μL concentration was injected in splitless mode at 250˚C; for SPME analysis, desorption was also in splitless mode at 250˚C for 5 min. The GC oven tempera- ture gradient was: 50˚C (held for 2 min) initially, and finally increased to 260˚C (held for 5 min) at 5˚C∙min−1. The transfer line temperature was 280℃. Electron impact (EI) spectra were recorded at 70 eV, the ion source temperature was 250˚C, and the mass spectra were scanned in an m/z range of 40 to 500 mass units. Compounds were tentatively identified by using the NIST147, NIST27 and WILEY7 mass spectra library. Each compound was further confirmed by comparing its mass spectra, linear retention index (LRI), and retention times with those obtained for the standards [7] [8]. 3. Results 3.1. Difference of the Environment Conditions under the Different Facilities As shown in Table 1, the actual transmittance of 75% and 50% sunshade net treatments 74.65% and 50.13%, respectively, and 65.44% for greenhouse cover, that is to say, the actual shading degree was 34.56%. Compared  M. Liu et al. with the open field, the temperature of greenhouse was 1.40˚C higher. However, that of 75% and 50% shading net were 2.40 and 2.60 lower, respectively (Table 2). The relative humidity of greenhouse, 75% and 50% shad- ing net inc re a sed by 4.80% , 7.6% and 2.8% , respective ly (Table 2). 3.2. Sunshade Net and Greenhouse Treatment Alters the Composition of Aroma Components An aroma extract obtained by HS-SPME extraction of the representative LJCY tea sample was subjected to GC-MS analysis. Ninety aroma-active compounds were perceived by panel-lists (Table 3 ), including 8 lactones, 4 alcohols, 5 allyl compounds other 2 compounds. It was obvious that were the major group in LJCY tea. Lac- tone compounds accounted for 43.16% of the total aroma constituents of LJCY grown in the open field com- pared to the ester compounds and contents of lactone compounds of LJCY grown under greenhouse and 50% shading net increased by 14.99% and 23.49%, respectively. However that decreased by 7.62% under 75% shad- ing net. Contents of alcohol components of LJCY grown under the different conditions but the open field were in- creased. They increased by 10.22% in greenhouse condition, and 6.62%, 9.94% for 50% and 75% shading net conditions, respectively. Likewise, the contents of allyl compounds of LJCY grown under different facilities were higher than that in the open field (Table 3). However, the contents of 3-methylene-1,1-2-methyl vinyl Table 1. Comparison of illumination intensity and light penetrability under the conditions of greenhouse, sunshade net and open field. The light penetrability is the ratio of the light intensity in facilities conditions and that in the open field. Time Illumination intensity (×102 Lux) Light penetrability (%) Open field Greenhouse Open field Greenhouse Fine days 8:00 545.9 137.1 273.2 313.4 0.0 25.1 50.0 57.4 13:00 813.2 218.6 408.7 556.1 0.0 26.9 50.3 68.4 17:00 156.6 40.7 77.8 104.4 0.0 26.0 49.7 66.7 Mean 505.2 132.1 253.2 324.6 0.0 26.0 50.0 64.2 Fine days 8:00 248.9 64.1 123.9 184.0 0.0 25.8 49.8 73.9 13:00 343.0 78.9 150.5 209.4 0.0 23.0 49.7 61.0 17:00 46.3 11.7 22.7 29.3 0.0 25.3 49.7 63.3 Mean 212.7 51.6 99.0 140.9 0.0 24.7 49.7 66.1 Table 2. Comparison of temperature and relative humidity under the conditions of greenhouse and sunshade net and open field. Time Temperature (˚C) Relative humidity (%) Open field Greenhouse Open field Greenhouse Fine days 8:00 27.1 25.0 25.5 27.9 40.7 48.6 48.5 49.8 13:00 33.0 30.4 29.6 34.2 32.3 36.7 33.0 34.9 17:00 27.6 25.7 25.6 28.3 56.9 60.6 52.1 53.4 Mean 29.2 27.0 26.9 30.1 43.3 48.6 44.5 46.0 Fine days 8:00 25.7 22.0 23.1 25.7 54.0 69.2 59.8 64.8 13:00 27.5 24.0 24.4 27.0 42.8 54.1 49.6 52.5 17:00 23.5 22.0 21.9 23.5 64.7 68.2 65.4 65.3 Mean 25.6 22.7 23.1 25.4 53.8 63.8 58.3 60.9  M. Liu et al. cyclohexane and 1-(2-aminoethyl) aziridine were decreased (Table 3). As shown in Figure 1, among all kinds of cultivation conditions tested, LJCY grown under 75% shading net Figure 1. The esters, menthyl salicylate, linalool and geraniol accumulations in LJCY tea buds under greenhouse, sunshade net and open field conditions. Error bars indicate Standard deviation ± SD of three biological replicates. The two asterisks show very significant differences at the 1% level. Table 3. Variation in the volatile flavour compounds of LJCY tea grown under greenhouse, sunshade net and open field. The ratio is the specific value of the aromatic substances contents in LJCY tea grown under greenhouse or sunshade net and that in the open field. the sign “−” denotes an negative growth. Aromatic substances Open field (CK) Greenhouse Ratio/% 50% sun- shade net Ratio/% 75% sun- shade net Ratio/% Hexenyl acetate 18.88 15.89 −15.84 14.75 −21.88 10.19 −46.03 Cis-3-hexenyl caproate 0.89 1.51 69.66 1.93 116.85 1.34 50.56 menthyl salicylate 18.88 29.65 57.04 32.73 73.36 25.22 33.58 Cis-3-hexenyl valerate 0.77 0.86 11.69 1.13 46.75 0.61 −20.78 Toluene acid butyrate 2.30 0.21 −90.87 0.72 −68.70 1.26 −45.22 Anti-2-hexenoic acid butyl ester 0.60 0.13 −78.33 0.41 −31.67 0.17 −71.67 Anti-2-hexenyl hexanoate 0.07 0.22 214.29 0.21 200.00 0.03 −57.14 CIS-3-hexene butyric acid ester 0.77 1.16 50.66 1.42 84.42 1.05 36.36 Total esters 43.16 49.63 14.99 53.30 23.49 39.87 −7.62 phytol 0.81 0.70 −13.58 1.27 56.79 1.81 123.46 linalool 0.60 11.60 1833.33 11.92 1886.67 7.17 1095.00 Geraniol 1.00 2.05 105.00 3.97 297.00 2.45 145.00 3-hexenol 13.01 11.29 −13.22 4.88 −62.49 13.93 7.07 Total alcohol 15.42 25.64 66.28 22.04 42.93 25.36 64.46 Caryophyllene 0.06 0.05 −16.67 0.05 −16.67 0.13 116.67 β-pinene 0.77 1.33 72.73 0.97 25.97 3.05 296.10 laurene 0.60 1.19 98.33 1.30 116.67 1.39 131.67 β-bourbonene 0.72 1.29 79.17 1.19 65.28 0.58 −19.44 α-muurolene 1.09 3.22 195.41 1.92 76.15 4.28 292.66 Total vinyl 3.24 7.08 118.52 5.43 67.59 9.43 191.05 1-(2-aminoethyl) aziridine 14.41 7.46 −48.23 8.67 −39.83 13.73 −4.71 3-methylene-1,1-2-methyl vinyl cyclohexane 18.88 1.50 −92.02 1.02 −94.60 2.43 −87.13  M. Liu et al. condition contained the lowest level of ester (p < 0.01) while the highest (p < 0.01) for tea plants grown under 50% shading net condition. The biggest increase of aroma components in LJCY tea grown under three condi- tions are methylis salicylas, followed by linalool and geraniol in ordercompared with the open field ( Figure 1). 4. Discussion The aromatic substances in tea is the general term for various kinds of volatile substances. The aroma indicates that the tea comprises at least one of certain numbers of odours that are desirable and are highly valued in “good quality tea”. Its composition is very complex, which included alcohol, aldehydes, acids, esters, ketones, terpenes and other aromatic substances in the fresh tea leaves [9] [10]. Besides the typical astringent and bitter taste, in particular, the charac teristic aroma of the tea beverage is an important criterion in the evaluation of the tea qua l- ity. Also LJCY tea is one of the most popular tea beverages in China, appreciated by consumers mostly for its characteristic taste, color and flavor. Optimum temperature for tea plants growth is between 20˚C and 30˚C and relative humidity of air is around 75%. Based on our research, as shown in Table 2, shading treatments on tea can reduce the temperature of summer. Temperature of greenhouse is slightly higher than the open field is due to the poor ventilation of greenhouse. The sunshade net and greenhouse covers can improve air relative humidity. As shown in Table 1 and Table 2, the sunshade net cultivation is more suitable for the growth of tea plants in summer. In alcohol components, the key aroma-active compounds were probably a-terpineol, b-linalool, linalool o xide III, linalool oxide IV and geraniol in terms of their aroma inten sities, and these alcohols also provide fruity and floral notes. It has been previously reported that a-terpineol was one of the major components contributing to the odour of smoked Lapsang Souchong [11] and that geraniol was found to be one of the characteristic volatile components in Keemun black tea [12] as well as Kangra orthodox black tea [13]. Furthermore, phytol was also detected in green tea powder produced from shade-grown leaves and used as an indicator of shading treatment [14]. Our research showed that LJCY tea harvested in autumn and grown under shading conditions released out more fruity and floral fragrance (Table 3), which is the same as the previous study [14]. Generally speaking, the content of aromatic substances in spring tea buds are higher than than that in autumn tea, which is one reason that the spring tea smell much more aroma. In fact, most acids existed in esters form or were changed into aldehydes, alcohols, hydrocarbons, or other secondary metabolites [15]. This research also showed that the contents of terpene alcohols such as linalool and geraniol with flower and fruit aroma in fresh tea buds grown under sunshade net and greenhouse were higher than that in the open field (Figu re 1). Tea plants grown und e r sunshade ne t a nd greenhous e we re richer of a roma substances in autumn tea. The aroma-active compounds detected above by our research were most likely the crucial and characteristic aromatic compounds determining the special flavour of LJCY tea. Previous studies showed that the low mole- cular chain of alcohols and esters are highly volatile with a very delicate odor, especially C5-C8 compounds [16]. Linalool is known for lily of the valley aroma and described as a complex woody and light scent, and reported as a major flavour component of orthodox Kangra tea [17]. In this stud y, the LJCY tea grown und er shading cond i- tions with higher lactones and inalool contents were found, which indicated that LJCY tea grown under shading facilities is highly delicate odor (Figure 1). 5. Conclusion In conclusion, shading in summer is helpful to improve the aroma quality of fresh buds of autumn tea and more conducive to improve the contents of ester and geraniol aromatic substances with floral and fruit flavor of fresh autumn tea buds, especially the 50% sun shade net. Acknowledgements We thank the experimental tea farm of the Tea Research Institute of Jiangsu province for all treatments and sampling. This research was financially supported by Jiangsu Science and Technolgy project (BE2012326). References [1] Horie, H., Fuka tsu, S. , Mukai, T., Kawanaka, T.G.M., Shimohara, T. and Sens (1992) Quality Evaluat ion of Green Tea (Sencha) by Sensory Test and NIR Method. Chagyo Kenkyu Hokoku (Tea Research Journal), 76, 39-44.  M. Liu et al. http://dx.doi.org/10.5979/cha.1992.76_39 [2] Togari, N., Kobayashi, A. and Aishim, T. (1995) Pattern Recognition Applied to Gas Chromatographic Profiles of Vo- latile Components in Thre e Tea Categories. Food Research International, 28, 495-502. http://dx.doi.org/10.1016/0963-9969(95)00029-1 [3] Yamanishi, T. (1981) In Tea, Coffee and Cocoa and Other Beverages. In: Teranishi, R., Flath, R.A. and Sigi sawa, H. Eds., Flavour Research, Marcell Dekker, New York, 231-304. [4] Li, W.J., Yang, P.X. and Li, X.P. (2003) Effects of Shading on the Tea Compounds of Tea New Shoots. China Tea. (In Chinese) [5] Jumtee, K., Komura, H., Bamba, T. and Fukusaki, E. (2011) Predication of Japanese Green Tea (Sen-cha) Ranking by Volatile Profiling Using Gas Chromatography Mass Spectrometry and Multivariate Analysis. Journal of Bioscience and Bioengineering, 112, 252-255. http://dx.doi.org/10.1016/j.jbiosc.2011.05.008 [6] Vichi, S., Gua dayol, J.M., Caixach, J., López-Tamames, E. and Buxaderas, S. (2007) Comparative Study of Differen- textraction Techniques for the Analysis of Virginolive Oil Aroma. Food Chemistry, 105, 1171-1178. http://dx.doi.org/10.1016/j.foodchem.2007.02.018 [7] Du, L.P., Li, J.X., Li, W., Li, Y.F., Li, T. and Xiao, D.G. (2014) Characterization of Volatile Compounds of Pu-erh Tea Using Solid-Phasemicroextraction and Simultaneous Distillation-Extraction Coupled with Gas Chromatography-Mass Spectrometry. Food Research International, 57, 61-70. http://dx.doi.org/10.1016/j.foodres.2014.01.008 [8] Tat, L., Comuzzo, P., Stolfo, I. and Battistutta, F. (2005). Optimization of Wine Head-Sp ace Analysis by Solid-Phase Microextraction Capillary Gas Chromatography with Mass Spectrometric and Flame Ionization Detection. F ood Che- mistry, 93, 361-369. http://dx.doi.org/10.1016/j.foodchem.2004.11.025 [9] Wang, L.F., Lee, J.Y., Chung, J.O., B aik, J.H., So, S. and Par k, S.K. (2008) Discrimination of Teas with Different De- grees of Fermentation by SPME-GC Analysis of the Characteristic Volatile Flavour Compounds. Food Chemistry, 109, 196-206. http://dx.doi.org/10.1016/j.foodchem.2007.12.054 [10] Xu, X., Yan, M. and Zhu, Y. (2005) Influence of Fungal Fermentation on the Development of Volatile Compo unds in the Puer Tea Manufacturing Process. Engineering in Life Sciences, 5, 382-386. http://dx.doi.org/10.1002/elsc.200520083 [11] Yao, S.S., Guo, W.F., Lu, Y. and Jiang, Y.X. (2005) Flavor Characteristics of Lapsang Souchong and Smoked Lapsang Souchong, a Special Chinese Bl ack Tea with Pine Smoking Process. Journal of Agricultural and Food Chemistry, 53, 8688-8693. http://dx.doi.org/10.1021/jf058059i [12] Wang, H.F., Takeo, T., Ina, K. and Li, M.J. (1993) Characteristic Aroma Components of Keemun Black Tea. Journal of the Tea Science, 13, 61-68. (in Chinese) [13] Rawat, R., Gulati, A., Babu, G.D.K., Acharya, R., Kaul, V.K. and Singh, B. (2007) Characterization of Volatile C om- ponents of Kangra Orthodox Black Tea by Gas Chromatography-Mass Spectrometry. Food Chemistry, 105, 229-235. http://dx.doi.org/10.1016/j.foodchem.2007.03.071 [14] Tontul, I., Torun, M., Dincer, C., Sahin-Nadeem, H., Topuz, A., Turna, T., et al. (2012) Comparative Study on Volatile Compounds in Turkish Green Te a Powder: Impact of Tea Clone, Shading Level and Shooting Period. Food Research International, 53, 744-750. http://dx.doi.org/10.1016/j.foodres.2012.12.026 [15] Romeo, V., Ziino, M., Giuffrida, D., Condurso, C. and Verzera, A. (2007) Flavour Profile of Capers (Capparis spinosa L.) from the Eolian Archipelago by HS-SPME/GC-MS. Food Chemistry, 101, 1272-1278. http://dx.doi.org/10.1016/j.foodchem.2005.12.029 [16] Wang, H.F. (1989) Tea flavor and Aroma. Chinese Tea. [17] Gulati, A. and Ravindranath, S.D. (1996) Seasonal Variations in Quality of Kangra Tea (Camellia sinensis (L) O Kuntze) in Himachal Pradesh. Journal of the Science of Food and Agriculture, 71, 231-236. http://dx.doi.org/10.1002/(SICI)1097-0010(199606)71:2<231::AID-JSFA573>3.0.CO;2-Y

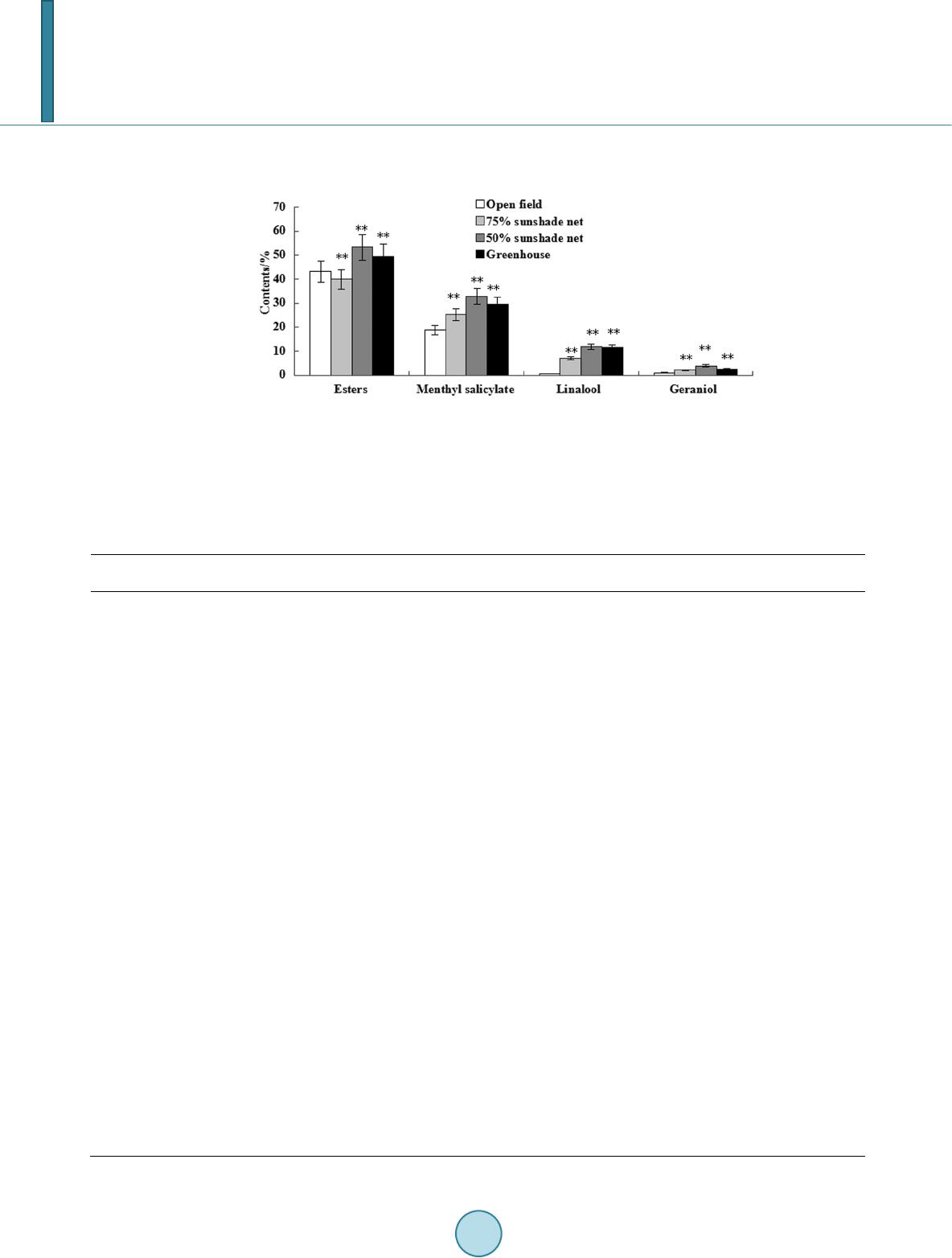

|