Engineering, 2011, 3, 435-444 doi:10.4236/eng.2011.35050 Published Online May 2011 (http://www.SciRP.org/journal/eng) Copyright © 2011 SciRes. ENG Sliding Mode Control, with Integrator, for a Class of MIMO Nonlinear Systems Anouar Benamor1, Larbi Chrifi-alaui2, Hassani Messaoud1, Mohamed Chaabane3 1Unit’e de Recherche en Automatique, Traitement du Signal et Image de l’ENIM, ATSI-ENIM, Monastir, Tunisie 2Laboratoire des Technologies Innovantes, Université de Picardie Jules Verne, Mitterrand, France 3Unité de Commande Automatique, l’Ecole Nationale d’Ingénieurs de Sfax, Sfax, Tunisie E-mail: anouar.benamor@yahoo.fr, hassani.messaoud@enim.rnu.tn, larbi.alaoui@u-picardie.fr, chaabane_uca@yahoo.fr Received January 24, 2011; revised March 8, 2011; accepted March 22, 2011 Abstract In this paper, the robust control problem of general nonlinear multi-input multi-output (MIMO) systems is proposed. The robustness against unknown disturbances is considered. Two algorithms based on the Sliding Mode Control (SMC) for nonlinear coupled Multi-Input Multi-Output (MIMO) systems are proposed: the first order sliding mode control (FOSMC) with saturation (sat) function and the FOSMC with sat combined with integrator controller. Those algorithms were simulated and implemented on the three tanks test-bed system and the experimental results confirm the effectiveness of our control design. Keywords: Sliding Mode Control, Integrator, Nonlinear Systems, Coupled, Mimo, Uncertain, Liquid Level Control 1. Introduction The SMC is a widely used approach to design robust control law of uncertain systems. The advantage of such approach is its robustness to parameter variations and disturbances [1,2]. But the major inconvenience of clas- sic sliding mode control is the existence of chattering phenomenon [3], which may induce many undesirable oscillations in control signal. Some attempts on chatter- ing [4] canceling have considered continuous functions instead of sign one. However the provided results lead to a large steady state error which can be reduced using the integral action [5-7]. Moreover even though there exist many works dealing with sliding mode control in the case of Single Input Single Output (SISO) systems [8], there is lock of results when the addressed process is Multi-Input Multi-Output (MIMO) one. This shortage is due to output coupling problem. In this paper, we propose a first order sliding mode control using Sat function and this control combined with an integrator corrector. Experimental results, oper- ated on a three tank system, are presented to illustrate the effectiveness of the proposed controllers. The paper is organized as follows. In Section 2 we re- mind the classical sliding mode control of coupled MIMO nonlinear systems and its robustness to parameter uncer- tainties and external disturbances. Section three is de- voted to SMC with sat function and integral action. The model of the coupled three tanks system and its control is presented in Section 4. The simulation and experimental results are presented in Sections 5 and 6. Finally Section 7 concludes the paper. 2. Sliding Mode Control Consider a MIMO non linear system with p inputs and m outputs defined by the following state representation: ,, , fxtgxtu ycxt (1) where x is the n-dimensional state vector and y is the m-dimensional output vector. 1 T n xxand is the m-dimensional vector, the coefficients of which are nonlinear functions ci(x,t), f(x,t) is the n-dimensional vector, the coefficients of which are nonlinear functions fi(x,t), g(x,t) is a 1 T m yy y pn matrix with coefficients are the nonlinear functions gij(x,t) and u is the p-dimensional control vector of coefficients ui.  A. BENAMOR ET AL. 436 1 T p uu u (2) 2.1. Classical Sliding Mode Control Consider the sliding surface [9] defined by: 1 T p ss (3) where: 1 0 , for 1,, i r ik iki k ei p (4) with: ri is the relative degree of the error ei i and for k = 1, , ri – 2, 11 i r i k are constants chosen so that 1 01 i i r p k ii 1i r pis a Hurwitz polynomial one and is the kth order derivative of the error ei. i e , 1,,1. d iii i eyyi r (5) where d i is the desired output. The derivative of si is: 1 01 de d i rn i ii k kj j se i j ttx (6) Replacing xj by its expression in (1) and omitting the index (x,t), relation (6) becomes. 1 0111 d d i rp nn i iii i kj kjlj jj see e jll gu ttxx (7) which can be written as: 11 1 d d p i iiiP Piil l l shbubu hbu t (8) with: 1 01 i rn iii ik kj j ss hf tx i and 1 01 i rn ii ik kjl kj j s bg x Then we can write the derivative of the surface vector as hbu (9) with: 111 1 and P1 PP hb hb hb P b b Theorem 1. The control law for the first order sliding mode control (FOSMC) of the system 1 so that the sliding surfaces go to zero in a finite time is defined by: 11 1 PP ksigns ubh ksigns (10) with ki a positive constant and b an invertible matrix. Proof. Consider the following Lyapunov function: 2 1 11 22 T 2 Vss ss (11) the derivative of V is: 11 T PP Vssss ss (12) Using (9) we have: T Vshbu (13) Replacing u by its expression (10) in Equation (9), we obtain: 11 PP ksigns s ksigns (14) then 11 11 0 pP T iii ii ii PP ksigns Vsksignss ks ksigns (15) Since ki (i = 1, , p) are positive we have V < 0. Then, the Lyapunov function V tends to 0 and there- fore all surfaces si tend to zero, hence the existence of the first order sliding mode. To prove the finite time convergence of our control we take the Equation (14), we have ii ii ksign ss then iii ii i skss , with 0i k ,which is the reachability condition [10], then the finite time conver- gence. 2.2. Robustness to Parametric Uncertainties and External Disturbances Consider an uncertain MIMO nonlinear system: ˆˆ ,,,, fxtfxtgxtgxtud (16) where n x is the state vector, uis the input- control bounded as maxii uu for i = 1 to p, the vector field ˆ ,, , xtf xtfxt is continuous and smooth, where ˆ, xt is the nominal part and , xt is the uncertain part bounded by a known function. n dD no minal pa represents the disturbances. The dynamic g(t,x the no ) is t exactly known an rt d it is written as the sum of ˆ, xt and the uncertain part , xt. Copyright © 2011 SciRes. ENG  A. BENAMOR ET AL.437 with: ˆ, 1 , ˆ, n ˆ xt fxt xt , ˆ, 1 ˆ, ˆ, n xt fxt xt , 1 n d d d 11 1 1 ˆˆ ,, ˆ, ˆˆ ,, P nnP xtg xt gxt xtgxt and 11 1 1 ,, , ,, P nnP xtg xt gxt xtgxt Then the derivative of the sliding surface takes the following form: 1 dˆˆ d p i i sh tiikik ki k hb bu (17) then: ˆˆ δ shh bbu 1 ˆ, ˆ, ˆ, p hxt hxt hxt , 1, , , p hxt hxt hxt , 1 δ δ δ 11 1 1 ˆˆ ,, ˆ, ˆˆ ,, p ppp bxtb xt bxt bxtbxt and Theorem 2. Consider the uncertain system defined by Equation trol law: (18) with ki satisfying: u (19) and wher 11 1 1 ,, , ,, p ppp bxtb xt bxt bxtbxt (16). The con 1 ˆˆ ksigns 11 PP ub h ksigns * max 1 δ p ii ikk k i k ei , ik , ties, te ti * δi 1 h, e and are of uncertaiand respectively, xpression of the derivative of the surface be- maxk u ik b, δi rgenc the upper bounds n fi conve k ensures thenime of the sliding surface to zero. Proof. The e u comes: ˆˆ δshh bbu (20) where s the p-dimensional vector wh are : δiose coefficients 1 δd for 1 to n i s ij jj ip x Using the control expression in (18) we ve: ha 11 ksigns δ PP sh ks igns bu (21) The derivative of the surface si is then written: δ ii i iikki shksigns bu 1 p k (22) and the derivative of the Lyapunov function given by (12) is: 1 ii i Vss n Veg isfied will be native if the following conditions are sat- : 0ss ii for i = 1 to p. If si > 0 then 0 i s , we have: p 1 δ0 ik i k hk iik bu (23) then i k 1 δ p iikki k hbu (24) If si < 0 then 0 i s , we have: 1 δ0 p i ki k h u iik k b (25) then i k 1 δ p iikki k hbu (26) The conditions (24) and (26) are satisfied if: * max δ ii kkii uk 1 p k (27) then 3. SMC with Sat t of classic sliding mode control is e existence of chattering phenomenon. To avoid this 0V The major inconvenien th Copyright © 2011 SciRes. ENG  A. BENAMOR ET AL. 438 problem, we approximate the «sign» function by con- tinuous functions such as sat function [9] defined by: if iii sign ss sat s if ii ii i ss 28) where ( i is a positive constant that defines the thickness of the ary layer. he first order sliding mode control h sat of the system (1) is defined by: bound Theorem 3. The control law for t (FOSMC) wit 11 1 ksats ubh PP ks ats (29) with ki a positive constant and b an invertible matrix. Proof. by n (11). Its derivative with using control defined in We consider the same Lyapunov function defined Equatio (31) is: ksats 11 T PP Vs ks ats (30) then i s (31) Using sat definition given by (28), w 1 p ii i Vksats e have: 2 0 if iii i sign sss 0 if ii i ii i sat s sss (32) Therefore: (33) then (34) ark. In the boundary layer the de 0 ii satss 0V Rem rivative of the surface is: i i i s (35) then ee ri ri ii tt tt iiri i sst (36) with: tri is the start time of boundary layer. then 0 for 1, iri , tt ip (37) order to solve a steady-state error problem, an inte- gral sliding manifold was proposed in [10] op (38) with In . This devel- ment is introduced and justified only by tests on spe- cific systems. Our idea consists on reconstituting a con- trol law to eliminate steady-state error created by distur- bance. To do so we added an integral action when the trajectories of states approach their references [11-14]. Proposition. Consider the uncertain system defined by Equation (1). aw FOSMC with integrator to eliminateThe control l steady-state error is defined by: 11 1 d d yy t ksats 11 11d d PP ub h K ksats yy t 11 1 1 pp KK K KK The coefficients Kij are the integrator constant defined by: j j ositive constant if > d ii yy 0 if ij d ii K yy (39) with j a positive constant. cription and Modeling tem, which ts on three 1 4. Validation 4.1. System Des The considered process is a three tank sys ave two inputs and three outputs. It consish cylindrical tanks with identical Section a supplied with distilled water, which are serially interconnected by two cylindrical pipes of identical Sections Sn. The pipes of communication between the tanks T1 and T2 are equipped with manually adjustable valves; the flow rates of the connection pipes can be controlled using ball valves az1 and az2. The plant has one outlet pipe located at the bot- tom of tank T3. There are three other pipes each installed at the bottom of each tank; they are provided with a di- rect connection (outflow rate) to the reservoir with ball valves bz1, bz2 and bz3, respectively, it can only be ma- nipulated manually. The pumps 1 and 2 are supplied by water from the reservoir with flow rates Q1(t) and Q2(t), respectively. The necessary level measurements h(t), Copyright © 2011 SciRes. ENG  A. BENAMOR ET AL. Copyright © 2011 SciRes. ENG 439 oming flow and the outgoing flo h2(t) and h3(t) are carried out by the piezo-resistive dif- ferential pressure sensors. The state Equations are obtained by writing that the variation of the water volume in a tank is equal to the difference between the inc 12 1, 2, 3, 4 jzjL BbSg j While taking B1 = B2 = B3 = 0, the three Equations of the system become (see Equation (44)): At equilibrium, for constant water level set point, the level derivatives must be zero. ws, that means, the water of the tanks 1 and 2 can flow toward the tank 3. Then, the system can be represented by the following Equations: 12 1 ,1,2,3 in outout ii ijij tQt Qt Qtij 123 0hhh (45) Therefore, using (45) in the steady state, the algebraic relationship holds. following h (40) 1 11313 =0 Q csignh hh h 11 31333232 0 a cs ignh hhhcsignhhhh where s the flow through pump i (i = 1; 2) and esents the flow rates of water betwee , and can be expressed in i Qti repr and j (, e law o 1out ij Qt tanks i n the (46) For the coupled tanks system, the fluid flow Q1 into tank 1, cannot be negative because the pump can dr From (47) we have 1,2,3 )iji j using thf Torricelli[15]. 1out ijzii j QtaS h i, j = 1, 3 (41) and 2out Qtrepresents the outfl 2 ni j signhh gh ow rate, given by: only ive water into the tank, then: Q1 ≥ 0 (47) ij 22 1, 2, 3 (42) out ijzj Li QtbSghj e hi(t), 1 11 13 3 s ignh hh ha and Q c wher in i Qtand out ij Qt are respectively the levels of t fle output The parameters of three tank system are defi ta he system can be considered as a multi input m water, the inpuow and thflow rates. ned in the 11313 signhh hh 3 3232 ccsignhh hh Then (h1-h3) ≥ 0 and (h3-h2) ≥ 0. Therefore if we as- sume. Table 1. The controlled signals are the water levels (h2, h3) of nks 2 and tank 3. These levels are controlled by two pumps. T 112 23 31122 , , , and hxh xhuQuQ (48) We h ulti output system (MIMO) where the input are inflow rates Q1, Q2 and the output are liquid levels h2, h3. Then the three tank systems can be modeled by the following three differential Equations as shown in (43): where the parameters ci, i = 1, 3 and Bj, j = 1, 2, 3, 4 are defined by: ave 1 1113 2 2332 42 3113 332 u xcxx a u xcxxBxa cxx cxx (49) 12 1, 3 izin caSg i 11 1131311 22 33232422 3 113133233323 d d d d d d hQ csignhhh hBh ta hQ csignh hh hBBh ta hcsign hhhhBBhcsign hhhh t 2 (43) 11 11313 22 3323242 3 1131333232 d d d hQ csignhhhh dt a hQ csignh hh hBh dt a hcsignhhhh csignhhhh dt (44)  A. BENAMOR ET AL. 440 which can be written in the same form of (1) as: , ftx gu ycx (50) where 123 T xxx, 12 T uuu, 23 T yxx 11 3 33 42 113332 ,ftxc xxB x cx xcxx cx x , 10 a 1 0g and 00 a 4.2. Sliding Mode Control of the Three Tank System The objective is to regulate the water levels of tank 2 and tank 3 by using both laws defined in Section 3. The vector of the sliding surface is given by: 010 001 c 12 T ss where: 122d xx and 23333dd xx xx x22 and tank n be written as follows: 2 d and x3d are the desired water levels of tank 3. The derivative of the sliding surface $s_1$ ca 11 12 lbu (51) with: 1332422d lcxxBxx and 1 12 ba Similarly, the derivative of s2 is: 22211222 lbubu (52) with: 11333211333242 221133323 1 1 2 d lc xxcxxxc x 3 3 2 xx 3 3 2 22 d cxx cxxcxxcxx c x x x B 22 3 1 2 bc axx and 21 1 1 2 bc axx 32 31 then lbu (53) ith: an ontrol SMC with sat vector is: with: w 1 2 l ll d b12 21 22 0b bb The C 1 1 22 ksign ubl ksign s 1 s (54) 313 2 cxx 13 11 11 3 2 1 0 ac xxax x c b a Control SMC with integrator vector is defined by: (55) with: The 11 11 1 22 22 () () d d yydt ksigns ubl K ksigns yydt 11 12 21 22 KK KKK 5. Simulation Results The controllers designed in Section 3 are simulated using the MATLAB software. The parameters of the three tank system Figure 1 are given in Table 1.The paraeters for the both controls for three tanks are m 0.6 , k1= 0.699, k2 = 0.53, K11 = 10−4, K12 = 18.10−3, K21 = 7.10−4 and K22 = −4 can notice that in the absence of chattering in controls u1 and u2 both controls proposed and both output h2 follows their desired references h2d and h3d. ver, when we inject a disturbance at t = 1500 s in low pipes of tank 2 and tank 3, the tow control- lers ensure the convergence of the water levels h3 and h2 to their desired references h2d and 3d. We see in the Figure 3 when we add integral action, the steady state This is the advantage of the -variables coupled system case. 10 . Simulation results are shown in Figures 2 to 4. We and h3 Howe the outf h error is almost eliminated. controls proposed in multi Copyright © 2011 SciRes. ENG  A. BENAMOR ET AL.441 a z1 b z4 h 2 h 3 h 1 b z3 b z1 b z2 Cuve T 3 Cuve Pomp 1 Q 1 Cuve T 2 Pomp 2 a z2 Q 2 Figure 1. Three tank system. 0200 400 600 80010001200 1400 1600 1800 2000 0 0.05 0.1 0.15 0.2 Time ( sec ) Water level h 2 ( m ) h 2 sat h 2 d h 2 sat+int Zo om Figure 2. Liquid level in tank 2. 1100 1200 13001400 15001600 17001800 19002000 0. 19 0. 195 0. 2 0. 205 0. 21 Ti me ( se c ) Wat er l evel h 2 ( m ) Zoom h 2 sat h 2 d h 2 sat+int Figure 3. Liquid level with zoom in tank 2. 6. Experim The proposed control algoithms were tested on the physical laboratory plant (Figure 8) consisting of inter- connected three tank system. The objective is to control the liquid level of tanks 2 and 3. The experimental schemes have been done under Matlab/Simulink, using Real-Time Interface, and run on the DS1102 DSPACE system, which is equipped by a power PC processor. The control algorithm is implemented on DSP (TMS 320C31). ental Results r 0200 400 60080010001200 1400 1600 1800 2000 0 0.0 5 0.3 5 0. 1 0.1 5 0. 2 0.2 5 0. 3 er level h3 ( m ) Time ( sec ) Wat h3sat h3d h3sat+int Zoom Figure 4. Liquid level in tank 3. Table 1. Numerical values for physical parameters of the three tank system. SymbolValue Meaning a 0.0154 m2 tank section Sn 2.5 10−5 m2 cross-section of valve aZi 01 zi a flow correction term (i = 1, 2, 3) zi b 01 zi b leakage flow correction term (i = 1, 2, 3) g 9.81 m/s2 gravity constant m/s2 hmax 0.6 m maximum water level in each tank (i = 1, 2, 3) Qimax 1.17 10−4 m3/smaximum inflow through pump i (i = 1, 2) 1100 1200 1300 1400 1500 1600 1700 1800 1900 0.23 0. 32 0.27 5 0.24 0. 245 0.25 0. 255 0.26 0. 265 Time ( se c ) Wa ter level h 3 ( m ) h 3 sat h 3 d h 3 sat+int Figure 5. Liquid level with z oom in tank 3. Copyright © 2011 SciRes. ENG  A. BENAMOR ET AL. 442 0.22 Figure 6. Input signals of control Q1. Figure 7. Input signals of control Q. 2 Figure 8. Real system. The parameters for both controls for three tanks are: , .10−5and k1 = 0.46, k2 = 0.32, K11 = 10−3, K12 = 3.10−4, K21 = 11 K22 = 7.10−4. For given references we remark that water levels h2d and h3d reach their references without overshooting. When we change the references we obtain the same re- sponse. In order to test the robustness of our strate with respecurbances, gy t to parameter uncertainties and dist 0200 400 600 8001000 1200 1400 1600 18002000 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 0.18 0.2 Wat er le v el h 2 ( m ) Time ( sec ) h 2 d h 2 sat+int h 2 sat Zoom Figure 9. Liquid level in tank 2. 11001200 1300 140015001600170018001900 2000 0. 185 0. 19 0. 195 0. 2 0. 205 Time ( sec ) Water lev el h 2 ( m ) h 2 d h 2 sat+int h 2 sat Figure 10. Liquid level with zoom in tank 2. we varied the parameters c1 and c3 by closing and open- ing a little bit the valves az1 and az2 and we introduce a permanent leakage in the outflow pipes of tank 2 and tank 3 at t = the outflow ipes of tank 2 and tank 3, the two controllers ensure the convergence of the water level h3 and h2 to their desired references h3d and h2d (Figures 9 and 11). Then, the advantage of the sliding mode control with integrator in simulation and experimental results is the attenuation of error static (Figures 3, 5, 10, and 12). Moreov er, we can also observe that control inputs Q1 and Q2 are smooth and the chattering phenomenon is almost eliminated (Figures 6, 7, 13 and 14). 7. Conclusion In this paper, robust sliding mode control for a class of MIMO nonlinear systems was presented. In order elimina state rror inds slid- g mode control, combined with a conditional integrator 1500 s. We remark at 1500 s in p to te chattering phenomenon and the steady uced by the use of sat function, continuoue in Copyright © 2011 SciRes. ENG  A. BENAMOR ET AL.443 0200 400 6008001000120014001600 1800 2000 0 0.05 0. 1 0.15 0. 2 0.25 0. 3 0.35 Time ( sec ) Wer level h 3 ( m ) at h 3 d h 3 sat+int h 3 sat Zoom Figure 11. Liquid level in tank 3. 11001200 1300140015001600 170018001900 0.225 0. 23 0.235 0. 24 0.245 0. 25 0.255 0. 26 0.265 0. 27 Time ( sec ) Water le vel h 3 ( m ) h 3 d h 3 sat+int h 3 sat Figure 12. Liquid level with zoom in tank 3. Figure 13. Input signals of control Q1 admittance coefficients of various pipes, leakage in the tanks and uncertainty due to neglected pump dynamics. was proposed. This control was applied to the level control ench ark. Tw ro- ustness to parameter variations such as tank Section, s - of MIMO nonlinear three tanks system b he simulation and experimental results shom b Figure 14. Input signals of control Q2. [1] V. Utkin, “Sliding Mode in Control and Optimization,” Springer-Verlag, Berlin, 1992 [2] V. Utkin, J. Guldner and J. Shi, “Sliding Modes Control in Electromechanical Systems,” CRC press, Boca Raton, 1999. [3] L. Fridman, “An Averaging Approach to Chattering,” IEEE Transactions on Automatic Control, Vol. 46, No. 8, 2001, pp. 1260-1265. doi:10.1109/9.940930 The simulation and experimental results, compared with those obtained without integrator, confirm the ef- fectiveness of our control strategy. 7. References [4] H. Abid, M. Chtourou and A. Toumi, “Robust Fuzzy Sliding Mode Controller for Discrete Nonlinear Sys- tems,” International Journal of Computers, Communica- tions and Control, Vol. 3, No. 1, 2008, pp. 6-20. [5] S. Mahieddine-Mahmoud, L. Chrifi-Alaoui, V. van Ass- che, J.-M. Castelain and P. Bussy, “Sliding Mode Control Based on Field Orientation for an Induction Motor,” IEEE Industrial Electronics Society, IECON, North Caro- lina, 6- ] H. Hashimoto, H. Yamamoto, S. Yanagisawa and F. 20 November 2005, pp. 181-186. [6 Harashima, “Brushless Servo Motor Control Using Vari- able Structure Approach,” IEEE Transactions on Industry Applications, Vol. 24, No. 1, 1988, pp. 160-170. doi:10.1109/28.87267 [7] I. Eker and S Integral Augm . A. Akinal, “Sliding Mode Control with ented Sliding Surface: Design and Ex- perimental Application to an Electromechanical System,” Electrical Engineering, Vol. 90, No. 3, 2008, pp. 189-197. doi:10.1007/s00202-007-0073-3 [8] A. Levant, “Chattering Analysis,” IEEE Transactions on Automatic Control, Vol. 55, No. 6, 2010, pp. 1380-1389. doi:10.1109/TAC.2010.2041973 [9] C. Edwards and S. Spurgeon, “Sliding Mode Control: Theory and Applications,” Taylor-Francis, London, 1998. [10] J. J. E. Slotine and W. Li, “Applied Nonlinear Control,” Copyright © 2011 SciRes. ENG  A. BENAMOR ET AL. Copyright © 2011 SciRes. ENG 444 echani- Prentice-Hall International, New Jersey, 1991. [11] I. Eker snd S. A. Akinal, “Sliding Mode Control with Integral Action and Experimental Application to an Elec- tromechanical System Application to an Electrom cal System,” IEEE-ICSC Congress on Computational In- telligence Methods and Applications, Istanbul, 2-14 De- cember 2005, p. 6. doi:10.1109/CIMA.2005.1662303 [12] S. Seshagiri and H. K. Khalil, “Robust Output Feedback Regulation of Minimum-Phase Nonlinear Systems Using Conditional Integrators,” Automatic, Vol. 41, No. 1, 2005, pp. 43-54. doi:10.1016/j.automatica.2004.08.013 [13] R. Benayache, L. Chrifi-Alaoui, P. Bussy and J. M. Cas- telain, “Sliding Mode Control with Integral Corrector: Design and Experimental Application to an Intercon- nected System,” Mediterranean Conference on Control and Automation, Thessaloniki, 24-26 June 2009, pp. 831-836. doi:10.1109/MED.2009.5164647 [14] T. Floquet, S. K. Spurgeon and C. Edwards, “An Output Feedback Sliding Mode Control Strategy for MIMO Sys- tems of Arbitrary Relative Degree,” International Journal of Robust and Nonlinear Control, Vol. 21, No. 2, 2010, pp. 119-133. doi:10.1002/rnc.1579 [15] K. Ogata, “System Dynamics,” Englewood Cliffs, New Jersey, 1978.

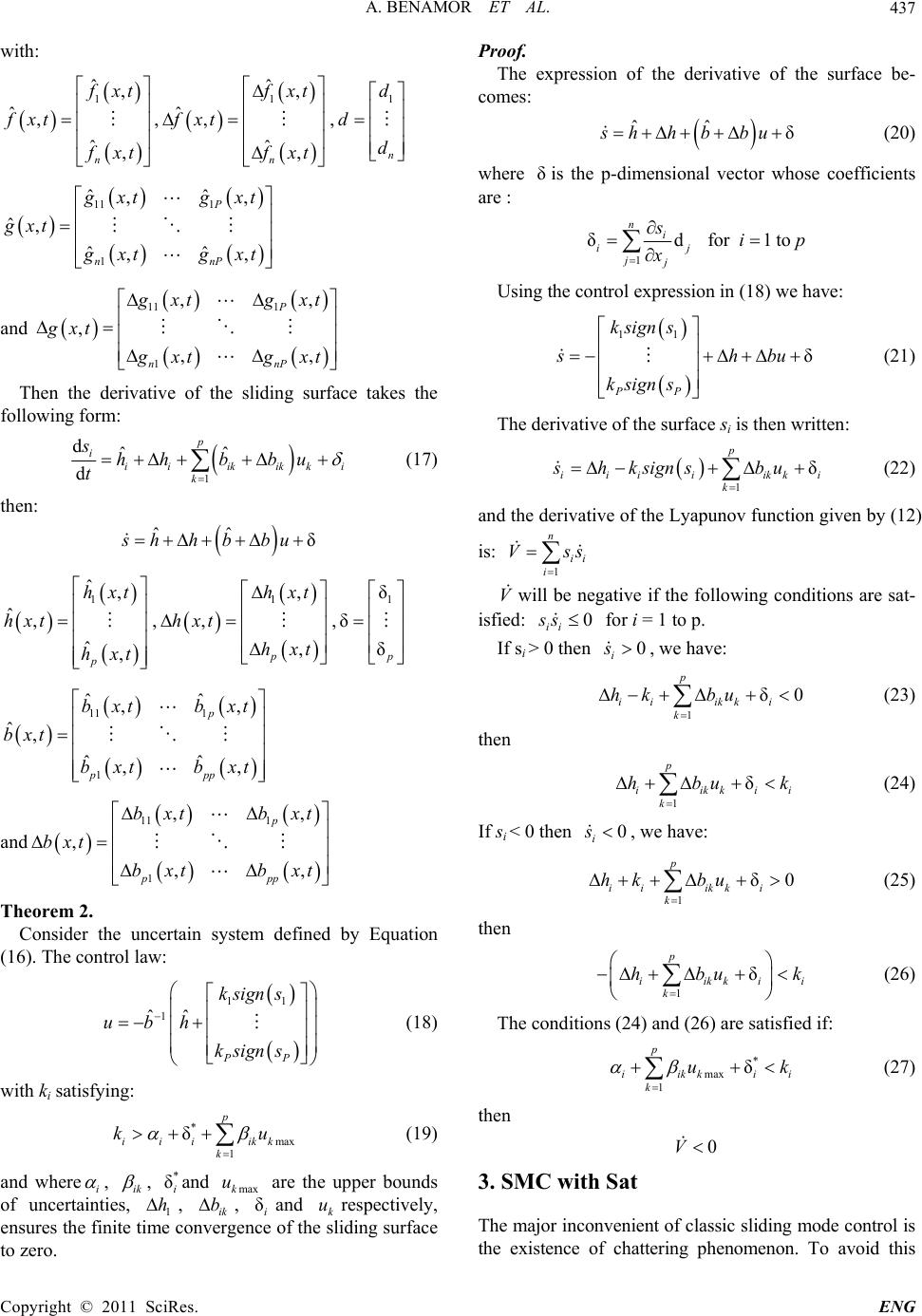

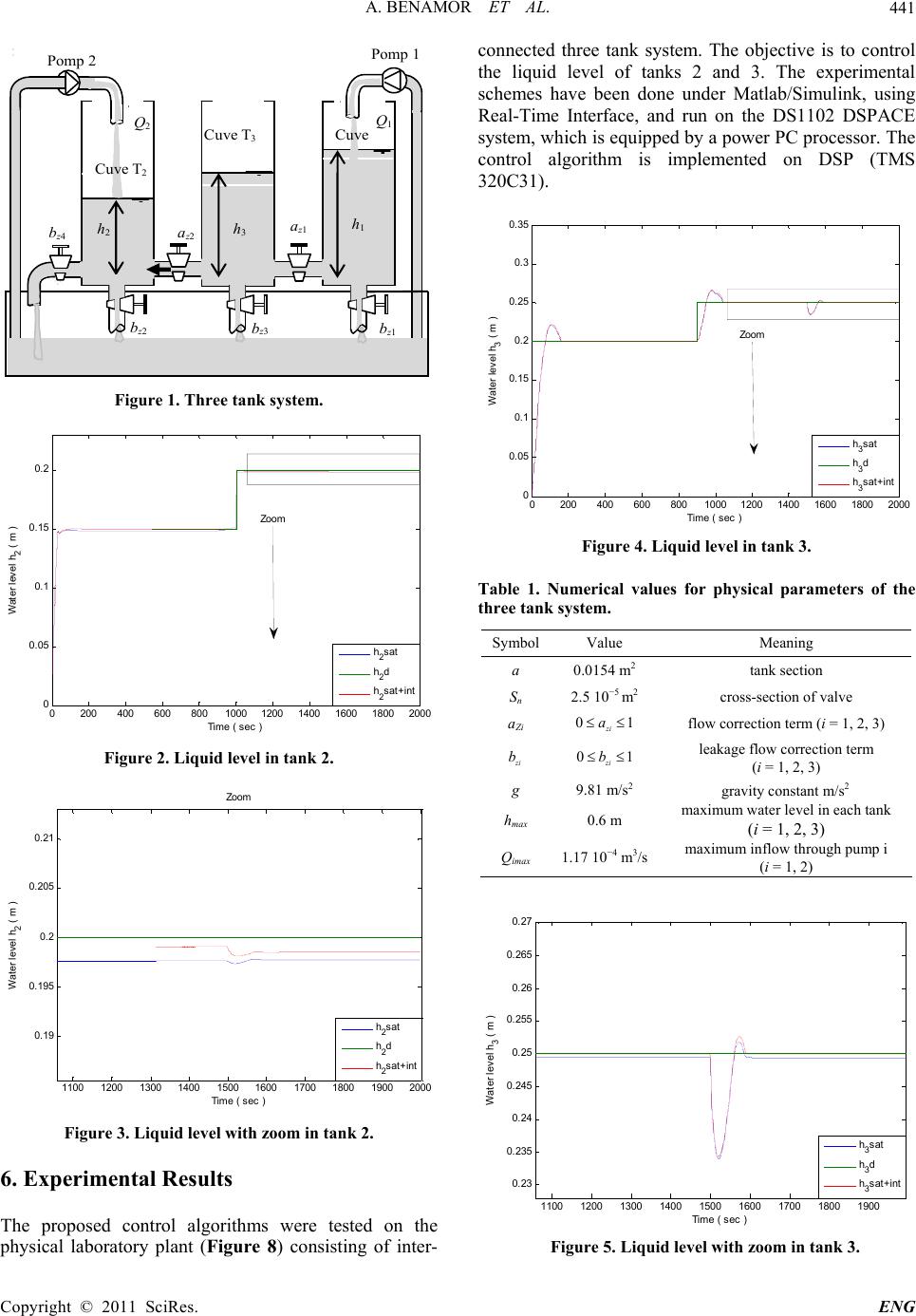

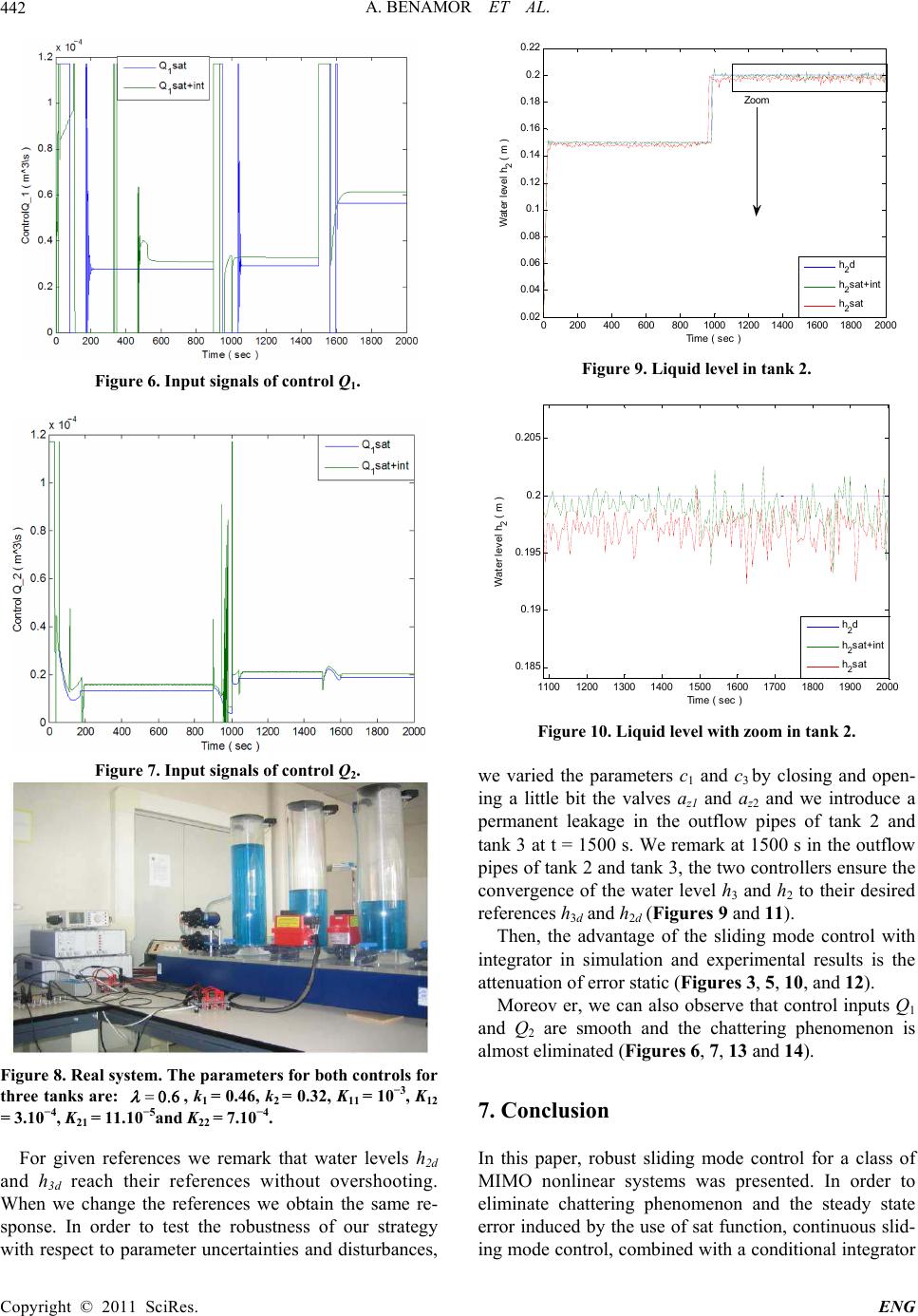

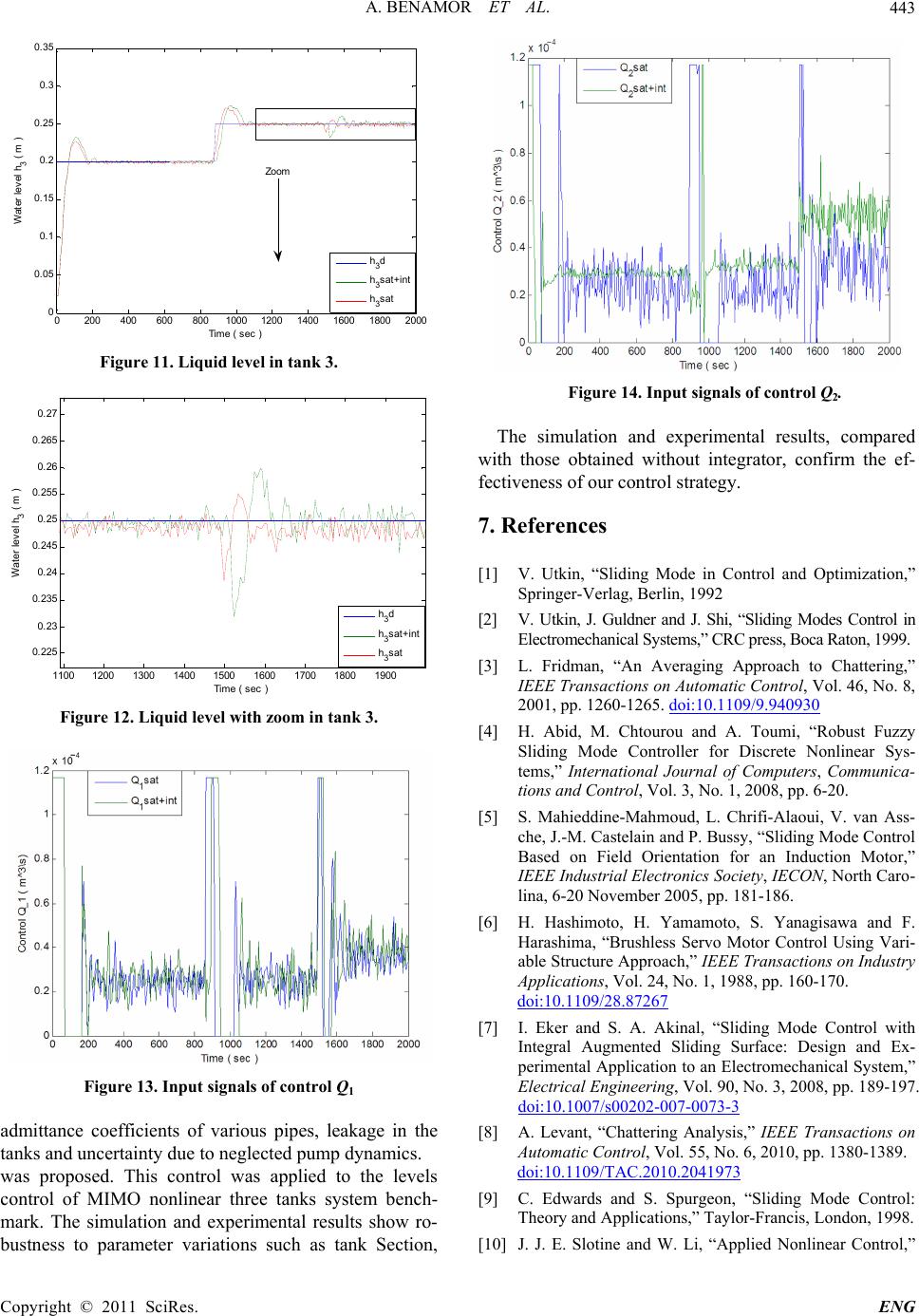

|