B. S. BUCK ET AL.

448

cent valve opening, and the velocity of air entering

though the aeration hatch.

4. Results

It was originally planned to record a baseline dissipation

measurement using cross-Section 1 without any of the

energy dissipation structures installed. However, the wa-

ter exiting the structure was moving at a high rate of ve-

locity and was far too turbulent to get any valid readings.

This visually confirmed the fact that simply changing the

direction of the jet from a Fixed-Cone valve does little as

far as power (energy) dissipation is concerned [2].

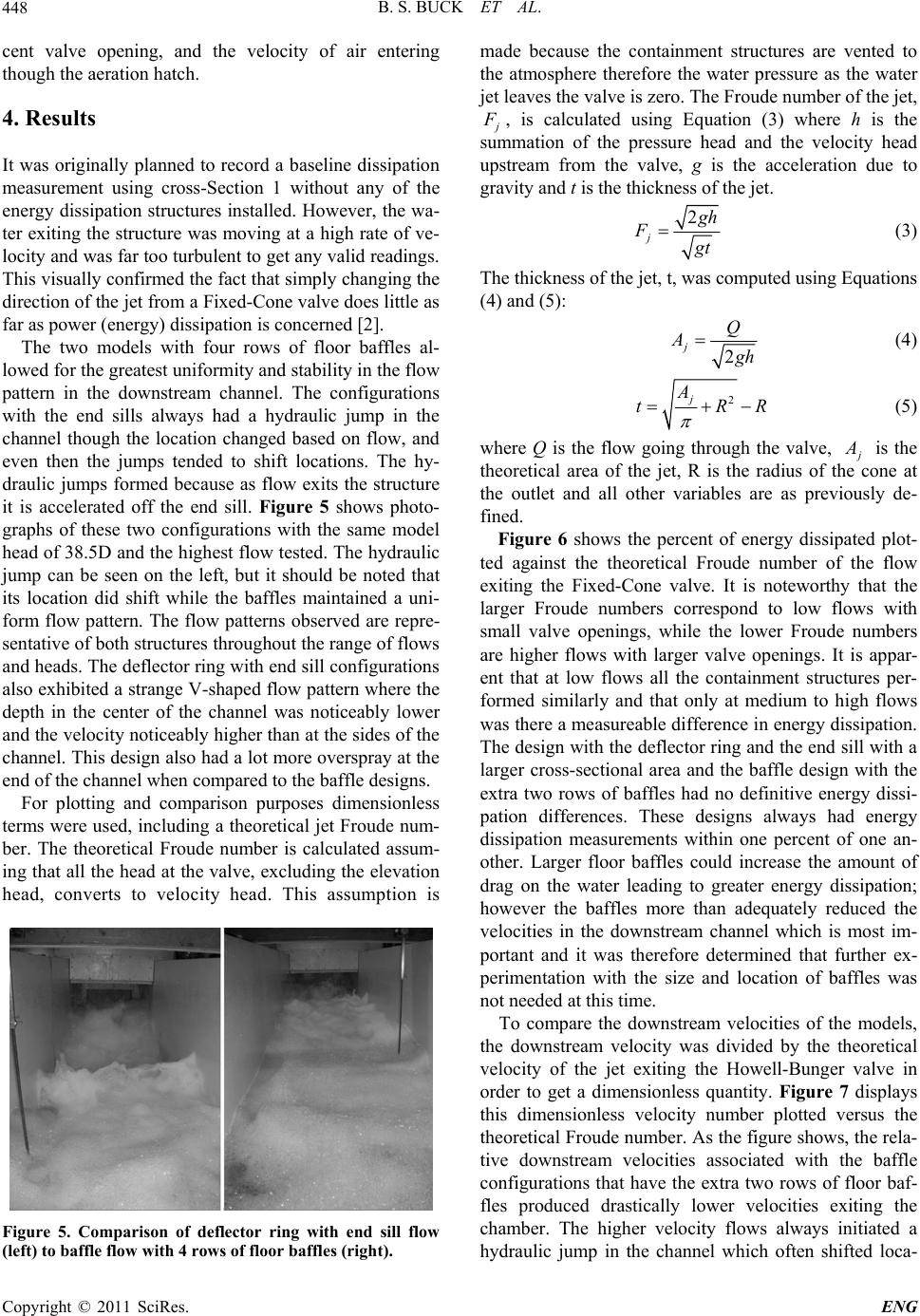

The two models with four rows of floor baffles al-

lowed for the greatest uniformity and stability in the flow

pattern in the downstream channel. The configurations

with the end sills always had a hydraulic jump in the

channel though the location changed based on flow, and

even then the jumps tended to shift locations. The hy-

draulic jumps formed because as flow exits the structure

it is accelerated off the end sill. Figure 5 shows photo-

graphs of these two configurations with the same model

head of 38.5D and the highest flow tested. The hydraulic

jump can be seen on the left, but it should be noted that

its location did shift while the baffles maintained a uni-

form flow pattern. The flow patterns observed are repre-

sentative of both structures throughout the range of flows

and heads. The deflector ring with end sill configurations

also exhibited a strange V-shaped flow pattern where the

depth in the center of the channel was noticeably lower

and the velocity noticeably higher than at the sides of the

channel. This design also had a lot more overspray at the

end of the channel when compared to the baffle designs.

For plotting and comparison purposes dimensionless

terms were used, including a theoretical jet Froude num-

ber. The theoretical Froude number is calculated assum-

ing that all the head at the valve, excluding the elevation

head, converts to velocity head. This assumption is

Figure 5. Comparison of deflector ring with end sill flow

(left) to baffle flow with 4 rows of floor baffles (right).

made because the containment structures are vented to

the atmosphere therefore the water pressure as the water

jet leaves the valve is zero. The Froude number of the jet,

, is calculated using Equation (3) where h is the

summation of the pressure head and the velocity head

upstream from the valve, g is the acceleration due to

gravity and t is the thickness of the jet.

2

j

h

F

t

(3)

The thickness of the jet, t, was computed using Equations

(4) and (5):

2

jQ

A

h

(4)

2

j

A

tR

R

(5)

where Q is the flow going through the valve,

is the

theoretical area of the jet, R is the radius of the cone at

the outlet and all other variables are as previously de-

fined.

Figure 6 shows the percent of energy dissipated plot-

ted against the theoretical Froude number of the flow

exiting the Fixed-Cone valve. It is noteworthy that the

larger Froude numbers correspond to low flows with

small valve openings, while the lower Froude numbers

are higher flows with larger valve openings. It is appar-

ent that at low flows all the containment structures per-

formed similarly and that only at medium to high flows

was there a measureable difference in energy dissipation.

The design with the deflector ring and the end sill with a

larger cross-sectional area and the baffle design with the

extra two rows of baffles had no definitive energy dissi-

pation differences. These designs always had energy

dissipation measurements within one percent of one an-

other. Larger floor baffles could increase the amount of

drag on the water leading to greater energy dissipation;

however the baffles more than adequately reduced the

velocities in the downstream channel which is most im-

portant and it was therefore determined that further ex-

perimentation with the size and location of baffles was

not needed at this time.

To compare the downstream velocities of the models,

the downstream velocity was divided by the theoretical

velocity of the jet exiting the Howell-Bunger valve in

order to get a dimensionless quantity. Figure 7 displays

this dimensionless velocity number plotted versus the

theoretical Froude number. As the figure shows, the rela-

tive downstream velocities associated with the baffle

configurations that have the extra two rows of floor baf-

fles produced drastically lower velocities exiting the

chamber. The higher velocity flows always initiated a

hydraulic jump in the channel which often shifted loca-

Copyright © 2011 SciRes. ENG